Index

Copyright ©2009 della Alpego spa ® -Tutti i diritti sono riservati. È espressamente vietata la ristampa o l’uso non autorizzato per iscritto da parte di Alpego spa

1. GENERAL INFORMATION........................................................................................................................................1

1.1. PURPOSE OF THE MANUAL .............................................................................................................................1

1.2. DOCUMENTS ACCOMPANYING THE MACHINE .............................................................................................1

1.3. WARRANTY.........................................................................................................................................................1

1.4. IDENTIFICATION OF THE MACHINE.................................................................................................................1

2. TECHNICAL SPECIFICATIONS................................................................................................................................2

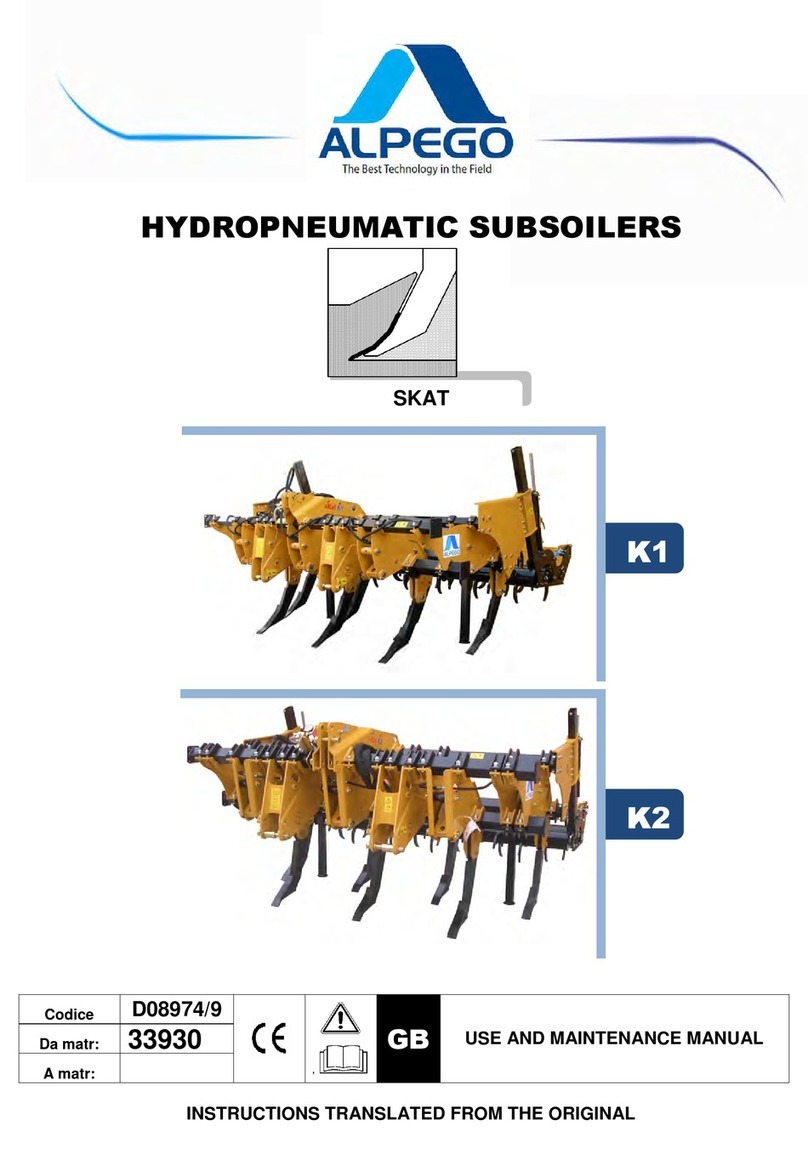

2.1. DESCRIPTION.....................................................................................................................................................2

2.2. IMPLEMENT COMPONENTS .............................................................................................................................3

