5

745-680-B10-001 Rev. A

Table of Contents

6.0 Charging ....................................................................................................................... 24

6.1 Constant voltage charge..................................................................................... 24

6.2 Charge acceptance............................................................................................. 25

6.3 Charge efciency ............................................................................................... 26

6.4 Temperature inuence ........................................................................................ 26

7.0 Commissioning ............................................................................................................. 27

7.1 Commissioning with constant current ................................................................ 27

7.2 Commissioning with constant voltage ................................................................ 27

8.0 Charging in operation ................................................................................................... 28

8.1. Two level charge................................................................................................ 28

8.2. Single level charge ........................................................................................... 28

9.0 Periodic Maintenance.................................................................................................... 28

Figures and Tables

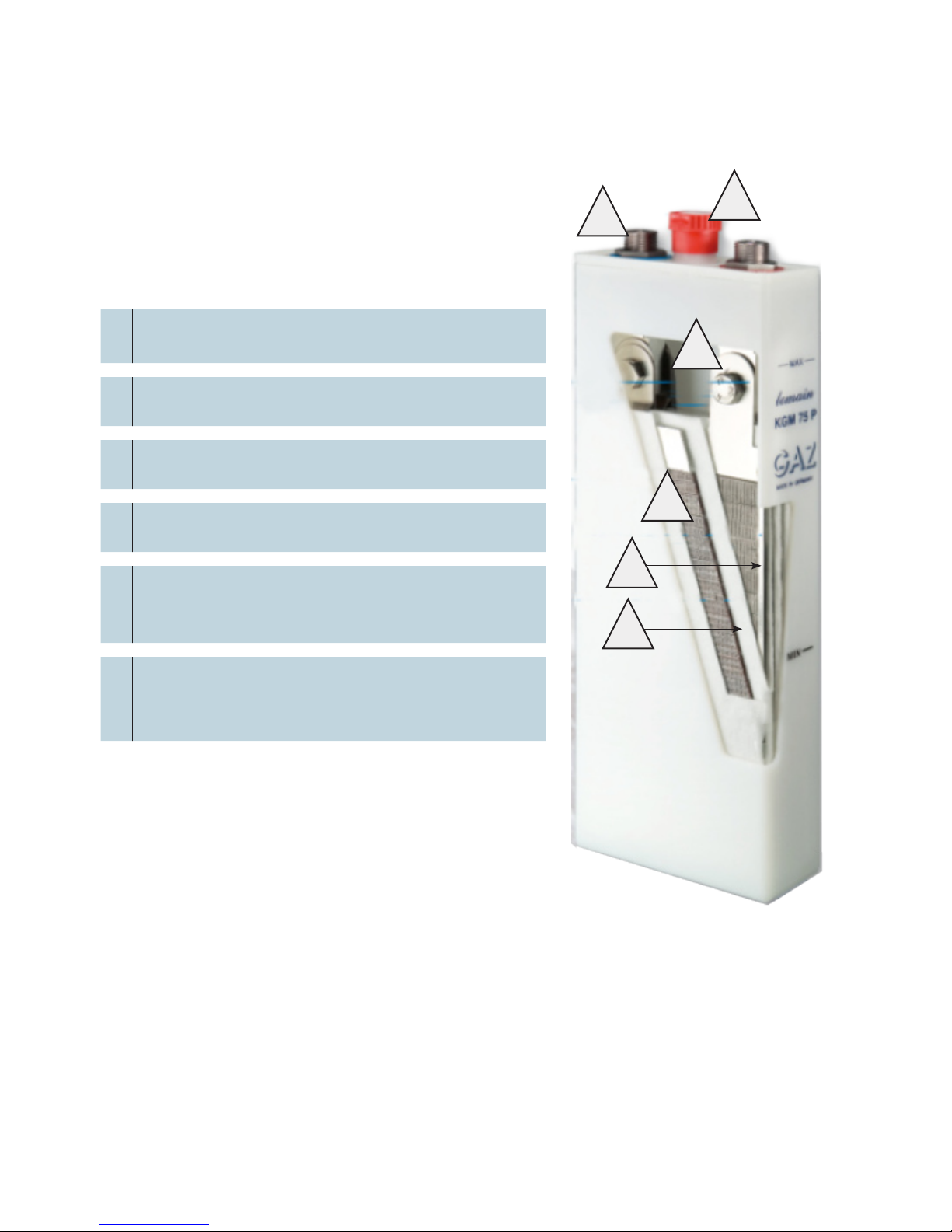

Fig. 1, Design of an Alpha Lomain Ni-Cd pocket plate cell ................................................................. 10

Fig. 2, Detail of plate design .................................................................................................................11

Fig. 3, Battery Vent .............................................................................................................................. 12

Fig. 4, Exploded view, Battery vent ..................................................................................................... 12

Fig. 5, Smaller Capacity Batteries ....................................................................................................... 13

Fig. 6, Larger Capacity Batteries ......................................................................................................... 13

Fig. 7, Terminal cross-section.............................................................................................................. 14

Fig. 8, Electrode Strip .......................................................................................................................... 14

Fig. 9, Strips connected....................................................................................................................... 15

Fig. 10, NiCd vs. Lead-Acid performance as a function of temperature.............................................. 18

Fig. 11, Discharge curve of 45A x 4 KGL225P post-2224h Float Charge @ 50°C.............................. 18

Fig. 12, Battery life at higher temperatures as percentage of +25°C lifetime ...................................... 19

Fig. 13, Cycle life vs. depth of discharge as a percentage of rated capacity (20°C) ........................... 20

Fig. 14, Available 5-hour-capacity of 5 x KGM 140P after 15 hours charging at 1.43 V/pc at 30°C.... 25

Fig. 15, Total Discharge time 4:43h = 94% of nominal capacity.......................................................... 25

Fig. 16, Available 5-hour-capacity of 5 x KGL 665P after 15 hours charging at 1.43 V/pc at 30°C ..... 25

Fig. 17, Total Discharge time 4:15h = 85% of nominal capacity.......................................................... 25