Alltech KEENAN MechFiber Plus User manual

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 1

General operator’s manual

All models

Revision A01 April 2022 EN

KEENAN MechFiber+

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 2

CONTENTS

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 3

KEENAN contact details

Head Office

Alltech Farming Solutions Limited (KEENAN)

Borris, Co. Carlow, R95 K223 Ireland

Telephone: +353 (0) 59 9771200

Fax: +353 (0) 59 9771227

Website: keenansystem.com

Alltech Global Headquarters

3031 Catnip Hill Road, Nicholasville, KY 40356, United States of America

Telephone: 859-885-9613

Website: keenansystem.com

Alltech Farming Solutions (U.K.) Limited KEENAN

Ryhall Road, Stamford, Lincolnshire, United Kingdom, PE9 1TZ

Tel. Administration: 0800 587 3296

24-Hour Service: 0800 587 3296

Fax: 0844 358 3880

Website: keenansystem.com

KEENAN Australia

53 Pratts Part Road, Bendigo, East Bendigo Vic 3550, Australia

Sales, Service and Parts: 1 800 KEENAN (1800 533 626)

Website: keenansystem.com

Action Agriculture Limited

14 Leslie Street, Kihikihi, Te Awamutu 3800, New Zealand

Telephone: 1 800 4 KEENAN

Website: keenansystem.com

KEENAN Canada Inc.

20 Cutten Place, Guelph, Ontario N1G 4Z7, Canada

Telephone: 519 763 3331

Fax: 519 763 5682

Website: keenansystem.com

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 4

SECTION CONTENTS PAGE

1 Introduction 5

2 Identification 8

3 Warranty 13

4 Safety 15

5 Operation 21

5.1 Set-up 21

5.2 Weighing system 24

5.3 Machine telematics (where fitted) 24

5.4 Machine storage 26

5.5 Diet feeder capacity 26

5.6 Loading and mixing 27

5.7 Feeding-out 28

5.8 Operating the KEENAN MechFiber diet feeder 30

5.9 Washing and chopping root crops 31

5.10 Lifting hooks and anchoring points 31

6 Troubleshooting 33

6.1 General troubleshooting 33

6.2 Weighing troubleshooting 36

7 General maintenance 37

7.1 Maintenance advice 37

7.2 Wheels 38

7.3 Rear feed-out (where fitted) 38

7.4 Side and stub elevator (where fitted) 39

7.5 Axle maintenance 40

This KEENAN service and maintenance operator’s manual presents contact details and information on

identification, warranty, safety and operation, as well as relevant information for operating, maintaining

and troubleshooting your trailed KEENAN MechFiber+ diet feeder.

Contents: General service and maintenance manual

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 5

KEENAN MechFiber+ diet feeder

Thank you for purchasing a KEENAN product —we appreciate your business. Your decision to

choose a KEENAN means that you are joining thousands of farmers worldwide who are

benefitting from the KEENAN system. The KEENAN MechFiber+ diet feeder is a total mixed

ration (TMR) feeder with a difference. It is a market leader due to its reliability, durability,

efficiency in mixing and low horsepower requirements.

Our machines chop and mix feed in a consistent manner so that the herd is receiving the same

homogenous mix every day. This ability is the cornerstone of the KEENAN MechFiber system,

delivering improved efficiency and profitability on the farm. Bale handler models have the

increased advantage of being able to handle bales of all sizes and types.

The minimum moving parts ensure a robust machine with high mechanical efficiency. Simple

routine maintenance and correct operation will deliver many years of service. However, in the

event of unforeseen problems, KEENAN’s world-class service means you can be assured of a

prompt solution.

The KEENAN MechFiber diet feeder is the cornerstone of the KEENAN

MechFiber system, delivering improved efficiency and profitability on

the farm.

Discharge chamber

Auger

Fixed knives

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 6

Part I: General service and maintenance

1 Introduction

1.1 Purpose of this manual

This manual has been designed to present the general information you need to operate and

maintain your machine. Further information on model- and equipment-specific operations and

maintenance is available in separate manual supplements.

1.2 Intended use of the machine

The KEENAN MechFiber diet feeder range is exclusively designed for professional use, in

accordance with the rules of agricultural practices. The operating functions are weighing,

chopping/mixing and feeding out.

KEENAN also manufactures customised solutions for industrial applications.

The KEENAN MechFiber diet feeder should only be used, maintained and repaired by people

who have technical knowledge of the machine and are aware of the possible risks. Proper use

requires strict adherence to the instructions in the operator’s manual. It is up to the user and

the owner to comply with the instructions for accident prevention as well as the general rules

on safety, occupational health and road legislation.

