3安全注意事项 SAFETY NOTES

安全注意事项 SAFETY NOTES

● 遥控直升机属高危险性商品,飞行时务必远离人群,人为组装不当或机件损坏,电子控制设备不良,以及操控上的不熟悉,都有可能导致飞行失控损伤

等不可预期的意外,请飞行者务必注意飞行安全,并需了解自负疏忽所造成任何意外之责任。

● 遥控直升机内部也是由许多精密的电子零组件组成,所以必须绝对的防治潮湿或水气,避免在浴室或雨天时使用,防止水气进入机身内部而导致机件及

电子零件故障而引发不可预期的意外。

● 在组装这架遥控直升机前,必须认真阅读本组装手册及各个设备商的使用手册。

● 初接触遥控直升机的人员,必须有专业人员陪同。

● 所有操作这架遥控直升机的人员,都必须采取适当的安全措施。

● 直升机飞行是具有一定的速度,相对的也潜在着危险性,场地的选择也相对的重要,请需遵守当地法规到合法遥控飞行场地飞行,必须注意周遭有没有

人、高楼、建筑物、高压电线、树木等等。避免操控的不当造成自己与他人财产的损坏。初次练习时。务必选择在空旷合法专属飞行场地并适当搭配练

习架练习飞行,这对飞行失误所造成的损伤将会大幅的降低。请勿在下雨、打雷等恶劣天气下操作,以确保本身及机身的安全。

● 操作遥控直升机可能有意想不到的危险行为发生,所以操作遥控直升机是非常危险的。

● 遥控直升机必须定期维护。

● Fly only in safe areas,away from other people.Do not operate R/C aircraft within the vicinity of homes or crowds of people. R/C aircraft are prone to

accidents, failures ,and crashes due to a variety of reasons inciuding,lack of maintenance ,pilot error,and radio interference. Pilots are responsible for

their actions and damage or injury occurring during the operation or as of a result of R/C aircraft models.

● R\C models are composed of many precision electrical components. It is critical to keep the model and associated equipment away from moisture

and other contaminants.The introduction or exposure to water or moisture in any form can cause the model to maifunction resulting in loss of use,

or a crash.Do not operate or expose to rain or moisture.

● This radio controlled helicopter must be built following these instructions. This manual provides the necessary information to correctly assemble the

model. It is necessary to carefully follow all the instructions.

● Inexperienced pilots must be monitored by expert pilots.

● All operators must wear safety glasses and take appropriate safety precautions.

● R\C helicopters fly at high speed,thus posing a certain degree of potential danger.Choose an a legal flying field consisting of fiat,smooth ground

withort obstacles.Do not fly near bulldings,high voltage cables,or trees to ensure the safety of yourself,others and your model.For the first practice,

please choose a legal flying field and can use a training skid to fly for reducing the damage.Do not fly your model in inclement weather,such as

rain, wind,snow or darkness.

● A radio controlled helicopter can behave in an unexpected manner, causing loss of control of the model, making it very dangerous.

● Lack of care with assembly or maintenance can result in an unreliable and dangerous model.

实机飞行前请严格执行飞行前检查义务 CAREFULLY INSPECT BEFORE REAL FLIGHT

● 每次飞行前应先确认所使用的遥控发射频率是否会干扰他人,以确保你自身与他人的安全。

● 每次飞行前确定您遥控器与接收器电池的电量是在足够飞行的状态。

● 开机前确认遥控器油门摇杆是否位于最低点,熄火降落开关,定速开关(IDLE)是否于关闭位置。

● 关机时必须遵守电源开关机的程序,开机时应先开启遥控器后,再插上接收器电源;关机时应先拔出接收器电源后,再关闭遥控器。不正确的开关程序

可能会造成失控的现象,影响自身与他人的安全,请养成正确的习惯。

● 开机请先确认遥控直升机的各个动作是否顺畅及方向是否正确,并检测舵机的动作是否有干涉或崩齿的情况,使用故障的舵机将导致不可预期的危险。

● 飞行前确认没有缺少或松脱的螺丝与螺帽,确认没有组装不完整或损毁的零件,仔细检测主旋翼是否有损坏,特别是接近主旋翼夹座的部位。损坏或组

装不完整的零件不仅影响飞行,更会造成不可预期的危险。注意:对损耗,有裂痕零件更新及定期保养检测的重要性。

● 检查所有的连杆头是否有松脱的情形,过松的连杆头应先更新,否则将造成直升机无法操控的危险。

● 确认电池及电源插头是否固定牢靠,飞行中的震动或激烈的飞行,可能造成电源插头松脱而造成失控的危险。

● Before flying, please check to make sure no one else is operating on the same frequency for the safety.

● Before flight, please check if the batteries of transmitter and receiver are enough for the flight.

● Before turn on the transmitter, please check if the throttle stick is in the lowest position. IDLE switch is OFF.

