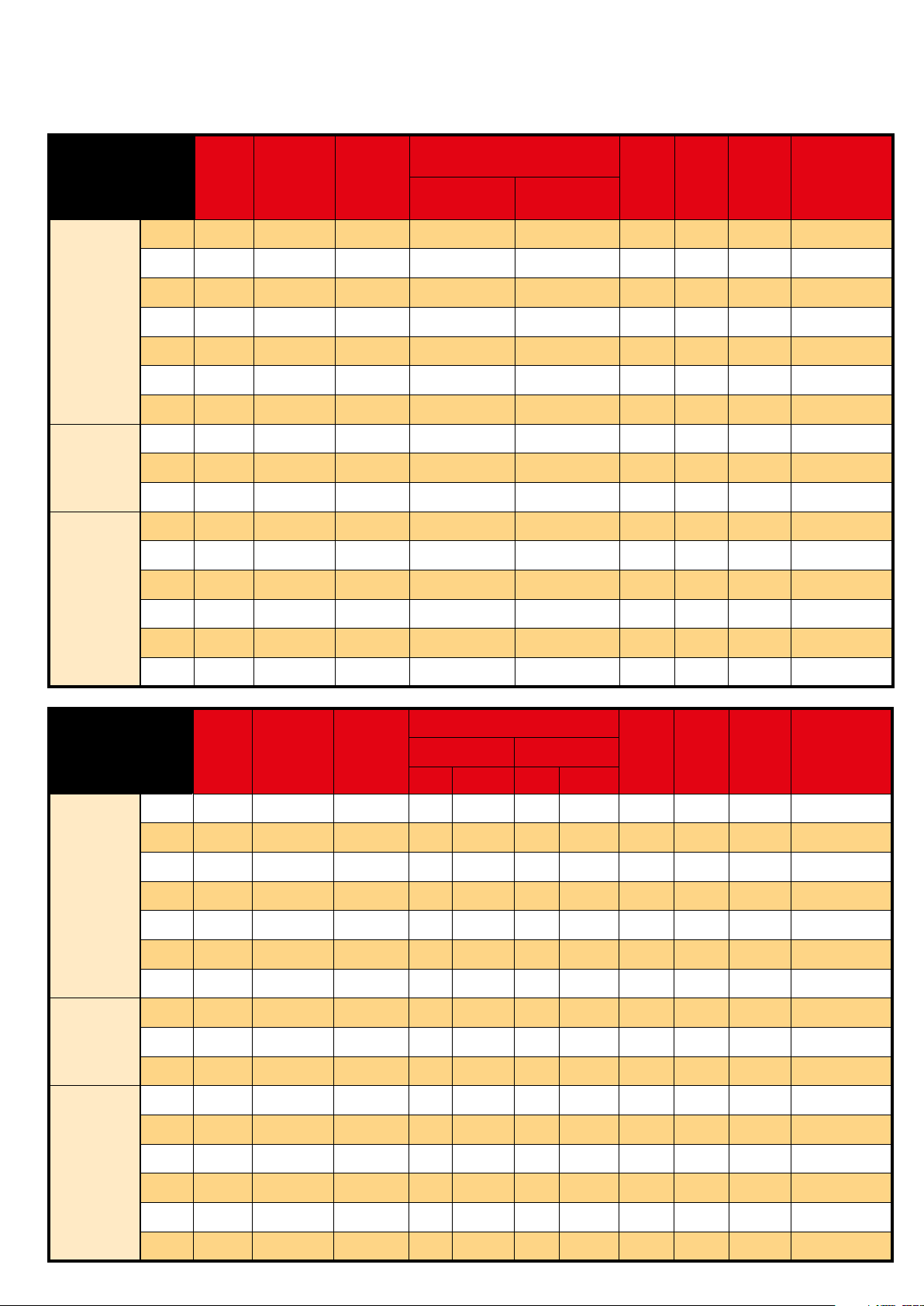

3- TECHNICAL CHARACTERISTICS

TRISEM-2110

TYPE OF MACHINE

WOR-

KING

WIDTH

(m)

TRANSPORT

WIDTH (m)

SPACING

ROW (cm)

HOPPER CAPACITY (Liters) TARE

(Kg.)

