10 C048-720-30 Rev. B (03/2021)

4.54.5 Emergency Power O Option Emergency Power O Option

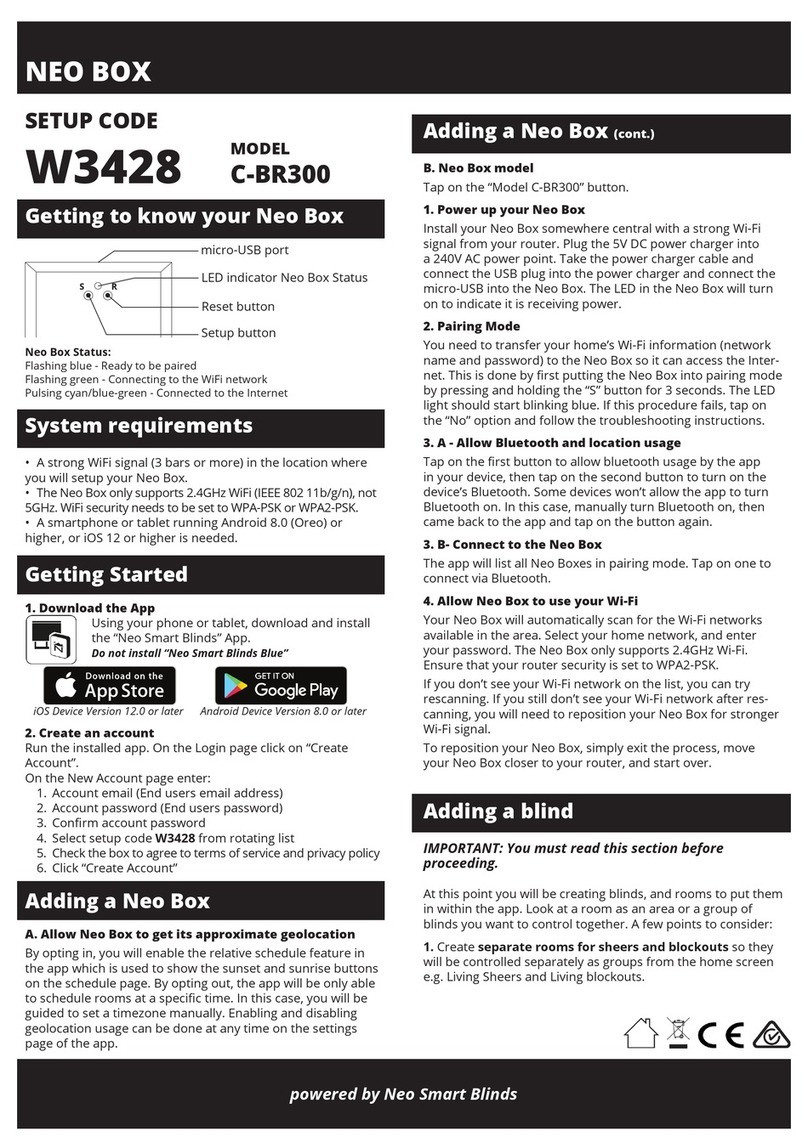

The DCX LP unit is equipped with a terminal block input

connection for a remote emergency power o (EPO) switch (see

Figure 12). External dry contact switch closure is required.

An external wall mount mushroom head switch is commonly

used for EPO functions. Route the two conductors from the

switch to the DCX LP unit terminal block positions labeled “EPO

SW COM” and “EPO SW N/O”. The DCX LP unit is shipped with

the EPO switch function disabled via a slide switch located on

the circuit board. Slide this switch to the “enabled” position if the

EPO function is desired. Figure 12. EPO Switch

DO NOT WIRE THE EPO INPUT IN COMMON WITH ANY OTHER ELECTRICAL DEVICE OR APPLY

A VOLTAGE ON THIS INPUT FROM ANY OTHER SOURCE OR DAMAGE WILL OCCUR THAT IS NOT

COVERED BY THE WARRANTY. ONLY CONNECT A DEDICATED EXTERNAL DRY CONTACT CLOSURE

NORMALLY OPEN SWITCH TO THIS CIRCUIT.

CAUTION!

4.64.6 Alarm ContactsAlarm Contacts

Step 1. The DCX LP unit comes with an alarm relay with contacts routed to the terminal block on the circuit board

assembly. The alarm contacts are rated 0.5A. Remote alarm sensing can be connected to the alarm contacts to

provide an alarm when the DCX LP units circuit breaker is o-line or there is an alarm condition.

The alarm relay contacts can be congured to monitor a "Normally Open" or "Normally Closed" state. The unit

ships congured to the "Normally Open" condition. The desired conguration can be selected using jumper "J8"

on the DCX LP unit termination board.

Step 2. Route the alarm wires securely via either of the two grommets on the right side of the assembly.

4.74.7 Electrical TestElectrical Test

Perform an electrical test prior to output cable installation.

Step 1. Flip the DCX LP breaker to the "OFF" position. Ensure that the battery positive termination plate is installed and

routed securely, and that the EPO switch and alarm contact wires are installed and secured (if used)�

Step 2. Ensure that the remote EPO switch is in the o position (if used). Connect the battery string cell connection bus

bars that were left disconnected for safety purposes during the DCX LP unit installation. Upon connection of the

series string, the DCX LP “OFF-LINE” LED will light up.

Step 3. Check voltage on the battery termination plate relative to battery positive and ensure that approximately 54 VDC

is measured. Ensure there are no cables connected to the DCX LP output bus bar and that the clear plastic

covers are installed

Step 4. Flip on the DCX LP breaker. The “ON-LINE” blue LED should light and the unit should be functional.

Step 5. To test the EPO trip, push in the remote EPO switch; the DCX LP breaker should trip to the o position and the

ON-LINE LED will go out and the OFF-LINE LED will turn on.

Step 6. The EPO TRIPPED LED will also turn on and will stay on as long as the remote EPO switch is closed.

Step 7. Reset the remote EPO switch to o, reset the DCX LP breaker to "ON". Observe correct LED indication of "ON-

LINE".

Step 8. The alarm contacts can be tested with an ohmmeter if desired by ipping the DCX LP breaker handle o and on

and observing the alarm contacts opening and closing with the ohmmeter. This completes the electrical test.

Step 9. Turn o the DCX LP breaker.