1

We reserve the right to any technical change.

Valid on 2021.11.29

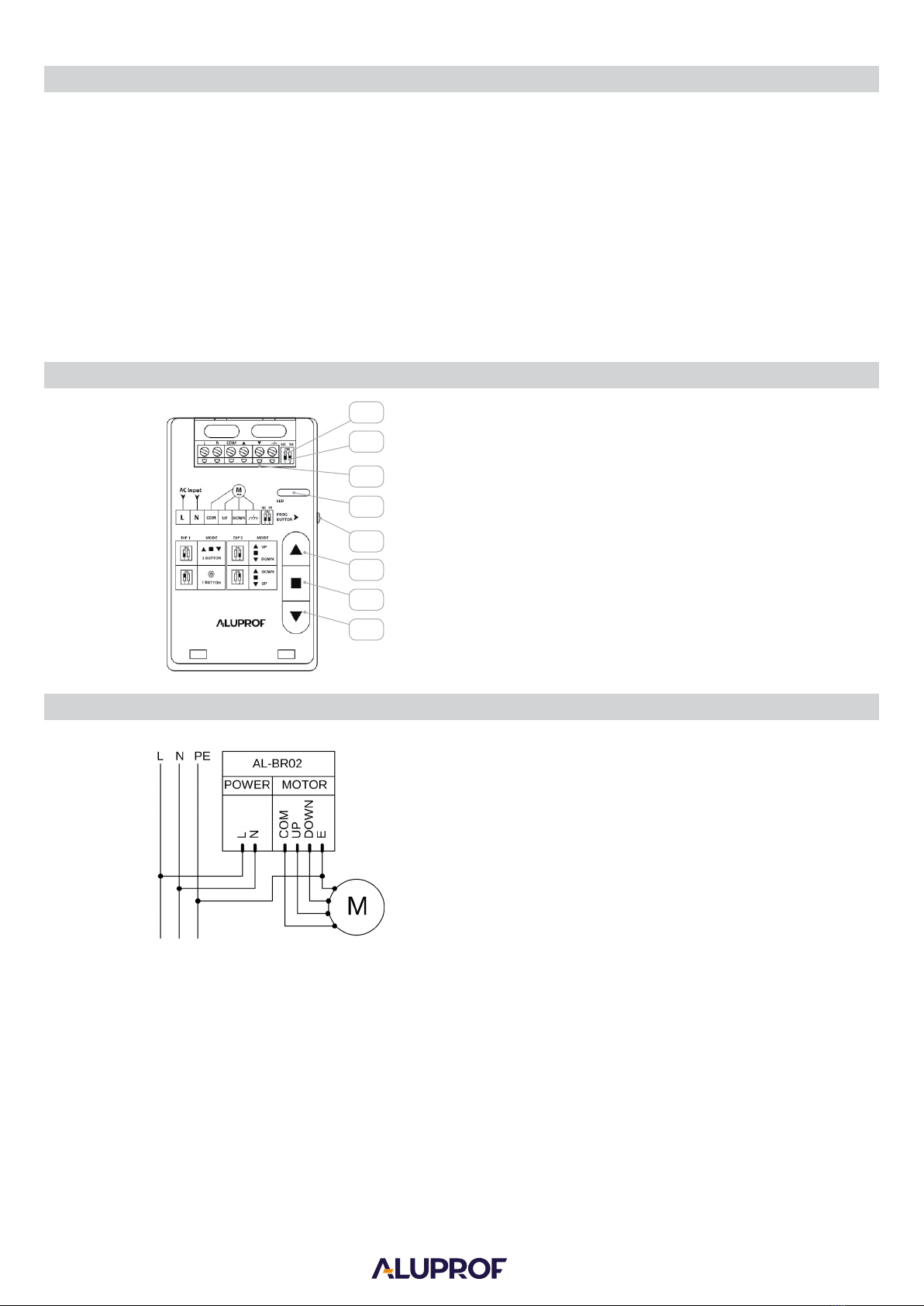

INSTALLATION, ASSEMBLY AND OPERATING MANUAL FOR THE GATE CONTROL UNIT ALBR02

Failure to comply with this Manual may result in injury or death.

Keep the Manual for reference.

1. Installation safety

NOTE: Follow these instructions: non-compliant installation and/or removal may cause severe injury!

- Read this Manual before installing the product.

- Have this control unit installed/removed and wired by a suitably licensed electrician (with an electrician’s license for electrical installations ≤ 1 kV).

- Caution: Disconnect the power cable from the supply voltage before removing the product.

- The control unit is intended for operation in dry indoor rooms. Do not expose it to weather.

- T

he control unit requires a separate power supply line, connected to the power sub-distribution switchboard with a short-delay current breaker,

e.g. a B10 over-current CB.

- If the control unit power cable is damaged, replace it.

- Fasten and route the power cable to prevent the condensate (water) from flowing into the control unit enclosure.

- A single control unit must not operate more than one drive unit

- Install the control switch at a safe distance from all moving parts of the roller shutter / gate and at a distance which will permit watching the

operation of the roller shutter / gate, and at least 1.5 m above the floor (the minimum height above the floor requirement does not apply to key-

operated switches).

- After installation, make sure that the gate / roller shutter inverts directions properly.

- The installer must comply with the standards and regulations in force in the country where the installation is carried out.

- Users should be trained to operate the control unit.

2. Safety of control unit operation and maintenance

NOTE: Follow these instructions: non-compliant operation and/or maintenance may cause severe injury!

- Keep children away from the central unit and its controls: they are not toys.

- Isolate the power supply from the control unit before cleaning, maintenance or replacement of parts.

- Do not operate the control unit if it needs to be repaired or readjusted.

- Whenever the roller shutter / gate is running there must be no obstacles on its way until is completely closed or open.

- Test the control unit for proper reversing of the sense of rotation at least every month.

- Do not attempt to open the roller shutter / gate if it is stuck with heavy ice.

- Do not attempt to alter or modify the product without authorization; otherwise your product warranty will be void and the product may become

hazardous in use. Have all maintenance and repairs done by a qualified technical service provider, the manufacturer, or the manufacturer’s

authorized agent.

In accordance with the provisions of the Directive of the European Parliament and of the Council 2012/19 / EU of 4 July 2012 on waste electrical

and electronic equipment (WEEE), it is prohibited to place of used equipment together with other wastes, marked with crossed out wheeled bin

symbol. The users are obliged to transfer their used equipment to a designated collection point for proper processing. The marking means, at the

same time, that the equipment was put on the market after 13 August 2005. These legal obligations have been introduced to reduce the amount

of waste generated from waste electrical and electronic equipment and to ensure an appropriate level of collection, recovery and recycling. The

equipment does not contain any dangerous components, which would have any particularly negative impact on the environment and human

health.