AIR LOGIC POWER SYSTEMS (ALPS) TABLE of CONTENTS

FLEX PITCH QUICK-START MANUAL ii TM 2012-005 REV01 © 5/26/2016

Table of Contents

Section 1: General Information 1

Machine Designation and Serial Number location ................................................................................................2

Section 2: Safety 3

Safety: Warning Labels and Descriptions .............................................................................................................3

DANGER! ARC, SHOCK, AND FLASH HAZARD:................................................................................................3

RISK OF HOT SURFACES HAZARD...................................................................................................................3

LOCK OUT / TAG OUT.........................................................................................................................................4

WARNING! WATCH YOUR HANDS AND FINGERS...........................................................................................4

DANGER! DO NOT OPERATE WITHOUT GUARDS IN PLACE.........................................................................4

DANGER: STARTS AUTOMATICALLY................................................................................................................4

Safety: Warning Messages 5

Lockout-Tag Out Air supply..................................................................................................................... 6

Safety: Machine is installed and ready for production...........................................................................................7

HMI Emergency Stop Palm Button- ........................................................................................................ 7

Resetting an E-Stop ................................................................................................................................ 7

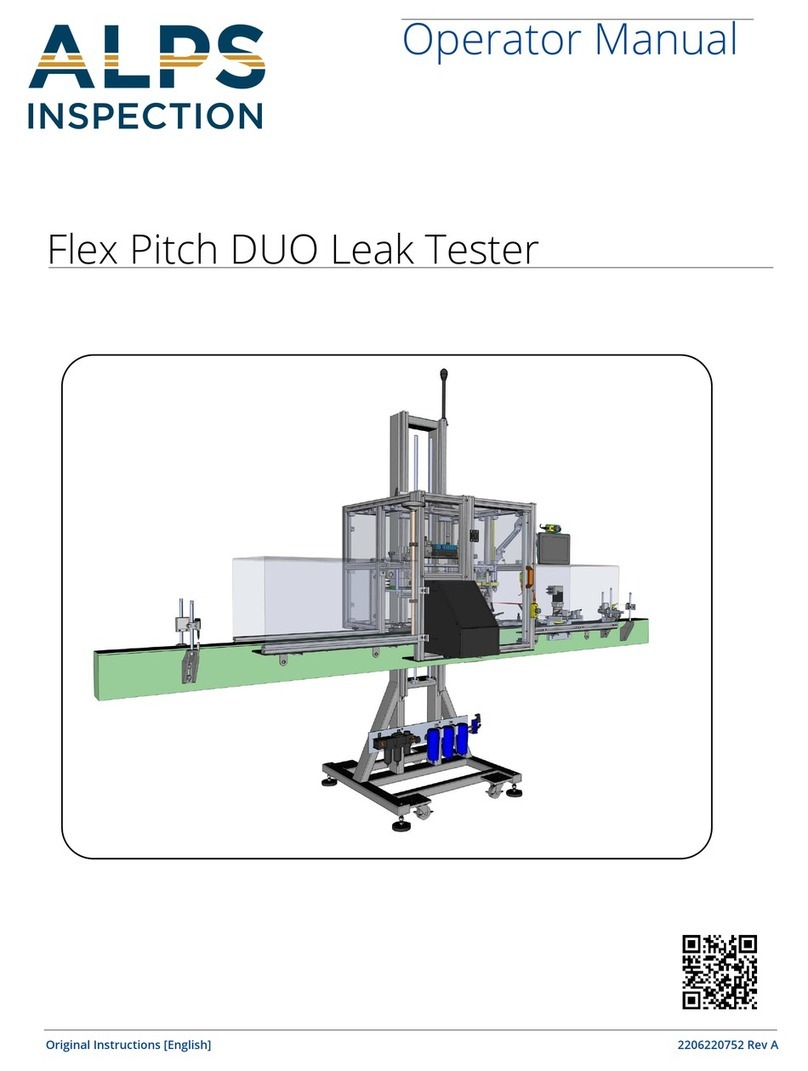

Section 3: Theory of Operations 9

Basic Theory of ALPS Leak Testing......................................................................................................................9

Theory of Operation- Photo Eyes..........................................................................................................................9

Positions and Functions: ......................................................................................................................... 9

Test Probes Carriage/Slide Introduction ............................................................................................... 10

Reject and Reject Verify PE’s Introduction............................................................................................ 11

Section 4: Getting Started 12

Main Electrical Power..........................................................................................................................................12

Air Supply ............................................................................................................................................................12

Air Supply Description Table...............................................................................................................................12

Air Pressure.........................................................................................................................................................12

Access Guards ....................................................................................................................................................13

E-Stops................................................................................................................................................................13

Container-Present and Reject Photo-Eyes .........................................................................................................13

Test Probe Carriage ............................................................................................................................................14

Reject Cylinder Position ......................................................................................................................................15

Section 5: Flex Pitch Quick Start Operations 16

About The Quick Start Manual ............................................................................................................................16

Section 6: HMI Control Panel Touchscreen Description 17

Section 7: HOME Screen and Main Menu Description 18

Home Screen Button Features and Functions TABLE........................................................................................18

Home Screen / Main Menu Directory Structural Hierarchy:................................................................................19

Section 8: Loading a Recipe 20

Recipes Menu Command Overview....................................................................................................................20

Section 9: Production 22