Strictly confidential information - All rights to the contents of this document are reserved. It is forbidden to copy, use, distribute, even partially or

otherwise circulate such information, unless expressly authorised by "ALPEGO S.p.a.". Violations will be prosecuted in accordance with the law.

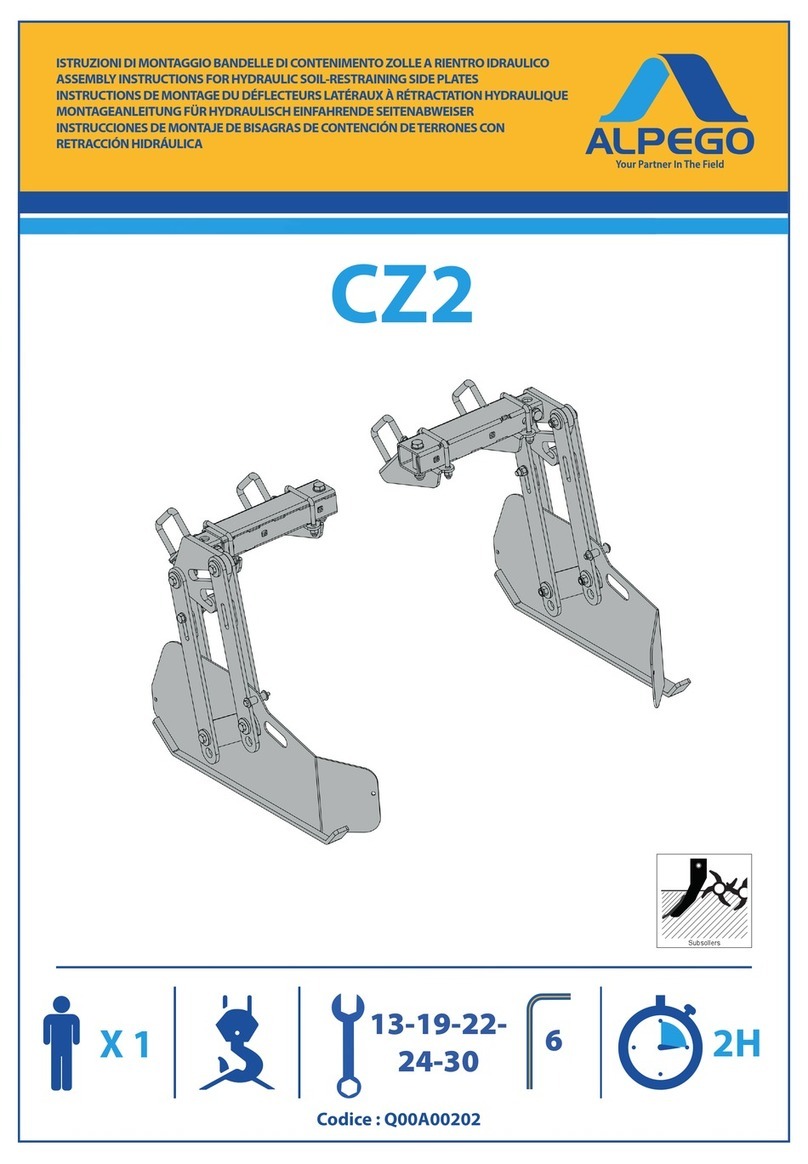

6Code : Q00A00203 - Rev. 00_07/2021

List of figures

⚠

The images in this manual are for illustrative purposes only and may not always accurately represent the

appearance of the product or its application.

Fig. 1 Marking data............................................................................................................................................15

Fig. 2 Parts overview KDyno .............................................................................................................................19

Fig. 3 Overview of parts KEvo ........................................................................................................................... 20

Fig. 4 Parts overview KForce............................................................................................................................. 21

Fig. 5 Ban points ascent .................................................................................................................................... 29

Fig. 6 No passing or parking points ................................................................................................................... 30

Fig. 7 Safety device (normal strain - overload)..................................................................................................32

Fig. 8 Safety warnings applied to the machine..................................................................................................35

Fig. 9 Lifting machine in "transport set-up .........................................................................................................37

Fig. 10 Lifting a mounted machine....................................................................................................................... 38

Fig. 11 Accessory lifting....................................................................................................................................... 39

Fig. 12 Incorrect weight distribution.....................................................................................................................40

Fig. 13 Correct weight distribution ....................................................................................................................... 40

Fig. 14 Counterweight calculation........................................................................................................................ 41

Fig. 15 KDyno connection procedure ..................................................................................................................43

Fig. 16 KEvo connection procedure..................................................................................................................... 44

Fig. 17 Categories KEvo bindings .......................................................................................................................45

Fig. 18 KForce connection procedure.................................................................................................................. 46

Fig. 19 Categories KForce bindings ....................................................................................................................47

Fig. 20 Hydraulic connection ...............................................................................................................................48

Fig. 21 Transit on public roads.............................................................................................................................50

Fig. 22 Working area ...........................................................................................................................................51

Fig. 23 Example of a 'machine under maintenance'sign .....................................................................................51

Fig. 24 Normal working zones with machine at standstill .................................................................................... 52

Fig. 25 Positioning support legs by working mode .............................................................................................. 53

Fig. 26 Positioning the side straps accessory in the working position................................................................. 54

Fig. 27 Side straps accessory (opening - closing)...............................................................................................55

Fig. 28 Side straps accessory (opening - closing)...............................................................................................56

Fig. 29 Correct use .............................................................................................................................................. 57

Fig. 30 Prohibited use.......................................................................................................................................... 58

Fig. 31 Accessory roller working angle adjustment .............................................................................................61

Fig. 32 Accessory roller working angle adjustment .............................................................................................62

Fig. 33 Mechanical roller depth adjustment.........................................................................................................63

Fig. 34 Hydraulic roller depth adjustment ............................................................................................................ 64

Fig. 35 Media lubrication...................................................................................................................................... 68

Fig. 36 Pin lubrication .......................................................................................................................................... 69

Fig. 37 Recommended spare parts .....................................................................................................................76

Fig. 38 KDyno protection replacement ................................................................................................................77

Fig. 39 KDyno ploughshare replacement ............................................................................................................ 77

Fig. 40 Replacement KDyno exploder.................................................................................................................77