Eryone Thinker SE User manual

Eryone Thinker SE

User Manual

Shenzhen Eryone Technology Co .,Ltd.

WhatsApp: +86 13670143392

1

Notices

Safety compliance

Protection

Legal

The printer must not be exposed to water or rain, or damage may occur. Do not

pull out the USB cable when loading a digital model, or the model data maybe lost.

When using the

Extruder function, keep at least 50mm between the nozzle and the platform. If too

close, the nozzle may get blocked. The printer is designed to work properly at an

ambient temperature between 10℃and 32℃and humidity of between 20% and

50%; Operating outside those limits may result in low quality models.

The printer can be only used with the power adapters supplied by this company, or

the product maybe damaged, with a risk of re. To avoid burning, or model defor-

mation, do not touch the model. Nozzle, or the platform by hand, or any other part

of the body, while the printer is working or immediately after it has nished printing.

There is a slight smell from ABS when it is being extruded. The smell is, however,

not too unpleasant. Operation in a well-ventilated room but draught free. Draughts

can aect warping of ABS prints. When ABS is burnt is release toxic fumes. Always

have adult supervision when Children are present. Please keep small printed parts

away from young children, choking hazards! There are several safety issues, small

tools and HOT objects and most parts used in connection with the 3D printer. Tie

back long hair and loose clothing.

Check the power input of power supply unit. You can choose either 110V or 220V

according to the Power regulation in your country.

Eryone makes no warranty of any kind with regard to this material, including, but

not limited to, the implied warrants of merchantability and tness for a particular

purpose. Eryone should not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing, performance, or use

of this material. Changes or modications to the system not expressly approved

by Eryone, the party responsible for compliance, could avoid the user`s authority

for use. This document is protected by copyright. All right reserved. No part of this

document maybe photocopied, reproduced or translated into another language

without the prior written consent of Eryone.

© Copyright 2018 Shenzhen Eryone technology Limited. All rights reserved.

Notices ------------------------------------------------------------------------------------------------

1. Overview of Eryone Thinker SE--------------------------------------------------------------

1.1 A glance of Thinker SE---------------------------------------------------------------------

2. Specications -------------------------------------------------------------------------------------

3. Printer assembly----------------------------------------------------------------------------------

4. First steps ------------------------------------------------------------------------------------------

4.1Test before print ------------------------------------------------------------------------------

-Movement test --------------------------------------------------------------------------------

-Preheat hotend and heated bed----------------------------------------------------------

-Load the lament------------------------------------------------------------------------------

4.2 Manual levelling-------------------------------------------------------------------------------

4.2.1 Levelling gantry frame---------------------------------------------------------------

4.2.2 Levelling the heated bed ------------------------------------------------------------

5. Printing ---------------------------------------------------------------------------------------------

5.1 Install the driver-------------------------------------------------------------------------------

5.2 Setting your 3d printer---------------------------------------------------------------------

5.3 Load printing model------------------------------------------------------------------------

5.4 Slice the model------------------------------------------------------------------------------

5.5 Printing via SD card------------------------------------------------------------------------

6. LCD layout----------------------------------------------------------------------------------------

7. Special function of Eryone Thinker SE ---------------------------------------------------

Table of contents

1

4

4

5

6

6

6

6

6

7

8

8

8

9

9

10

12

12

13

14

15

2

8. FAQ-Common assembly issues ------------------------------------------------------------

8.1 X carriage loose --------------------------------------------------------------------------

8.2 Z axis stuck----------------------------------------------------------------------------------

9. FAQ-Print problem------------------------------------------------------------------------------

9.1 Filament doesn't stick to the heated bed--------------------------------------------

9.2 Extruder under extrusion----------------------------------------------------------------

10.FAQ-Error messages--------------------------------------------------------------------------

10.1 Mintemp error -----------------------------------------------------------------------------

10.2 Maxtemp error----------------------------------------------------------------------------

10.3 Thermal runaway-------------------------------------------------------------------------

*Add the auto level sensor-----------------------------------------------------------------------

