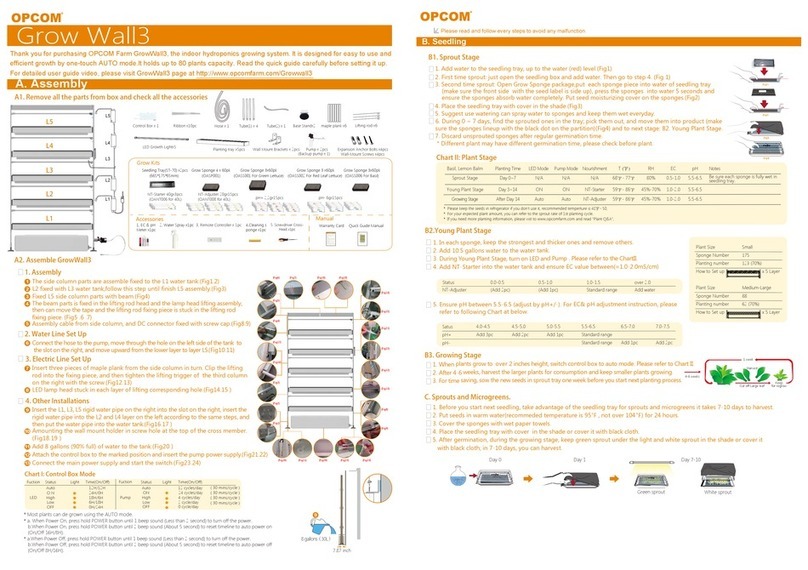

Allied Systems Freeman 370 Installation and operating instructions

Sidefeed Gearbox Baler, 3-Tie

OPERATOR’S AND PARTS ADDENDUM

A Product of

Sherwood, Oregon USA

89-096 S/N: STARTING WITH S/N 375E21G032

Important: Be certain to specify the

serial number of your Baler when

ordering parts.

Contents

Safety.............................................................................................. 3-7

Serial Number Location ..................................................................... 9

Maintenance .................................................................................... 10

Gearbox Baler Parts ........................................................................ 11

Front End Installation, Gearbox 37X................................................ 12

. Front End Assembly, Gearbox 37X ........................................... 14-15

Engine Installation, Gearbox 37X ............................................... 16-19

. Engine Assembly, Tier 4-Interim, Gearbox 37X ........................ 20-23

. Air Cleaner Assembly..................................................................... 24

Gearbox Installation, 16” Chamber ............................................. 26-30

Gearbox Installation,(37X) 15” Chamber .................................... 31-35

Gearbox Installation,(37X) 14” Chamber .................................... 36-40

Gearbox Installation,(37X) 14” X 21” Chamber........................... 41-45

Gearbox ...................................................................................... 46-47

Knotter Drive Installation, Gearbox Baler ................................... 48-49

Shield Installation, LH...................................................................... 50

Shield Installation, Crank Arm ......................................................... 51

Plunger Assy, 16”x22”................................................................. 52-55

Plunger Assy, Kittted for 15”x22” ................................................ 56-59

Plunger Assy, Kittted for 14”x22” ................................................ 60-63

Plunger Assy, Kitted for 14”x21” ................................................. 64-66

Connecting Rod Assy, Gearbox Baler, 15/16” 3-Tie ....................... 67

Connecting Rod Assy, Gearbox Baler, 14” 3-Tie ............................ 68

Tensioning/Rear Mnt Inst, 37X - 16” ........................................... 69-72

Tensioning/Rear Mnt Inst, 37X - 16” Ktd - 15”............................. 73-76

Tensioning/Rear Mnt Inst, 37X - 16” Ktd - 14”............................. 77-80

Tensioning/Rear Mnt Inst, 37X - 16” Ktd - 14”x21”...................... 81-84

Tensioning/Rear Mnt Inst - 380/385, 14” Kitted .......................... 85-86

Frame & Axle, 16” ........................................................................... 87

Frame & Axle, 14 X 21” ................................................................... 88

Chamber Inst, 14x21 Gearbox 3 Tie .......................................... 86-95

Chamber Installation Gearbox 3 Tie 14x22,15x22,16x22 ........ 96-106

See alliedsystems.com for our most current documents.

2

89-096 Rev: 11-2016

389-096Rev: 11-2016

Safety

General

The following pages contain general safety warnings

which supplement specific warnings and cautions ap-

pearing elsewhere in this manual. All electrical and

hydraulic equipment is potentially hazardous. You must

thoroughly review and understand this Safety Section

before attempting to operate, troubleshoot, maintain or

service this baler.

Time, money and effort have been invested in making

your Baler a safe product. The dividend from this invest-

ment is YOUR PERSONAL SAFETY.