1.3 Ordering this manual

You can order this operator’s manual by sending a request to:

Alltech Farming Solutions Ltd

Borris

Co. Carlow

R95 K223

Ireland

Telephone: +353 (0)59 977120

Email: keenaninfo@alltech.com

1.4 Reference and version of this manual

The version of this manual is displayed in the footnotes of each page and is composed as

follows:

•Operator’s manual containing general information or type(s) of machine(s)/model(s)

concerned

•Manual version

•Language version

The cover page also shows the date of publication of this document.

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 7

1.5 Description and warning terms

Please read this manual carefully before operating your new KEENAN MechFiber diet feeder,

paying particular attention to the warning notes, as explained here.

There are three different types of notes, as follows:

Note:

Texts with this heading give general information that improves the operational

efficiency of your KEENAN MechFiber diet feeder.

WARNING:

Texts with this symbol contain safety information.

They warn you of serious dangers, possibly involving accident or injury.

CAUTION:

Texts with this symbol draw your attention to a possible risk of damage to your

KEENAN MechFiber diet feeder. Failure to observe the information contained in a

caution note may invalidate your warranty.

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 8

2 Identification

2.1 General view of the machine

Figure 1

Figure 2

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 9

Reference

Description

1

Weigh box

2

Drive system covers

3

Drawbar

4

Stand

5

Feed-out tray

6

Lighting

7

Bale handler (optional)*

8

Paddle rubber

9

Bale handler cradle arm/tine location (optional)*

10

VFC-door

11

Auger

12

Body blades

13

Chassis and wheels

14

Paddle

15

Rotor

16

Top knife

Table 1

*Optional; see bale handler operator’s manual supplement for information.