16

16

16

17

17

17

17

17

17

17

17

3

4

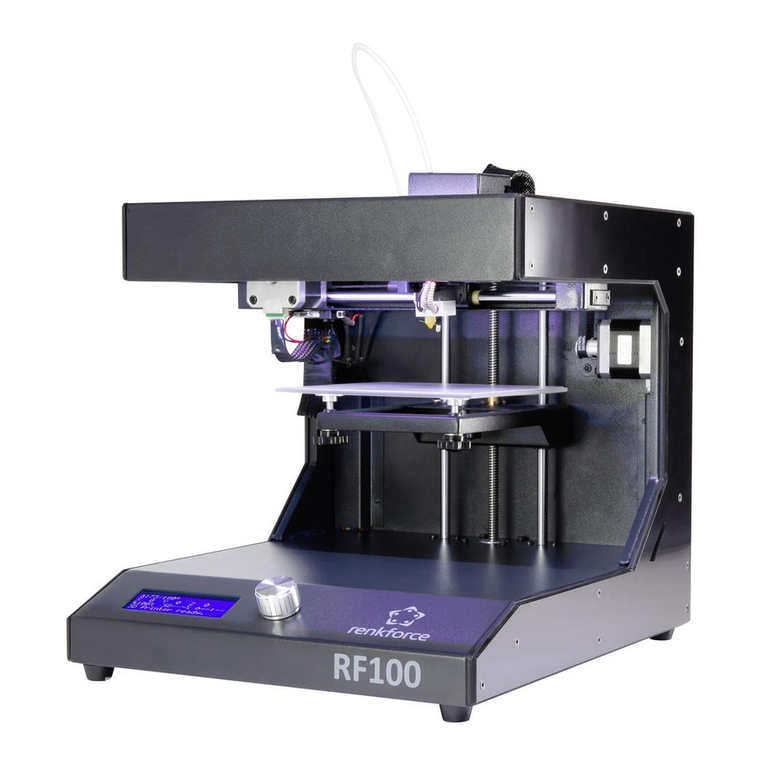

1. Overview of Eryone Thinker SE

Please carefully read and understand the contents of this user manual before you

use Eryone Thinker SE. Failure to read the manual may lead to personal injury,

damage to Thinker SE.

Learn everything about Using your Eryone Thinker SE by following the instructions

in this user manual, you will nd that using 3D printer is such an easy thing.

You might be familiar with 3D printers, however, it is still essential to read this user

manual carefully in order to make you understand Eryone Thinker SE well.

