v

Contents

Safety Summary ...................................................................i

General ............................................................................. 1-1

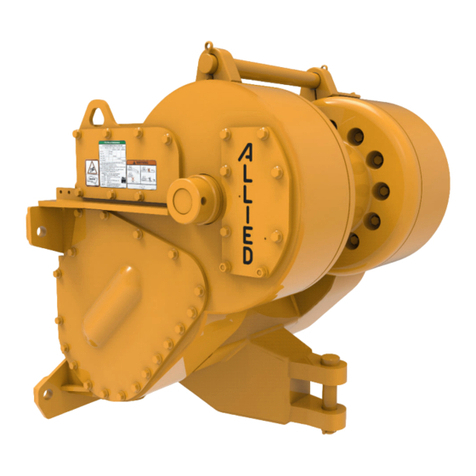

Introduction........................................................................ 1-1

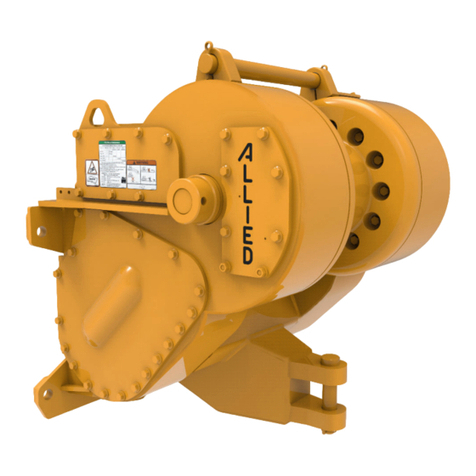

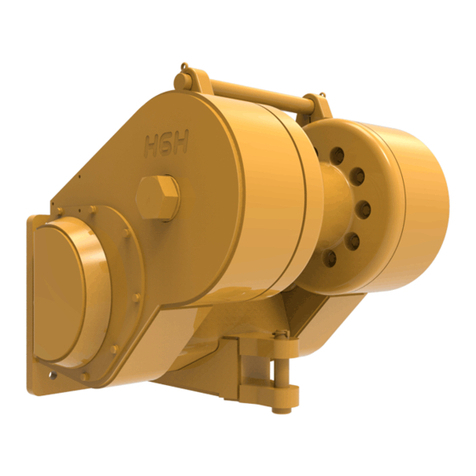

Description ........................................................................ 1-1

Unit Identification........................................................ 1-2

Serial Number Codes................................................. 1-4

Nameplate.................................................................. 1-4

Specifications .................................................................... 1-5

Drum Wire Rope Capacities....................................... 1-5

Hydraulic Specifications ............................................. 1-5

Oil Specifications........................................................ 1-5

Oil Capacity................................................................ 1-5

Maintenance Decal..................................................... 1-5

Torque Specifications ................................................. 1-6

Gear Train ......................................................................... 1-7

FREESPOOL Operation............................................. 1-8

Operation and Control ....................................................... 1-9

Hydraulic System............................................................. 1-10

Motor ....................................................................... 1-11

Brake ........................................................................ 1-12

Planetary Reducer ................................................... 1-13

Counterbalance Relief Manifold ............................... 1-14

Directional Manifold.................................................. 1-15

Control Manifold ....................................................... 1-16

Operator Control Panel ............................................ 1-17

Sequence of Operation, Option Code B.......................... 1-18

BRAKE-ON............................................................... 1-18

LINE-IN..................................................................... 1-20

LINE-OUT................................................................. 1-22

BRAKE-OFF............................................................. 1-24

FREESPOOL ........................................................... 1-26

Sequence of Operation, Option Code D.......................... 1-28

BRAKE-ON............................................................... 1-28

LINE-IN..................................................................... 1-30

LINE-IN Hi-Speed..................................................... 1-32

LINE-OUT................................................................. 1-34

BRAKE-OFF............................................................. 1-36

FREESPOOL ........................................................... 1-38

Schematics...................................................................... 1-41

Troubleshooting............................................................... 2-1

General.............................................................................. 2-1

Step-By-Step Pump & Controller Troubleshooting............. 2-1

Troubleshooting Analysis Check Chart.............................. 2-3

Service.............................................................................. 3-1

General ............................................................................. 3-1

Maintenance...................................................................... 3-1

Maintenance Points .................................................... 3-1

Maintenance Schedule............................................... 3-1

Checks Before Operation ........................................... 3-2

Checks During Operation........................................... 3-2

FREESPOOL Drag Adjustment......................................... 3-2

Hydraulic System Pressure Checks .................................. 3-2

Preparation................................................................. 3-2

Pressure Gauges ....................................................... 3-2

Pilot Supply Pressure Check...................................... 3-3

Directional Valve Pressure Check............................. 3-3

Motor Supply Pressure Check.................................... 3-3

Brake Pressure Check................................................ 3-3

Brake Valve Pressure Check ...................................... 3-3

FREESPOOL Pressure Check................................... 3-4

BRAKE-OFF Pressure Check.................................... 3-4

LINE-IN Pressure Check............................................ 3-5

LINE-OUT Pressure Check ........................................ 3-5

Valve Setting Procedures .................................................. 3-5

Brake Release Valve .................................................. 3-5

Pilot Supply Reducing Valve....................................... 3-5

Hydraulic System Pressure Tests ...................................... 3-6

Repairs ............................................................................ 4-1

General ............................................................................. 4-1

Winch Removal.................................................................. 4-1

Winch Disassembly ........................................................... 4-1

Intermediate & FREESPOOOL Shaft Removal.......... 4-2

Drum Shaft & Drum Removal..................................... 4-6

Hydraulic System Disassembly ................................ 4-10

Motor Shaft Removal & Disassembly....................... 4-14

BRAKE-OFF Clutch Disassembly ............................ 4-18

Brake Disassembly................................................... 4-20

Planetary Reducer Disassembly .............................. 4-22

Winch Assembly .............................................................. 4-24

Visual Inspection ...................................................... 4-24

Planetary Reducer Assembly................................... 4-26

Brake Assembly ....................................................... 4-28

BRAKE-OFF Clutch Assembly ................................. 4-30

Motor Shaft Assembly & Installation ........................ 4-34

Hydraulic System Assembly..................................... 4-38

Drum & Drum Shaft Installation ............................... 4-42

Intermediate & FREESPOOL Shaft Installation ....... 4-48

Winch Installation ............................................................ 4-52

Contents