However, it must be realized that no power-driven equip-

ment can be any safer than the person behind the con-

trols. If you don’t operate and maintain your Freeman

Baler safely, our efforts will have been in vain.

The safety instructions and warnings, as documented

in this manual and shipped with the machine, provide

the most reliable procedures for the safe operation and

maintenance of your Baler. It’s your responsibility to see

that they are carried out.

Allied Systems Company cannot anticipate all worksite

conditions, local regulations, etc. It is the responsibil-

ity of the end user to be aware of and obey any specific

worksite, local, state, or national regulations or proce-

dures that are applicable to operating this baler.

NOTE: All possible safety hazards cannot be antici-

pated so as to be included in this manual. Therefore,

you must always be alert to potential hazards that

could endanger personnel and/or damage the equip-

ment.

Safety Symbols

The following symbols/terms are used to emphasize

safety precautions and notices in this manual:

DANGER

The “DANGER” symbol indicates a hazardous

situation which, if not avoided, will result in

death or serious injury. Carefully read the mes-

sage that follows to prevent serious injury or

death.

WARNING

The “WARNING” symbol indicates a hazardous

situation which, if not avoided, could result in

death or serious injury. Carefully read the mes-

sage that follows to prevent serious injury or

death.

CAUTION

The “CAUTION” symbol indicates a hazardous

situation which, if not avoided, could result in

minor or moderate injury, or equipment dam-

age. Carefully read the message that follows to

prevent minor or moderate injury.

NOTICE

The “NOTICE” symbol alerts to a situation that is not

related to personal injury but may cause equipment

damage.

NOTE: …

The term “NOTE” highlights operating procedures or

practices that may improve equipment reliability and/or

personnel performance, or to emphasize a concept.

Intended Use Statement:

This baler is intended to gather and compress

loose, fibrous material (i.e., hay) and form it

into rectangular bales. Use in any other way is

considered to be contrary to the intended use.

If you are unsure of the material you intend to

bale, consult the factory.

4

89-096 Rev: 11-2016

Operation Warnings

WARNING

Failure to observe the following safety rules may

result in extreme personal injury, dismember-

ment or death. It is the operator’s responsibility

to understand the proper and safe use of this

baler.

• Make sure that you read, understand, and obey all of

the safety precautions and operating instructions in

this Operator’s Manual.

• Keep this Operator’s Manual and the Safety Card

(Allied form #89-028) with the baler at all times.

• Do not operate the baler unless you are authorized

and trained to do so. If it has been some time since

you last operated the baler, re-familiarize yourself

with the baler before starting, then proceed slowly.

• Do not operate the baler if you are aware of any mal-

functions, needed maintenance or repairs.

• Stop the baler immediately if any problems arise.

• Never allow others to ride on the baler.

• Never allow anyone with-

in 10 ft of the baler while

the baler is in operation.

• Never operate the baler

without all safety shield-

ing in place.

• Keep hands, feet, hair,

jewelry and clothing

away from moving parts,

including but not limited

to the pickup, knotter,

and PTO shaft.

• Avoid wearing loose

clothing which can eas-

ily be caught in moving

parts.

• Use appropriate signs (i.e., Slow Moving Vehicle

sign), signals or warning lights when transporting on

highways.

• Always use lights when working at night or in low

light conditions.

• Know your job-site rules. Some have site specific

directions and procedures. The methods outlined in

this manual provide a basis for safe operation of the

baler. Because of special conditions, your com-

pany’s baling procedures may be somewhat different

from those shown in this manual.

• Do not start the tractor if the key had been marked

with a “DO NOT START” or “RED” tag.

• Never operate any of the tractor’s controls from any-

where other than the operator’s seat.

• Alert personnel in the area before starting the en-

gine, and make sure everyone is clear. Be sure that

all controls are in neutral and the baler is disen-

gaged before starting the engine.

• Each country has its own safety legislation. It is in

the operator’s own interest to be conversant with

these regulations and to comply with them in full.

This also applies to local bylaws and regulations in

force on a particular worksite.

• Should the recommendations in this manual deviate

from those in the user’ country, the national regula-

tions should be followed.

• Never attempt to disconnect any of the safety de-

vices built into the baler or tractor.

• Maintain proper clearance from energized equip-

ment, energized power lines or other power sources.

High voltage electricity can discharge to ground with-

out direct contact with the baler’s or tractor’s struc-

ture. If the baler or tractor contacts energized equip-

ment, or if electrical energy does discharge through

the machine—stay clear, and prevent anyone else

from coming in contact with the baler or tractor. If

you are on the tractor, stand fast, avoid contact with

metal surfaces, and do not permit anyone to come

into contact with the tractor or baler. Finally, Do not

jump off.

