Alltech KEENAN MechFiber345 User manual

MechFiber345 & MechFiber365 Operator’s Manual1Revision A.01 11th Nov 2016

KEENAN

MechFiber345

MechFiber365

Effective from models MF345H100 & MF365H100

MechFiber345 & MechFiber365 Operator’s Manual2Revision A.01 11th Nov 2016

Contents

SECTION CONTENTS PAGE

PART I (Service & Maintenance)

1 Introduction 5

2 Warning Notes 6

3 Warning Signs 7

4 Operating Principles 8

4.1 Weighing 8

4.2 Chopping / Mixing 8

4.3 Feeding Out 9

4.4 Maintenance 9

4.5 Safety Precautions 10

5 Safety 10

6 Weighing System 14

7 Operation 15

7.1 Set-Up ` 15

7.2 Hitch Height Adjustment 17

7.3 Mixer Wagon Capacity 18

7.4 Loading & Mixing 19

7.5 Operating the KEENAN MechFiber Mixer Wagon 20

7.6 Operating the KEENAN Bale Processor 21

7.7 Specific Instructions for Bale Processor Models 22

7.8 Washing and Chopping Root Crops 23

7.9 Feeding Out 23

8 Maintenance 24

8.1 Chains 24

8.2 Oil Level 25

8.3 Chain Tensioning 26

8.4 Greasing 29

8.5 Blade Maintenance 32

8.6 Maintenance for Bale Processor Models 32

8.7 Shear Bolts 34

8.8 Nuts & Bolts 35

8.9 Tyres 35

8.10 Wheels 36

8.11 Rear Feed-out Elevator (Where Fitted) 36

8.12 Side & Stub Feed-out Elevator (Where Fitted) 37

8.13 Axle maintenance 38

9 Maintenance Checklist 39

10 Specifications 40

PART II (Spare Parts)

11 Parts List 41

11.1 Hydraulic System Parts 42

11.2 Chassis Parts 43

11.3 Front Cover Parts 45

11.4 Standard Feed-Out Tray Parts 47

11.5 Fold Down Tray Options 49

11.6 Rear Parts 52

11.7 Weighing System Parts 53

MechFiber345 & MechFiber365 Operator’s Manual3Revision A.01 11th Nov 2016

11.8 VFC Door Parts 54

11.9 VFC Door Indicator Parts 55

11.10 Driveline Parts 56

11.11 Rotor & Paddle Parts 61

11.12 Auger Parts 62

11.13 Body Sealing Parts 63

11.14 Body Blade Parts 64

11.15 Bale Processor Parts 65

11.16 Axle Parts 70

11.17 Ancillary Parts 71

12 Troubleshooting 72

12.1 General Troubleshooting 72

12.2 Weighing Troubleshooting 75

13 Warranty 76

14 E.C. Declaration of Conformity/CE Certification 77

15 Contact Details 78

MechFiber345 & MechFiber365 Operator’s Manual4Revision A.01 11th Nov 2016

PART I

(Service & Maintenance)

MechFiber345 & MechFiber365 Operator’s Manual5Revision A.01 11th Nov 2016

Introduction

1. Introduction

KEENAN MechFiber Mixer Wagon and KEENAN MechFiber Bale Processor

Thank you for purchasing a KEENAN product. The KEENAN MechFiber Mixer Wagon is a

TMR feeder with a difference. The original KEENAN mixer wagon became a market leader

due to its reliability and durability, founded on simplicity, fast efficient mixing and feed out and

low horsepower requirements. The KEENAN MechFiber Mixer Wagon has built on these

capabilities by adding the ability to chop and present in a consistent fashion, time and time

again. This ability is the cornerstone of the KEENAN MechFiber System, delivering improved

efficiency and profitability on the farm. More recently, the Bale Processor models have

introduced the ability to handle bales of all sizes and types.

The minimum moving parts ensure a robust machine with high mechanical efficiency. Simple

routine maintenance and correct operation will deliver many years of service. However in the

event of unforeseen problems, KEENAN’s world class service means you can be assured of

a prompt solution.

