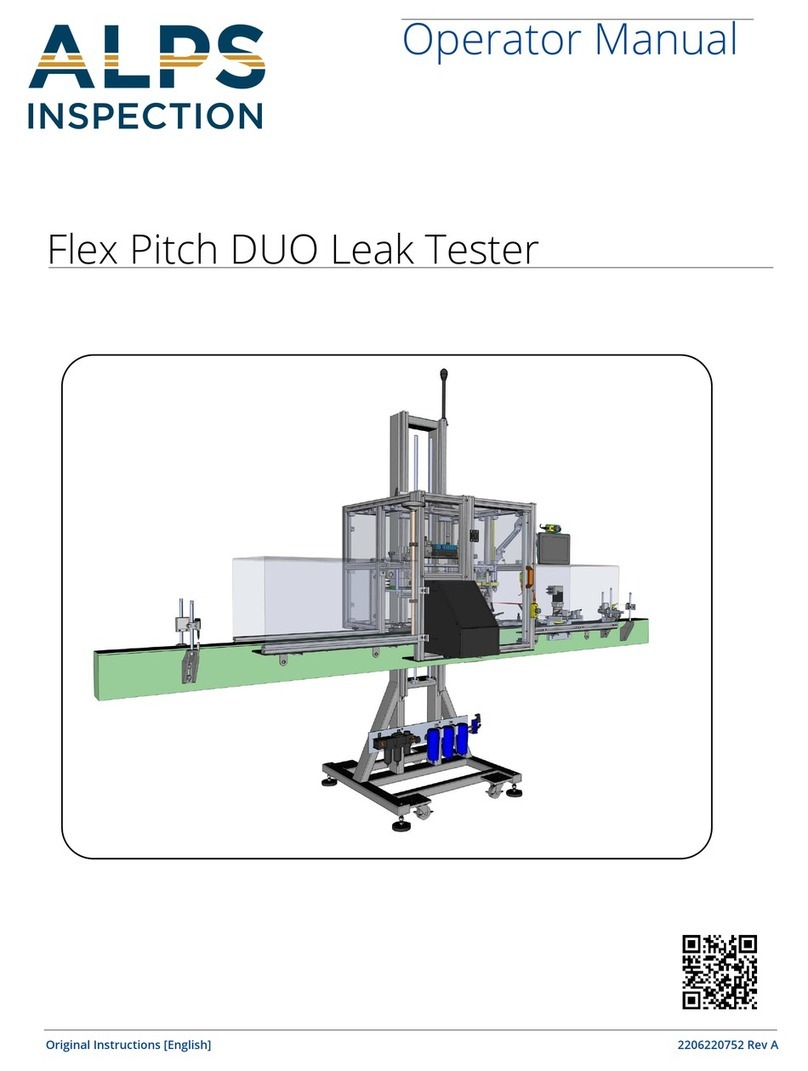

AIR LOGIC POWER SYSTEMS (ALPS) Flex Pitch

FLEX PITCH INSTALLATION MANUAL ii TM 2017-014 REV01 © 8/2/2017

Table of Contents

Notices: i

Documentation........................................................................................................................................................i

Software..................................................................................................................................................................i

System Modifications..............................................................................................................................................i

Trademark and Patent Acknowledgments .............................................................................................................i

Contact Information ................................................................................................................................................i

Copyright © 2017 by Air Logic Power Systems LLC..............................................................................................i

General Information 1

Introduction............................................................................................................................................................1

Warnings and Cautions .........................................................................................................................................1

ALPS Flex Pitch Multi-Moving Head Leak Tester .................................................................................................2

General Information................................................................................................................................. 2

Linear Dimensions (Top View) ................................................................................................................ 2

Linear Dimensions of the Flex Pitch machine .......................................................................................................3

Section 1: Location Site and Installation Requirements 4

Location .................................................................................................................................................................4

Electrical Power Requirements .............................................................................................................................4

Air Supply ..............................................................................................................................................................4

Section 2: Components Inventory 5

Common Components shipped with the Flex Pitch...............................................................................................6

Common components boxed separately with shipment.......................................................................... 6

Tunnel Shielding...................................................................................................................................... 6

Set of Legs............................................................................................................................................... 6

Common Components...........................................................................................................................................7

Photo-Eyes and Photo-Eye brackets ...................................................................................................... 7

Section 3: Installation to Conveyor System 8

Vertical Adjustment for Probe Carriage.............................................................................................................. 18

Section 4: Installing Peripheral Devices 20

Photo-Eyes and support brackets ...................................................................................................................... 20

1. Photo-Eyes and Photo-Eye brackets ............................................................................................. 20

2. Photo-Eyes: Placement and Positioning ........................................................................................20

3. Photo-Eyes: Mounting and Positioning on Conveyor.....................................................................21

Tuning Container Present and Reject Photo-Eyes............................................................................................. 21

Banner Q4X Laser Sensor Tuning and Adjustment..............................................................................21

Tuning Downstream Jam and Reject Verification Photo-Eyes........................................................................... 21

OPTEX DR-Q150TCN Sensor tuning and adjustment..........................................................................21

Change Mode Button Options...............................................................................................................22

Installing the Encoder to the Conveyor .............................................................................................................. 24