589-096Rev: 11-2016

Hydraulic Hazards

Be aware of the hazards of pressurized hydraulics:

• Wear personal protective equipment, such as gloves

and safety glasses, whenever servicing or checking

a hydraulic system.

• Assume that all hydraulic hoses and components are

pressurized. Relieve all hydraulic pressure before

disconnecting any hydraulic line.

• Never try to stop or check for a hydraulic leak with

any part of your body; use a piece of cardboard to

check for hydraulic leaks.

• Small hydraulic hose leaks are extremely dangerous,

and can inject hydraulic

oil under the skin, even

through gloves.

• Infection and gangrene

are possible when

hydraulic oil penetrates

the skin. See a doctor

immediately to prevent

loss of limb or death.

Maintenance Safety

• Perform all routine maintenance outlined in this Op-

erator’s Manual in the time intervals indicated.

• Maintenance, lubrication and repair of this machine

can be dangerous unless performed properly. In

order to ensure safety, each person working on this

baler must have the necessary skills, information,

tools and equipment, and satisfy himself that his

work method is safe, correct, and meets his own

company’s requirements.

• Do not attempt to make adjustments, or perform

repairs unless you are authorized and qualified to do

so.

• Never attempt to service energized equipment.

• Do not rely on the hydraulic system to support any

part of the baler during maintenance or lubrica-

tion. Never stand under a baler component that is

supported only by the hydraulic system. Ensure

components are resting on their mechanical stops

or supported with appropriate safety stands during

maintenance or lubrication.

• Never attempt servicing while the baler is moving.

Shut off the tractor and secure power.

• Shut off tractor and baler engine, engage the parking

brake, disengage the baler, and wait for all move-

ment to stop before adjusting, lubricating, cleaning,

or servicing the baler.

• Tag the key switch with a ”DO NOT START” sign

and/or remove the key.

• Always perform all maintenance and lubrication

procedures with the baler on level ground, parked in

a safe area.

• Block the tires to keep the machine from rolling.

• Any unauthorized modifications made to the baler

by the customer or parties other than Allied Systems

will relieve Allied Systems Company and your Free-

man dealer of any liability for damage or injury.

• Replace any worn parts only with genuine Freeman

parts. Call your dealer for assistance.

• Unless specified in service procedures, never at-

tempt maintenance or lubrication procedures while

the baler is moving or the engine is running.

• Engine exhaust fumes

can cause death. If it

is necessary to run the

engine in an enclosed

space, remove the

exhaust fumes from the

area with an exhaust

pipe extension. Use

ventilation fans and open

shop doors to provide

adequate ventilation.

• DO NOT remove the ra-

diator cap when the en-

gine is hot. The coolant

will be under pressure

and can flash to steam

with explosive force,

causing severe burns. To

prevent burns, remove

the radiator cap only

when the engine is cool.

• Batteries contain sulfuric acid which can cause se-

vere burns. Avoid contact with skin, eyes or clothing.

6

89-096 Rev: 11-2016

• Batteries produce explo-

sive gases. Keep sparks,

flame and cigarettes

away. Ventilate when

charging or servicing

in an enclosed space.

Always shield your eyes

when working near bat-

teries. When removing

battery cables, disconnect the negative (-) cable

first. When installing a battery, always connect the

positive (+) cable first. This procedure will help to

prevent a spark which could cause an explosion.

• Before making adjustments to the engine or chassis

electrical system, disconnect the battery. An elec-

trical spark could cause a fire, explosion or severe

burns.

Safety Equipment

• Ensure test equipment is in good condition.

• If an instrument must be held while taking measure-

ments, ground the case of the instrument before

energizing equipment.

• Do not touch live equipment or personnel working

on live equipment while holding a multimeter. Some

types of measuring devices should not be ground-

ed—do not hold such devices while taking measure-

ments.

• Prevent personal injury or equipment damage by us-

ing a lifting device with a lifting capacity greater than

twice the weight of any equipment to be lifted.

• Always use personal protective equipment (PPE) ap-

propriate to the situation. This may include the use

of hearing protection, eye protection, a respirator, a

hard hat, leather gloves, steel toed boots, etc.

Electrical Hazards

• An electric shock could

be fatal. Ensure power to

the baler is “OFF” before

opening electrical panels.

• All electrical cables and

connectors must be in

good condition (free

of corrosion, damage,

etc). Use caution in wet

weather to avoid danger

from electrical shock.

Never attempt electrical

testing or repair while

standing in water.

• Do not wear electrically

conductive jewelry, cloth-

ing, or other items while working on the electrical

system.

Hot Oil Hazards

• Burns from hot oil can be severe—Always allow

lubricating and hydraulic oil to cool before draining.

Compressed Air Hazards

• When using compressed air to dry parts, pressure

should not exceed 30 psi (200 kPa).

