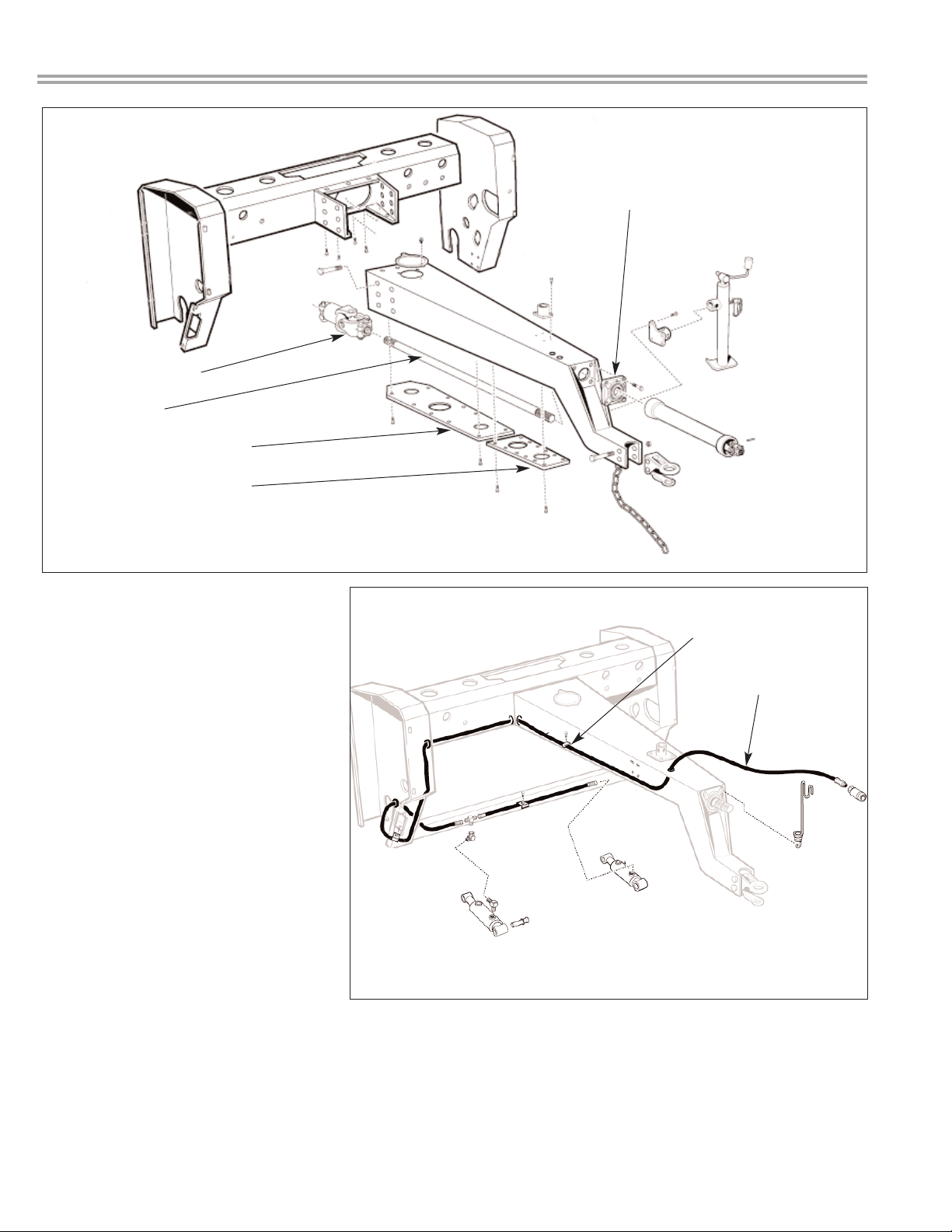

BEARING REPLACEMENT

Sealed ball bearings are held in position on the shaft

by a locking collar, figure 1, which is rotated to lock

the assembly on the shaft and secured by a set

screw. To remove Bearing:

1. Loosen set screw

2. Use a drift punch inserted in the drift pin hole to

rotate and loosen the locking collar (1). Rotate the

locking collar counter clock wise.

3. Remove the locking collar.

4. Support the shaft, for easier assembly later.

5. Remove the bolts for the bearing flanges.

6. Slide the bearing and the flanges from the shaft.

Note: Cleaning paint and corrosion from the shaft will

make removal easier.

7. Put on the new bearings and flanges.

8. Replace locking collar on the shaft. Rotate the lock-

ing collar clockwise until lightly engaged. Tighten the

collar by hitting it with a drift pin punch inserted in the

drift pin hole rotating it further clockwise.