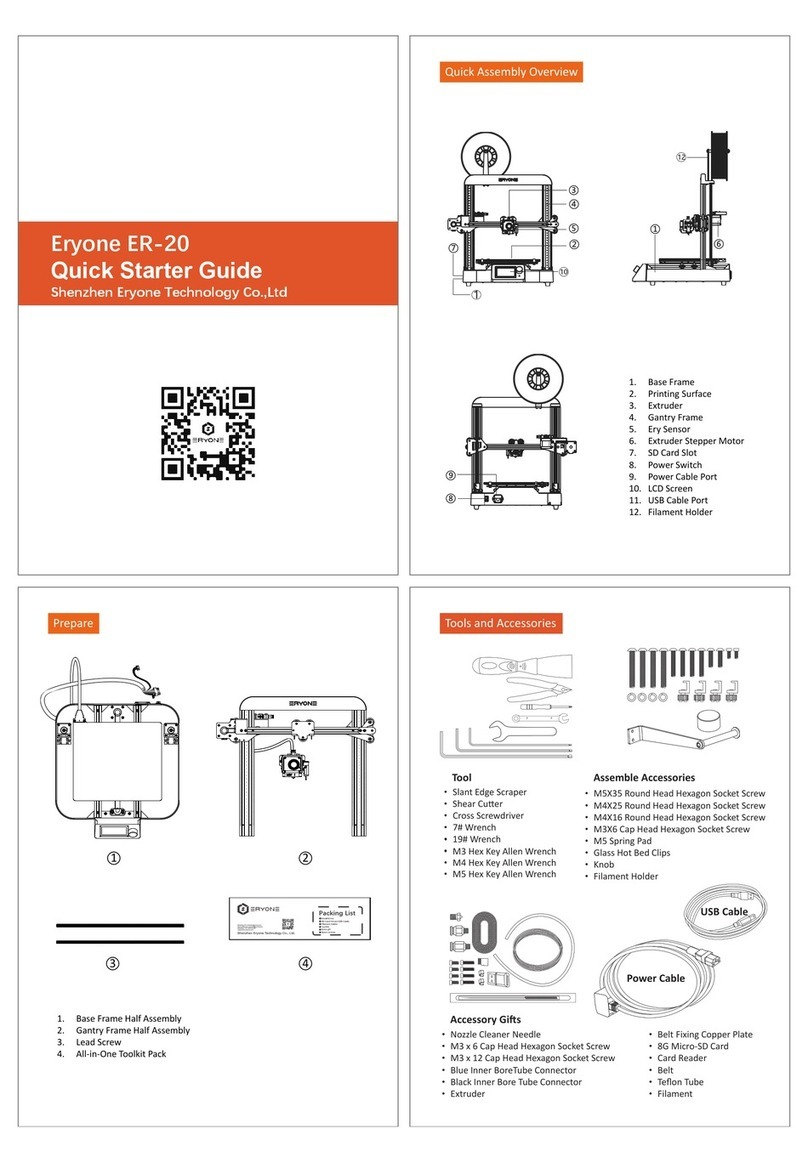

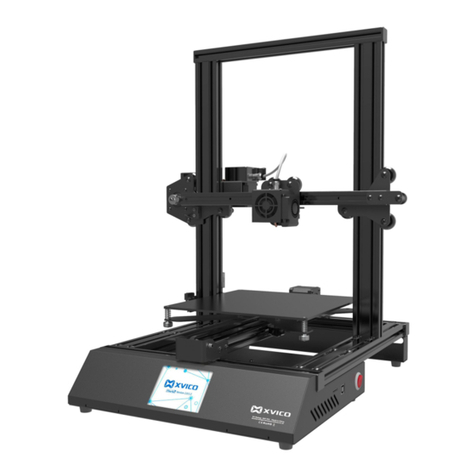

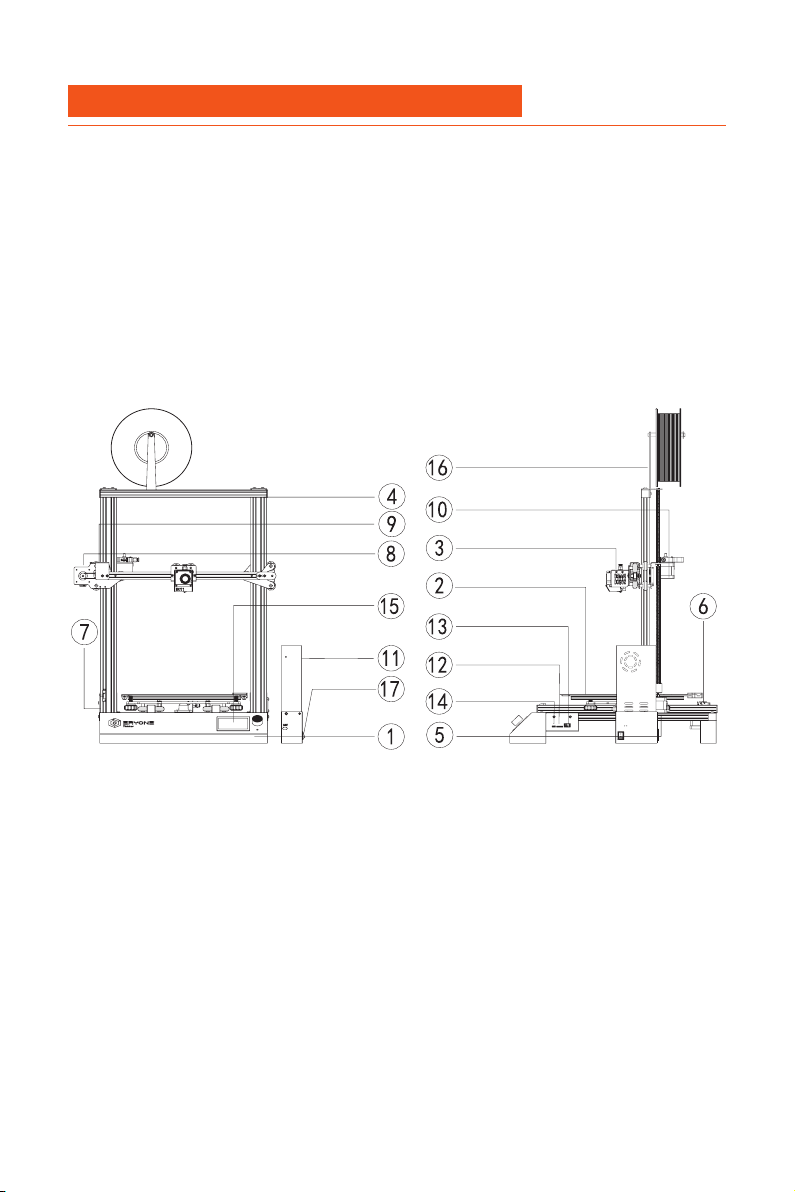

1.1 A Glance of Thinker SE

1. Base frame

2. Printing surface

3. Extruder

4. Gantry frame

5. Z stepper motor

6. Y stepper motor

7. Z axis limit switch

8. X stepper motor

9. X axis limit switch

10. Extruder stepper motor

11. Power supply unit

12. Micro SD card slot

13. Power supply unit port

14. Micro USB port

15. LCD display

16. Filament holder

17. Power switch

5

2. Specications

Printer and printing properties

Software

Electrical

Physical dimensions

Temperature

Environmental conditions

Print technology

Build volume

Print precision

X, Y, Z accuracy

Filament diameter

Default nozzle diameter

Print speed

Filament support

Average operating sound

Power supply unit input

Power supply unit output

Printer operating voltage

Printer operating current

Standby power

Desktop space

Shipping dimension

Nett weight

Gross weight

Nozzle max temperature

Heated bed max temperature

Nozzle heating time(20℃ ~180℃ )

Heated bed heating time(25℃ ~60℃ )

Operating environment

Non-operating environment

Slicer software support

Print le type

Supported OS

Firmware type

File transfer

Fused Filament Fabrication(FDM)

300mm x 300mm x 400mm

0.05mm

12.5 μm / 12.5μm / 2.5μm

1.75mm

0.4mm

30mm/s~145mm/s

PLA, PETG, ABS,TPU,etc

~49dBA

100~135V/200V~264V 6A

50~60Hz

24V/14.5A,350W

24V

13A

~15W

510*415*652mm

675 x 550 x 240mm

9.3kg

13.6kg

250℃

100℃

~1min

3min

10~32℃

0~32℃

Cura, Simply3D, Prusa slic3r,

Repetier-host,etc

GCO,GCODE

Windows/Mac OS/Linux

Marlin(open source)

USB print/Stand-alone SD card print

6

3. Printer Assembly

4. First steps

For the Eryone Thinker SE 3d printer, we suggest you following the “Eryone Thinker SE

Quick Starter Guide”

After a successful completion, continue to the next step.