This manual has been designed to present the information you need to operate and maintain

your machine. Most sections of the manual apply to both the KEENAN MechFiber Mixer

Wagon and the KEENAN MechFiber Bale Processor machines. Sections which do not apply

to both machines will be clearly stated in the heading and the text. Recent revision updates

are indicated by a line in the right hand column as shown to the right.

If you require further assistance or information, please contact your Physical Nutritionist.

Telephone numbers are listed on the back cover of this manual.

The KEENAN MechFiber Mixer Wagon is the cornerstone of the KEENAN MechFiber

System delivering improved efficiency and profitability on the farm.

MechFiber345 & MechFiber365 Operator’s Manual6Revision A.01 11th Nov 2016

Using the manual

2. Warning Notes

Please read this manual carefully before operating your new machine, paying particular

attention to the warning notes, explained here.

There are 3 different types of notes, as follows:

Note:

Texts with this heading give general information which improves the operation

efficiency of your KEENAN MechFiber Mixer Wagon.

The KEENAN MechFiber Mixer Wagon and the KEENAN MechFiber Bale Processor machines are subject to

International patents including the following:

Europe: E0, 833,558 USA: 5,967,433

Japan: Pending Canada: Pending

Australia: 691418 New Zealand: 305943

South Africa: 96/3148

WARNING:

Read the safety section (section 5) before attempting to operate the machine.

WARNING:

Texts with this symbol contain safety information.

They warn you of serious dangers, possibly involving accident or injury.

CAUTION:

Texts with this symbol draw your attention to a possible risk of damage to your

KEENAN MechFiber Mixer Wagon. Failure to observe the information contained in

a caution may invalidate your warranty.

MechFiber345 & MechFiber365 Operator’s Manual7Revision A.01 11th Nov 2016

Do not stand between the tractor

and mixer wagon while it is in

operation.

Read the operators

manual before

using the machine.

Danger of flying

objects.

Keep a safe distance

from the machine.

Stay clear of sharp

blades.

Do not open or remove

safety guards while the

machine is connected to

the tractor.

Shut off the engine and

remove the key before

performing maintenance or

repair work on the machine.

Never reach into

the rotating auger.

Danger of

entrapment.

Do not ride on the

platform or ladder.

Warning Signs

Look out for

overhead power

lines.

Apply the handbrake

when parked.

Warning signs

3. Warning Signs

Warning signs

MechFiber345 & MechFiber365 Operator’s Manual8Revision A.01 11th Nov 2016

Weighing

4. Operating Principles

The KEENAN MechFiber Mixer Wagon’s main operating functions are weighing,

chopping/mixing and feeding out.

4.1 WEIGHING

The KEENAN MechFiber Mixer Wagon’s electronic weighing system allows the exact

quantity of individual materials to be loaded into the mixing chamber for accurate rationing.

Individual loads can be weighed or successive loads accumulated to give total weight of feed.

See Section 6 (Weighing System) and the Readout Manual for more detailed information.

4.2 CHOPPING / MIXING

Load ingredients in sequence recommended by your KEENAN Physical Nutritionist, or as

suggested in Section 7 (Operation).

For non Bale Processor models, ensure bales are broken up prior to loading. For Bale

Processors, wait until the bale has been taken in completely before adding further bales. As a

general rule, material should be tumbling freely when mixing. If not then the machine is

overloaded and will not achieve the desired mix quality. Mixing is carried out by a centrally-

mounted rotor fitted with 6 angled paddles revolving at 5-6rpm. Each paddle imparts a

shearing action, sweeping the feed ingredients onto the strategically placed knives to

produce a consistent and thorough mix with all types of materials, including baled silage, hay

or straw, roots and liquids.

The angled paddles help mixing by sweeping the material from end to end. The placement of

the blades ensures the materials reach optimum size/length, without grinding it down and

destroying the all important ‘scratch factor’ of the forages producing a MechFiber mix.

Mixing time will be determined by the required chop length. Follow procedures contained in

this manual or consult your KEENAN Physical Nutritionist for further information.

For Bale Processor models, do not load a complete 6x4 round bale onto the machine as it

may potentially be unstable, possibly falling off and causing injury. 6x4 round bales should be

first broken up and then loaded onto the machine in sections; alternatively the bale may be

held in place by the loader until sufficiently chopped down, 1/3 to 1/2 way, to allow it safely

complete chopping on the top of the machine. If in doubt consult your local KEENAN

representative for the recommended safe operation of the machine to suit your particular

application.

