KEENAN MechFiber 250 and 280 Operator’s Manual 12 Revision C01, 04th Dec 2019

s) The noise emission level of the KEENAN MechFiber250 has been recorded at 89.4dB.

Noise emission levels above 90dB would require the wearing of suitable ear protection.

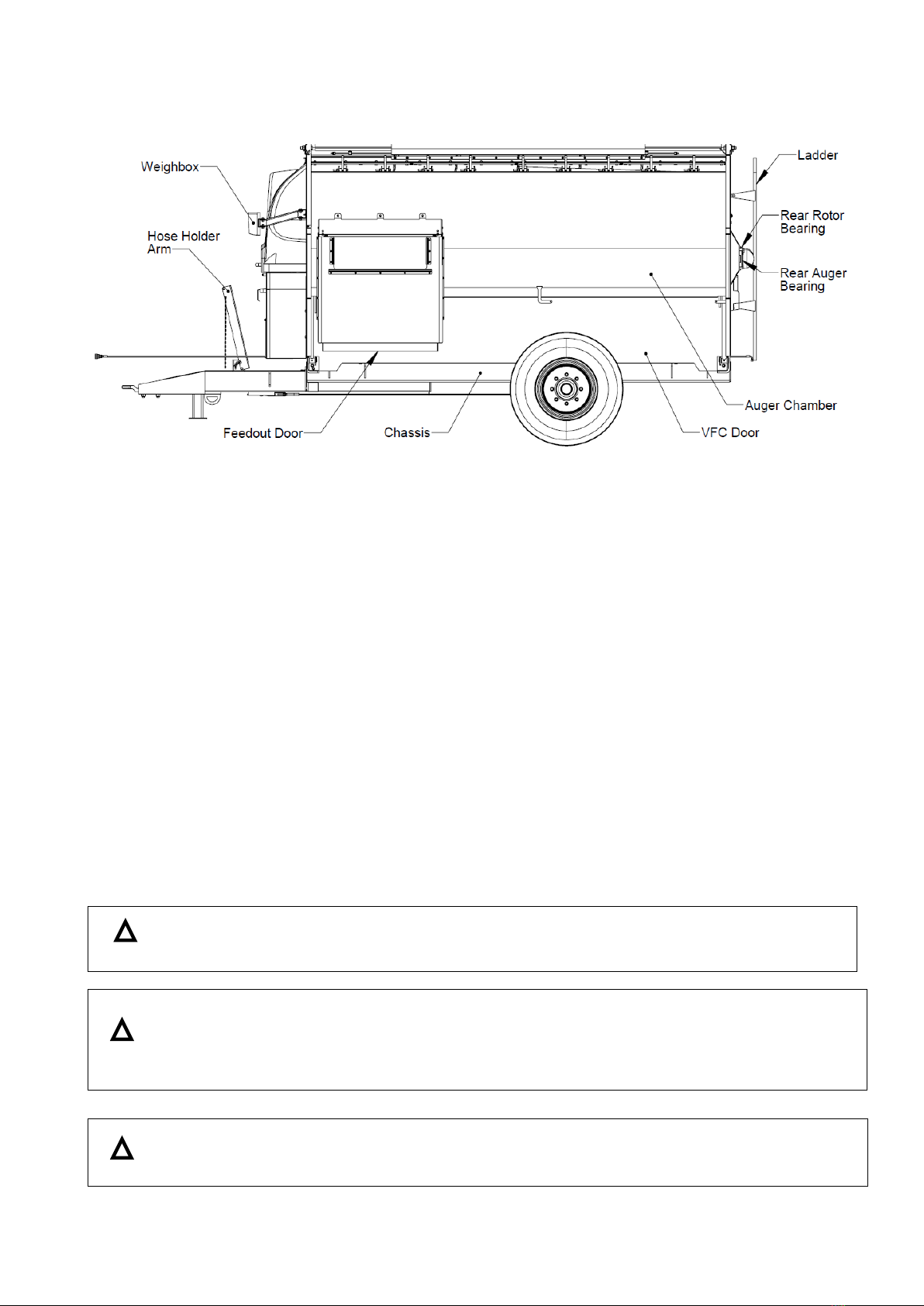

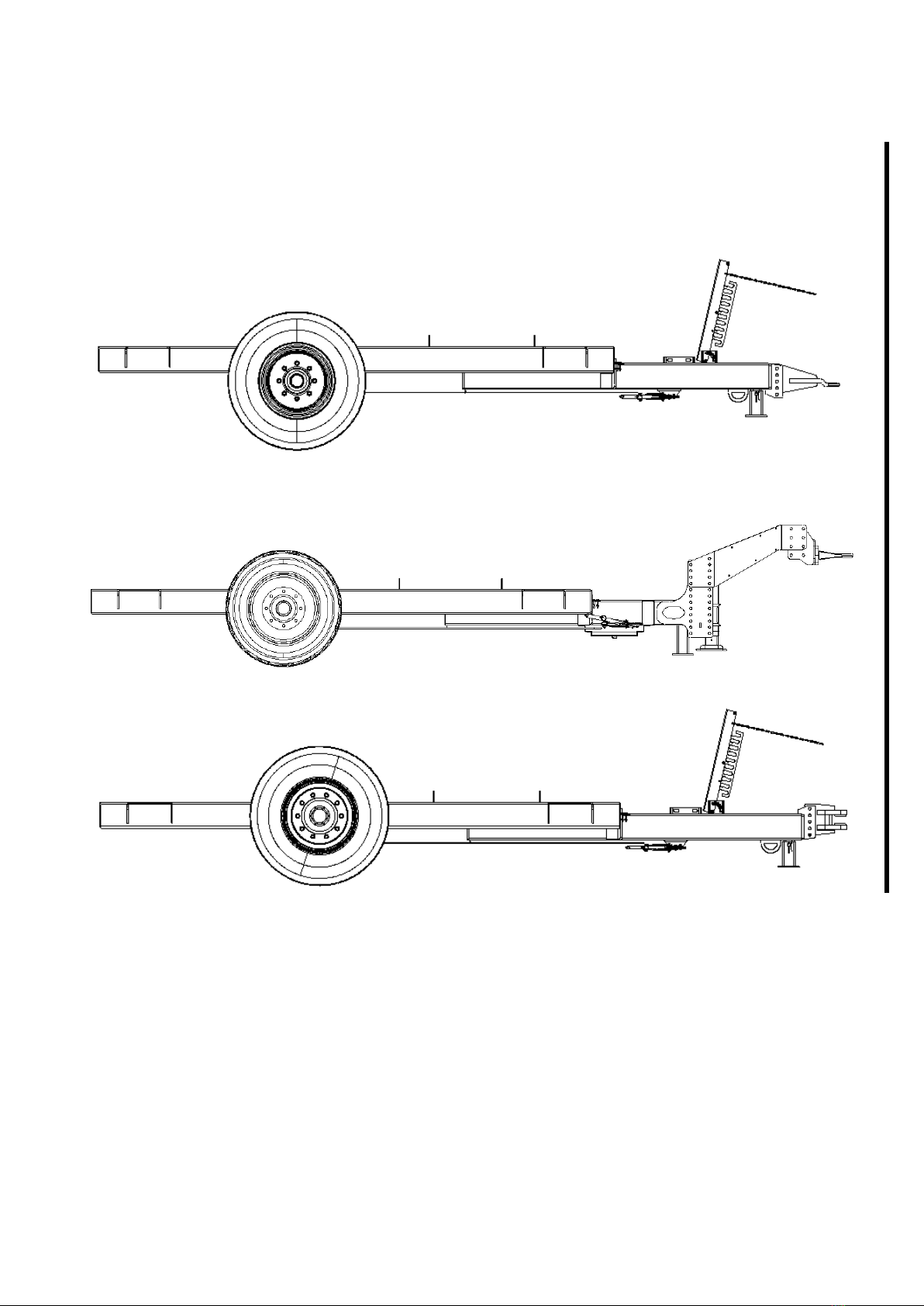

t) The Breakaway Safety Brake device should be attached to the tractor at all times. Cable

ties fix the wire rope along the handbrake handle in place. Cable tie the wire rope to the

drawbar (see figure 4). Fix the other end of the wire rope to a solid location on the back

of the tractor (e.g., the top link pin). In the event that the Breakaway Safety Brake device

has been activated or damaged, it is recommended that KEENAN Service is contacted

for directions to reset.

u) Routine cleaning may be carried out using a power washer. Isolate any power sources

before beginning. If washing the inside the Mixing Chamber, open the drain bung

underneath the body to allow water to escape. Always disconnect PTO shaft from the

tractor & stand on suitably safe ladder or platform. Do not to climb on top of the machine

or into the Mixing Chamber.

v) It is recommended that only trained and qualified KEENAN maintenance

personnel enter the mixing chamber.

In the case of an untrained person entering the mixing chamber, at the very minimum,

the following precautionary safety guidelines should be strictly adhered at all times.

1. Ensure the PTO and hydraulic hoses are disconnected

2. Apply the mixer wagon handbrake and disconnect the tractor from the machine on

level ground

3. Use suitable PPE such as protective footwear, eyewear and gloves

4. Personnel should make themselves familiar with the location of all potential

hazards before entering the machine, in particular, the location of the top knife and

body blades.