Assembly guide video: https://www.youtube.com/c/Eryone3D

4.1Test before print

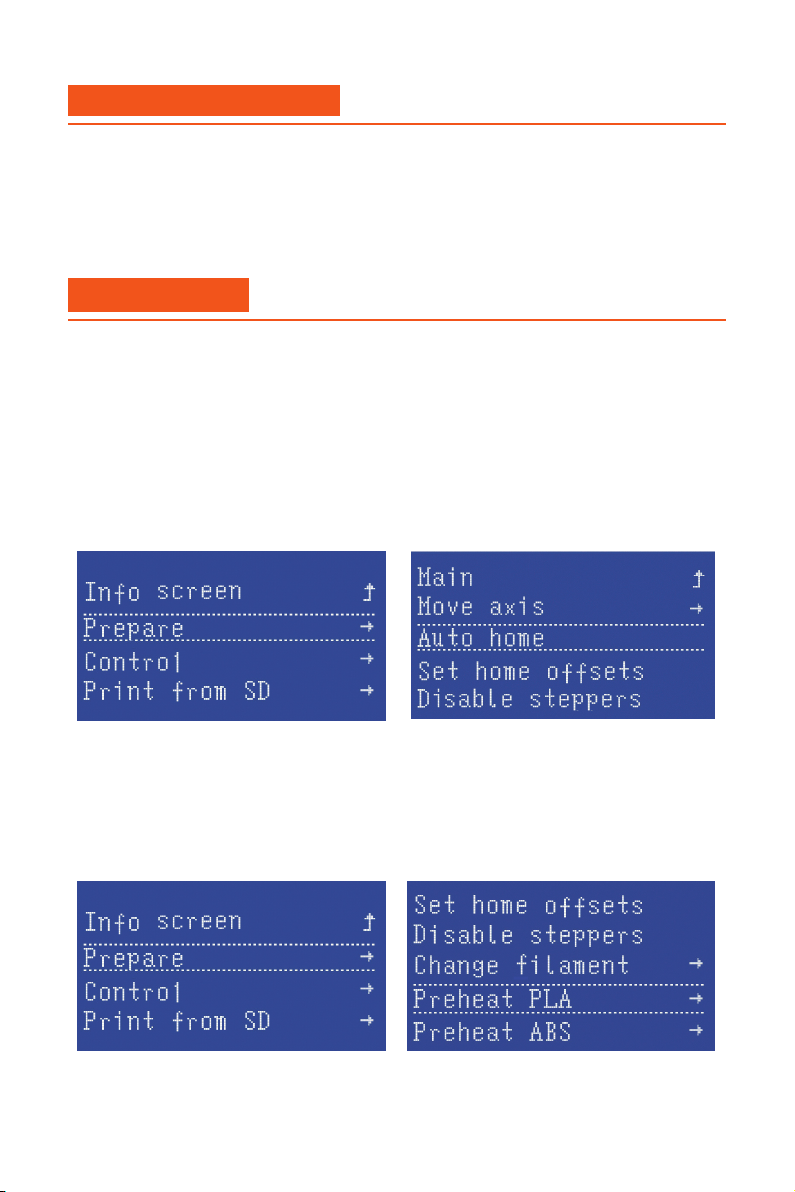

About the LCD layout, you can refer chapter 6.

Click LCD button :

LCD→Prepare→Auto home

Then the 3d printer all axis will home all axis by hitting the limit switch.

Click LCD button:

LCD→Prepare→Preheat PLA→Preheat PLA

Then the 3d printer hotend and heated bed will heat to the correct temperature.

