5

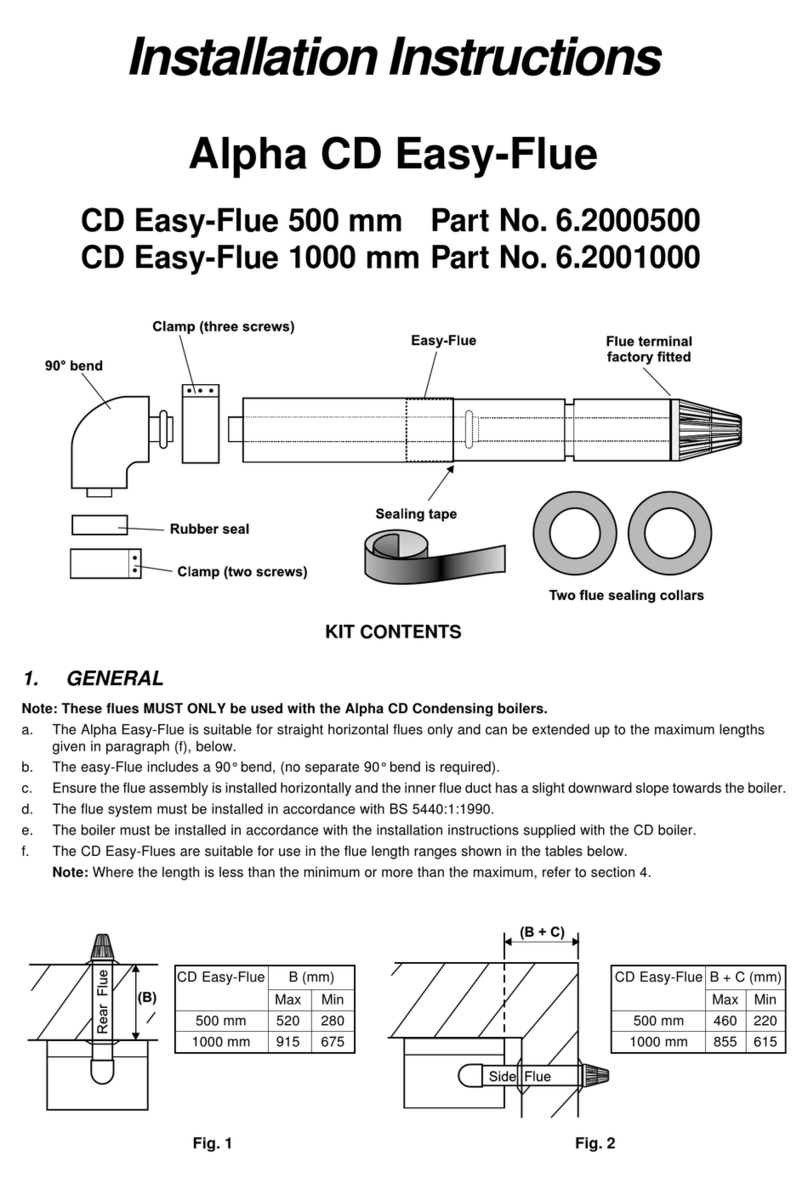

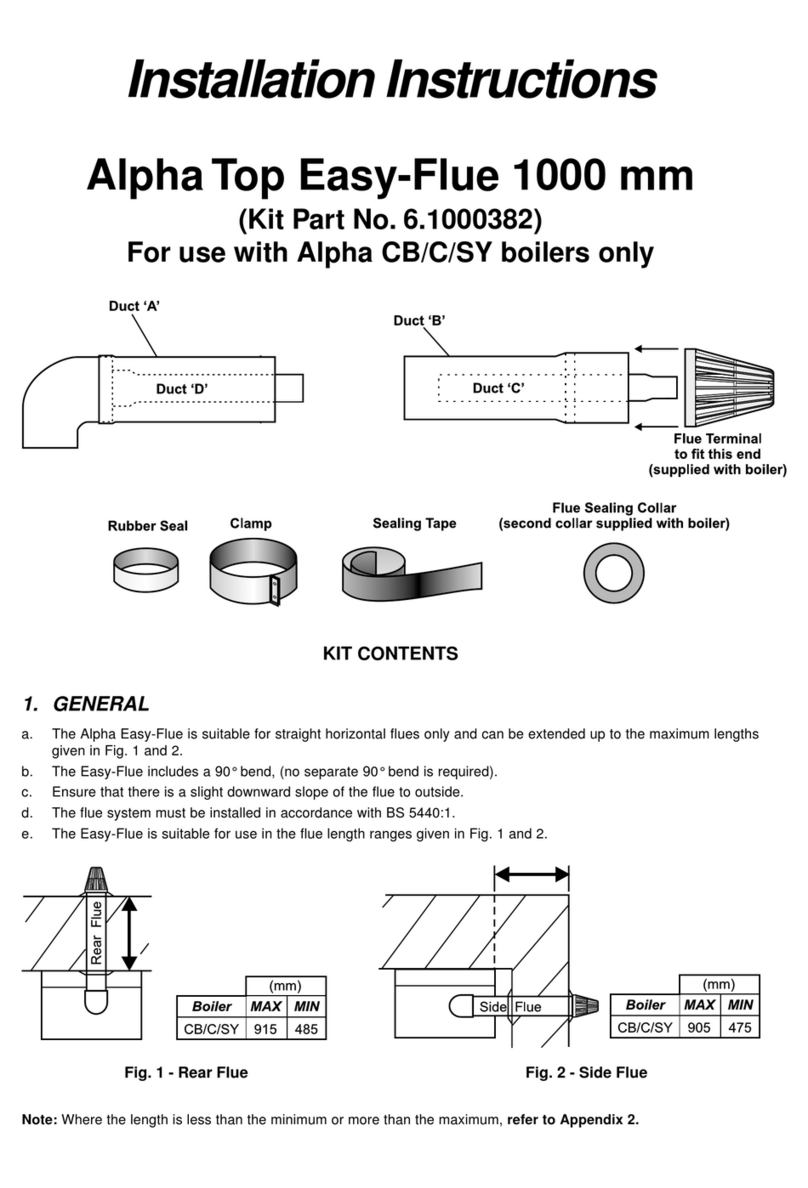

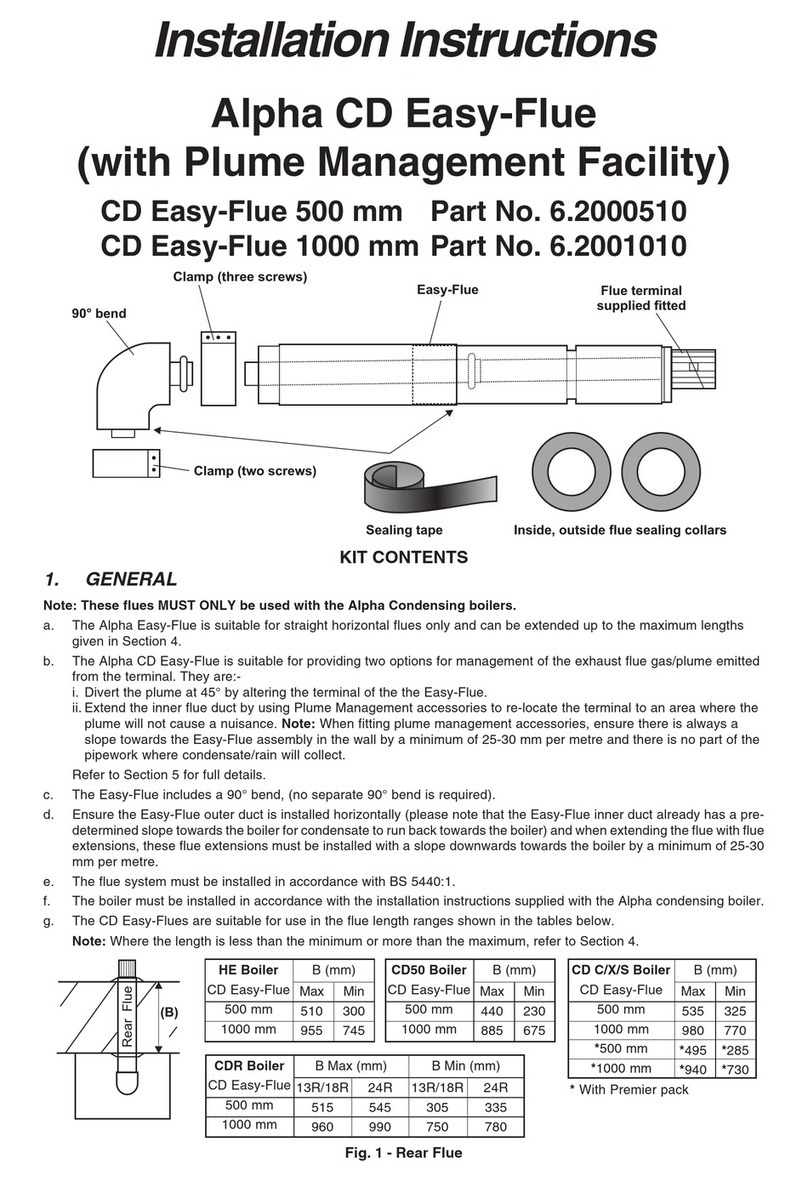

5. FIT PLUME MANAGEMENT COMPONENTS - (OPTIONAL)

The following procedures detail the options for management of the exhaust flue gas/plume emitted from the terminal.

a. The terminal supplied with the Easy-Flue can be altered to divert exhaust flue gas/plume at an angle of 45° from the

terminal. Three directions can be selected upwards, to the left and to the right.

i. Release the screw (1) securing the terminal and remove the terminal by turning anti-clockwise (2) and pulling it

from the flue assembly (3) as shown in Fig. 7.

ii. Release the two screws (4) securing the end part of the terminal. Reposition this part (5) at an angle of 45° onto

the terminal and secure with the two screws previously removed, as shown in Fig. 7.

Note: Do not overtighten the screws.

