01.05/WE 17

ORGAPACK CR 25 A

1TECHNICAL DATA

TABLE OF CONTENTS

Weight 3.2 kg (7 lbs)

Dimensions Length 302 mm (17.75")

Width 130 mm (5")

Height 180 mm (7")

Tensionforce Up to approx. 3000 N

Tensionspeed 75 mm/s (3“/s)

Air pressure Maximum 6 bar static

Air consumption

– Tensioning 4 Nl/s

– Sealing 3.4 Nl

Air connection G 1/4“ ( 1/4“ NPT)

Sealing Sealjoint with 1 notch

Emission sound pressure

levels,measurement

type A (EN ISO 11202) LpA 83 dB (A)

Vibrations at handle

(EN ISO 8662-1) ah,w < 2,5 ms-2

STEELSTRAP

Strap width 13, 16, 19 mm

(1/2", 5/8", 3/4")

Normalquality:

Strap thickness 0.40–0.63mm (.015"–.024")

Tensilestrength Up to approx. 850 N/mm2

(117'000lbs/in2)

Highstrength

quality:

Strap thickness 0.40–0.63mm (.015"–.024")

Tensilestrength Up to approx. 1100 N/mm2

(156'000lbs/in2)

SEALS

Strap width 13 mm CSP 411

Strap width 16 mm CSP 511

Strap width 19 mm CSP 611