CAUTION:

For Bale Processor models, do not load a complete 6x4 round bale, or more than one

5x4 or 4x4 round bale onto the machine at any one time. Overloading the machine

may seriously affect the safe operation and life of the machine, and will invalidate the

warranty.

Chopping/Mixing

MechFiber345 & MechFiber365 Operator’s Manual9Revision A.01 11th Nov 2016

4.3 FEEDING OUT

During mixing, the mixing chamber is separated from the feed out chamber by a Variable

Feed Control (VFC) or guillotine door, thus ensuring complete mixing. The feed out chamber

contains an auger which runs the entire length of the machine.

When chopping/mixing is complete, the feed out tray should be set to the required position,

and the VFC door dropped, allowing the material to be swept up by the paddles and pushed

onto the auger –see figure 2. The VFC door should be partially opened at first, ¼ ways, and

when feed is seen discharging then 15-20 seconds should be allowed before opening the

VFC door fully. Door position and ground speed should be set/used to allow an even feed

out rate.

CAUTION:

The VFC door should only be opened or closed when the PTO is engaged (paddles

turning) when material is in the machine.

4.4 MAINTENANCE

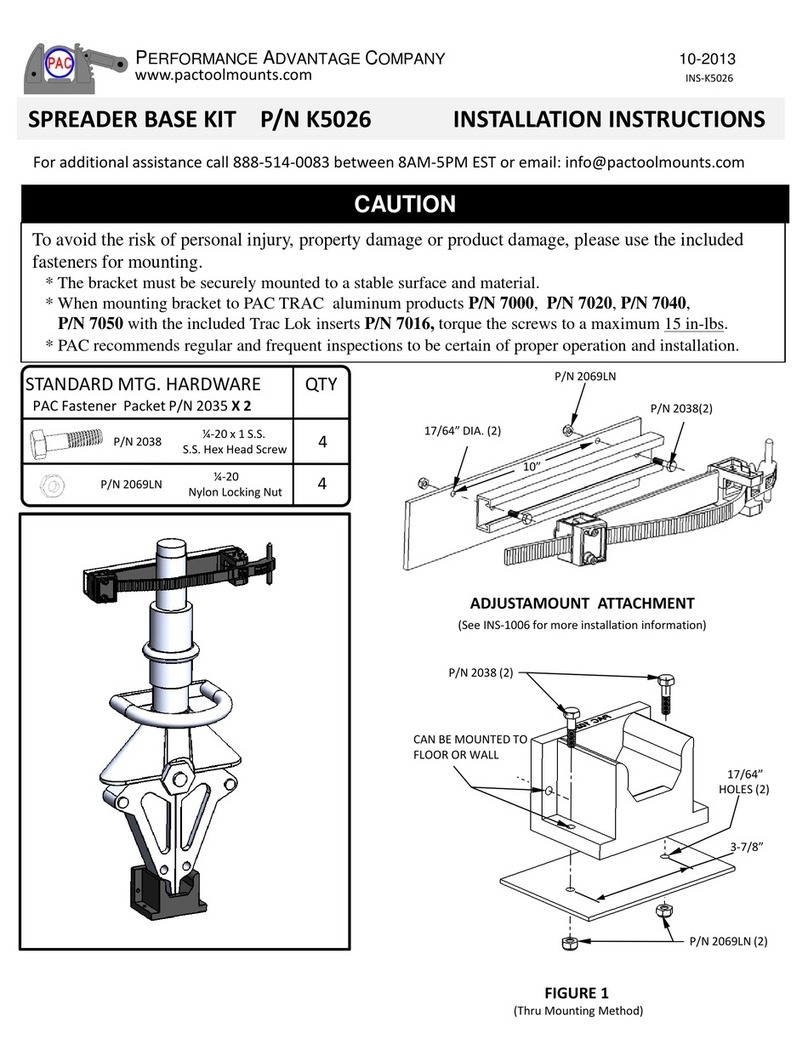

Figure 1: KEENAN MechFiber Mixer Wagon (Bale Processor Option Shown)

A properly operated and maintained KEENAN mixer wagon will give years of trouble free

operation. Regular maintenance of the machine is essential both for long machine life

and also to meet the warranty requirements. Refer to instructions in maintenance section

of this manual. Weekly cleaning of the machine is recommended to prevent corrosion to the

mixer body from old feed. The level of cleaning required will depend on the material

being mixed, but any material which sits or lodges on the machine may both adversely

affect the operation of the machine and affect the quality of the mix if it subsequently

falls into the feeder during mixing. It is therefore essential that routine cleaning and

washing down of the feeder is completed.

