Save This Manual: It contains important installation and operating instructions. Keep it in a safe place.

Table of Contents

The emergency shutdown procedure is on the inside rear cover

DANGER

Risk of Electrical Shock

To reduce the risk of electrical shock and to ensure the safe operation of the Novus FXM UPS, the fol-

lowing symbols are used throughout this manual. Where they appear, only qualied personnel should

carry out these instructions.

A dangerous voltage exists in this area. Use extreme caution at all times.

Attention: Important operating instructions. Follow them exactly.

1 Introduction................................................. 1

1.1 Safety Checklists ................................... 2

1.1.1 UPS Safety Checklist..................... 2

1.1.2 Battery Safety Checklist................. 3

1.2 Unpacking and Inspection Checklist ...... 4

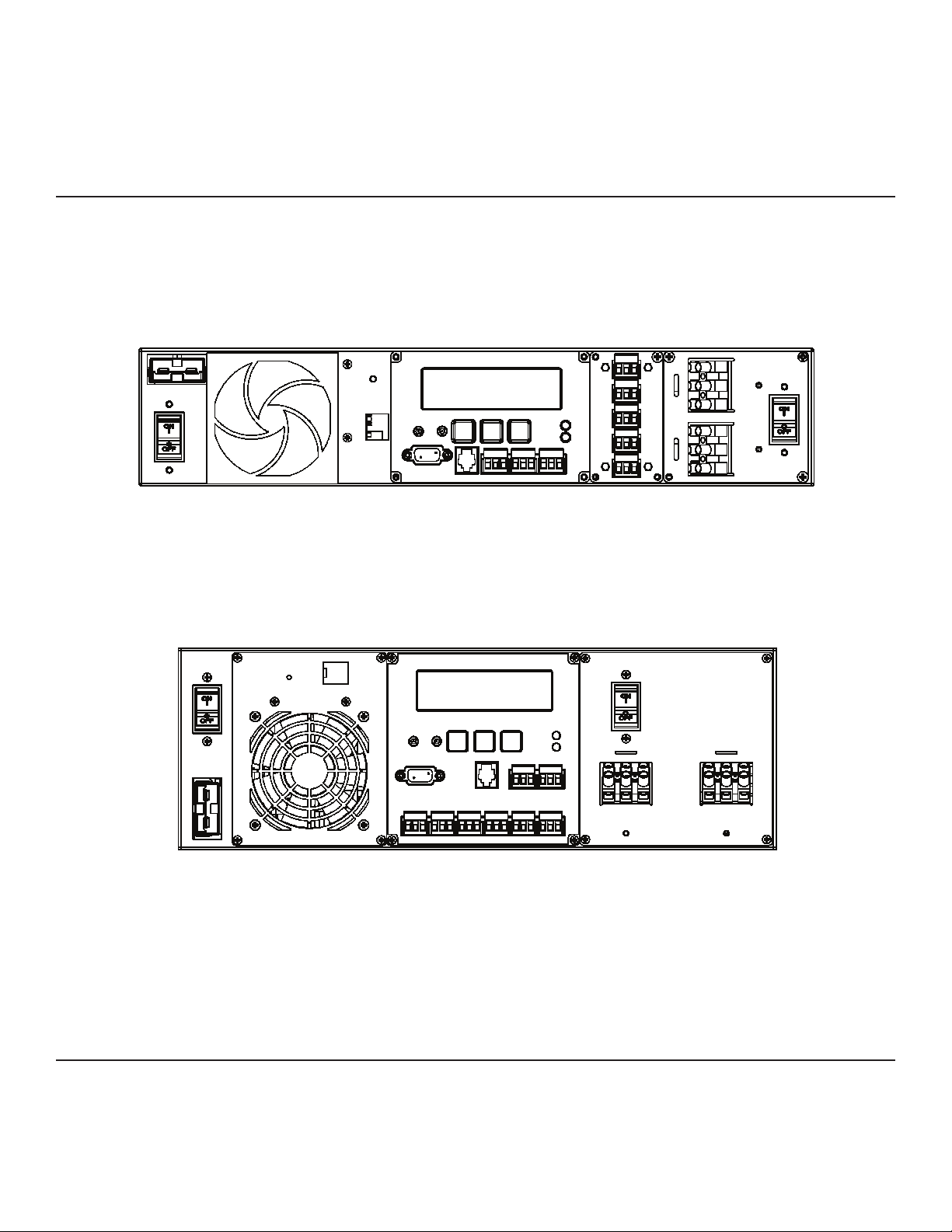

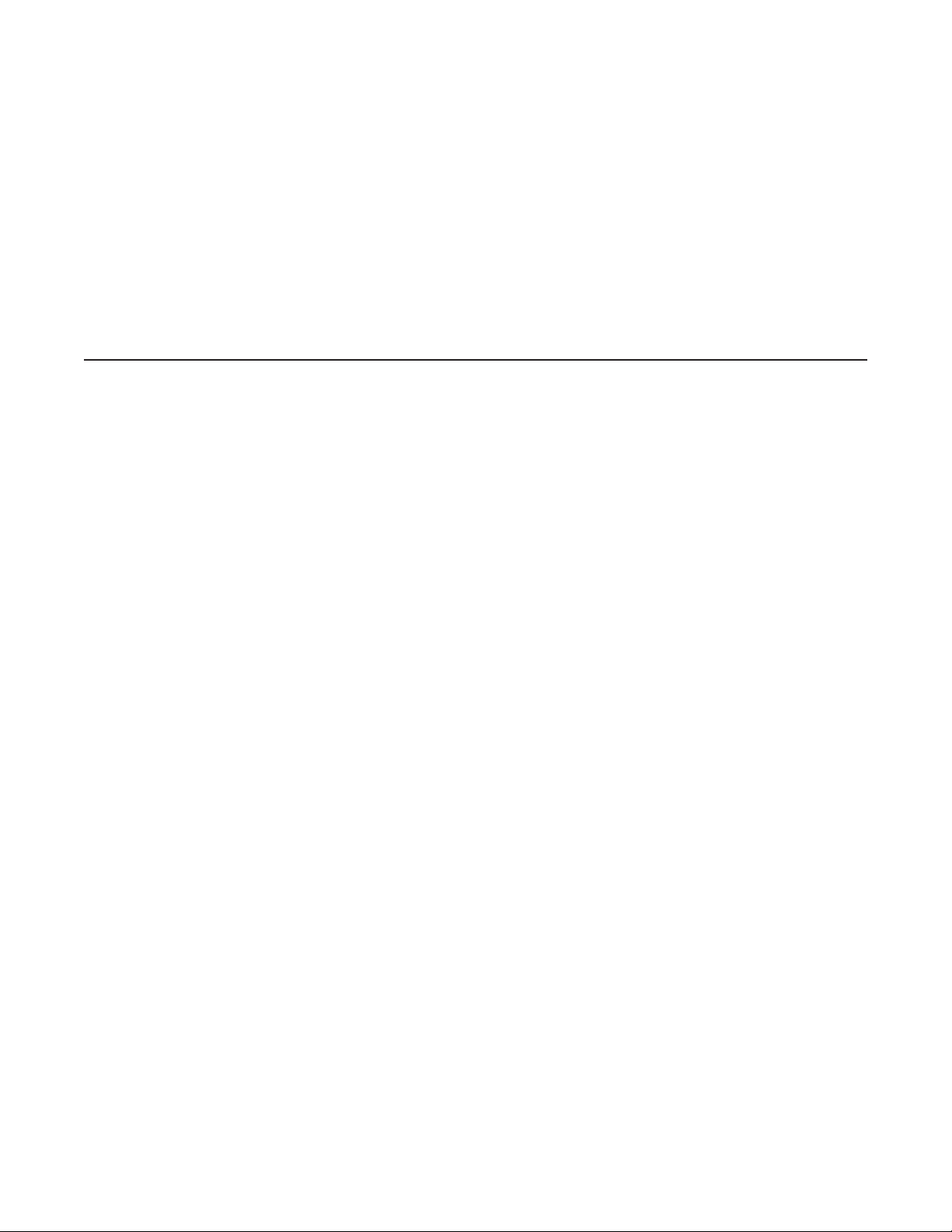

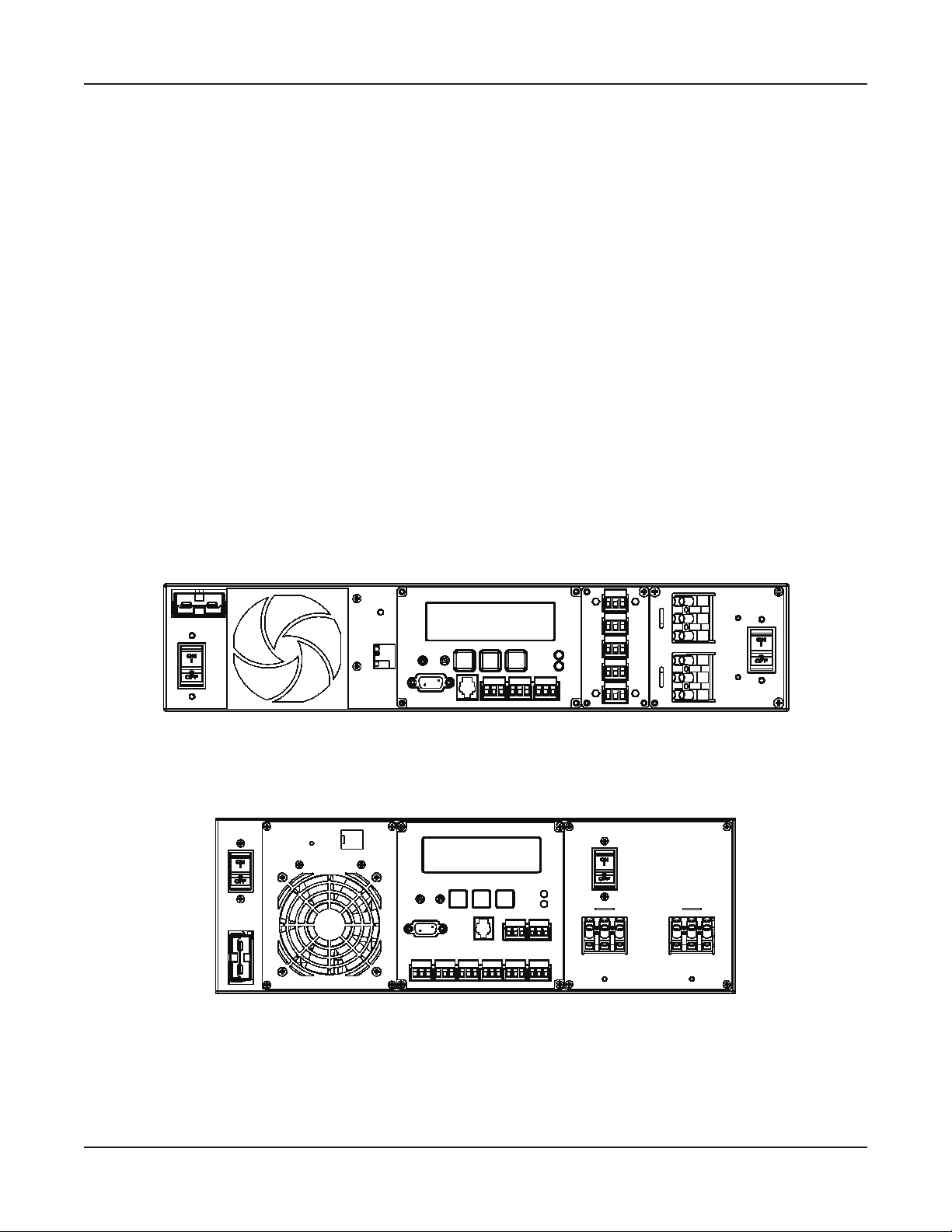

1.3 The FXM Front Panel............................. 5

