Sommario

Copyright ©2009 della Alpego spa® - All rights are reserved. Reprinting or unauthorized use of this manual is strictly forbidden without written permission by Alpego spa

1. GENERAL INFORMATION........................................................................................................................................1

1.1. PURPOSE OF THE MANUAL .............................................................................................................................1

1.2. DOCUMENTS THAT COME WITH THE MACHINE............................................................................................1

1.3. GUARANTEE.......................................................................................................................................................1

1.4. MACHINE IDENTIFICATION...............................................................................................................................1

2. TECHNICAL SPECIFICATIONS................................................................................................................................2

2.1. MACHINE DESCRIPTION...................................................................................................................................2

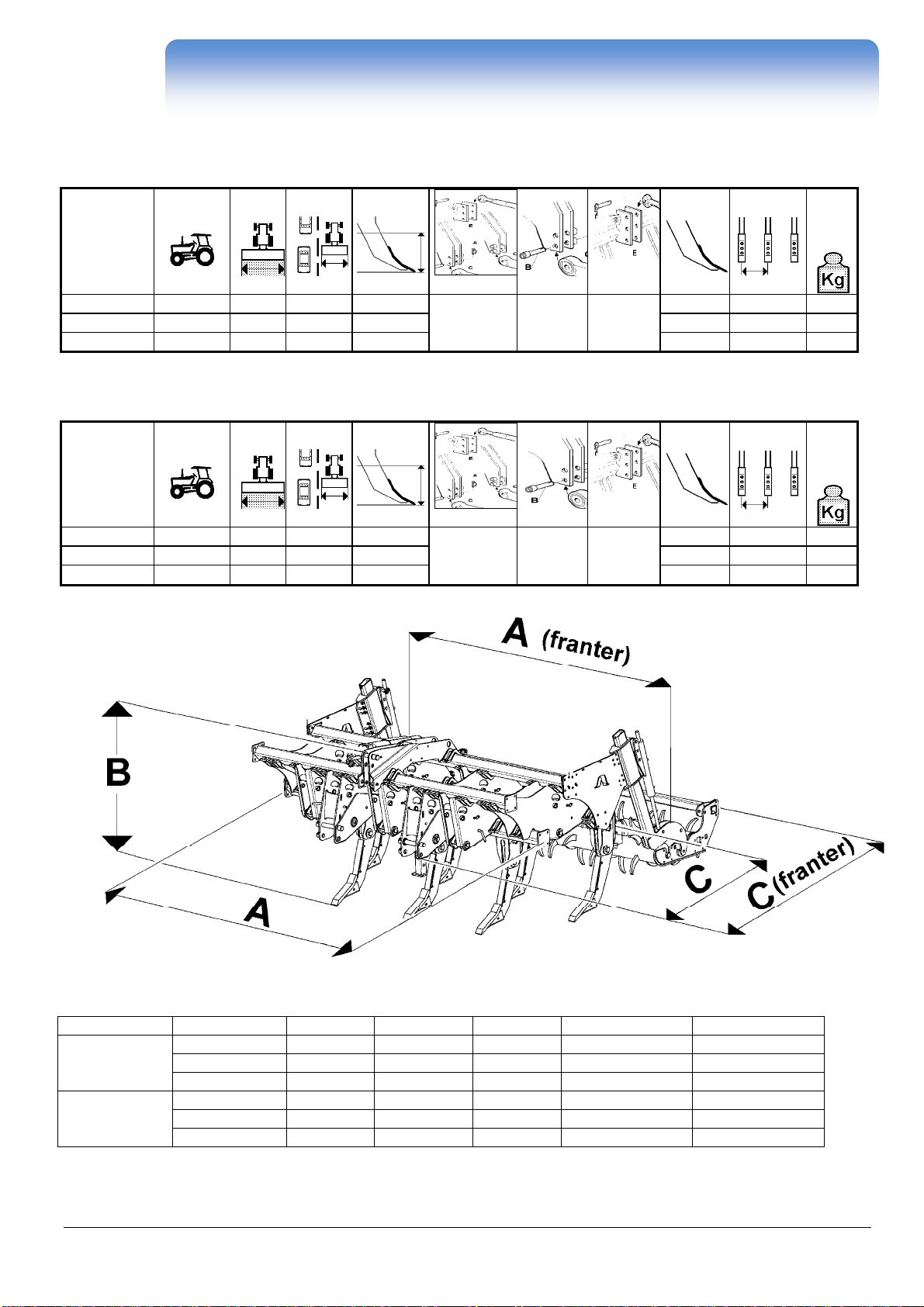

2.2. TECHNICAL INFORMATION CHART K1..........................................................................................................3

2.3. TECHNICAL INFORMATION CHART K2...........................................................................................................3