Page

1 Technical data 17

2 General information 18

2.1 Information on environmental protection 18

3 Safetyinstructions 19

4 Description 20

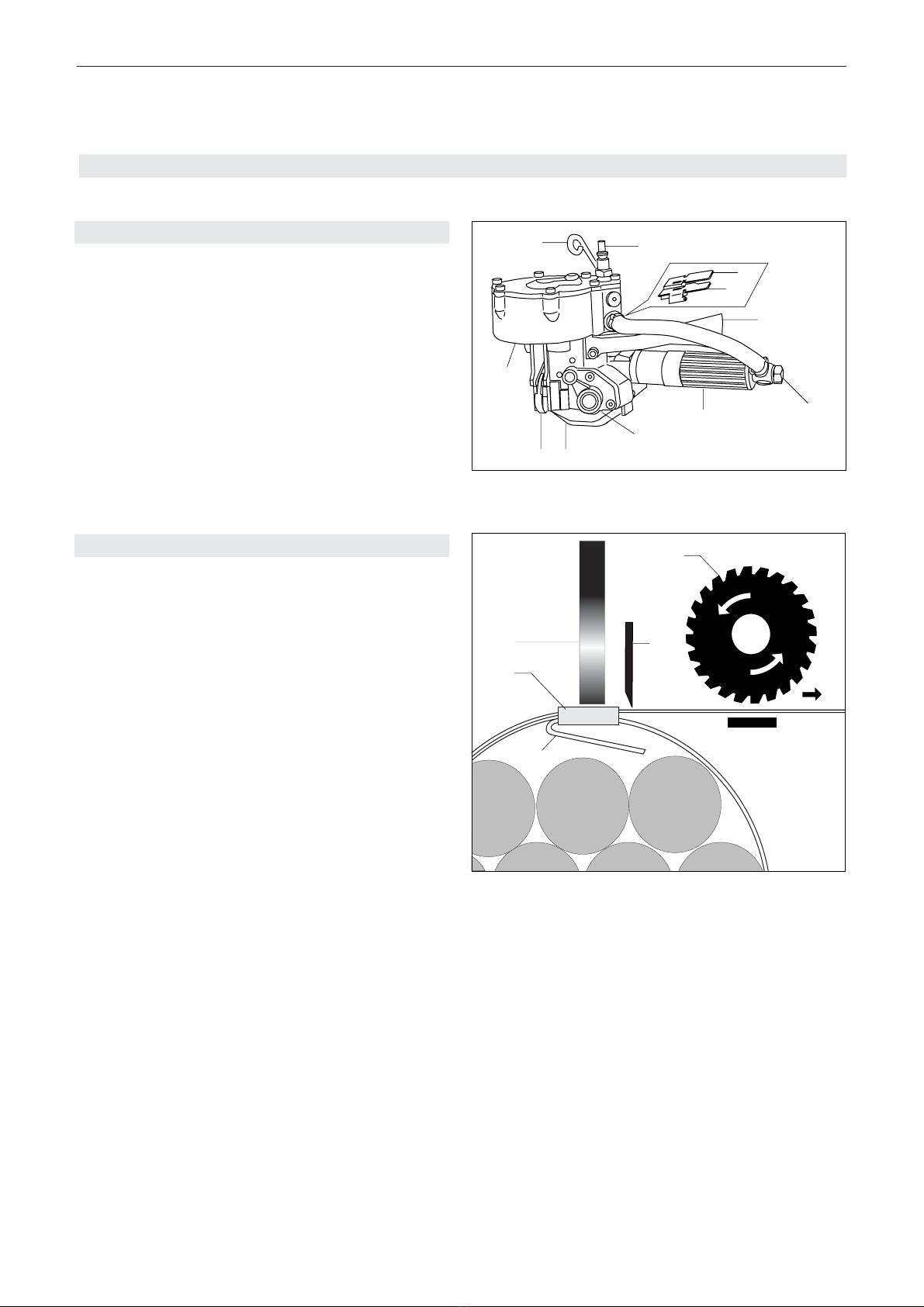

4.1 Design 20

4.2 Function 20

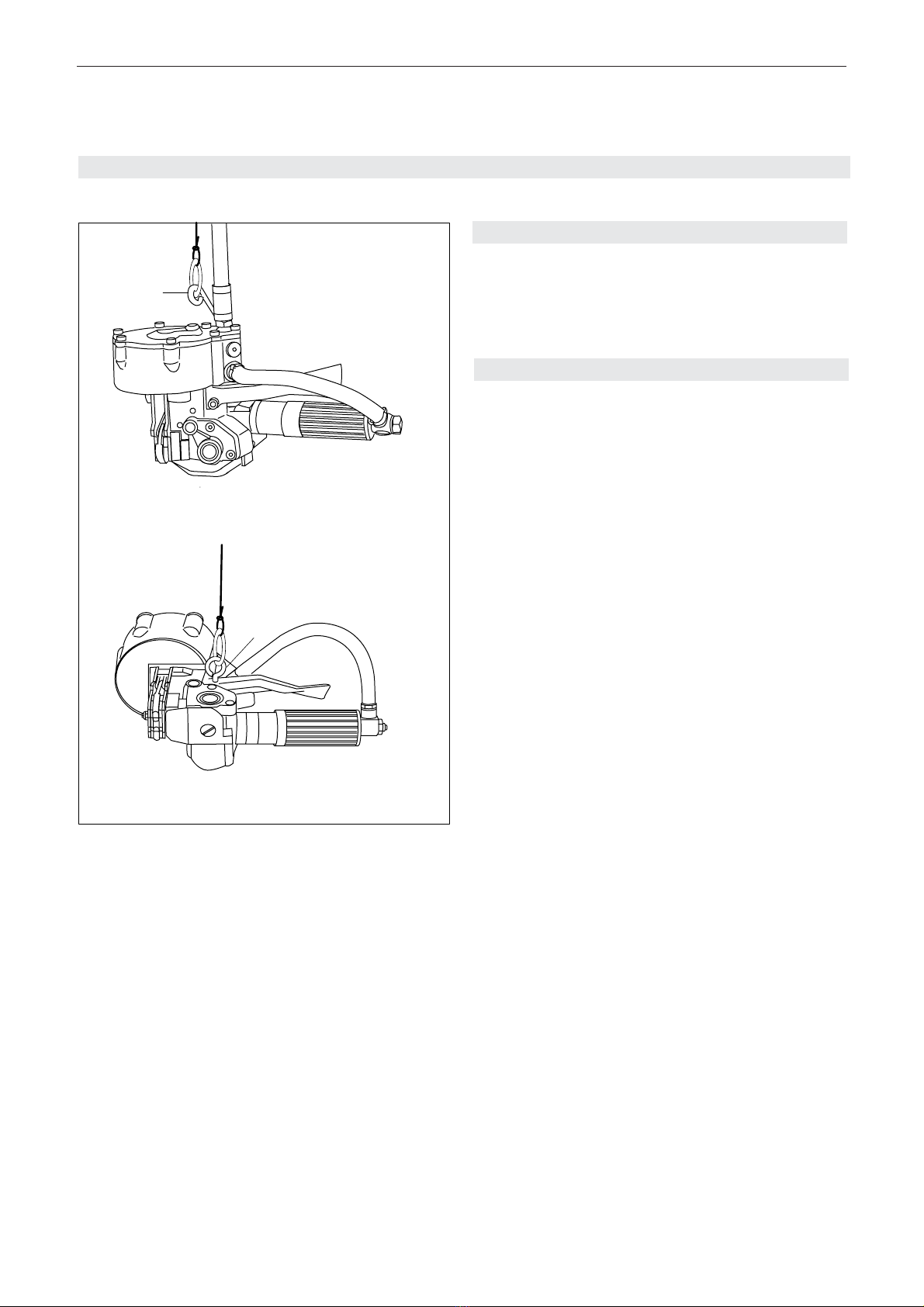

5 Initial operation 21

5.1 Suspending the tool 21

5.2 Compressed-air connection 21

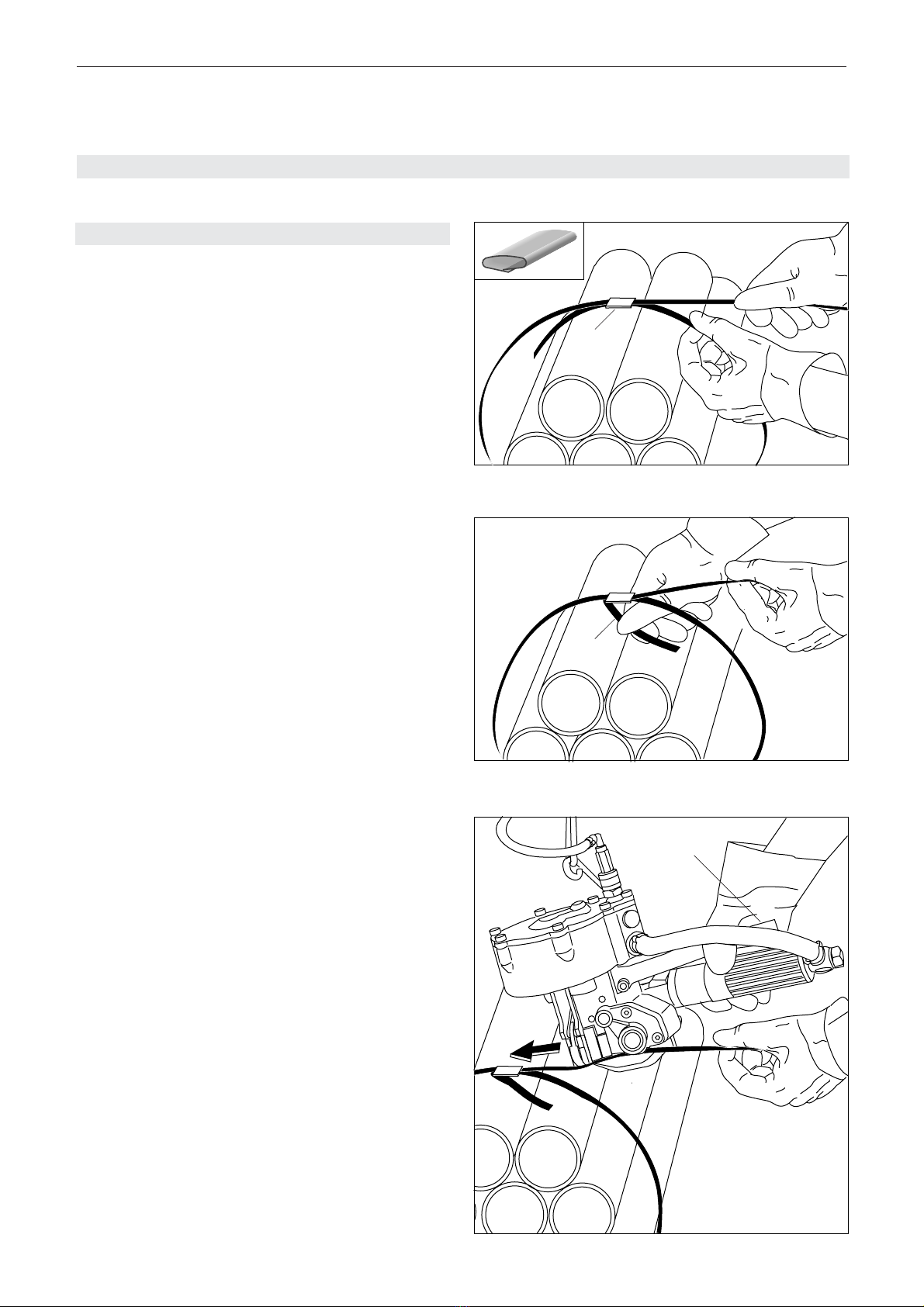

6 Operatinginstructions 22

6.1 Operating the tool 22