Feeding Out

Maintenance

MechFiber345 & MechFiber365 Operator’s Manual10 Revision A.01 11th Nov 2016

Safety

4.5 SAFETY PRECAUTIONS

KEENAN mixer wagons have been designed to reduce risk to a minimum. However, as with

any machine, careful observation of safety procedures is necessary to prevent accidents.

See inside for further details on each section. If you have any further questions please

contact your local KEENAN centre for advice.

WARNING:

Read the following safety section (section 5) before attempting to operate the

machine.

5. Safety

The KEENAN MechFiber Mixer Wagon has many safety features built into its design but

ultimately, safe operation requires the vigilance of the operator and an understanding of

potential safety hazards. The machine is designed to be used as a mixer/chopper wagon for

mixing animal feeds. It should not be used for any other purpose which will affect its

performance or safety.

Figure 2: KEENAN MechFiber Rear View

WARNING:

The operator is responsible for the safe operation of the machine at all times. This

machine should only be operated by one person at all times. The machine should

never be left unattended during operation.

WARNING:

The Breakaway Safety Brake Device should be attached to the tractor at all times.

MechFiber345 & MechFiber365 Operator’s Manual11 Revision A.01 11th Nov 2016

The following safety points are general guidelines. Given the wide variety of possible

operating conditions other safety risks may exist which are not captured in the list over.

a) Always park the mixer wagon on level ground and apply the handbrake when not in

use.

b) Do not exceed 15 km/h (10 mph) when in use/transit. Local road traffic laws will apply

when machine is in transit on public road, on which the maximum permissible speed is

25 km/h. Exceeding this will compromise the life and safety of major components such

as the hitch, axle, wheels and chassis.

c) Ensure the VFC Door is closed and all Feed-Out Trays / Elevators are in the closed &

transport position prior to using on the public road.

d) Exercise extreme caution for possible overtaking traffic at either side when turning.

e) Do not stand on the ladder whilst the feeder is in transit. The mixer wagon should

never be used for the transport of people, animals or objects.

f) Do not stand between the tractor and mixer wagon while it is in use.

g) Use only a PTO shaft with a properly fitted safety guard and correct shear bolt.

h) Always connect the PTO shaft with the shear bolt end to the machine. The operating

speed of the PTO is 540 rpm and the direction of rotation is marked on the front cover.

Always use a well maintained PTO shaft and keep the safety covers in good condition.

i) Ensure all trailing leads, hoses, etc. are well clear of the PTO.

j) Never operate the PTO in “ground speed mode” or drive the PTO in reverse.

k) Make sure all covers/guards are fitted and closed correctly. Never remove guards

when the mixer wagon is connected to the tractor.

l) Ensure the mixer wagon and the immediate area surrounding it is clear of people,

especially children, before commencing operation. Ensure that there is sufficient

visibility for the operator to observe all danger zones and that the tractor is equipped

with mirrors to enable the operator to see both sides of the machine while it is in

operation.

m) When connecting the tractor to the mixer wagon only connect using the ring hitch/hitch

on the mixer wagon to ensure safe coupling. Ensure that the hitch is connected

properly to the tractor and that all pins and clips are properly installed. Then connect

the PTO shaft in the correct fashion. Connect the hydraulic hoses ensuring that the

functions match the indicated valve on the tractor.

n) When disconnecting always ensure that a stand or jack is used to secure the mixer

wagon in the park position and ensure that the handbrake is properly applied. Before

driving the tractor away from the mixer wagon ensure that all hoses and cables are

disconnected.

Safety

MechFiber345 & MechFiber365 Operator’s Manual12 Revision A.01 11th Nov 2016

o) Load only from the side indicated –see figure 7 (auger chamber side), using suitable

equipment.

p) Standing level with or above the machine in order to load manually is not permitted.

