2

Contents

1. Brief Description of Each Section .........................................................................................3

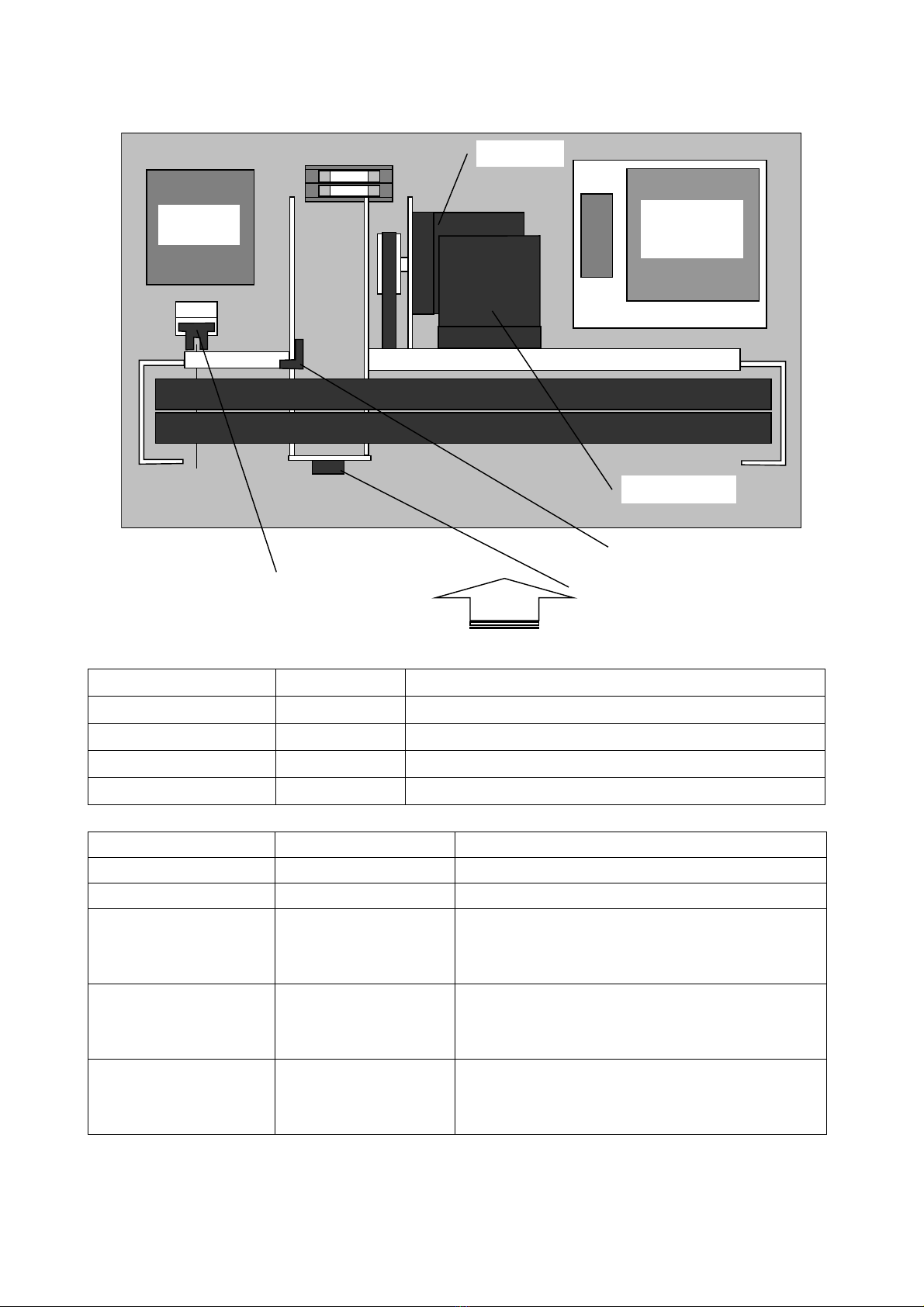

1. Reference assembly drawing of each section [Brief functional description of each section] 3

2. Function of each sensor or switch .......................................................................................... 4

3. Inching.................................................................................................................................... 5

2. Adjustment of Main Frame Section...................................................................................... 6