9. Tighten set screw.

REPLACING OR REPACKING WHEEL BEARINGS

1. Remove wheel hubs and disassemble.

2. Clean bearings, seals, caps, washers, nuts and

hubs with kerosene or other solvent.

3. Replace bearings or seals if worn or damaged.

4. Pack bearing cones and seals with No. 2 multi-pur-

pose lithium grease or equivalent.

5. Reassemble hub and bearings. ( figure 2 )

a. Press cups against the shoulder in the hub.

b. Press seal flush into hub after bearing.

c. Place hub on shaft taking care not to damage

the seal!

d. Tighten the wheel bearing nut. Do not

overtighten.

e. Secure nut with a cotter pin.

f. Be sure to replace hub cap.

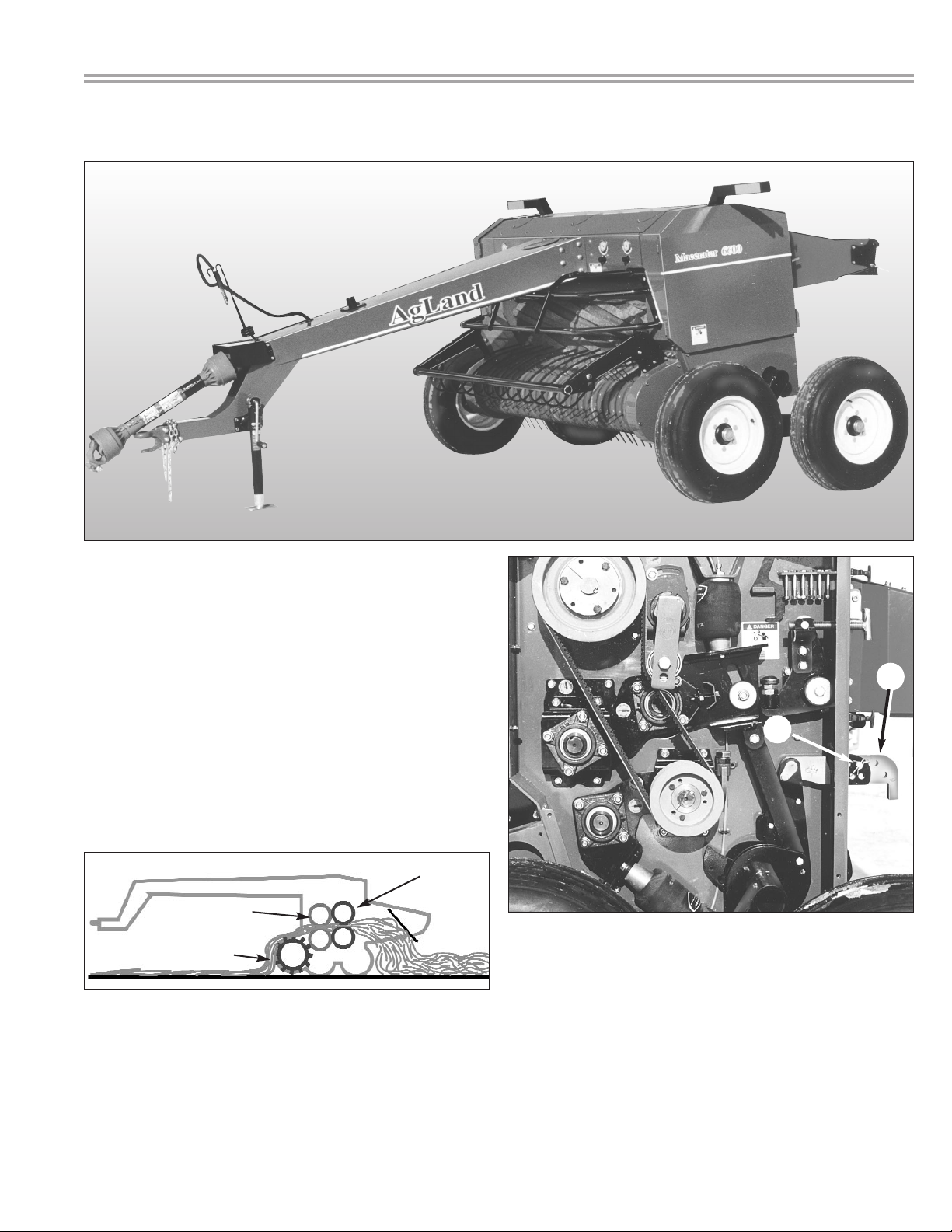