Loading should only be carried out with suitable equipment.

q) Regularly inspect all chains (at least weekly), sprockets and moving parts for wear and

check all nuts and bolts for tightness.

r) The ladder on the rear of the mixer wagon is to be used as a viewing point for the

mixing chamber. It should not be used as a means of access to the mixing chamber

nor onto the body of the machine. It is strictly forbidden to climb on the upper brim of

the machine body. The height of the machine presents a potential fall hazard during

entry and exit.

s) The noise emission level of the MechFiber 345 has been recorded at 89.4dB. Noise

emission levels above 90dB would require the wearing of suitable ear protection.

t) The Breakaway Safety Brake device should be attached to the tractor at all times.

Cable ties fix the wire rope along the handbrake handle in place. Cable tie the wire

rope to the drawbar (see figure 4). Fix the other end of the wire rope to a solid location

on the back of the tractor e.g.: using the top link pin. In the event that the Breakaway

Safety Brake device has been activated or damaged, it is recommended that KEENAN

Service are contacted for directions to reset.

u) Routine cleaning may be carried out using a power washer. Isolate any power sources

before beginning. If washing the inside the Mixing Chamber, open the drain bung

underneath the body to allow water escape. Always disconnect PTO shaft from the

tractor & stand on suitably safe ladder or platform. Do not to climb on top of machine

or into the Mixing Chamber.

v) It is recommended that only KEENAN trained and qualified maintenance

personnel enter the mixing chamber.

In the case of an untrained person entering the mixing chamber, at the very minimum,

the following precautionary safety guidelines should be strictly adhered at all times.

1. Ensure the PTO and hydraulic hoses are disconnected

2. Apply the mixer wagon handbrake and disconnect the tractor from the machine on

level ground

3. Use suitable PPE such as protective footwear, eye wear & gloves

4. Personnel should make themselves familiar with the location of all potential

hazards before entering the machine, in particular the location of the top knife and

body blades.

5. Be aware that sharp components may be hidden in or under material within the

mixing chamber

6. The top knife should always be fitted with the supplied guard (Figure 3b) before

entering the machine. Begin by fitting the first 500mm of guard from the rear of the

machine. Then as you enter continue to fit the guard along the full length of the

Top Knife

Note: the machine is supplied with a top knife guard which can be found inside the

driveline covers of the mixer wagon

Safety

MechFiber345 & MechFiber365 Operator’s Manual13 Revision A.01 11th Nov 2016

Safety

7. Use a suitable & secure ladder for access to and from the mixer wagon. Note: The

ladder at the rear of the machine is provided as a means of viewing the ration only

and should not be used as a means of access the mixing chamber.

8. Always maintain 3 points of contact while entering, exiting & moving within the

mixing chamber of the machine

9. When entering the base of the body, it is recommended to cover the body blades in

the vicinity of where work is to be carried out.

10.When removing trapped objects, be aware that some machine components may

move unexpectedly when cleared.

11.Take extreme care when moving around inside the body as surfaces may be slippy

SODAGRAIN: Additional safety instructions and warnings are available and covered in a soda grain

leaflet which should be read carefully before soda treating grain. When finished treating grain, clean

out any remaining material in the mixing and/or auger chamber by loading in 200-300 kg of silage or

50 kg of straw and allow the machine to mix before unloading in the normal manner. Note that when

mixing soda grain, the maximum gross load that can be mixed in the KEENAN MechFiber345 is 5,000

kg and for the KEENAN MechFiber365 is 6,000 kg.

WARNING:

Failure to follow the safety guidelines above may lead to accident or injury.

Blade

When entering the mixing

chamber, always fit the safety

beading that is provided for the

top knife.

Figure 3b: Top Knife Protection

Figure 3a: Body blade & blade cover

Figure 4: Breakaway Safety Brake

MechFiber345 & MechFiber365 Operator’s Manual14 Revision A.01 11th Nov 2016

Weighing System

6. Weighing System

The weighing system is designed to be simple to operate, accurate and robust. It consists of

four load cells connected to a weigh box unit (readout box) at the front of the machine. The

system uses 12 volt DC power from the tractor, or battery if fitted. The weigh box unit can be

rotated for visibility during loading and from the tractor cab, but should be folded out of the

line of the tractor wheel for road work. Loads are displayed in kilograms or lbs with scale

increments of 5 kg/10 lb. The unit is capable of measuring up to 18,140 kg (39,999 lbs) with

the appropriate weight bars. The system is maintenance-free, being fully electronic with no

moving parts. All components are sealed against moisture and dust and are resistant to frost

and corrosion. The unit should, however, not be directly exposed to a high pressure water jet.