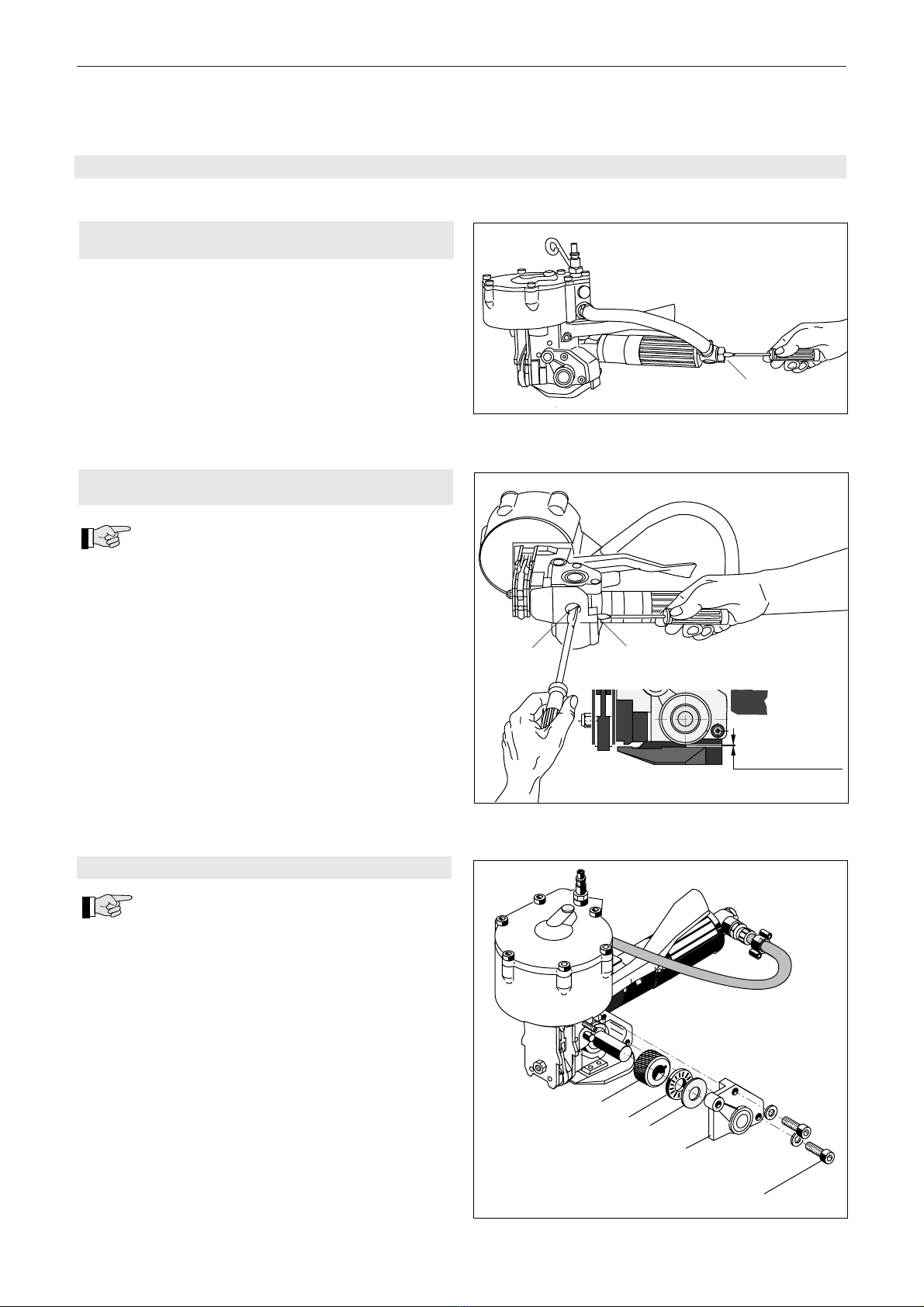

7 Preventive and corrective maintenance 24

7.1 Adjustingtensioning force/tensioning speed 24

7.2 Setting clearance between tension wheel and

tension plug 24

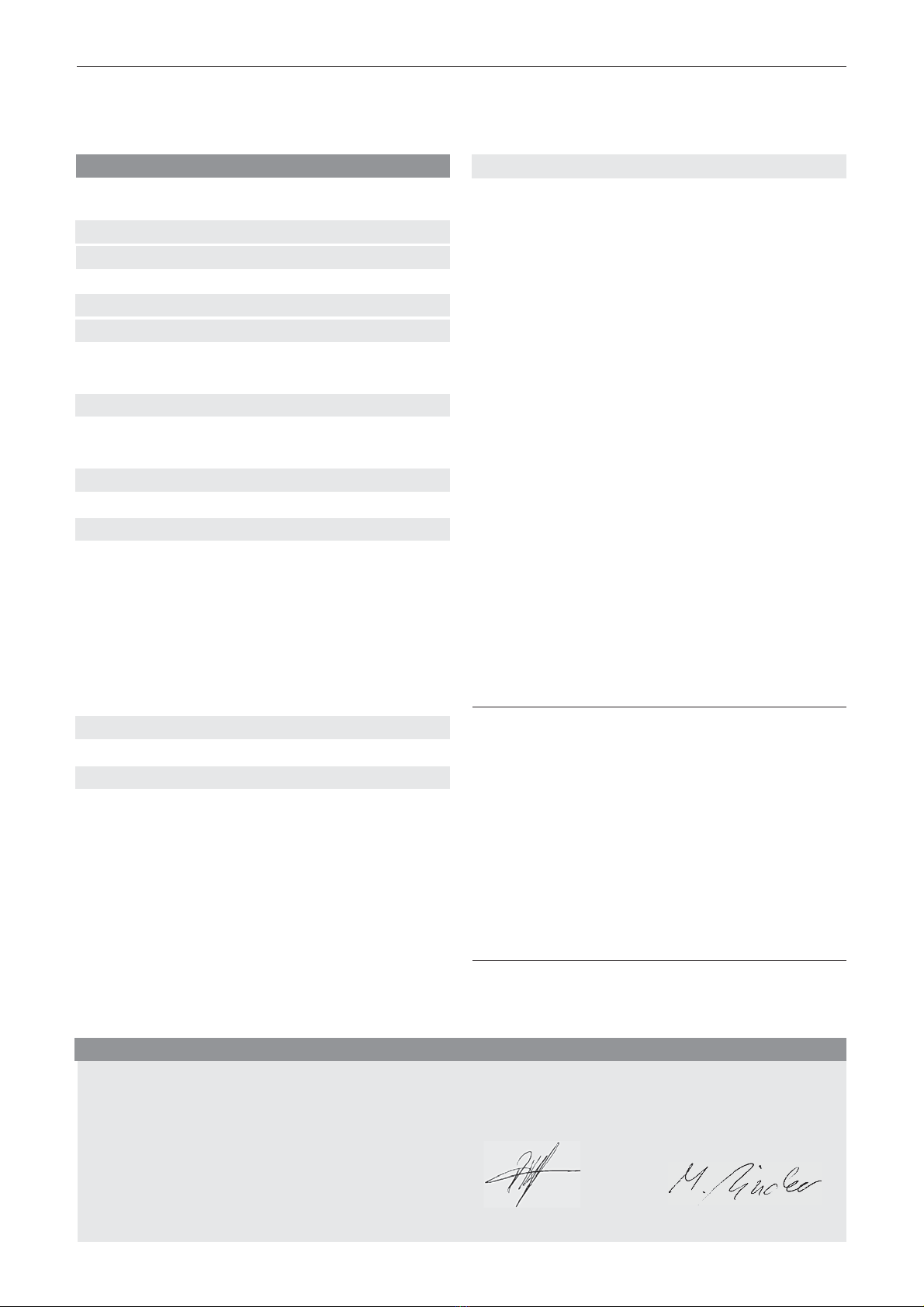

7.3 Replacingtension wheel 24

7.4 Replacing cutting knife 25

7.5 Replacing jaws and notcher 25

7.6 Cleaning the tool 25

8 Partslist 26

Explosiondrawing 28

9 Parts list compressed air motor 29

Explosiondrawing 30

We take sole responsibility for declaring that the

tool CR 25 A, to which this declaration refers, is in

full compliance with the current requirements of the

guidelines laid down by the council on 22th June

1998(98/37/EEC), “Machine Guidelines“.

According to norm:

EN 292-1, EN 292-2, EN 349, EN 983, EN 1050

prEN792-2

CH-8953Dietikon, February 2002

Manager Manager

Sales & Marketing: Engineering:

R.Kieffer M. Binder

DECLARATION OF AGREEMENT