3. SAFETY REGULATIONS ..........................................................................................................................................4

3.1. USING THE MACHINE SAFELY.........................................................................................................................4

3.2. CARRYING OUT MAINTENANCE SAFELY .......................................................................................................5

3.3. HYDRAULIC CONNECTION...............................................................................................................................5

3.4. ROAD CIRCULATION .........................................................................................................................................5

3.5. CLOTHING...........................................................................................................................................................5

3.6. ECOLOGY............................................................................................................................................................5

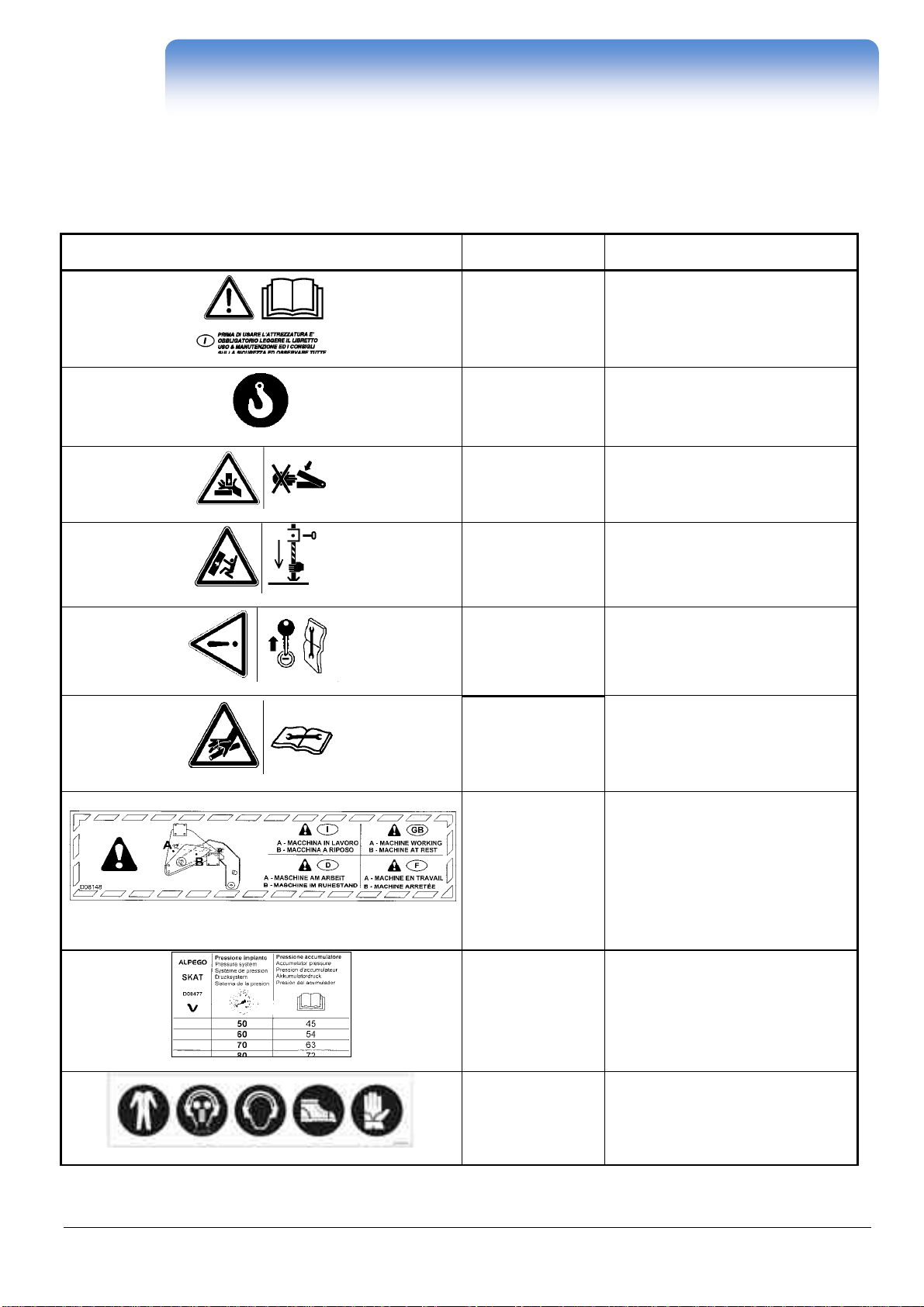

3.7. SAFETY SIGNS...................................................................................................................................................6