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 10

2.2 Identification plates

Figure 3 Figure 4

Figure 5

Figure 6

The serial number plate is located on the front left-hand drive system cover

Table 2

Reference

Description

1

Machine type/version

2

Gross vehicle weight in kilograms

3

Axle weight in kilograms

4

Hitch weight in kilograms

5

Year of manufacture

6

Machine serial number

6

1

2

3

4

5

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 11

Axle identification plate type 1

Figure 7

Figure 8

Table 3

Axle identification plate type 2

Figure 9

Reference

Description

1

Axle type

2

Brake type

3

Homologation number CEMAGREF

4

Loads

5

Homologation number TUV-speed-load

6

Axle code

7

Order number

8

Identification plate number

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 12

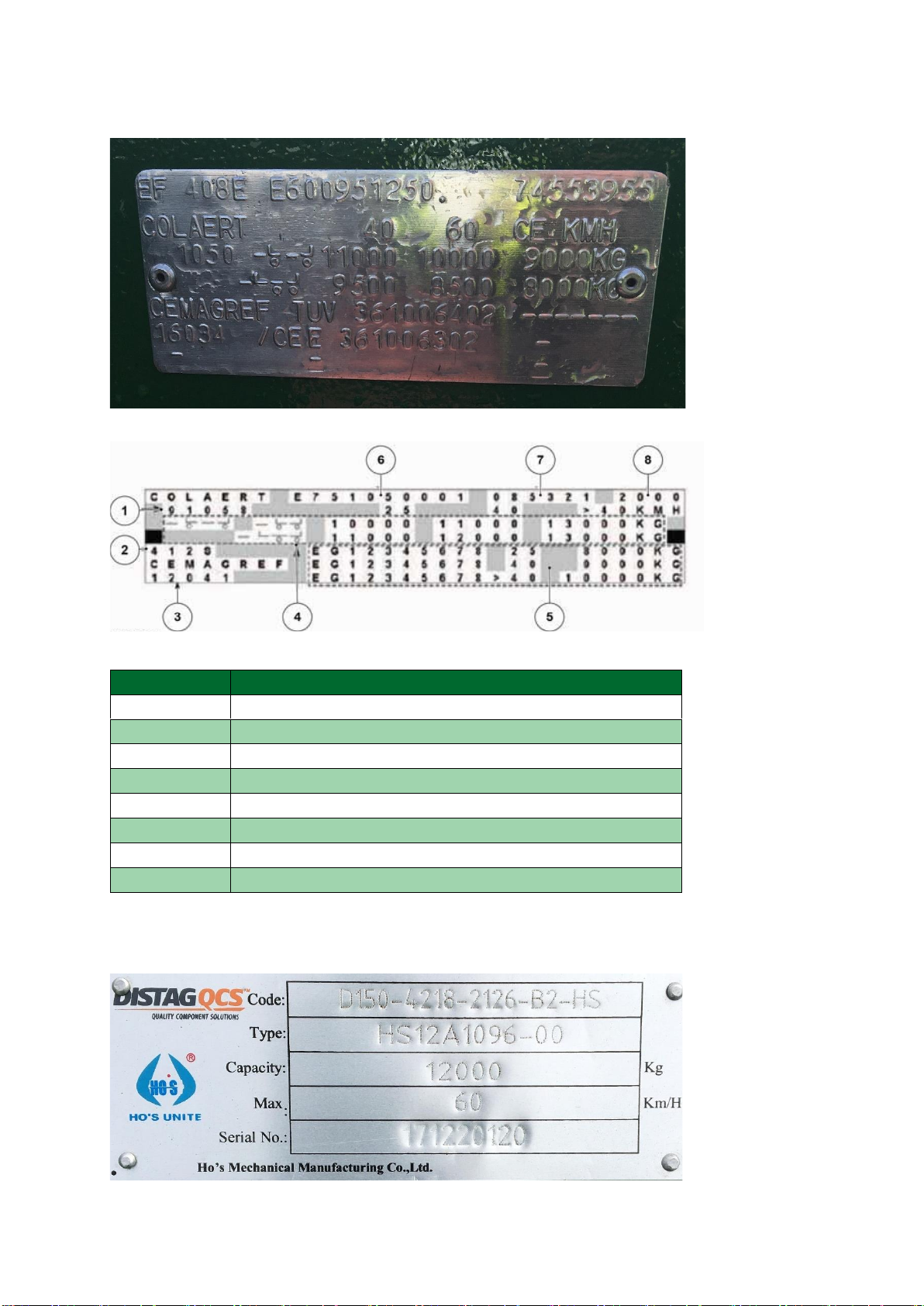

2.3 Machine identification

When receiving the machine, please enter the corresponding data below.

This document must remain within this user manual.

Table 4

Information

Complete this column with the requested information

Machine type

Serial number

Year of manufacture

Options

Date of first use

Dealer name

Dealer address

Dealer telephone number

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 13

3 Warranty

3.1 KEENAN Warranty policy

Alltech Farming Solutions Limited, trading as “KEENAN” (the “Company”), shall

undertake to correct by repair or replacement, only at the Company’s option, any defect

of material or workmanship that occurs in any of its products as listed herein within the

following warranty period. This Warranty is for the benefit of the initial owner as notified

to the Company. This Warranty shall also apply to new and unused goods being resold

by authorised dealers and/or distributors of the supplier. The Warranty period from the

date of commissioning is twelve (12) months for new equipment and such shorter

periods as may be agreed upon from time to time in writing for other products. This

Warranty shall cease to apply on any resale or alteration or incorrect usage of the

equipment by the initial owner.

The Warranty shall not apply to:

A) Any machine used by a third party who has not had instruction in the correct use of

the machine by an official representative of KEENAN.

B) Any machine that has sustained damage through general wear and tear or neglect or

use for which the machines were not intended to be used by the Company.

C) Bearings, sprockets, chains and other wearing parts, unless clear evidence of

immediate working failure that is directly attributable to such parts can be furnished.

Wearing parts include paddle rubbers, chains, jockeys, wheels and tyres.

D) Any consumable or perishable parts, such as knives, blades, rubber seals, hydraulic

components, shear-bolts, brake liners, electric components and running gear, unless

clear evidence of immediate working failure that is directly attributable to such parts can

be furnished.

E) Any machine from which the identification marks have been removed or altered.

F) Any machine that has not received effective routine maintenance using

recommended KEENAN products as outlined in the operator’s manual.

G) Any machine that has received repairs or modifications by a person unauthorised by

KEENAN.

H) Any machine fitted with spurious or non-genuine spare parts and attachments or

spare parts or attachments not approved by the Company.

I) Any machine damaged in transit whilst being loaded or unloaded on premises other

than those owned by the Company.

J) Parts that may be defective or that may have failed and are not retained on-site

pending further investigation by the Company. Such parts may need to be inspected in

situ by a Company representative.

K) Any machine damaged or any damage incurred prior to the machine being

commissioned by an authorised representative of the Company.

L) Any machine not used in accordance with the instructions for use of the machine.

M) Any machine that has been altered or tampered with in a manner not approved by

the Company.

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 14

The sole and exclusive claim against the Company made by the person specified above

shall be for the repair or replacement of defective parts without prejudice to any rights

pursuant to the Liability for Defective Products Act (1991). No other claim —including,

but not limited to, for incidental, direct or indirect or consequential damages or for lost

profits, lost sales, lost business, lost savings, loss of goodwill or loss of reputation or any

other loss of whatever nature, however sustained —shall be available.