-Movement test

-Preheat hotend and heated bed

7

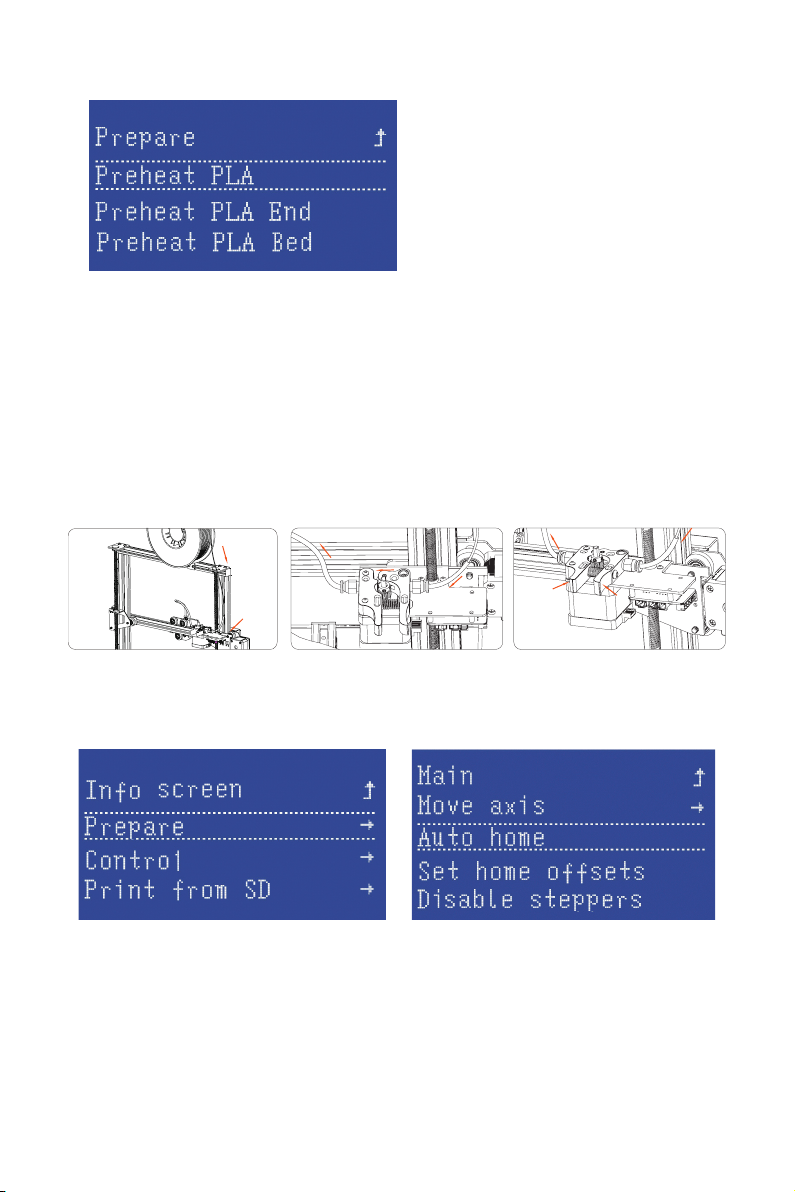

Note: The extruder will not work until the temperature is higher than 170℃.

(Temperature protection feature)

Preheat your hotend at rst. Click your LCD button→Prepare→Preheat PLA End.

Insert lament into the Teon tube. When the lament goes though extruder block,

with one hand press the handle, make sure the lament can go though the slot of

the gear, then guide lament in by hand till lament starts to string from the hotend.

After pushing the lament into the bottom of hotend,

click LCD button→Prepare→Auto home.

When homing the axis is nished. You can click LCD button→Prepare→Change

lament

Choose “Preheat PLA” the hotend will heating then you need to click the LCD but-

ton to continue.

You can click” Purge more” a few times till the lament comes out of the nozzle.

-Load the lament

8

4.2 Manual levelling

4.2.1 Levelling gantry frame

4.2.2 Levelling the heated bed

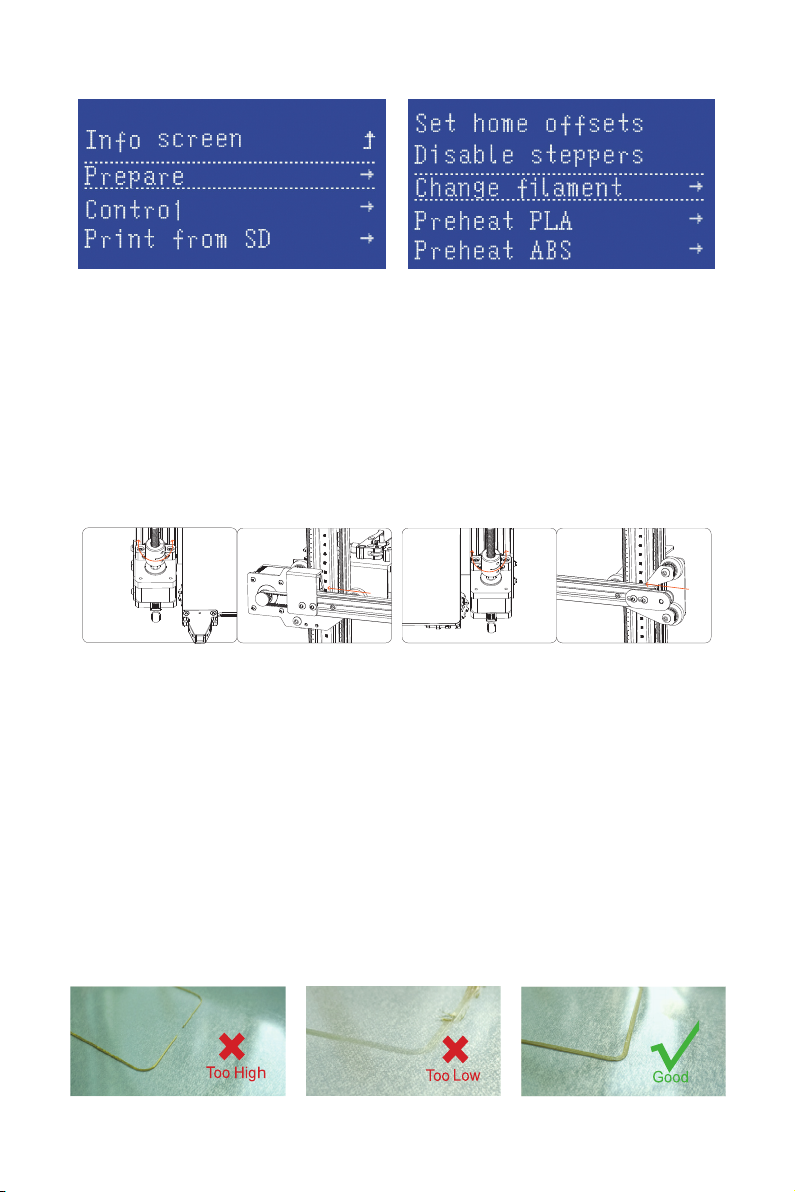

To make 3d printer have better printing result, levelling bed before printing.You can

refer to these steps to levelling the 3d printer.