TARE

HIGH

HOPPER

(Kg.)

MÍN.

POWER

(HP)

TYRES

NORMAL HIGH

TINE

COULTER

300/22 33,28 13,6 1.270 1.565 970 1.000 110 10.0/75-15.3 12PR

300/25 33,28 12 1.270 1.565 1.000 1.030 110 10.0/75-15.3 12PR

350/25 3,5 3,77 14 1.270 1.565 1.070 1.100 120 10.0/75-15.3 12PR

350/28 3,5 3,77 12,5 1.270 1.565 1.100 1.140 120 10.0/75-15.3 12PR

400/28 44,26 14,3 1.270 1.565 1.140 1.190 130 10.0/75-15.3 12PR

400/31 44,26 12,9 1.270 1.565 1.180 1.230 130 10.0/75-15.3 12PR

400/33 44,26 12,1 1.270 1.565 1.200 1.250 130 10.0/75-15.3 12PR

SUFFOLK

COULTERS

300/25 33,28 12 1.270 1.565 110 10.0/75-15.3 12PR

350/28 3,5 3,77 12,5 1.270 1.565 120 10.0/75-15.3 12PR

400/33 44,26 12,1 1.270 1.565 130 10.0/75-15.3 12PR

DOUBLE

DISC

300/19 33,28 15,8 1.270 1.565 110 10.0/75-15.3 12PR

300/21 33,28 14,3 1.270 1..565 110 10.0/75-15.3 12PR

350/21 3,5 3,77 16,7 1.270 1.565 120 10.0/75-15.3 12PR

350/25 3,5 3,77 14 1.270 1.565 120 10.0/75-15.3 12PR

400/25 44,26 16 1.270 1.565 130 10.0/75-15.3 12PR

400/29 44,26 13,8 1.270 1.565 130 10.0/75-15.3 12PR

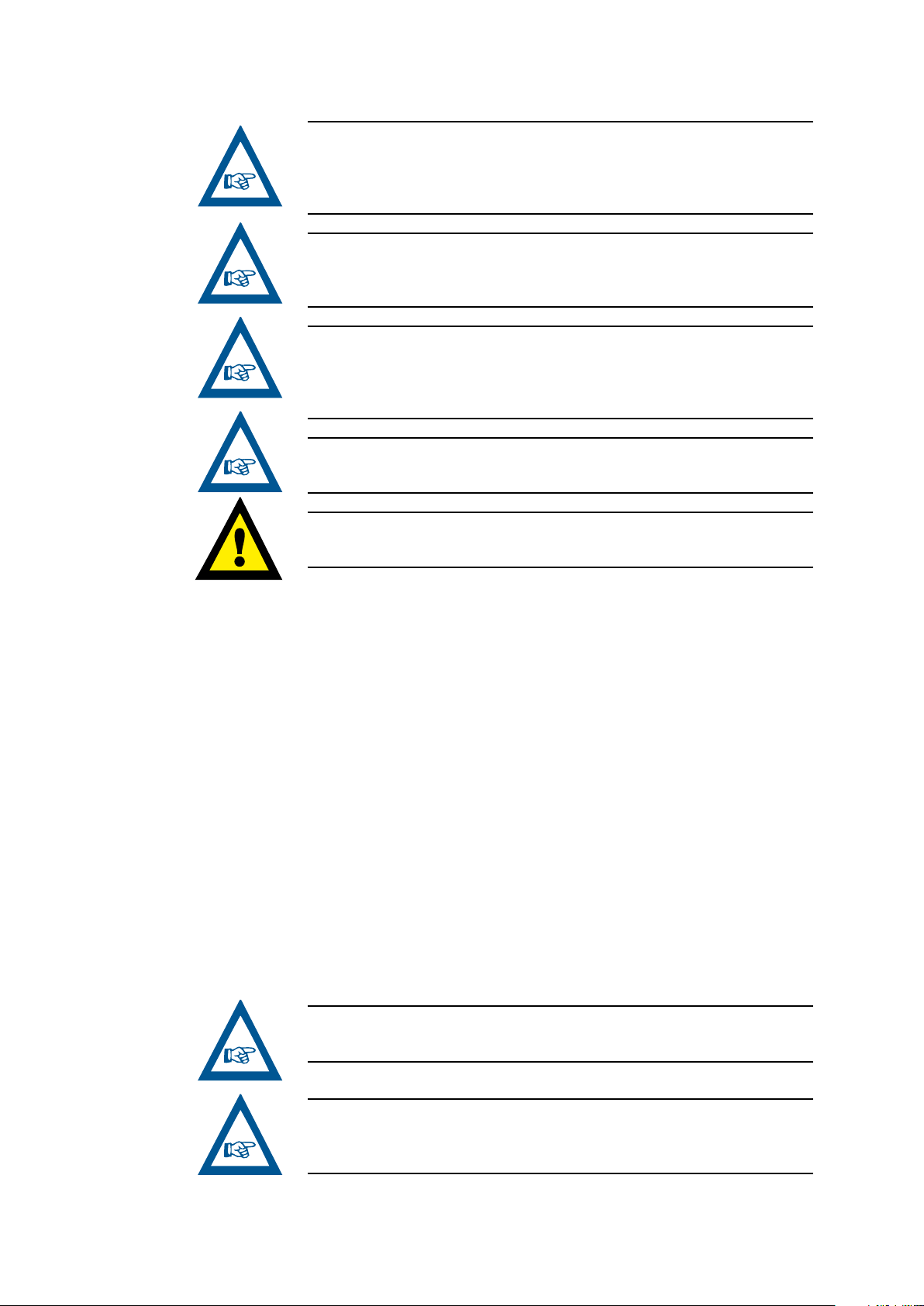