The weigh box unit may vary from model to model and region to region. A separate manual is

supplied for your weigh box unit, which you should refer to for specific operating instructions.

INSTRUCTIONS FOR ELECTRONIC READOUT BOX ARE CONTAINED IN A

SEPARATE MANUAL

MechFiber345 & MechFiber365 Operator’s Manual15 Revision A.01 11th Nov 2016

Set-up

7. Operation

The simplicity of the KEENAN MechFiber Mixer Wagon design is reflected in its low power

requirement. The power required varies, depending on the mix used, the dry matter, and the

amount of chopping required.

If a tractor is at its limit during mixing, this will translate into extra strain on moving parts as

there will be surges in power as the engine recovers during certain periods of the mix.

A tractor that has sufficient power will provide a much smoother drive to the mixer wagon

during all stages of operation.

7.1 SET-UP

1. Ensure the machine is level when hitched up. If the machine is un-level, this can be

corrected by adjusting the hitch height. The hitch height on the KEENAN MechFiber

Mixer Wagon provides a certain level of adjustment from the manufactured height.

2. The PTO shaft should be attached with the shear bolt end coupled to the machine.

Make sure that the PTO guard is in good condition and well secured.

3. Connect the hydraulic hoses (see table 1) from the machine to double and single

acting spool valves on the tractor, as appropriate.

4. Examine the mixing chamber to ensure that:

• All blade covers have been removed, where fitted.

• All spare parts and foreign objects have been removed.

• No damage has occurred during transport.

5. Check the weigh box and ensure the power lead from the weighing system is either

connected to the tractor battery via a direct fused line, 7 pin plug or to a 12v battery

located in the side box of the feeder. To zero the weigh box press and hold the ‘zero’

and ‘minus’ keys together and hold until ‘end’ appears on the screen then release the

buttons. If the power is supplied through a 7 pin lights connection, the tractor lights will

need to be switched on to provide power to the weigh box. If you stand on the ladder,

at rear of the machine, you can check the reading on the weigh box against your

known weight, this may require assistance.

6. With the tractor running, check that the VFC door opens fully and closes completely.

Similarly check the movement of the feed out tray. Engage the PTO and check the

turning of the paddles. The initial turning of the paddle rubbers against the side of the

KEENAN MechFiber Mixer Wagon will generate noise but this will decrease as the

paddle rubbers become more pliable.

CAUTION:

Do not operate the PTO in “ground speed” mode. Reversing the drive on your

machine will cause serious damage.

MechFiber345 & MechFiber365 Operator’s Manual16 Revision A.01 11th Nov 2016

Set-up

Hydraulic and brake hoses

Operation

Colour

VFC Door

Red & yellow

Feed-out Tray

Blue

Bale Processor Creel

Green

Brakes

White

Beet-grid

Black

Table 1: Hydraulic and brake hoses

Note:

A: The design life of hydraulic hoses is subject to the level of wear and tear/usage and also

factors like harsh climate. It is recommended that they be reviewed periodically (yearly) and

typically replaced after ten years of operation if necessary.

B: The maximum oil pressure of the hydraulic system is 3000 psi.

C: If there is a valve chest fit to the MechFiber machine, it is very important to connect the

valve chest hydraulic feed and return pipes correctly. The return pipe is not designed to take

the hydraulic pressure normally seen in the valve chest feed pipe, and so seals and/or the

valve chest itself may be damaged if oil flows in the wrong direction through the chest.

Typically the hydraulic return pipe on the valve chest is fit with a one-way flow valve to

prevent oil being fed to the valve chest in the wrong direction. This is identifiable as a steel

connection on the end of the pipe with an arrow stamped on its side to indicate the direction

of oil flow through it. Oil flows into the valve chest through holes marked P (Pressure) and out

through holes marked T (Tank), see Figure 5 below.