iii. Locate the terminal in one of the three positions, as required, by turning clockwise and secure in position using

the screw previously removed as shown in Fig. 7.

Note: Altering the terminal to give this 45° deflection reduces the maximum equivalent flue length by 0.9 m.

Fig. 7

b. The CD Easy-Flue can be converted to allow the inner flue duct to be extended so as to position the terminal in an

area where the exhaust flue gas/plume will not cause a nuisance. This can be done before or after installation of the

flue, providing there is access to the terminal from outside.

i. Release the screw securing the terminal and remove the terminal by turning anti-clockwise and pulling it from the

flue assembly.

ii. Locate a 93° Plume Management bend into the flue assembly and rotate it to the direction required.

iii. Connect to the 93° bend the required Plume Management components as detailed and refer to Fig. 8.

Notes:

1.The wall support brackets must be used to secure the Plume Management pipework to the wall and

prevent disconnection of the 93° bend from the flue assembly or any other component.

2.Each joint must be secured with one of the screws provided to prevent accidental disconnection.

3.Ensure there is always a slight slope towards the flue assembly fitted in the wall and there is no part of

the plume management pipework where condensate/rain will collect and cause a blockage or any

restriction.

iv. Terminate the Plume Management pipework by fitting the terminal previously removed and secure in position with

the screw previously removed. Refer to Fig. 8.

v. The Plume Management components available for extending the inner flue duct are as follows:-

Plume Management 93° bend 60 mm dia. (each 93° bend equivalent to 1.3 m flue length)

Plume Management 45° bend 60 mm dia. (each 45° bend equivalent to 0.9 m flue length)

Plume Management 1000 mm extension 60 mm dia. (equivalent to 1 m flue length)

60 mm dia. wall bracket