• Air pressure penetrating your skin can be fatal.

Never direct compressed air at anyone.

789-096Rev: 11-2016

Fire Safety

WARNING

Diesel fuel and hydraulic oil are flammable.

Never smoke while handling fuel or working on

the fuel system. The fumes in an empty fuel

container are explosive. Never cut or weld on or

near fuel lines, tanks, or containers. Keep open

flames and sparks away from the machine.

Reduce the Risk of Fire

• Keep the baler free of oil,

grease, hay, and trash

accumulations. Regular

cleaning is recommend-

ed for fire prevention

and general safety. Use

an approved solvent to

clean machine parts.

Never use gasoline or

diesel fuel.

• Shut off the engine and electrical equipment while

filling the fuel tank. Use extra caution when fueling a

hot engine. Always ground the fuel nozzle against

the filler neck to avoid sparks.

• Never overfill the fuel or hydraulic tanks. Any

overflow could cause a fire. Immediately repair any

hydraulic or fuel leaks and clean up any spills.

• Handle all solvents and dry chemicals according to

procedures identified on manufacturer’s containers.

Work in a well-ventilated area. Make sure you know

where fire extinguishers are kept and how to use

them.

• Avoid spilling fuel or other hazardous liquids. If

a spill occurs, follow local or state regulations for

clean-up. Contact your state’s OSHA office for

details.

• Always ensure that excess grease and oil accumula-

tion, including spillage, is cleaned up immediately.

• Inspect the baler daily for potential fire hazards and

make any necessary repairs immediately.

• Check all the electrical wiring and connections for

defects, and repair or replace as necessary. Keep

battery terminals clean and tight.

• Never perform welding operations until the entire

machine has undergone a thorough cleaning. In

addition, cover rubber hoses, disconnect the battery,

and have at least a fire extinguisher at hand.

• Hydraulic fluid is flammable. Do not weld on or near

pipes, tubes, or hoses that are filled with fluid. Do not

smoke when checking or filling the tank. Keep open

flames and sparks away from the baler.

• Hay dust is combustible. Do not have an open flame

or weld in dusty environments.

• Maintain the engine cooling system to avoid over-

heating.

• Remember, there is always a risk of fire.

Fire Fighting Equipment

• It is recommended to carry an “ABC” fire extin-

guisher on the baler or in the pull vehicle at all times.

Install it within easy reach of the operator in a posi-

tion that protects it from damage. Use only a “quick

release” type of mount. It is also recommended to

carry a four gallon water container with a pump, or

as required by local and state law.

• Keep your fire extinguisher(s) fully charged and in

good working order. Know how to use them.

• Read and understand the instructions printed on the

canisters and learn how to operate them. Learn how

to remove the canisters from their mounting brackets

in the shortest amount of time.

• Service the extinguisher according to the manufac-

turer’s specifications. Service after every use, no

matter how short a time.

Fire Suppression

• Do not panic. At the first sign of trouble (burning

smell, smoke, visible flame, etc), stop the tractor and

turn off the engine in the clearest area available, with

the tractor upwind from the baler if possible.

• If the fire cannot be extinguished safely, immediately

evacuate the area. DO NOT attempt to extinguish it.

DO NOT risk personal injury. Contact your local fire

department.

• If you have determined that the fire may be safely

extinguished, use the fire extinguisher according

to the manufacturer’s instructions, or use the water

pump, aiming water at the base of the fire.

• When the baler has fully cooled, thoroughly inspect,

and make all necessary repairs to return the baler to

normal operation.

• Recharge or replace the extinguishers before return-

ing to work.

Intentionally Left Blank

8

89-096 Rev: 11-2016

Serial Number Location

Each Freeman Baler is identified by means of a baler model number and baler serial number. As a further identifica-

tion, all power units are provided with a serial number. The serial number is an important piece of information about

the machine and it may be necessary to know it before obtaining the correct replacement part. The serial number

is located on the top chamber rail on the rear left-hand side, above the tool box. To ensure prompt, efficient service

when ordering parts or requesting repairs from your authorized Freeman dealer, record the serial numbers in the

spaces provided.

Baler Serial Number

Rear, left side of baler on upper frame.

Power Unit Serial Number

Deutz Diesel - forward side of engine on block.

Driveline P.T.O. 540 RPM - top of gearbox.

NOTE: Reference to left-hand and right-hand used throughout the manual are understood to mean from a posi-

tion facing in the direction of travel.