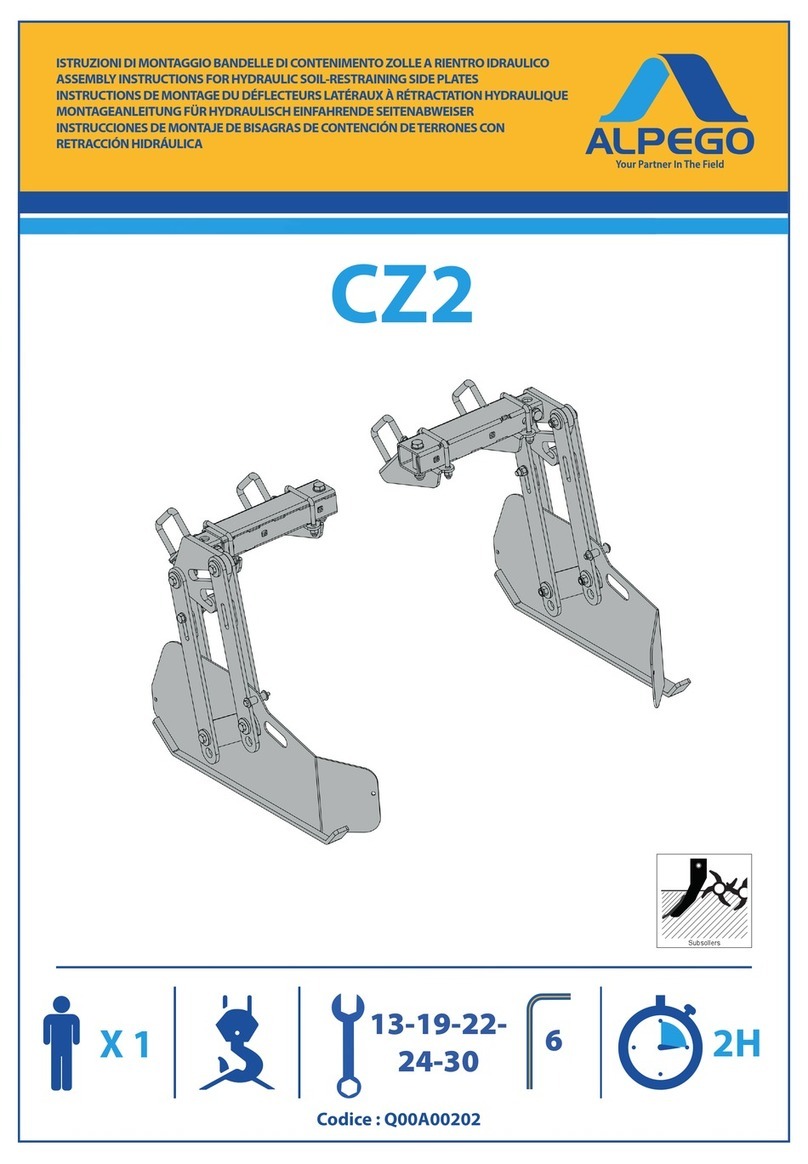

4. INSTALLATION .........................................................................................................................................................7

4.1. LIFTING................................................................................................................................................................7

4.2. PREPARATION BEFORE USE...........................................................................................................................7

4.3. CONNECTION TO TRACTOR K1......................................................................................................................9

4.4. CONNECTION TO TRACTOR K2......................................................................................................................9

4.5. CHECKING THE TRACTOR LIFTING FORCE AND STABILITY.....................................................................10

4.6. CONNECTION TO A 3 POINT HITCH K1-K2 ...................................................................................................11

4.7. HYDRAULIC CONNECTIONS TO THE TRACTOR..........................................................................................12

5. USER INSTRUCTIONS............................................................................................................................................13

5.1. USE WITH TRACTORS EQUIPPED WITH CONTROLLED LIFTER STRESS................................................13

5.2. USE WITH TRACTORS WITHOUT CONTROLLED LIFTER STRESS............................................................13

5.3. HYDRRAULIC OPERATION..............................................................................................................................13

5.4. SPECIAL VALVE OPERATION.........................................................................................................................14

5.5. VALVE SETTING – ACCUMULATOR SETTING ..............................................................................................14

5.6. MECHANICAL SAFETY.....................................................................................................................................15

5.7. END OF SEASON OPERATIONS.....................................................................................................................15

6. MAINTENANCE .......................................................................................................................................................16

6.1. CHECKS AND CONTROLS...............................................................................................................................16

6.2. LUBRICATION...................................................................................................................................................16

7. ACCESSORIES........................................................................................................................................................17

7.1. SOD CONTAINING KIT.....................................................................................................................................17

7.2. WINGED SOIL SWEEP....................................................................................................................................17

7.3. REAR WHEEL SET ...........................................................................................................................................17

7.4. FRANTER ROLLER SET K1 – K2.....................................................................................................................18