(The valve chest is set up for open centre hydraulics. If the tractor has an alternative

hydraulic system (other than open centre) then contact should be made with the tractor

agent. To alter to closed centre hydraulics, there is a plug that can be fitted to the spool valve

block and is available from KEENAN Service on request.)

Figure 5: Valve Chest

P

T

MechFiber345 & MechFiber365 Operator’s Manual17 Revision A.01 11th Nov 2016

Set-up

7.2. HITCH HEIGHT ADJUSTMENT

The MechFiber345 & MechFiber365 hitch has been designed to allow for a number of

various hitch height options with same components used, the hitch height is normally

selected for the application and set at the factory per the options below.

The main standard hitch assembly is a bolt on assembly and once the main setting is

completed at the factory, it may also be adjusted on farm by moving the assembly up or

down within the bolt holes, or turning the complete hitch over, as it is suitable to operate

facing either way up.

Note:

1: A minimum of four M20 x 100mm Grade 8.8 bolts must be used to secure the Swivel Ring Hitch & the Clevis

Hitch to the drawbar.

2: Care must be taken, when adjusting the hitch height, so that there is adequate PTO clearance and that there

is enough ground clearance below the stand.

Figure 6.1: Standard Hitch Adjustment

Figure 6.2: High Hitch Adjustment

Figure 6.3: Clevis Hitch Adjustment

MechFiber345 & MechFiber365 Operator’s Manual18 Revision A.01 11th Nov 2016

Mixer wagon capacity

7.3 MIXER WAGON CAPACITY

Due to the diversity of the materials available for feeding and the KEENAN MechFiber’s

ability to incorporate a wide range of feed types into the ration the capacity of the machine

will vary. Ensure that overloading is avoided at all times as mix quality will be seriously

affected and potential machine damage may result.

Overloading must be avoided because:

• The mix will not be homogenous (evenly mixed), preventing the maximum benefit being

gained from the machine.

• Mechanical failure will result. Due to the nature of the loading this may occur at load levels

below that necessary to break the shear bolt.

The overall amount of material that can be chopped/mixed in one load depends on the

following:

• Machine size.

• Overall dry matter of the TMR.

• The chop length and quality of the material added.

• The loading procedure and loading order of the materials used (this has a major effect on

machine capacity, e.g. the addition of straw first or last).

• Tractor H.P. rating.

CAUTION:

The machine can be overloaded, before the shear bolt breaks. Therefore not

breaking a shear bolt is not an indication that the machine is not being overloaded.

Figure 6: Photograph illustrates a well mixed ration showing

consistent fibre length and integration of forages and grains.

MechFiber345 & MechFiber365 Operator’s Manual19 Revision A.01 11th Nov 2016

Loading and mixing

7.4 LOADING & MIXING

Note: The unique tumbling action of the machine is what carries out the mixing. If the

machine is overloaded or loaded in an incorrect order, or insufficient time is allowed for

proper chopping, this tumbling action will not take place correctly. In addition to reducing mix

quality, it increases the horsepower requirements and reduces the life of the machine.

The effectiveness and speed of chop is determined by:

• The number of effective (sharp and intact) blades.

• The dry matter of the material to be added.

• The amount of pre-chopping of material.

• The loading sequence.

• The total amount of material to be chopped.

• The density of the bale.