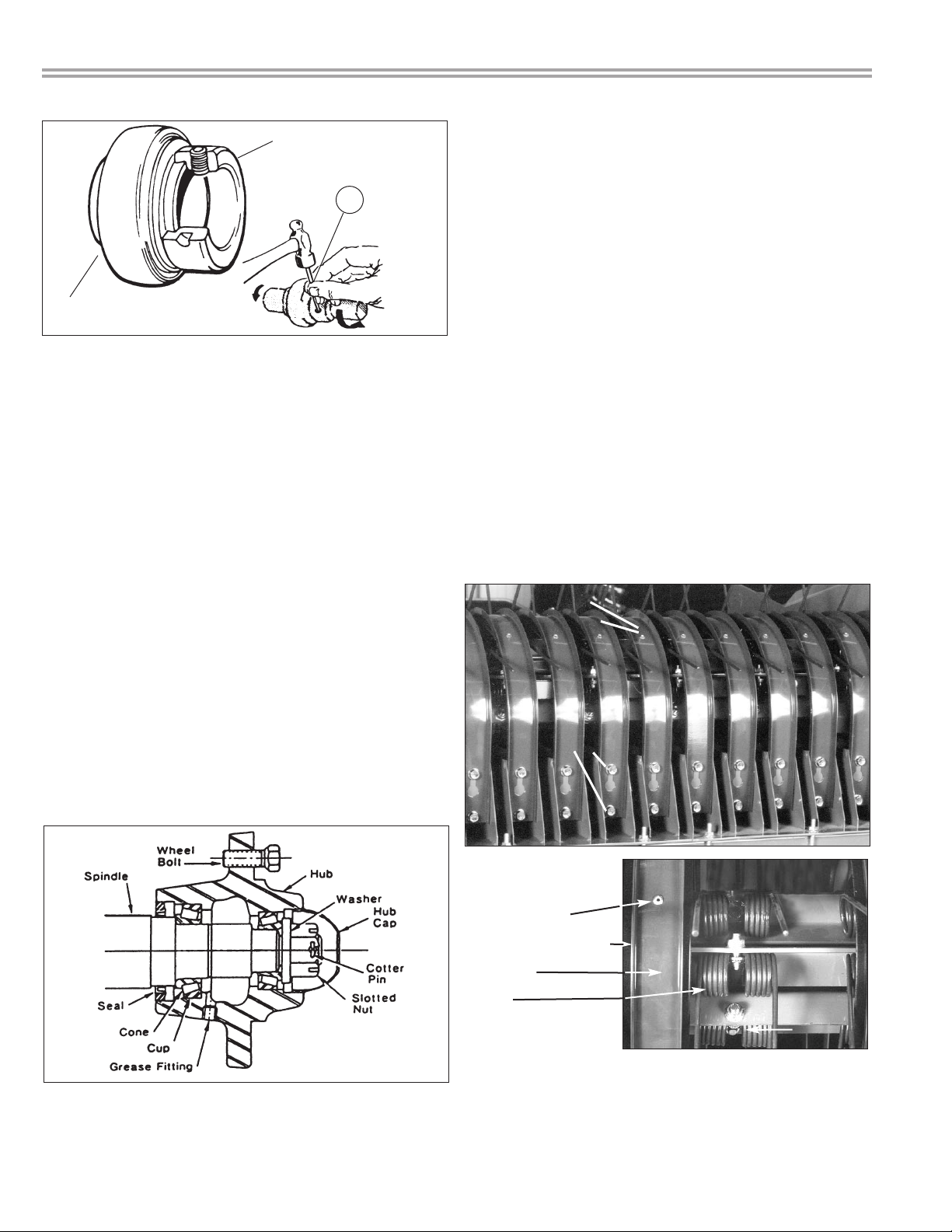

PICKUP TEETH, WRAPPERS, WEAR STRIPS

Check for bent, broken or loose parts. If it is necessary

to replace teeth or related parts, proceed as follows.

1. Ensure that your Macerator is blocked securely.

Loosen the bolts, holding the wrapper(s) on pickup. (fig.

3) Slide wrapper forward, and remove the wrapper from

the bolts.

“Pop”Rivets

Plastic Wear Strips

Wrapper

Teeth

2. Should the plastic wear strip require removal and

replacement, drill out or carefully grind off the “pop”

rivets. Replace strip with new rivets (figure 4).

3. Install new teeth or wrapper(s).

MAINTENANCE

Figure 4

Figure 3

16

two rivets

two bolts

1

locking collar

bearing

Figure 2

Figure 1