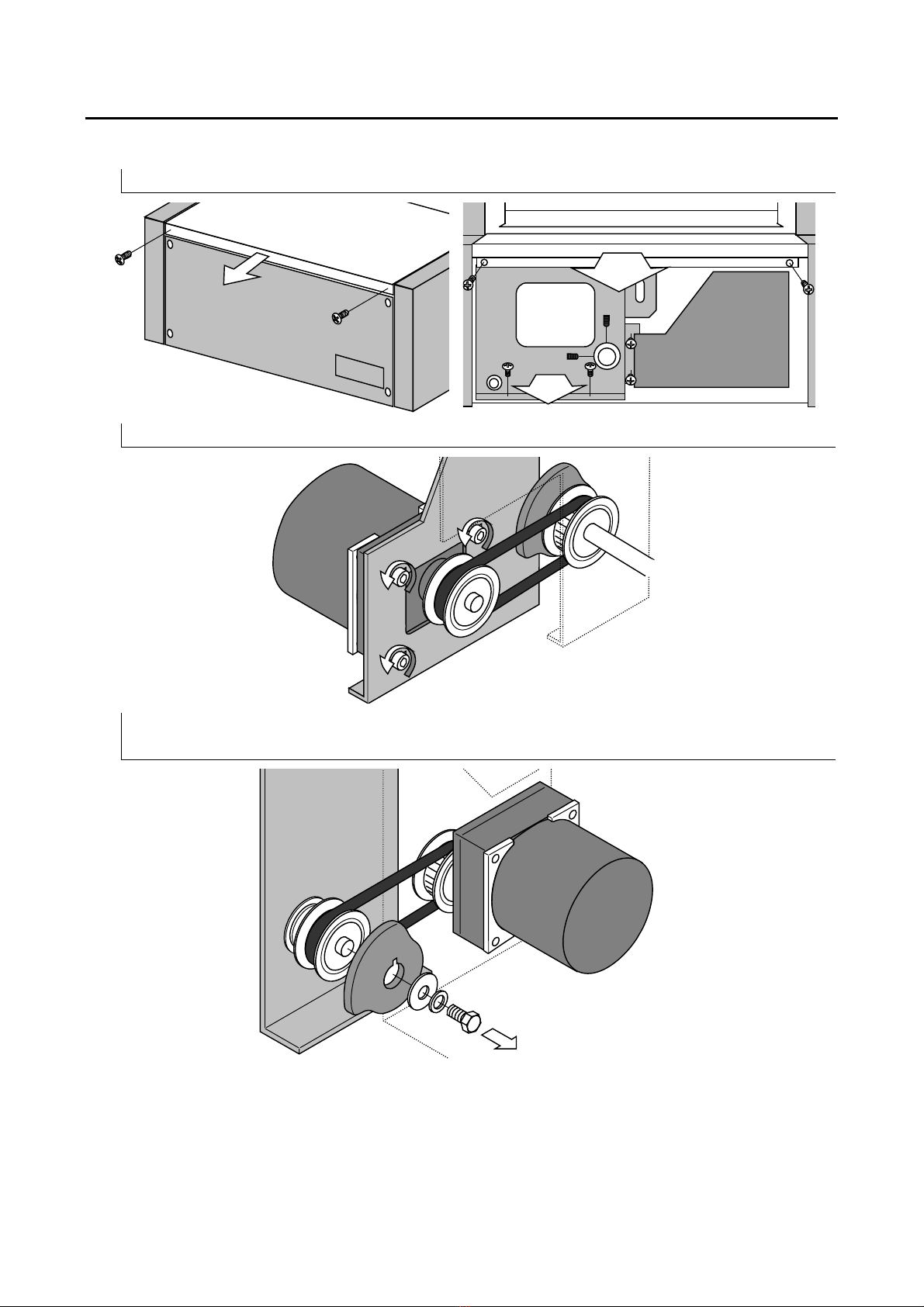

1. Replacement of spindle timing belt........................................................................................ 6

2. Adjustment of main spindle timing belt ................................................................................. 8

3. Adjustment of cutter section ...............................................................................................10

1. Replacement of cutter...........................................................................................................10

4. Adjustment of heater...........................................................................................................15

1. Replacement of heater.......................................................................................................... 15

5. Adjustment of hold plate section.........................................................................................18

1. Position check of sensor mounting plate.............................................................................. 18

2. Adjustment of sensor mounting plate................................................................................... 20

3. Adjustment of tape detecting plate....................................................................................... 23