Before you levelling the heated bed, please make sure gantry frame is perpen-

dicular to Z axis aluminum extrusions, you can calibrate the couplers to make the

frame same scale on both Z axis aluminum extrusions.

The recommended distance between the nozzle and printing surface is

0.05~0.1mm(Thickness of A4 paper). There are 4 knobs under the heated bed,

by which you can tighten or loosen the springs to reduce or increase the distance

between the nozzle and printing surface. The distance from nozzle will increase if

you tighten knobs, otherwise, it will decrease distance from nozzle.

Step1: Click “Prepare”→“Auto home”→“Disable steppers”

Step2: Manually move the extruder to the 1st right hand corner of the heated bed,

you need to place a piece of A4 paper between the nozzle and the heated bed,

ne-tuning until you feel slight friction from the paper when you pull on it(Repeat

for all 4 corners and centre of the bed)

36mm

36mm

(Right) (Left)

�$

9

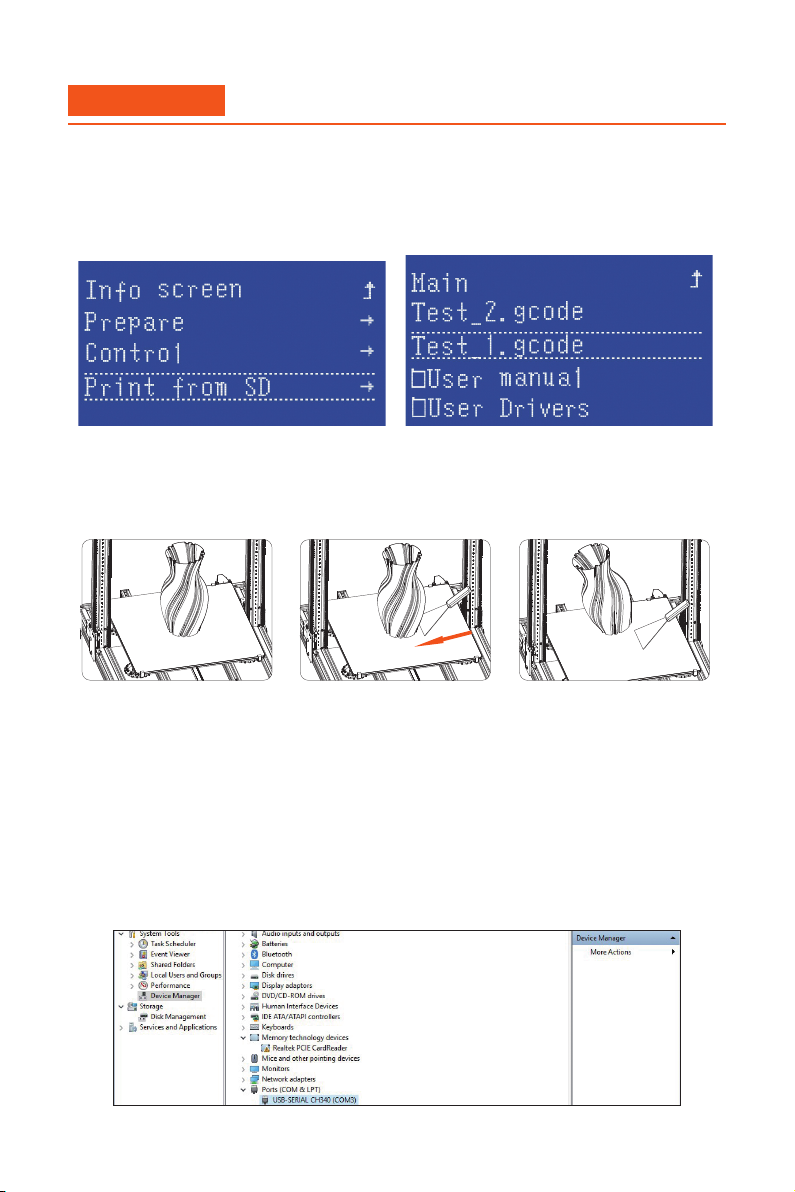

5.1 Install the driver

Connect Eryone Thinker SE to your PC/laptop via USB cable. Normally the driver

will be installed automatically, the same way as you use your keyboard. If your PC

can’t get the driver automatically, please insert the SD card to your PC with SD

card reader(Package included it).

