Abrasion Tester BYK-Gardner

6 298 023 140 E 2308

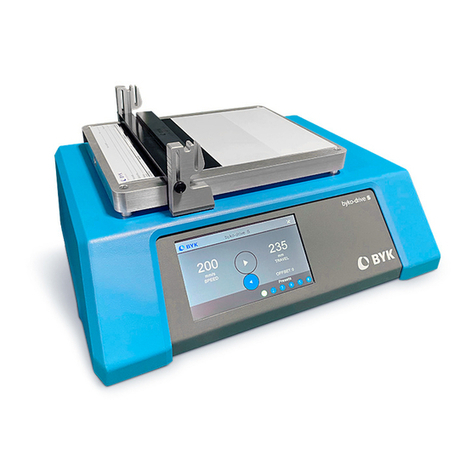

3 System Description

The Gardner-scrub Abrasion Tester helps evaluate washability and abrasion re-

sistance of a material. The tester reciprocates an abrasive device linearly over a

sample. The abrasion device can be a brush, sponge, abrasive pads, and other

abraders. The traversing carriage is designed to hold 1, 2 or 3 abrading devices

depending on their size.

Two sample clamps slide on shafts at the rear of the instrument to allow vari-

ous sized samples to be held in place during testing. The clamps will also hold

“Lilly Frames” or other accessories in place.

Gardner-scrub with 3 ASTM brush boxes mounted

The Gardner-scrub incorporates a precise speed control to maintain a constant

speed for the test. The instrument is preset at 37 strokes per minute to coincide

with most standardized tests but may be adjusted within the range of 6 to 60

strokes per minute. Unlike some other instruments on the market, the Gardner-

scrub maintains a linear speed over its travel length. The result is a more consis-

tent and repeatable test.

A front mounted, color touch screen is provided for user interaction. All adjust-

ments are available in the setup screen to provide a flexible interaction with

the user.

The instrument is setup at the factory for a center-to-center stroke length of 10

inches. Stroke lengths of 9 or 11 inches may be achieved by means of a me-

chanical adjustment. This adjustment must be performed by the factory o ran

authorized service center.