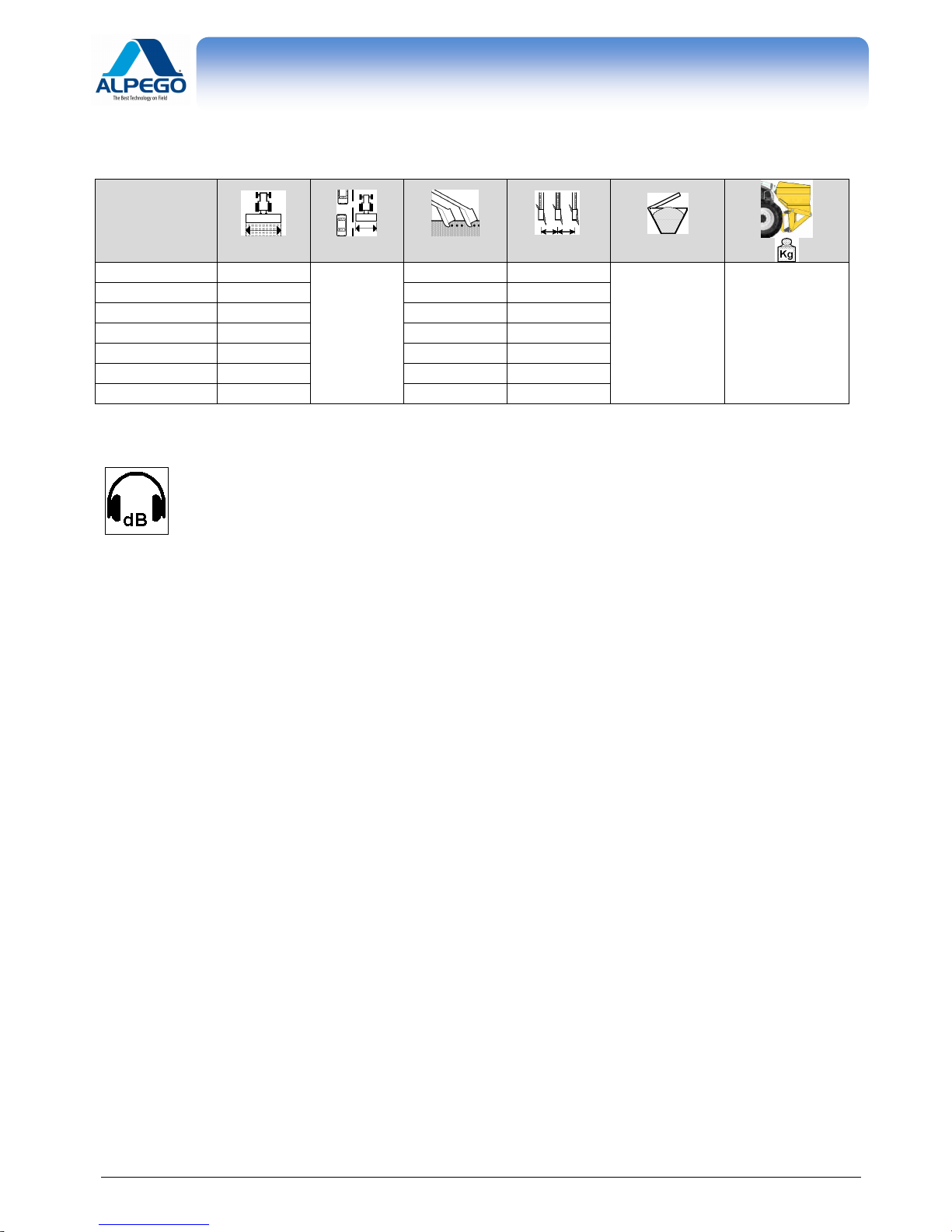

2.3. CHART OF TECHNICAL DATA...........................................................................................................................4

2.4. SOUND LEVEL....................................................................................................................................................4

3. SAFETY REGULATIONS ..........................................................................................................................................5

3.1. USE THE MACHINE SAFETY.............................................................................................................................5

3.2. HYDRAULIC CONNECTIONS.............................................................................................................................6

3.3. ASSEMBLY OF ELECTRIC AND ALECRONIC INSTRUMENTS AND COMPONENTS ...................................7

3.4. CARRYING OUT MAINTENANCE SAFETY.......................................................................................................7

3.5. TRAVELLING ON ROADS...................................................................................................................................8

3.6. CLOTHING...........................................................................................................................................................8

3.7. ECOLOGY............................................................................................................................................................8

3.8. SAFETY SIGNALS...............................................................................................................................................8

4. INSTALLATION ........................................................................................................................................................9

4.1. TRANSPORT O ...................................................................................................................................................9

4.2. LIFTING..............................................................................................................................................................10

4.3. CONNECTING THE FRONT HOPPER TO THE TRACTOR............................................................................10

4.4. RADAR INSTALLATION....................................................................................................................................11

4.5. ASSEMBLING THE SEEDER BAR ..................................................................................................................11

4.6. FITTING THE SEED COVERING HARROW ....................................................................................................11

4.7. ASSEMBLING THE SEEDER PIPES...............................................................................................................12

4.7.1. ASSEMBLYING THE SEEDING PIPES ON THE POWER HARROW.......................................................16

4.8. CONNECTING SYSTEM BETWEEN FRONT HOPPER AND REAR DISTRIBUTION HEAD.........................17

4.8.1. MAIN COMPONENTS.................................................................................................................................17

4.8.2. INSTALLATION OF THE CONNECTING SYSTEM ON THE TRACTOR..................................................18

4.8.3. CONNECTING THE HOPPER WITH THE IMPLEMENT...........................................................................19

4.9. CHECK OF THE TRACTOR STABILITY AND ITS LIFTING POWER..............................................................20

5. INSTRUCTIONS FOR USE......................................................................................................................................21

5.1. OPERATION OF THE BLOWER.......................................................................................................................21

5.1.1. HYDRAULIC CONNECTION WITH THE TRACTOR .................................................................................21

5.1.2. ADJUSTEMENT OF THE OIL FLOW WITHOUT A VARIABLE DISPLACEMENT PUMP........................22

5.2. DISTRIBUTION..................................................................................................................................................22

5.3. UNHITCHING THE FRONT HOPPER...............................................................................................................22

5.4. UNHITCHING THE REAR IMPLEMENT ...........................................................................................................22

6. MAINTENANCE .......................................................................................................................................................23

6.1. CHECKS AND CONTROLS...............................................................................................................................23

6.2. LUBRICATION...................................................................................................................................................23

6.2.1. LUBRICATING THE GREASERS...............................................................................................................23

6.3. END OF SEASON OPERATIONS.....................................................................................................................24

7. ACCESSORIES........................................................................................................................................................25

7.1. ROW MARKING DISC.......................................................................................................................................25

7.2. PRE-SPROUTING DISCS.................................................................................................................................25