Copy the drivers to your PC and install it.(Refer to link: https://sparks.gogo.co.nz/

ch340.html)

After downloading and installation, you will find the corresponding serial port in

windows “Device manager”

The printer is now ready to print, we can print the test gcode at rst.

1) You need to insert the SD card to printer.

2) Then click LCD button→Print from SD card→Select “Test_1.gcode”

After test model is complete. You need to learn how to slice till les to be able to

print your own model.

Removing a stuck 3d print from the print surface

Turn the heat o on your heated bed and wait for it to cool. The closer to room

temperature, the easier it will be to remove.

Recommended temperature: Lower than 40°C

5. Printing

10

5.2 Setting your 3D printer

Copy these code to your Start-Gcode area:

1.Open the Cura then add the new printer :

Click “Custom” →“Custom FFF printer” then input your printer name

G28 ;Home

M205 X8.00 Y8.00 Z0.40 E1.50 ; sets the jerk limits

G1 Z10 F1000;

G1 Y-3 F1000;Move Y axis

G1 X100 Z0.2 E6 F1000;lines

G1 X150 E12 F1000;lines

For the End Gcode, you can use the default of the Cura

2.Set the correct values on machine settings

Eryone thinker SE

11

3.Set the correct nozzle size and lament diameter

The printer prole and lament prole is on your SD card. :Proles\Cura 4.0\

Or this link: http://dwz1.cc/a2BtbPv

4.Import the printer prole

5.Import the lament prole to Cura:

12

Click this icon to import the stl le

When you import the stl le nished, you need to adjust your model.

Move your model:

Left click the model→Click the arrow to adjust your model

Red arrow is X axis,Green arrow is Y axis,Blue arrow is Z axis

5.3 Load printing model

5.4 Slice the model

If you nd the model is too small or too big

You can click this icon to scaling your model:

Scale

Eryone thinker SE

13

Power on your 3d printer at rst. Insert the SD card into the printer then click LCD

button.Click the menu “Print from SD card “ and choose the le you saved. When

the printer is up to temperature the print will begin.

5.5 Printing via SD card

If you nd that the model is not placed well. Then you can click rotation icon to

adjust it.

After that, you can click the slice icon and you can save it to SD card

Rotation

14

This section is for LCD layout. Items not mentioned below are not used for the

common print setup-you should not change any of the unmentioned items unless

you are absolutely sure what you are doing.

(The LCD layout based on the latest rmware) Please click the link below to get

the latest rmware: http://dwz1.cc/1obP362

□ Info screen

□ Prepare

□ Move axis

□ Move X

□ Move Y

□ Move Z

□ Auto home

□ Store settings

□ Set Home osets

□ Disable steppers

□ Change lament

□ Preheat PLA

□ Preheat PLA End

□ Preheat PLA Bed

□ Preheat ABS

□ Preheat ABS End

□ Preheat ABS Bed

□ Control

□Temperature

□ Nozzle

□ Bed

□ Fan Speed 1 :

□ Fan Speed 2 :

□ Fan Speed 3 :

□ Auto temp

□ MIN

□ Max

□ Fact

□ PID-P

□ PID-I

□ PID-D

□ Preheat PLA conf

□ Preheat ABS conf

6. LCD layout

15

□ Motion

□ Velocity

□ Acceleration

□ Jerk

□ Steps/mm

□ Filament

□ E in mm3

□ Unload mm

□ Load mm

□ Store settings

□ Load settings

□ Restore failsafe

□ Initialize EEPROM

□ Print from SD

7. Special Function of Eryone Thinker SE

We choose TMC2208 as stepper motor driver and quite fans but powerful which

dramatically decreases the noise and improve the printing quality as well. The av-

erage operational noise is 49dBA, working aside the 3D printer is not only

a dream.

The base and gantry of this 3D printer have been pre-assembled, what you need

to do is put those two parts together and wire a few interfaces.

The printing volume is 300*300*400mm, with carefully-selected components, after

3 steps installation, the printer will be printing pretty well, almost no need to

calibrate.

Super quiet

Assembly nished within 10 minutes

Large Volume and high quality

Power failure resume feature: Built-in supercapacitor and circuit designing, the

mainboard will store the height value of Z-axis when the power o. When the pow-

er system resume, the printer can resume the print.