Side Feed Baler Serial Number Format

As Of 2011

3 8 5E16-12 3

Drive Type

E - Engine

H - Hydro

D - Driveline

S - Self Propelled

Plunger Size

14”, 15”, 16”

Sequential

Number

Twines/Bale

2 - 2-Tie

3 - 3-Tie

Knotter

0 - Conventional

5 - Tailless

Model

7 - Base

8 - Premium

Dash - Bullgears

G - Gearbox

Serial Number Location

989-096Rev: 11-2016

WARNING

Chock baler wheels to prevent baler from mov-

ing and make sure baler and tractor are both

turned off and all moving parts have come to a

complete stop before starting any maintenance.

Contact with moving equipment can cause seri-

ous injury or death.

Use Mobilube HD Plus 80W-90 Gear Oil, Allied P/N

235720.

Check oil level daily:

With the baler sitting level, remove the fill/check plug. Oil

should be level with the bottom of the opening (see Fig-

ure 2.) Add oil as necessary through the same opening.

Replace plug and tighten securely.

Change oil after first 50 hours, then every 250 hours:

1. Place a catch pan beneath the gearbox, under the

drain plug.

2. Remove the drain plug from the bottom of the gear-

box (see Figure 2) and let oil drain into catch pan.

3. Replace the drain plug.

4. Add new oil through the fill/check plug opening until

the oil is level with the bottom of the opening (see

Figure 2.) Replace plug and tighten securely.

5. Dispose of used oil in accordance with local regula-

tions.

Check Bolts on Crank Arm Every 3 months/125

hours/25,000 bales, whichever comes first

(see Figure 1).

1. Torque the

four (4)

retaining cap

bolts to

340 ft-lbs.

2. Torque the

one (1)

clamp bolt

to 750-755

ft-lbs.

Maintenance

Fill/Check Plug

Drain Plug

Figure 2 - Gearbox

Connecting Rod/Crank Arm:

Grease the connecting rod bushing daily until you just

see grease emerging from around the bushing (see

Figure 3).

Grease the gearbox crank arm bearings at the beginning

of every season, and then every 50 hours (see Figure 3).

Figure 3 - Gearbox Lubrication (Top View)

Gearbox Crank

Arm Bearing

Grease Fitting

Connecting

Rod Bushing

Grease Fitting

4 Retaining Cap Bolts

340 Ft-Lbs

1 Clamp Bolt

750-755 Ft-Lbs

Figure 1 - Crank Arm Torque

10

89-096 Rev: 11-2016

This section contains all components of the Gearbox

baler that are not included in the standard Engine/

Hydro Parts Manual. This includes all parts that can

be separately identified as well as parts necessary for

equipment support.

Illustrations

Illustrations are provided whenever possible to rep-

resent component parts and the mounting location of

those parts. The numbered labels correspond to the

item numbers in the parts list.

Parts Lists

Component parts lists are presented in a 5-column

format:

Item: Index numbers found in this column correspond

to the numbers found on the respective parts loca-

tion illustration. Some items are shown for reference

purposes only to illustrate their relationship to other

systems.

Notes: This column identifies footnotes applicable to

specified items.

Part Number: This column lists the Allied Systems

Company Part Number.

Quantity: This column lists the total number of a

specific item required per assembly or subassembly.

This number may not necessarily be the number of

items used in the end item or system. Only one set of

components is listed whenever the components of two

assemblies are the same.

“A/R” (as required) identifies bulk items whose

length or other dimension must be specified when

requisitioning.

“Ref” identifies items shown for reference purposes

only to illustrate their relationship to other systems.

“NSS” (not sold separately) identifies items such as

valve housings and spools, ring gears and pinions,

etc., which must be ordered as a set because they

are closely mated at manufacture.

Description: This column lists the item nomenclature

along with those modifiers necessary to identify the

item. Additionally, cross references for repairable sub-

assemblies are listed in this column. One dot preced-

ing the description indicates that the item is a compo-

nent part of the previously listed item or assembly with

no dot. Two dots indicate that the item is part of the

previously listed item with one dot.

Example:

Engine Installation

. Engine Assembly

. . Manifold Assembly

. . Control Box Assembly

. . . Module Assembly

The Engine Assembly is a first level subassembly of

the Engine Installation as indicated with one dot. The

Manifold Assembly and the Control Box Assembly are

second level components of the Engine Assembly as

indicated by the two dots. The Module Assembly is a

third level component of the Control Box Assembly

which is indicated with three dots.

