9

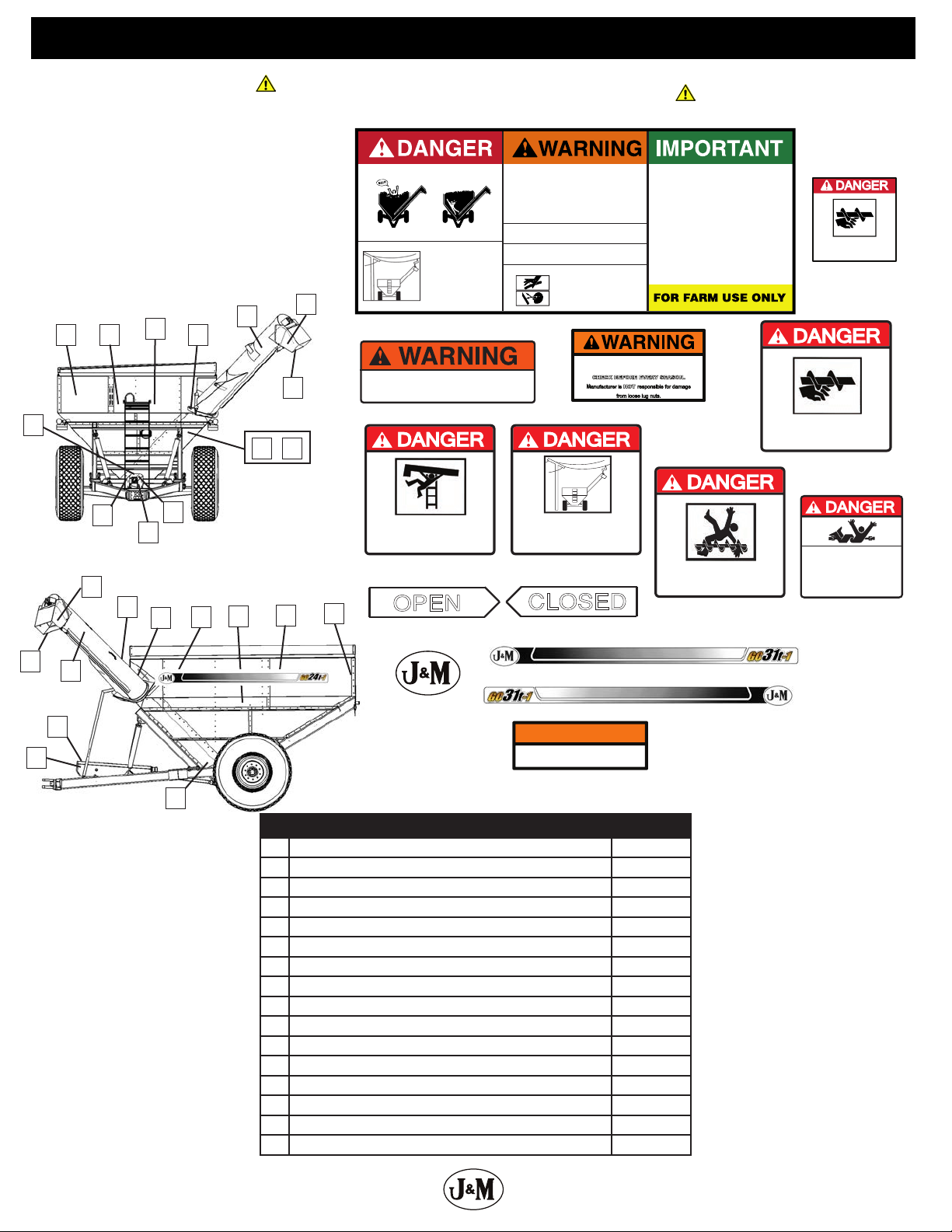

Safety Decals

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged or Missing

IMPORTANT: Install new safety signs if the

old signs are destroyed, lost, painted over

or cannot be read. When parts are replaced

that have safety signs, make sure you install

a new sign with each new part. New signs

are available from the manufacturer or your

authorized dealer.

1

2

34

5

10 11

6 7

8 9

DO NOT ENTER GRAIN TANK WHEN

AUGER IS RUNNING.

1

9 3

77

5

2

916

9

9

12

13

12 & 13

14

15

16

SERIOUS INJURY OR DEATH CAN RESULT

FROM CONTACT WITH ELECTRIC LINES.