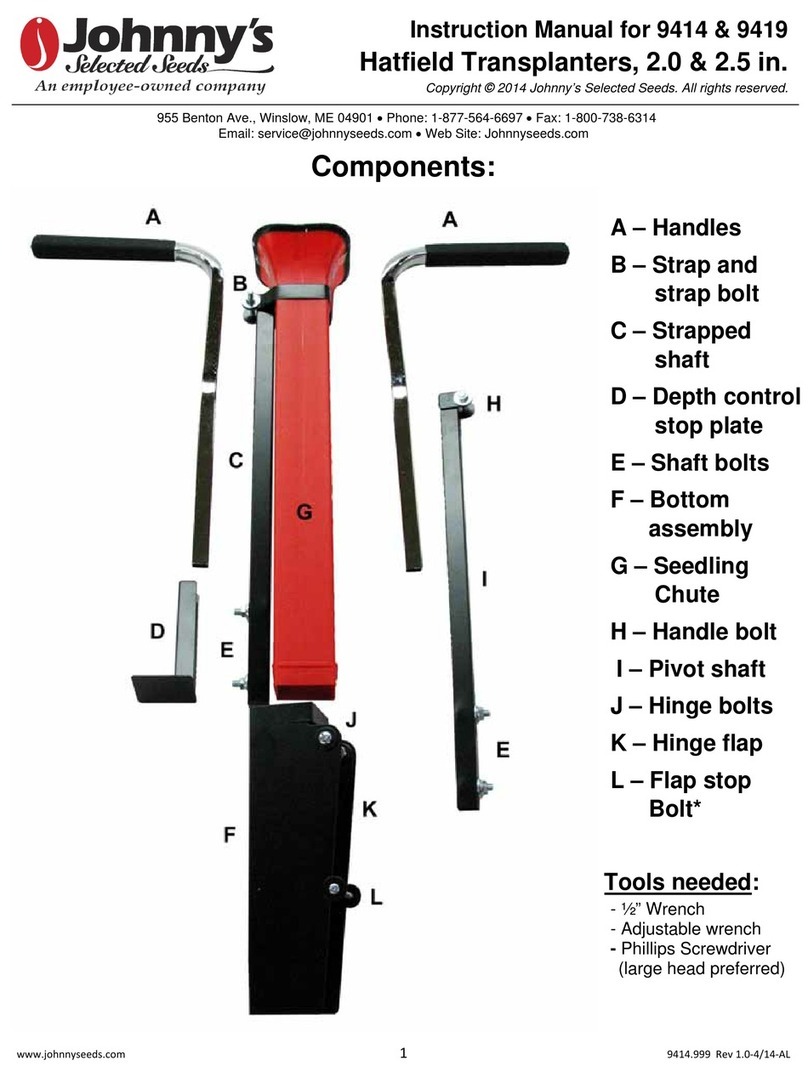

Figure 7: Loading the KEENAN MechFiber mixer wagon

CAUTION:

Overloading will seriously affect machine performance and life, and will invalidate

your warranty.

MechFiber345 & MechFiber365 Operator’s Manual20 Revision A.01 11th Nov 2016

Loading your KEENAN

7.5 OPERATING THE KEENAN MECHFIBER MIXER WAGON

Table 2: Loading the KEENAN MechFiber Mixer Wagon

LOADING THE KEENAN MECHFIBER MIXER WAGON

GENERAL

• Park on level ground.

• Ensure the variable feed control door (VFC) (guillotine door) is closed.

• Do not start PTO when VFC door is open.

LOADING AND MIXING SEQUENCE

• Load feed as close as possible to the loading side of the unit.

• Load concentrate feeds along the length of the machine.

• Load forages to the front, back and centre of the unit in alternate grabs during the mixing

process.

• Remove all twine, wrap or polythene from bales.

• Round or square bales should be split or broken into 4 pieces minimum.

Use front grab or forks as required.

• Load in the order shown below.

Load Order

Feed Ingredients

Paddle RPM

Tractor Engine

Speed RPM

1st

Water, Liquid feeds

All at

5-8 RPM

1300-1600 RPM

2nd

Straw

3rd

Minerals, Protein

meals, Pulps, Cereal

grains

4th

Grass silage

5th

Maize silage, Cereal

silage.

• Mixing time will depend on chop length required.

• Stop PTO before moving to feed out area.

Other manuals for KEENAN MechFiber345

1

This manual suits for next models

3

Table of contents

Other Alltech Farm Equipment manuals

Alltech

Alltech KEENAN MechFiber340 User manual

Alltech

Alltech KEENAN MechFiber400 User manual

Alltech

Alltech KEENAN MechFiber345 User manual

Alltech

Alltech KEENAN I Series User manual

Alltech

Alltech KEENAN MechFiber380 User manual

Alltech

Alltech KEENAN MechFiber250 User manual

Alltech

Alltech KEENAN MechFiber270 User manual

Alltech

Alltech KEENAN MechFiber Plus User manual

Alltech

Alltech KEENAN MechFiber300 User manual

Alltech

Alltech KEENAN MechFiber380+ User manual