Gearbox Baler Parts

11 89-096Rev: 11-2016

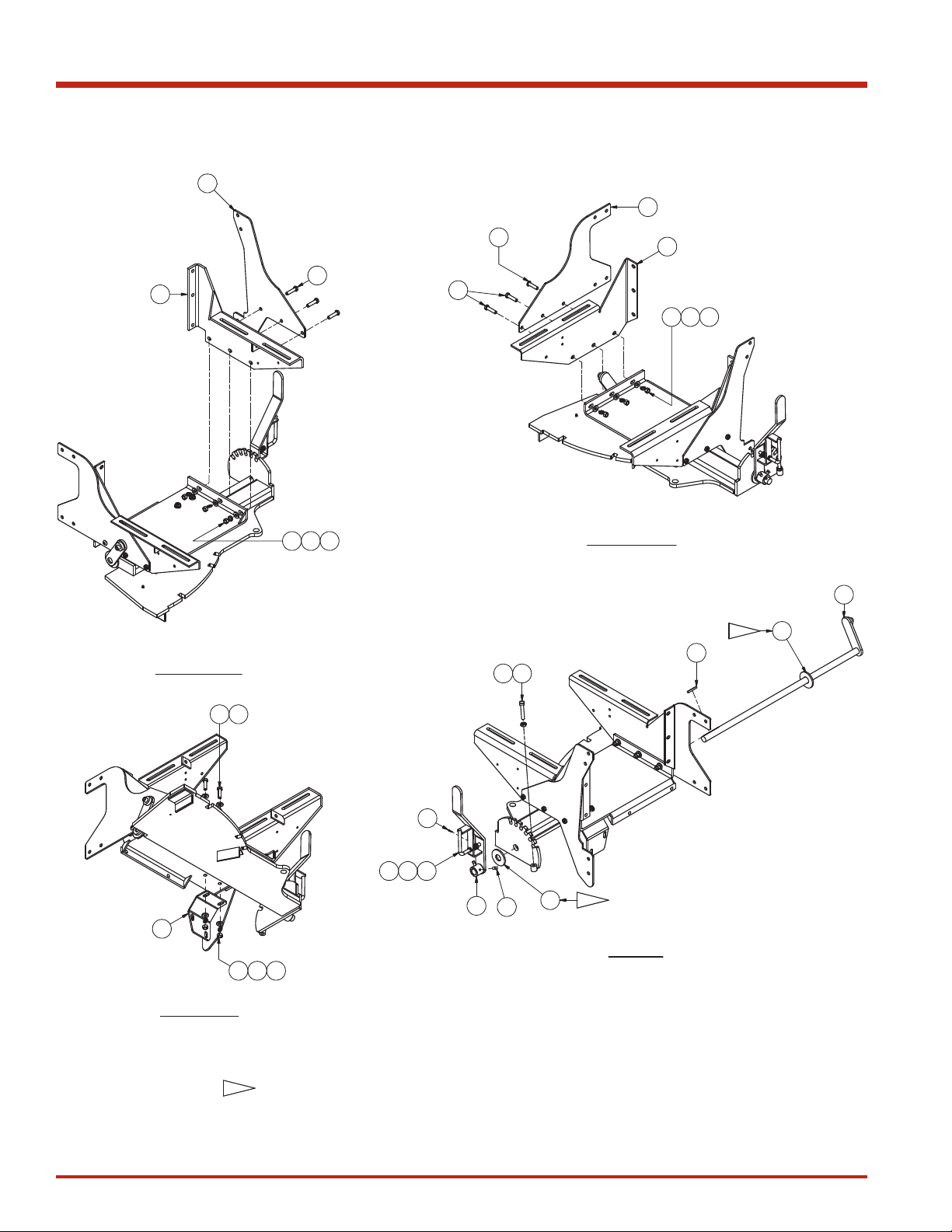

Front End Installation, Gearbox 37X

Page 1 of 1

Front End Installation, Gearbox Baler

Page 1 of 1

Item Part No. Qty Description Item Part No. Qty Description

906814 Installation, Front End

1 * 906815 1 . Front End Assembly

2 R13806345 2 . Capscrew

3 221771W 10 . Hard Washer

4 R13812516 18 . Lockwasher

5 221712W 8 . Hex Nut

6 Y25G-0824 2 . Capscrew

7 200454W 8 . Capscrew

8 221711W 8 . Hex Nut

9 234176 6 . Capscrew

* See Separate Coverage

Rev B

9 5 4 3

784

684

7

34

2X

8 4 7

X2

847

X2

5439

3X

2X

2X

1

X3

2

4

5

3

2X

12

89-096 Rev: 11-2016

Intentionally Left Blank

13 89-096Rev: 11-2016

Front End Assembly, Gearbox 37X

Page 1 of 2

Front End Assembly

Page 1 of 2

RH MOUNT

LH MOUNT

LEVER

BRACKET

24

7

19 18 14

8

X3

3X

13

24

19 18 14

4

6

X3

12 14

19 18 14

11

2X

X2

9

22

21

2317

115

X2

5

1620

5

NOTES:

- USE WASHERS (ITEM 5) AS NEEDED TO LIMIT SIDE-TO-SIDE MOVEMENT, BUT STILL ALLOW LEVER TO ROTATE FREELY.