This Warranty constitutes the only warranty made by the Company and supersedes and

overrides all oral and written statements or representations made by any Company

representative or dealer or any other agreement, arrangement, practice, custom or

understanding between the parties. Any claim under the Warranty must be promptly

notified to the Company in writing at the address on the invoice.

This Warranty shall be construed in accordance with Irish law and shall be subject to the

exclusive jurisdiction of the Irish Courts.

3.2 Product changes and improvements

Due to our policy of continuous improvement, Alltech Farming Solutions Ltd reserves the right

to make changes in design, to add improvements or to otherwise modify any of its products

without incurring any obligation on products previously supplied.

3.3 International patents

The KEENAN MechFiber diet feeder and the KEENAN MechFiber bale handler machines are subject to

international patents, including the following:

Europe: E0, 833,558 USA: 5,967,433

Japan: Pending Canada: Pending

Australia: 691418 New Zealand: 305943

South Africa: 96/3148

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 15

4 Safety

4.1 Safety instructions

The KEENAN MechFiber diet feeder has many safety features built into its design, but ultimately,

safe operation requires the vigilance of the operator and an understanding of the potential safety

hazards. The machine is designed to be used as a mixer/chopper wagon for mixing animal feeds.

It should not be used for any other purpose that could affect its performance or safety.

For industrial applications, machines will be designed to suit individual requirements.

The following safety points are general guidelines. Given the wide variety of possible operating

conditions, other safety risks may exist that are not captured in the list included here.

a) Always park the diet feeder on level ground and apply the handbrake when not in use.

b) Do not exceed 15 km/hour (10 mph) when in use/transit. Local road traffic laws will apply

when the diet feeder is in transit on public roads, on which the maximum permissible speed

is 25 km/hour. Exceeding this speed will compromise the life and safety of major

components, such as the hitch, axle, wheels and chassis.

c) Ensure that the VFC-door is closed and that all feed-out trays/elevators are in the closed and

transport position prior to using on a public road.

d) Exercise extreme caution for possibly overtaking traffic on either side when turning.

e) Do not stand on the ladder whilst the feeder is in transit. The diet feeder should never be

used for the transport of people, animals or objects.

f) Do not stand between the tractor and the diet feeder while it is in use.

g) Use only a PTO shaft with a properly fitted safety guard and correct shear bolt.

h) Always connect the PTO shaft with the shear bolt end to the machine. The operating speed

of the PTO is 540 RPM, and the direction of rotation is marked on the front cover. Always use

a well-maintained PTO shaft and keep the safety covers in good condition.

i) Ensure that all trailing leads, hoses, etc., are well clear of the PTO.

j) Never operate the PTO in “ground speed mode” or drive the PTO in reverse.

k) Make sure all covers/guards are fitted and closed correctly. Never remove guards when the

diet feeder is connected to the tractor.

l) Ensure that the diet feeder and the immediate area surrounding it are clear of people,

especially children, before commencing operation. Ensure that there is sufficient visibility

for the operator to observe all danger zones and that the tractor is equipped with mirrors to

enable the operator to see both sides of the machine while it is in operation.

m) When connecting the tractor to the diet feeder, only connect it using the ring hitch/hitch on

the diet feeder to ensure safe coupling. Ensure that the hitch is connected properly to the

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 16

tractor and that all pins and clips are properly installed. Then connect the PTO shaft in the

correct fashion. Connect the hydraulic hoses, ensuring that the functions match the

indicated valve on the tractor.

n) When disconnecting, always ensure that a stand or jack is used to secure the diet feeder in

the park position, and ensure that the handbrake is properly applied. Before driving the

tractor away from the diet feeder, ensure that all hoses and cables are disconnected.

o) Load only from the side indicated (see Figure 22; auger chamber side), using suitable

equipment.

p) Standing level with or above the machine in order to load manually is not permitted.

Loading should only be carried out with suitable equipment.

q) Regularly inspect all chains (at least weekly), sprockets and moving parts for wear and check

all nuts and bolts for tightness.

r) The ladder on the rear of the diet feeder is to be used as a viewing point for the mixing

chamber. It should not be used as a means of access to the mixing chamber nor onto the

body of the machine. It is strictly forbidden to climb on the upper brim of the machine body.

