12.12.2022

SUGGESTED JACK TESTING and REFILL PROCEDURES

CHECKING OIL LEVEL

The easiest method is to simply pump the unloaded jack to its maximum length.

If the jack reservoir contains adequate oil it will reach its full extended length and the jack handle will

become difficult to pump as you will feel the oil bypassing.

If the jack reservoir contains inadequate oil it will not reach its full extended length and the jack handle

will be less difficult to pump and the ram will not advance upward.

ADDING HYDRAULIC JACK OIL

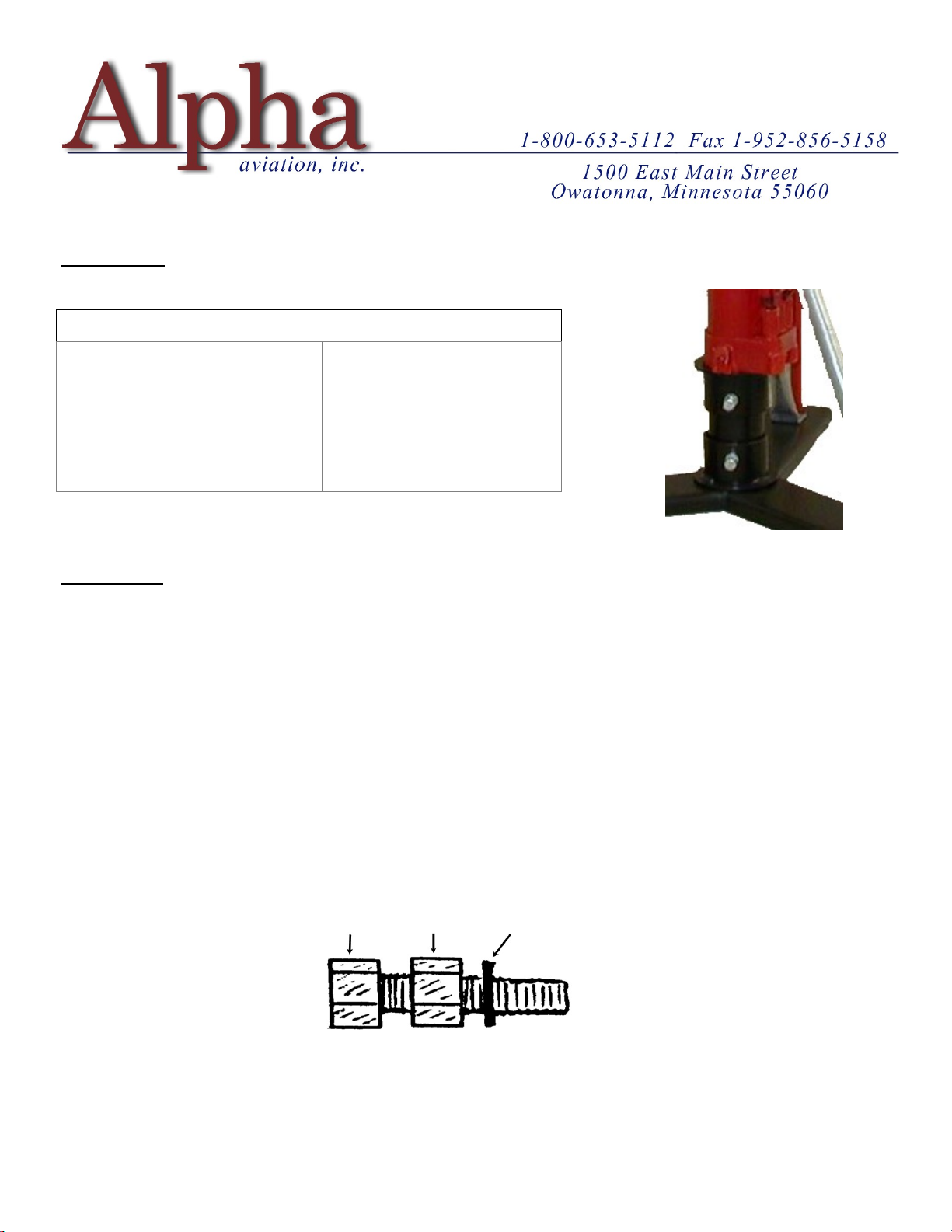

Stand the jack on its base and carefully remove the rubber drain plug by twisting as you work it out from the

side of the jack body.

Place the jack on its side with the fill hole up and add oil using a small funnel.

An ounce of oil will gain you about an inch of lift – do not over fill – As you add oil periodically stand the

jack up and pump it to determine if it has adequate oil to reach full extension.

If the jack reservoir contains adequate oil it will reach its full extended length and the jack handle will

become difficult to pump as you will feel the oil bypassing.

When filled, carefully reinstall the plug. Place the plug at a slight angle to the hole and assist the bulbous

end into the hole using a small flat blade screw driver. Once it is started twist and push the plug until it is

seated against the jack housing.

HOW MUCH OIL WILL I NEED & WHAT OIL SHOULD I USE?

From empty, depending on the model, each jack will take between 1 and 2 quarts of commercially available

hydraulic jack oil (10W). If a commercial product is unavailable 10W Mineral Oil or 10W non-detergent

motor oil can be substituted.

MY JACK ONLY RISES ON ONE STROKE - NOT BOTH

That is a common problem when a new jack is placed into service. Long ram jacks are designed to be used

in the vertical but by necessity are shipped in the horizontal.

What has happened is that air has entered the hydraulic chamber and an air lock has occurred. To clear the

air lock, pump the jack up about 12”, open the valve and physically push the Ram down, you should hear a

burp. Retest.

If the problem has not cleared, next place the jack on the floor, open the valve and manually pull the Ram

up out of the cylinder to its full extension. This will pull oil from the reservoir through both pump chambers

and into the ram chamber.

At this point, manually push the Ram down to the bottom of its stroke – listen for air (Burp) toward the end

of the stroke. Retest.

If the problem has not cleared please call for assistance, repair or replacement.