5. Be aware that sharp components may be hidden in or under material within the

mixing chamber

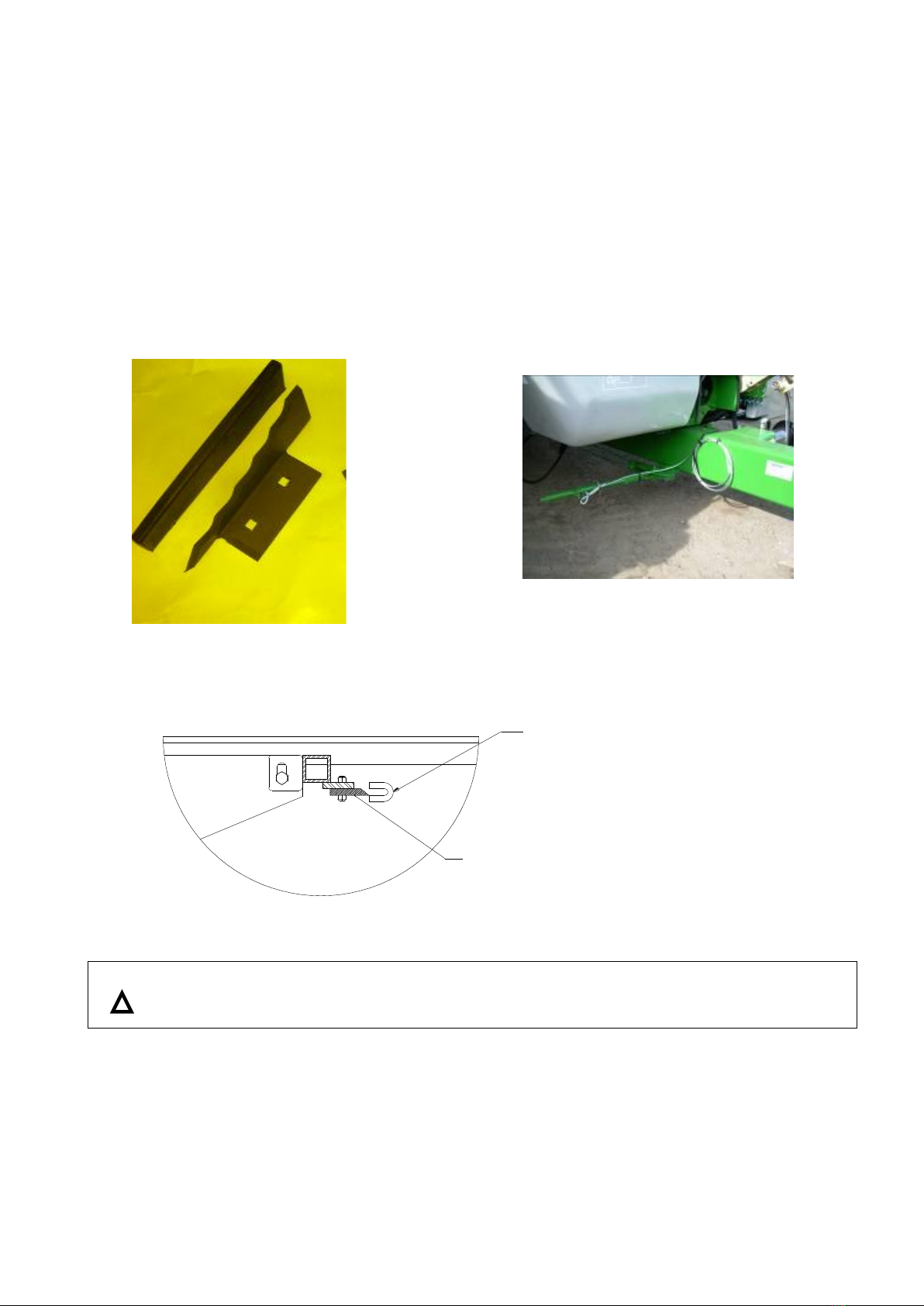

6. The top knife should always be fitted with the supplied guard (Figure 3b) before

entering the machine. Begin by fitting the first 500 mm of the guard from the rear of

the machine. Then as you enter, continue to fit the guard along the full length of the

Top Knife

Note: the machine is supplied with a top knife guard, which can be found inside the

driveline covers of the mixer wagon

7. Use a suitable & secure ladder for access to and from the mixer wagon. Note: The

ladder at the rear of the machine is provided as a means of viewing the ration only

and should not be used as a means of access the mixing chamber.

8. Always maintain 3 points of contact while entering, exiting & moving within the

mixing chamber of the machine

9. When entering the base of the body, it is recommended to cover the body blades in

the vicinity of where work is to be carried out.

10.When removing trapped objects, be aware that some machine components may

move unexpectedly when cleared.

11.Take extreme care when moving around inside the body as surfaces may be

slippery.