6. Adjustment of tape reel section...........................................................................................25

1. Replacement of tape brake. .................................................................................................. 25

2. Adjustment of tape break........................................................................................................ 27

7. Adjustment of tape guide section........................................................................................28

1. Adjustment of wire............................................................................................................... 28

8. Adjustment...........................................................................................................................29

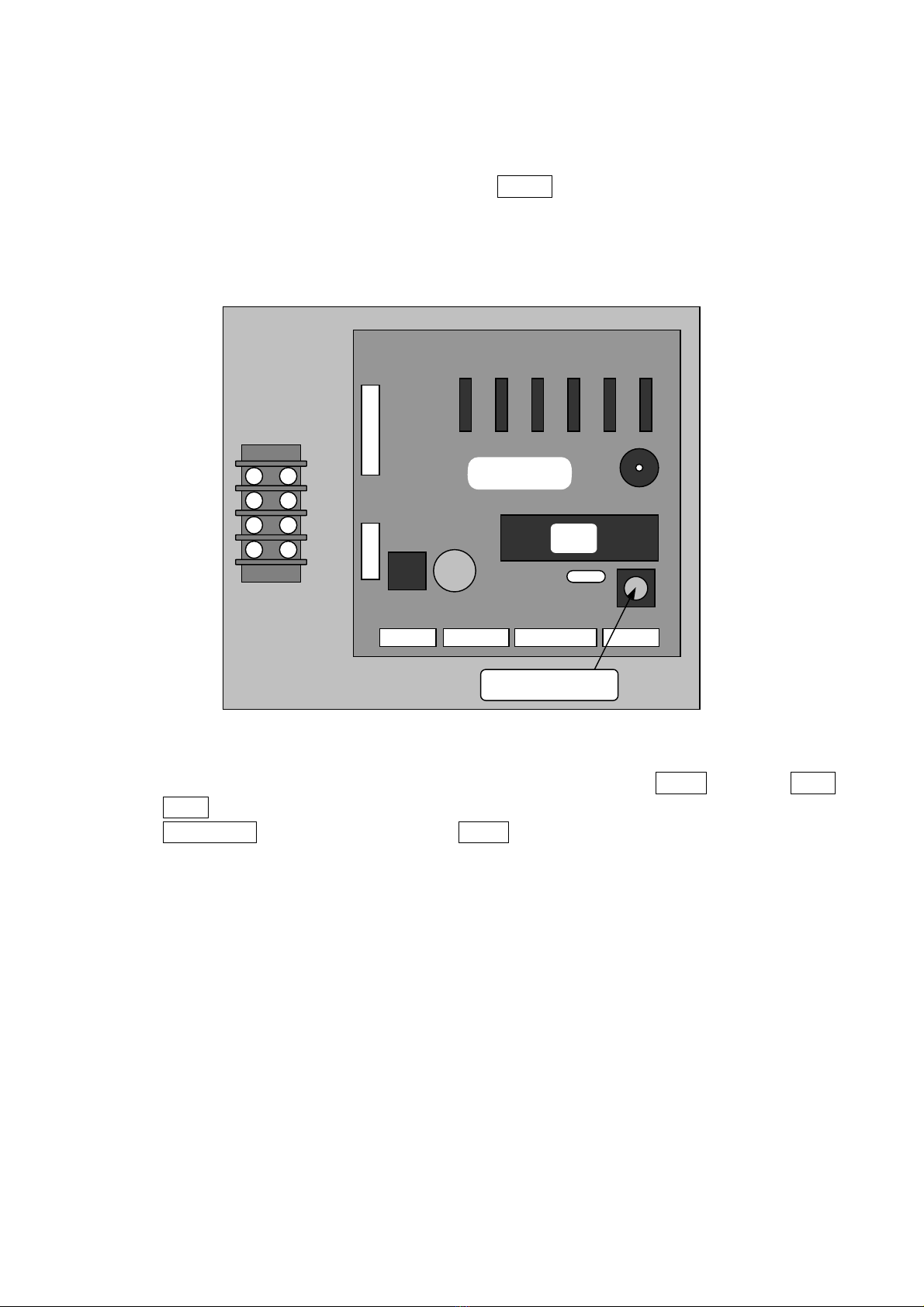

1. Installation of foot switch.....................................................................................................29

2. Starter Switch ....................................................................................................................... 29