1-1

1-1

1-1

14

89-096 Rev: 11-2016

Front End Assembly, Gearbox 37X

Page 2 of 2

Item Part No. Qty Description Item Part No. Qty Description

906815 Front End Assembly

1 F000007539 1 . Lever Weldment

2 F000007540 1 . Pin, Lift Lever Adj

3 F000007541 1 . Compression Spring

4 906822 1 . Engine Mounting Weldment, RH

5 F000008247 2 . Washer

6 GUS0024467 1 . Plate,Support Gusset

7 904463 1 . Plate,Support

8 906824 1 . Engine Mounting Weldment, LH

9 PLF0026952 1 . Lever Weldment

10 906825 1 . Hitch Base Weldment

11 904477 1 . Plate, Front Gusset

12 221569W 2 . Capscrew

13 Y25G-0832 1 . Capscrew

14 221771W 10 . Hard Washer

15 SQS3750750 2 . Square Head Screw

16 SQS5003000 1 . Screw, Set

17 223634 1 . Flat Washer

18 R13812516 8 . Lockwasher

19 221711W 8 . Hex Nut

20 234218 1 . Jam Nut

21 15223W 1 . Pin, Cotter

22 48688 1 . Key

23 11079 1 . Fitting, Lube

24 R13811077 5 . Capscrew

Rev -

Front End Assembly

Page 2 of 2

10

23

15 89-096Rev: 11-2016

Engine Installation, 37X

Page 1 of 4

Engine Installation, 37X

Page 1 of 4

Item Part No. Qty Description Item Part No. Qty Description

906189 Engine Installation

1 * 906188 1 . Assembly, Engine

2 252293 1 . Muffler

3 F000007742 1 . Battery Ground Strap 12 Volt

4 CLP0035751 1 . Clamp, Exhaust

5 EXH0011007 1 . Cap, Exhaust

6 F000007010 2 . Bolt, Adjusting

7 253403 1 . Gauge

8 F000007000 1 . Belt, Drive

9 * 254896 1 . Air Cleaner Assembly

10 ACL0004307 2 . Band, Air Cleaner

11 207146 3 . T-Bolt Clamp

12 207147 1 . T-Bolt Clamp

13 225370 2 . T-Bolt Clamp

14 ACL0000005 1 . Insert, Rubber

15 4200115 1 . Elbow, Rubber

16 255118 1 . Reducer

17 255120 1 . Reducer

18 00273802 4 . Nut, Serrated

19 SMS0000184 4 . Bolt, Whiz

20 902789 1 . Plate

21 252742 1 . Precleaner

22 ACL0000004 1 . Indicator

23 902904 1 . Tube, Spacer

24 902909 1 . Elbow

25 902913 1 . Tube

26 221569W 2 . Capscrew

27 234665 4 . Lockwasher

28 221771W 14 . Hard Washer

29 221711W 8 . Hex Nut

30 221576W 2 . Capscrew

31 HYD5275032 1 . Connector, Bulkhead

32 399741W 2 . Screw, Flange

33 R13812213 2 . Flat Washer

34 09416918 2 . Nut, Serrated

* See Separate Coverage

N/A Not Applicable

Rev - AA

NOTES:

1-1 ENSURE 84 TO 86 PLUNGER STROKES PER MINUTE

AT ENGINE FULL THROTTLE.

1-2 ENSURE 33 TO 35 PLUNGER STROKES PER MINUTE

AT ENGINE LOW IDLE.

1-3 906189 ASSY SHOWN

16

89-096 Rev: 11-2016

Engine Installation, 37X

Page 2 of 4

Engine Installation, 37X

Page 2 of 4

FLYWHEEL BELT MOUNTING

BELT SHIELD NOT SHOWN

370/375 BALER SHOWN

BATTERY STRAP & CABLE MOUNTING

370/375 BALER SHOWN

DETAIL A

1

8

RED 12 GA WIRE

FROM CONTROL BOX

HARNESS

3

NEG

POS

REFERENCE EXISTING BATTERY

CABLE ON ENGINE ASSEMBLY

2-2

2-1

A

REFERENCE

#BAT0277000

12V BATTERY

2-4

2-3

REFERENCE

EXISTING BATTERY

CABLE ON ENGINE

ASSEMBLY

RECOMENDED BELT TENSION

BELT DEFLECTION FORCE

F000007000 0.75" 16 LB

256812 0.63" 16 LB

2-1

17 89-096Rev: 11-2016

Engine Installation, 37X

Page 3 of 4

Engine Installation, 37X

Page 3 of 4

ENGINE BELLY PAN

TO FRONT END

ASSY. MOUNTING

29 27 28

29 27 28 28

29

27

28

28

30

28

28

26

28

28

30 28 28

26 28 28

629 29

27

28

NOTES:

MOUNT BATTERY GROUND CABLE TO

THIS FASTENER ON THE ENGINE.

