Index

Copyright ©2009 della Alpego spa® - All rights are reserved. Reprinting or unauthorized use of this manual is strictly forbidden without written permission by Alpego spa

1. GENERAL INFORMATION........................................................................................................................................1

1.1. PURPOSE OF THE MANUAL .............................................................................................................................1

1.2. DOCUMENTS THAT COME WITH THE MACHINE............................................................................................1

1.3. GUARANTEE.......................................................................................................................................................1

1.4. MACHINE IDENTIFICATION...............................................................................................................................1

2. TECHNICAL SPECIFICATIONS................................................................................................................................2

2.1. MACHINE DESCRIPTION...................................................................................................................................2

2.2. COMPOSANTS DU BROYEUR ..........................................................................................................................2

2.3. TECHNICAL INFORMATION CHART.................................................................................................................3

2.4. IDENTIFYING THE CARDAN JOINT ..................................................................................................................6

3. SAFETY REGULATIONS ..........................................................................................................................................7

3.1. USING THE MACHINE SAFELY.........................................................................................................................7

3.2. SAFE MAINTENANCE.......................................................................................................................................10

3.3. CLOTHING.........................................................................................................................................................11

3.4. ECOLOGY..........................................................................................................................................................11

3.5. SAFETY SIGNS.................................................................................................................................................12

3.6. SOUND LEVEL..................................................................................................................................................14

3.7. STICKERS INDICATING IMPORTANT POINTS...............................................................................................14

4. INSTALLATION .......................................................................................................................................................15

4.1. LIFTING THE MACHINE....................................................................................................................................15

4.2. MACHINES THAT ARE SUPPLIED PARTIALLY ASSEMBLED.......................................................................15

4.3. HITCHING TO THE THREE POINT HITCH OF THE TRACTOR .....................................................................16

4.4. CONNECTING THE CARDAN JOINT...............................................................................................................17

4.5. TRACTOR STABILITY AND LIFTING CAPACITY CHECK ..............................................................................18

5. INSTRUCTIONS FOR USE......................................................................................................................................19

5.1. “NO STOP” SAFETY DEVICE...........................................................................................................................19

5.2. HYDRAULIC SHOCK ABSORBER ...................................................................................................................20

5.3. ADJUSTING THE WORKING DEPTH...............................................................................................................21

5.4. HAMMERS.........................................................................................................................................................22

5.5. SIDE SHIFTING.................................................................................................................................................22

5.6. HOW TO USE....................................................................................................................................................23

5.7. USEFUL ADVICE...............................................................................................................................................23

5.8. UNHITCHING.....................................................................................................................................................24

5.9. STORING THE IMPLEMENT.............................................................................................................................24

5.10. TROUBLESHOOTING.....................................................................................................................................24

5.11. OTHER ADVICE FOR TRACTOR DRIVERS..................................................................................................26

6. MAINTENANCE .......................................................................................................................................................26

6.1. CHECKS AND CONTROLS...............................................................................................................................26

6.2. LATERAL TRANSMISSION TRANSMISSION..................................................................................................27

6.3. REPLACING THE HAMMERS..........................................................................................................................28

6.4. LUBRICATION...................................................................................................................................................28

6.5. LUBRICATION PLAN.........................................................................................................................................29

6.6. LUBRICANTS TO BE USED ( L.= litres ) .......................................................................................................30

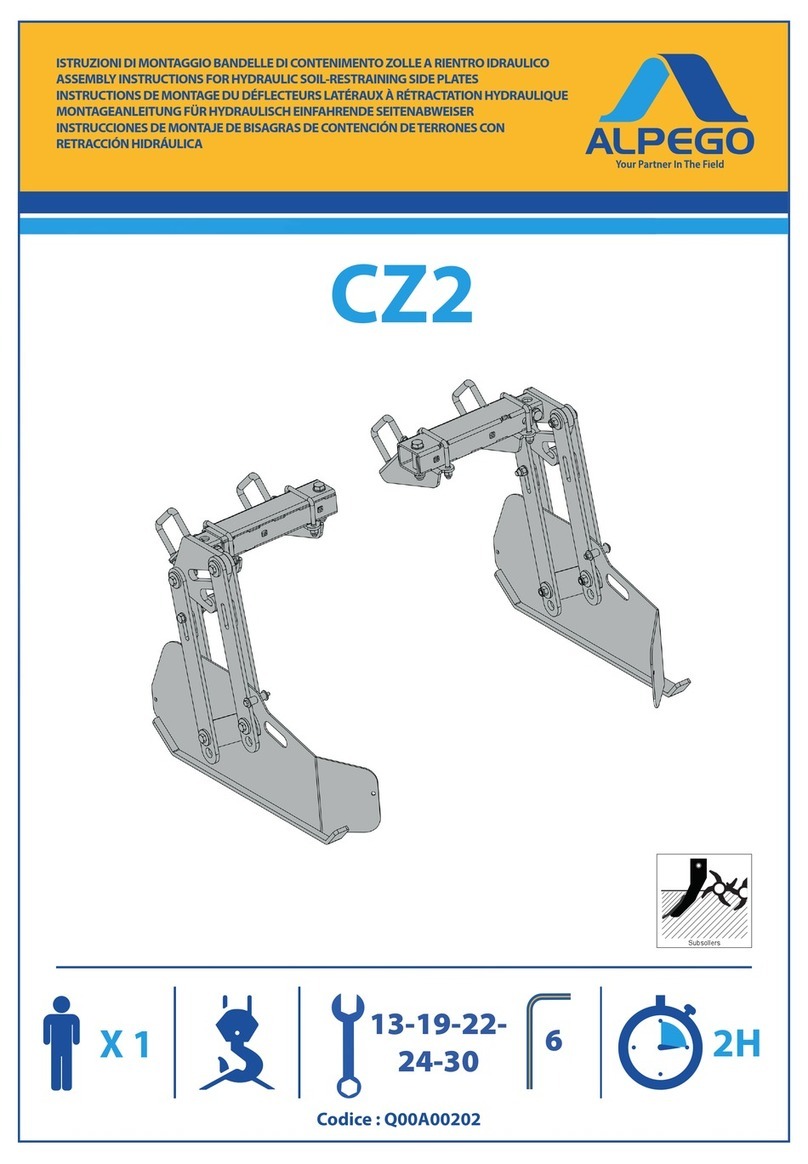

7. ACCESOIRES..........................................................................................................................................................31