2 Installation................................................. 11

2.1 Site Preparation Checklists .................. 12

2.2 Mounting the UPS ............................... 13

2.3 Wiring the External Batteries ............... 14

2.4 Wiring the UPS.................................... 16

2.5 ATS/GTS Option .................................. 17

3 Operation................................................... 18

3.1 Operating the Control Panel................. 19

3.2 Turning the UPS On and Off................ 21

3.3 Replacing the Batteries........................ 23

3.4 Operating the UPS .............................. 24

3.5 Making Measurements ........................ 26

3.6 Troubleshooting the UPS..................... 28

3.7 Viewing the 25-Event Log.................... 30

4 Communication ........................................ 31

4.1 Wiring the RS-232 Port ........................ 32

4.2 Using the Main Menu........................... 33

4.2.1 Main Menu Screen....................... 33

4.2.2 RS-232 Menu Tree....................... 34

4.2.3 Line Status................................... 35

4.2.4 Output Status............................... 35

4.2.5 Fault and Alarm Displays ............. 36

4.3 Adjusting and Controlling the UPS....... 37

4.4 Programming the Dry Contacts and the

Clock ..................................................... 38

4.4.1 Programming the Dry Contacts ... 38

4.4.2 Setting the Timer Contact ............ 39

4.4.3 Setting the Date and Time ........... 39

4.5 100-Event Log ..................................... 40

4.6 Novus User Software........................... 41

4.6.1 Introduction .................................. 41

4.6.2 Checking Your Windows Computer

for the .NET Framework............... 41

4.6.3 Installation and Set Up................. 42

4.6.4 Operation ..................................... 43

5 Maintenance.............................................. 46

5.1 Updating the Software ......................... 47

Specications .............................................. 49

Index ............................................................. 51

Warrant ......................................................... 54