TRICOMBI-2110

TYPE OF MACHINE

WOR-

KING

WIDTH

(m)

TRANSPORT

WIDTH (m)

SPACING

ROW (cm)

HOPPER CAPACITY (Liters)

TARE

(Kg.)

TARE

HIGH

HOPPER

(Kg.)

MÍN.

POWER

(HP)

TYRES

NORMAL HIGH

SEED FERTILIZER SEED FERTILIZER

TINE

COULTER

300/22 33,28 13,6 713 583 - - 10.0/75-15.3 12PR

300/25 33,28 12 713 583 - - 10.0/75-15.3 12PR

350/25 3,5 3,77 14 846 692 - - 10.0/75-15.3 12PR

350/28 3,5 3,77 12,5 846 692 - - 10.0/75-15.3 12PR

400/28 44,26 14,3 978 800 - - 10.0/75-15.3 12PR

400/31 44,26 12,9 978 800 - - 10.0/75-15.3 12PR

400/33 44,26 12,1 978 800 - - 10.0/75-15.3 12PR

SUFFOLK

COULTERS

300/25 33,28 12 713 583 - - 10.0/75-15.3 12PR

350/28 3,5 3,77 12,5 846 692 - - 10.0/75-15.3 12PR

400/33 44,26 12,1 978 800 - - 10.0/75-15.3 12PR

DOUBLE

DISC

300/19 33,28 15,8 713 583 - - 10.0/75-15.3 12PR

300/21 33,28 14,3 713 583 - - 10.0/75-15.3 12PR

350/21 3,5 3,77 16,7 846 692 - - 10.0/75-15.3 12PR

350/25 3,5 3,77 14 846 692 - - 10.0/75-15.3 12PR

400/25 44,26 16 978 800 - - 10.0/75-15.3 12PR

400/29 44,26 13,8 978 800 - - 10.0/75-15.3 12PR