Allied Systems W6F User manual

Table of contents

Other Allied Systems Winch manuals

Allied Systems

Allied Systems H5C Series User manual

Allied Systems

Allied Systems W3C User manual

Allied Systems

Allied Systems W8L User manual

Allied Systems

Allied Systems H12A Guide

Allied Systems

Allied Systems W6G User manual

Allied Systems

Allied Systems W12E User manual

Allied Systems

Allied Systems W8L User manual

Allied Systems

Allied Systems H6H User manual

Allied Systems

Allied Systems H4A User manual

Allied Systems

Allied Systems H6H User manual

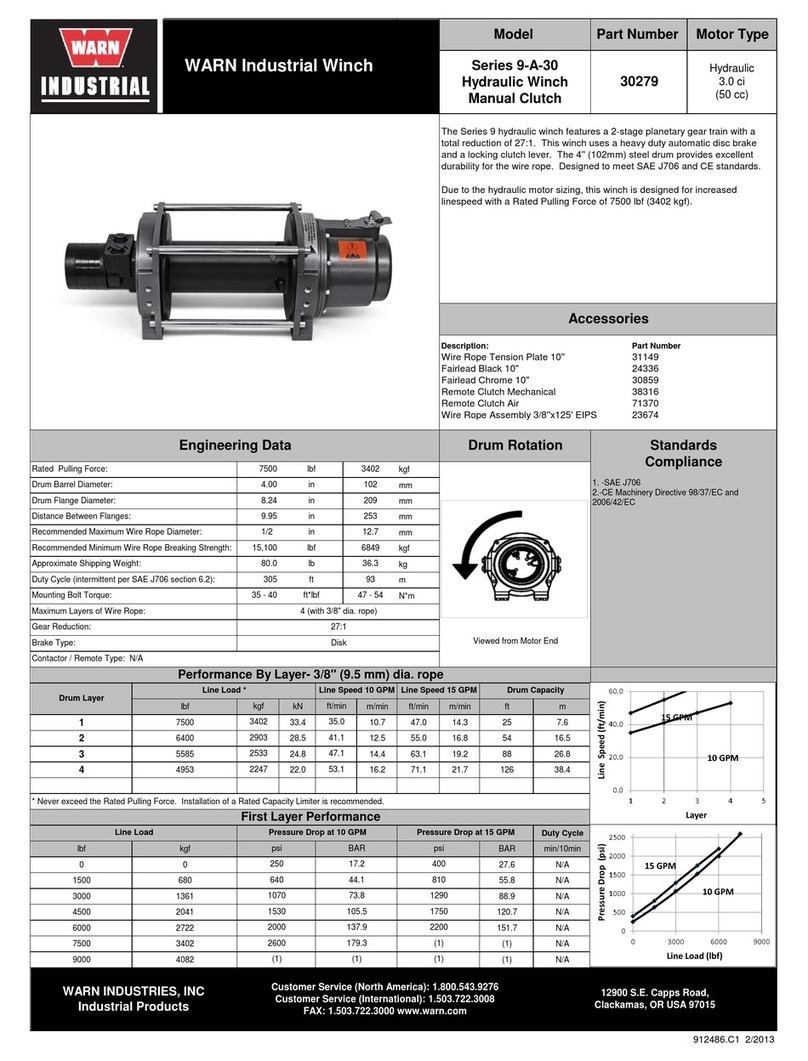

Popular Winch manuals by other brands

Harken

Harken 1130 User and maintenance manual

Ingersoll-Rand

Ingersoll-Rand HU Series Operation and maintenance manual

Portable Winch

Portable Winch PCA-1264 user manual

Ramsey Winch

Ramsey Winch HD-P10000 Operating, Service and Maintenance Manual

Ramsey Electronics

Ramsey Electronics DCY200 Fitting & operating instructions

Thern

Thern 465 owner's manual