GEARBOX BALER ONLY:

ROUTE GROUND WIRE BEHIND ENGINE TO BATTERY.

SEE TABLE FOE RECOMENDED BELT DEFLECTION

AND DOWNWARD FORCE AT CENTER OF BELT SPAN.

FOR GEARBOX BALER ENSURE ENGINE PUMP IS PRIMED PRIOR

TO STARTING ENGINE. CAN FILL HYDRAULIC RESERVOIR AND

LET SIT FOR 8 HRS TO PRIME PUMP.

906189 ASSY SHOWN.

2-1

2-2

2-3

2-4

2X 2X

2-5

18

89-096 Rev: 11-2016

Engine Installation, 37X

Page 4 of 4

Engine Installation, 37X

Page 4 of 4

MUFFLER AND TENSION CONTROL

370/375 BULLGEAR BALER SHOWN

AIR CLEANER ASSEMBLY

5

2

4

1

31

7

AIR CLEANER ASSEMBLY

14

13

15

11

23

11

24

11

22

9

16

12

17

13

25

21

20 18 19

10

1

32

32

34 33

34 33

REFER TO 906705 FOR ADDITIONAL

AIR CLEANER ASSEMBLY NOTES

AIR CLEANER MOUNT

LOCATION ON SNORKEL

USE EXISTING HARDWARE

19 89-096Rev: 11-2016

Engine Assembly

Page 1 of 4

In Baler Parts Manual

Engine Assembly

Page 1 of 4

Item Part No. Qty Description Item Part No. Qty Description

906188 Assembly, Engine

1 * 903907 1 . Control Box Assembly

2 CBL1743180 1 . Cable, Control

3 CLH0001084 1 . Clutch

4 CLV1756012 1 . Clevis Assembly

5 * 258766 1 . Engine, Deutz 4 Cylinder

6 900537 1 . Arm Extension Weldment

7 EXH0013806 1 . Tube, Exhaust

8 900534 1 . Plate,Mounting

9 F000007699 1 . Pulley, Motor

10 MNT0018340 1 . Belly Pan Weldment

11 F000007013 1 . Bracket

12 252601 2 . Fitting

13 231486 1 . Set Screw

14 STS5000750 1 . Set Screw

15 SHD0028273 1 . Plate,Shield

17 R13811085 4 . Capscrew

18 Y09C-M0616 1 . Capscrew

20 Y09C-M1030 22 . Capscrew

25 221771W 8 . Washer

26 234589 22 . Lockwasher

27 292680W 1 . Washer

28 296420W 18 . Hard Washer

29 220044 1 . Hex Nut

32 223587 4 . Nut, Esna

33 235620 2 . Nut, Esna

37 R13810989 2 . Capscrew

38 R13811014 2 . Capscrew

39 232939 2 . Nut, Esna

40 905246 16 . Washer, Fender

41 904697 1 . Restrictor

42 201431 1 . Hose Clamp

43 CBL0000126 1 . Cable Assembly,Battery

44 906659 1 . Fitting

45 906660 1 . Hose Assembly

46 236077 3GL . Oil, Engine

47 293613W 1 . Capscrew

48 WLKM000080 1 . Lockwasher

49 WCTM100080 1 . Washer

50 209588 1 . Clip

* See Separate Coverage

Rev A

9

NOTES:

AFTER INSTALLING PULLEY CUT AWAY EXCESS SHAFT FROM

CLUTCH. REMAINING SHAFT SHOULD EXTEND PAST PULLEY

APPROXIMATELY 0.25".

TRIM SIDE CONNECTING TAB BEFORE TAPING.

SET FINAL TOP ENGINE RPM AT FULL THROTTLE TO 2200 TO 2250

(84 TO 86 PLUNGER STROKES PER MINUTE).

SET FINAL LOW ENGINE RPM AT FULL THROTTLE TO 1000 TO

1025 (33 TO 35 PLUNGER STROKES PER MINUTE).

ALL MEASUREMENTS ARE TO BE TAKEN AT THE PULLEY OFF

THE ENGINE. REFER TO ENGINE ASSEMBLY NOTES (ITEM 0, PN

906640) FOR MORE DETAILED INSTRUCTIONS.

1-1

1-1

RED / WHITE

16 GA WIRE

RED YELLOW

WHITE

WHITE

CONNECT TO ENGINE WIRE

HARNESS, THEN TAPE

CONNECTORS TOGETHER.

WIDE TAB

NARROW TAB

TEMP SENSOR

CONNECT WIRE END

TO NARROW TAB.

ENGINE HARNESS

1-2

1-2

1-2

1-3

1-4

1-5

20

89-096 Rev: 11-2016

Table of contents