USE CARE WHEN MOVING OR OPERATING

THIS MACHINE NEAR ELECTRIC LINES

TO AVOID CONTACT.

KEEP HANDS, FEET, HAIR AND

CLOTHING AWAY FROM MOVING PARTS

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH.

KEEP AWAY!

• Keep all guards in place when operating.

• Do NOT stand on steps or climb ladder until

all power is shut off.

• Keep hands, feet, hair and clothing away

from moving parts.

10

6

4

11

7

5

16

9

12

15

14

13

Do not inflate tires more than 6 PSI over the recommended

pressure printed on the side of the tire.

CHECK TIRE INFLATION

OPERATING INSTRUCTIONS

Do not operate or service machine until you

read and understand operator’s manual.

Dealer or manufacturer is not responsible for damaged caused by

loose wheel nuts.

CHECK ALL WHEEL NUTS

To prevent serious injury or death:

• R elieve pressure on system before

r epairing, adjusting or disconnecting.

• W ear proper hand and eye protection

w hen searching for leaks.

• K eep all components in good repair.

HIGH-PRESSURE FLUID HAZARD

Do not adjust, service, clear, or lubricate the machine until all

power is shut off.

Keep all safety shields in place.

Keep people and objects clear of equipment before applying

power or moving machine.

Before highway travel, secure a slow-moving vehicle emblem to

the rear of the machine in accordance to the state and local

laws.

Make sure all flashers and turn/brake lights are working properly

BEFORE incidental highway travel.

•

•

•

•

•

•

FLOWING GRAIN TRAPS AND SUFFOCATES VICTIM IN SECONDS!

With the gate indicator in the closed position, fill the box with

grain.

With the PTO disengaged, fold discharge auger to upright

position.

After auger is in the upright position, start the PTO at a SLOW

RATE OF SPEED until the pin on the upper auger engages the

drive dog on the bottom auger(failure to follow this procedure

may cause extensive damage to both the drive dog and the pin).

Increase PTO speed to 1000 RPM and open inner gate until the

pointer is in the halfway position. When grain begins flowing

from the discharge auger, open gate to the full position.

Once the grain has ceased to flow, return the gate to the closed

position (for complete clean-out, gradually close gate, allowing

the opening to be reduced). Disengage the PTO and allow its

rotation to come to a complete stop. Auger is now ready to be

returned to the lowered position.

•

•

•

•

SERIOUS INJURY OR

DEATH CAN RESULT WITH

ELECTRIC LINES.

USE CARE WHEN MOVING

OR OPERATING MACHINE

NEAR ELECTRIC LINES TO

AVOID CONTACT.

NEVER PLAY IN OR

ON GRAIN CART YOU CAN DIE IN

SECONDS IN

FLOWING GRAIN!

JM0037665

KEEP HANDS AND CLOTHING

AWAY FROM MOVING PARTS.

JM0076817

CHECK WHEEL LUGS

CHECK BEFORE EVERY SEASON.

Manufacturer is NOT responsible for damage

from loose lug nuts.

JM0025435

CHECK PTO OVERLAP

CHECK MANUAL FOR PTO LENGTH.

INCORRECT PTO OVERLAP MAY CAUSE

EXTENSIVE DAMAGETO DRIVE SYSTEM.

Description Part No.

1 Danger_Warning_Important JM0037665

2 Danger, Keep Hands and Clothing Away Decal (Small) JM0076817

3 Warning, Keep Hands Away Decal JM0018039

4 Warning, Keep Lug Nuts Tightened Decal 1-5/8”x 4” JM0010150

5 Danger, Keep Hands and Clothing Away Decal JM0018035

6 Danger, Keep O Ladder Decal JM0018034

7 Danger, Electric Lines Decal JM0015099

8 Danger, Do Not Enter Grain Tank Decal JM0018033

9 Danger, Rotating Driveline Decal JM0018036

10 Open Decal JM0025433

11 Closed Decal JM0025434

12 J&M Oval Decal (Large) 9-1/2” x 15” JM0015151

13 J&M Oval Decal (Medium) 5-1/2”x8-1/2” JM0010179

14 GC31t-1 OAS Stripe Complete JM0046656

15 GC31t-1 AS Stripe Complete JM0046655

16 Check PTO Overlap Decal JM0025435