The following safety points are general guidelines. Given the wide variety of possible

operating conditions, other safety risks that are not listed here may exist.

a) Always park the diet feeder on level ground and apply the handbrake when not in

use.

b) Do not exceed 15 km/h (10 mph) when in use/transit. Local road traffic laws will apply

when machine is in transit on public roads, on which the maximum permissible speed

is 25 km/h. Exceeding this will compromise the life and safety of major components,

such as the hitch, axle, wheels and chassis.

c) Ensure the VFC-door is closed and all feed-out trays/elevators are in the

closed/transport position prior to using on a public road.

d) When turning, exercise extreme caution for any potentially overtaking traffic on either

side.

e) Do not stand on the ladder whilst the feeder is in transit. The diet feeder should never

be used for the transport of people, animals or objects.

f) Do not stand between the tractor and diet feeder while it is in use.

g) Only use a PTO shaft with a properly fitted safety guard and the correct shear bolt.

h) Always connect the PTO shaft with the shear bolt end to the machine. The standard

operating range of the PTO is 540 RPM. However, an optional operating range of

1000 RPM may be available if the machine has been built to that specification. This

will be clearly marked on the front of the machine and on the operation procedure

decal. The direction of rotation is marked on the front cover (clockwise when

viewing from rear of machine). Always use a well-maintained PTO shaft and keep

the safety covers in good condition.

i) Ensure all trailing leads, hoses, etc., are well clear of the PTO.

j) Never operate the PTO in “ground speed mode” or drive the PTO in reverse.

k) Make sure all covers/guards are fitted and closed correctly. Never remove guards

when the diet feeder is connected to the tractor.

l) Ensure that the diet feeder and the immediate area surrounding it are clear of people,

especially children, before commencing operation. Ensure that there is sufficient

visibility for the operator to observe all danger zones and that the tractor is equipped

with mirrors to enable the operator to see both sides of the machine while it is in

operation.

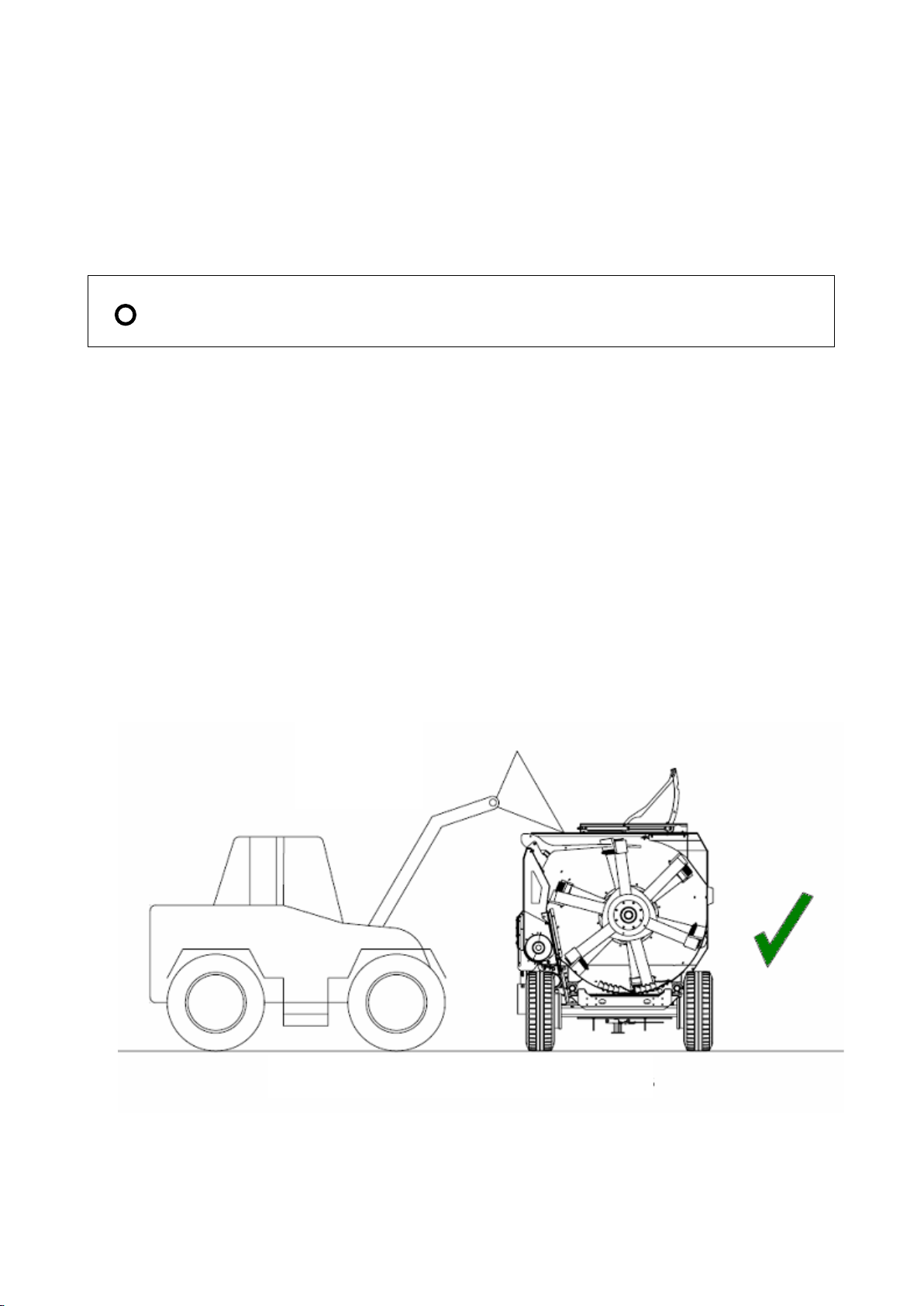

m) When connecting the tractor to the diet feeder, only connect using the ring hitch/hitch

on the diet feeder to ensure safe coupling. Ensure that the hitch is connected properly

to the tractor and that all pins and clips are properly installed. Then, connect the PTO

shaft in the correct fashion. Connect the hydraulic hoses, ensuring that the functions

match the indicated valve on the tractor.

n) When disconnecting, always ensure that a stand or jack is used to secure the diet

feeder in the park position and that the handbrake is properly applied. Before driving