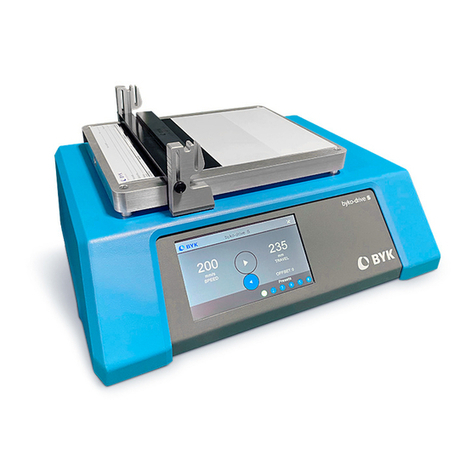

BYK-Gardner byko-drive S

285 025 845 E 2106 3

Table of Contents

1 Introduction .............................................................................................................. 4

1.1 About this Document .................................................................................................. 4

1.2 Safety Information ...................................................................................................... 5

1.2.1 Safety Instructions ......................................................................................... 5

1.2.2 General Information...................................................................................... 6

1.2.3 Operation Information.................................................................................. 6

1.3 Copyright Information ................................................................................................ 6

2 System Description................................................................................................... 7

3 System Preparation .................................................................................................. 8

3.1 Delivery Content.......................................................................................................... 8

3.2 Control Elements ......................................................................................................... 9

4 System Operation..................................................................................................... 10

4.1 Start Up ........................................................................................................................ 10

4.2 User Interface............................................................................................................... 10

4.2.1 Home Screen .................................................................................................. 10

4.2.2 Set Speed........................................................................................................ 12

4.2.3 Set Length ...................................................................................................... 12

4.2.4 Set Start Point ................................................................................................ 13

4.2.5 Set Units ......................................................................................................... 14

4.2.6 Set Language ................................................................................................. 15

4.2.7 Set Brightness................................................................................................. 15

4.3 Film Application........................................................................................................... 16

5 Maintenance and Repair .......................................................................................... 17

5.1 Exchanging Glass Plate with Vacuum Plate ............................................................... 17

5.2 Exchanging Vacuum Plate with Glass Plate ............................................................... 18

5.3 Cleaning and Routine Maintenance........................................................................... 18

5.4 Service and Spare Parts ............................................................................................... 19

5.5 Ordering Information.................................................................................................. 19

5.5.1 Basic Device.................................................................................................... 19

5.5.2 Accessory Parts............................................................................................... 19

6 Technical Data........................................................................................................... 20

7 Service Points............................................................................................................ 21