Power failure protection

16

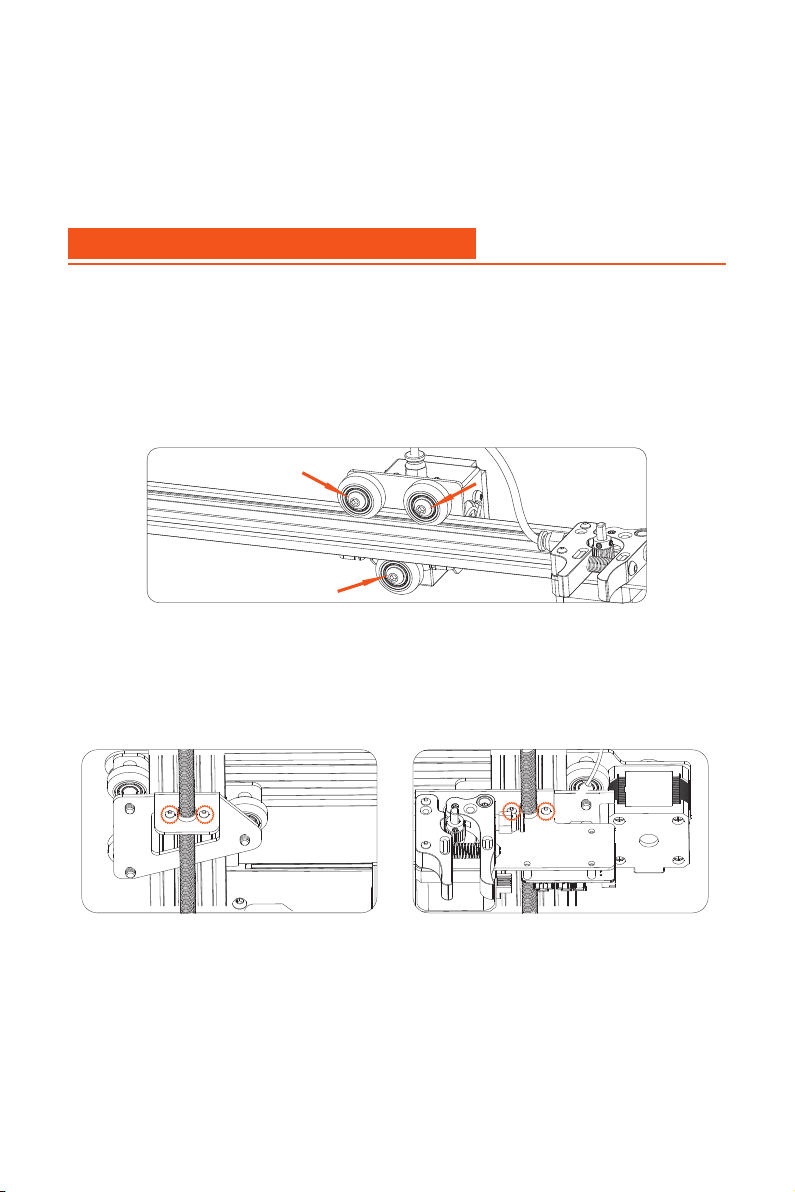

8. FAQ-Common Assembly issues

If you nd your X carriage is loose. You can use the wrench to tight the nut and

this will remove wobble and slack in the X carriage.

Refer to our forum to get more info if the problem is not listed or the solutions

doesn’t work : https://eryone.com/forum

1) Check if the stepper motor cable is loose

2) You need to check your wires at rst. If it is ok, you can loosen the brass nut

screw a little, this will help it move correctly.

3) Add the lubricant oil to the T8 rod

With pre-designed interface for BLtouch and proximity switch, update Eryone

Thinker SE rmware to enable the auto-leveling function is easily.

8.1 X carriage loose

8.2 Z axis stuck

Compatible with auto-leveling sensors(Not included sensor)

17

10.FAQ-Error messages

The mintemp error occurs when at least one of the temperature readouts of the

hotend or the heated bed drops below 5°C. It is a safety feature which prevents

the printer from overheating in case of a fault.

If you nd this info occurs on your LCD, you can:

1) Check your thermistor wires are tight inserted to the correct port

2) Check your thermistor wires are damaged or not

The maxtemp error occurs when at least one of the temperature readouts of the

hotend or the heated bed more than the limit values.

Check if the thermistor cable is not damaged and look for any overtightened zip-

ties around the cables leading to the electronics board.

Please click to this link to get the guide: http://dwz1.cc/DSeUTP3

(Package doesn’t include the sensor,you can purchase it by yourself)

This error occurs when the temperature of he hotend or heated bed can’t be raise

to the correct temperature and has been heating for a long period. The rmware

protect feature will activate and error will appear on the LCD.

1) You can add the silicone sock to the heated block

2) You need to check your cable is tight and not damaged.

It is an common issue for all FDM 3d printer. You can try to:

1) Check your lament moving or not;

2) Check your lament temperature is correct;

The dierent PLA lament brands have dierent required temperatures, you should

refer to this then re-slice if needed;

3) Clean the hotend with cleaning needle

Preheat the hotend to 240°C(You can click the LCD button then choose ”Preheat

ABS End” )

10.1 Mintemp error

10.2 Maxtemp error

*.Add the auto level sensor

10.3 Thermal runaway

9.2 Extruder under extrusion

It is a common issue for newcomer. Check your lament type at rst.Then re-level

your heated bed (Refer to the chapter 4.2), you can also use the “Z babystep fea-

ture”.When it is printing, double click LCD button→tune the distance between the

nozzle and heated bed

9. FAQ-Print problem

9.1 Filament doesn’t stick to the heated bed

You can feel free to contact us via

Shenzhen Eryone Technology Co., Ltd.

Facebook:

https://www.facebook.com/groups/247271792709370

Youtube:

https://www.youtube.com/c/Eryone3D

Email:

2F, building B, Hongwan Technology Park, Gushu community Bao`an District,

Shenzhen city, Guangdong Province, China

Table of contents

Other Eryone 3D Printer manuals