● When turn off the unit, please follow the power on/off procedure. Power ON-please turn on the transmitter first, and then turn on receiver. Power

OFF-Please turn off the receiver first and then turn off the transmitter. Improper procedure may cause out of control, so please to have this correct

habit.

● Before operation, check every movement is smooth and directions are correct. Carefully inspect servos for interference and broken gear.

● Check for missing or loose screws and nuts. See if there is any cracked and incomplete assembly of parts. Carefully check main rotor blades and

rotor holders. Broken and premature failures of parts possibly cause resulting in a dangerous situation.

● Check all ball links to avoid excess play and replace as needed. Failure to do so will result in poor flight stability.

● Check the battery and power plug are fastened. Vibration and violent flight may cause the plug loose and result out of control.

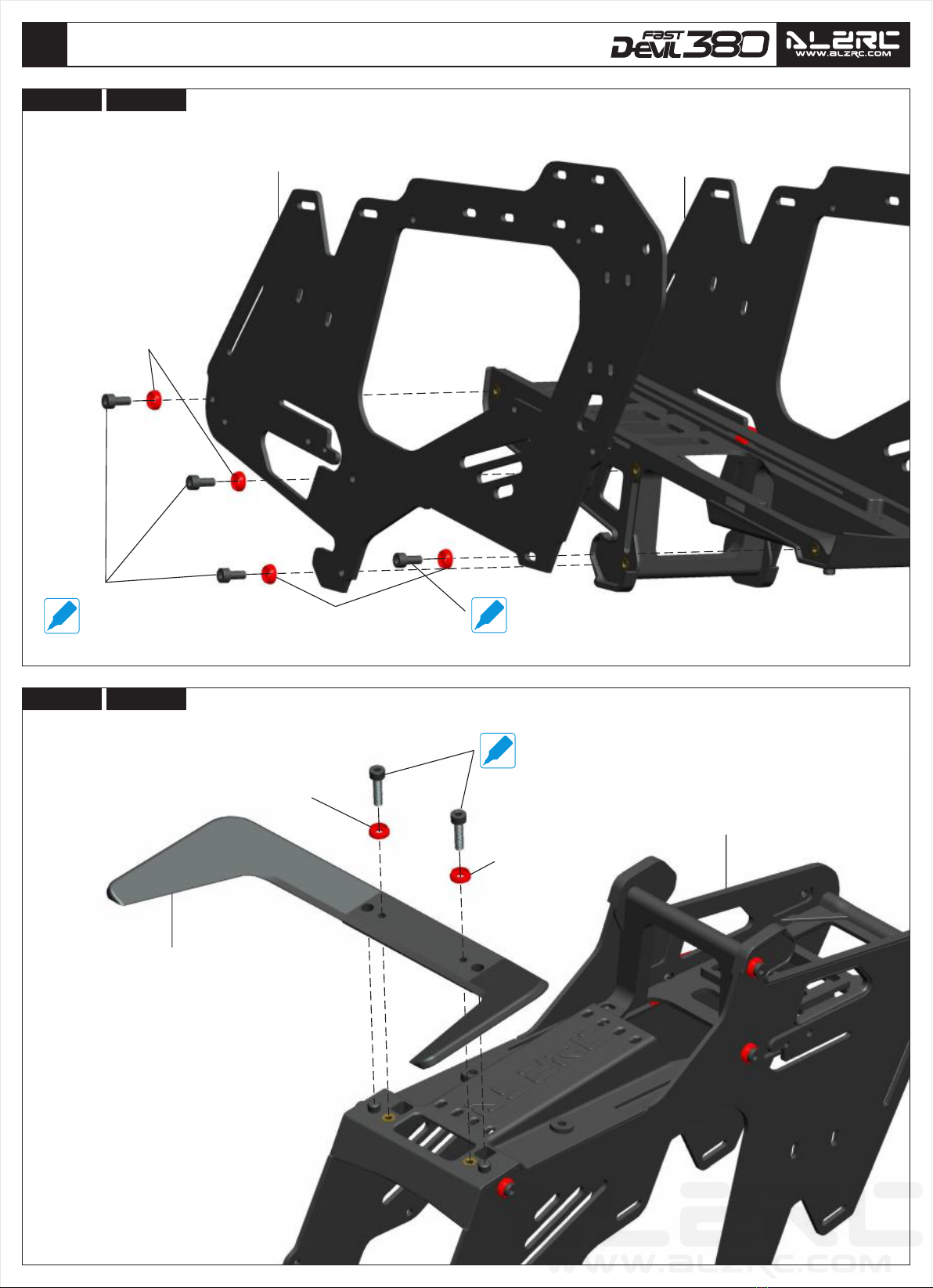

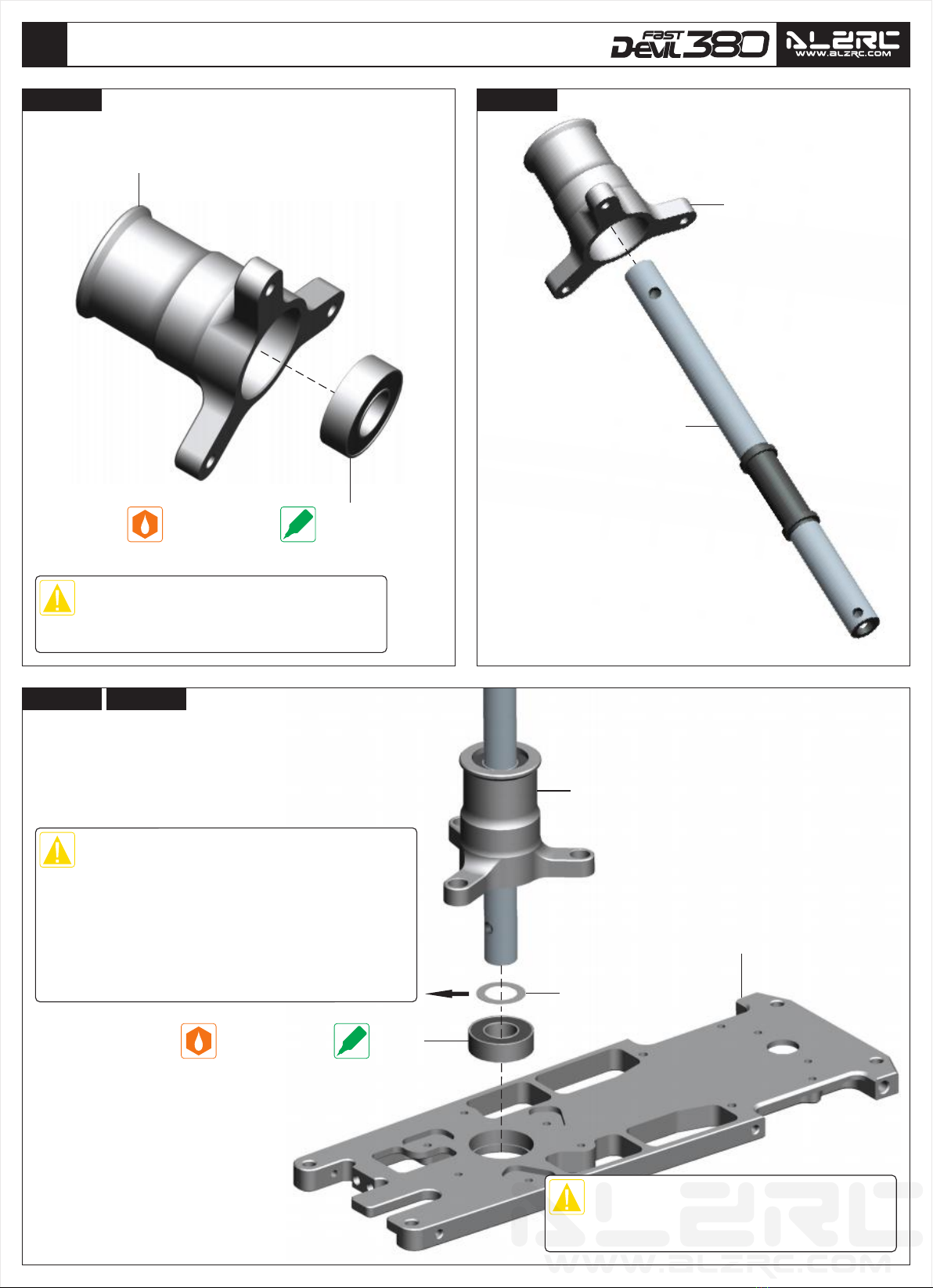

标符注释 LEGEND

在组装过程中,如果出现以下标符,请

认真执行每个标符的操作。

It is necessary to pay attention to the

symbols listed below.

注意

CAUTION

因为疏忽这些操作说明,

可能造成不必要的麻烦。

而安装错误可能造成危险。

Mishandling due to failure

to follow these instructions

may result in danger.

螺丝胶

THREAD LOCK

使用螺丝胶固定。

Apply Thread Lock to fix.

24

3

轴承胶

ANAEROBICS RETAIN

使用金属管状固定缺氧胶固定。

Apply Anaerobics Retain to fix.

6

48

润滑油

GREASE

涂上润滑油。

Apply grease.

瞬间胶

CA GLUE

使用瞬间胶固定。

Apply CA glue to fix.

CA

Glue

已经完成组装

AIready Assembled

螺丝胶涂于螺丝的螺纹上。

长度约1mm。

Glue width: approx.1mm

轴承胶涂于轴承的外圈。

Glue width: approx.1mm