The height of the machine presents a potential fall hazard during entry and exit.

s) The noise emission level of the range of KEENAN MechFiber diet feeders has been recorded

at 89.4 dB. Noise emission levels above 90 dB would require the wearing of suitable ear

protection.

t) The breakaway safety brake device should be attached to the tractor at all times. The wire

rope is connected to the hose holder (see Figure 11). Connect one end of the wire rope to

the ring on the handbrake handle and fix the other end of the wire rope to a solid location

on the back of the tractor (e.g., using the top link pin). In the event that the breakaway

safety brake device is activated or damaged, it is recommended that KEENAN service is

contacted for directions to reset.

u) Routine cleaning may be carried out using a power washer. Isolate any power sources before

beginning. If washing the inside of the mixing chamber, open the drain bung underneath the

body to allow water to escape. Always disconnect the PTO shaft from the tractor and stand

on a suitably safe ladder or platform. Do not to climb on top of the machine or into the mixing

chamber.

v) It is recommended that only KEENAN-trained and qualified maintenance personnel

enter the mixing chamber.

In the case of an untrained person entering the mixing chamber, at the very minimum, the

following precautionary safety guidelines should be strictly adhered to at all times:

1. Ensure that the PTO and hydraulic hoses are disconnected.

2. Apply the diet feeder handbrake and disconnect the tractor from the machine on level

ground.

3. Use suitable PPE, such as protective footwear, eyewear and gloves.

4. Personnel should make themselves familiar with the location of all potential hazards

before entering the machine, particularly the location of the top knife and body blades.

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 17

5. Be aware that sharp components may be hidden in or under material within the mixing

chamber.

6. The top knife should always be fitted with the supplied guard (see Figure 12) before

entering the machine. Begin by fitting the first 500 mm of guard from the rear of the

machine. Then, as you enter, continue to fit the guard along the full length of the top

knife.

Note: The machine is supplied with a top knife guard, which can be found inside the

driveline covers of the diet feeder.

7. Use a suitable and secure ladder for access to and from the diet feeder.

Note: The ladder at the rear of the machine is provided as a means of viewing the ration

only and should not be used as a means of access to the mixing chamber.

8. Always maintain three (3) points of contact while entering, exiting and moving within the

mixing chamber of the machine.

9. When entering the base of the body, it is recommended to cover the body blades in the

vicinity of where work is to be carried out.

10. When removing trapped objects, be aware that some machine components may move

unexpectedly when cleared.

11. Take extreme care when moving around inside the body, as surfaces may be slippery.

KEENAN diet feeders have been designed to reduce risk to a minimum. However, as with any

machine, the careful observation of safety procedures is necessary to prevent accidents.

Blade

When entering the mixing

chamber, always fit the safety

beading that is provided for the

top knife.

Figure 11: Breakaway safety brake

Figure 11: Breakaway safety brake

When entering the mixing

chamber, always fit the safety

beading that is provided for the

top knife.

Blade

Figure 12: Top knife protection

Figure 10: Body blades

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 18

See further details in each section. If you have any further questions, please contact your local

KEENAN service partner for advice.

WARNING:

Failure to follow the safety guidelines above may lead to accident or injury.

WARNING:

Read the safety section before attempting to operate the machine.

WARNING:

The operator is responsible for the safe operation of the machine at all times. The

KEENAN MechFiber diet feeder should only be operated by one person at all times.

The diet feeder should never be left unattended during operation.

WARNING:

The breakaway safety brake device should be attached to the tractor at all times.

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 19

4.2 Safety signs and locations

3

7

2

6

9

4

1

10

Operator’s manual

Figure 14

Figure 15

Figure 16

Figure 17

Figure 13

KEENAN MechFiber+ General Operator’s Manual Rev A01 April 2022 20

Do not open or remove

safety guards while the

machine is connected to

the tractor.

Do not stand between the tractor

and diet feeder while it is in

operation.

Read the operator’s

manual before

using the machine.

Danger of flying objects.

Keep a safe distance

from the machine.

Stay clear of sharp

blades.

Shut off the engine and

remove the key before

performing maintenance

or repair work on the

machine.

Never reach into the

rotating auger.

Danger of

entrapment.

Do not ride on the

platform or ladder.

Look out for

overhead power

lines.

1 2 3

5 6 7 8

Apply the handbrake

when parked.

4

9

10

Table of contents

Other Alltech Farm Equipment manuals

Alltech

Alltech KEENAN MechFiber400 User manual

Alltech

Alltech KEENAN MechFiber270 User manual

Alltech

Alltech KEENAN MechFiber380+ User manual

Alltech

Alltech KEENAN MechFiber345 User manual

Alltech

Alltech KEENAN I Series User manual

Alltech

Alltech KEENAN MechFiber340 User manual

Alltech

Alltech KEENAN MechFiber300 User manual

Alltech

Alltech KEENAN MechFiber250 User manual

Alltech

Alltech KEENAN MechFiber345 User manual

Alltech

Alltech KEENAN MechFiber380 User manual