Vipros 357 Queen with Fanuc 18PC User Pre-installation Guide ©Amada America, Inc.

Print Date 01/24/2001 Revision 4.0 This document available on the World Wide Web at http://www.amada.com Page 3 of 37

Contents

Introduction ......................................................................................................................................................................................5

Specifications - Motion Package......................................................................................................................................................6

Specifications - Punching System....................................................................................................................................................7

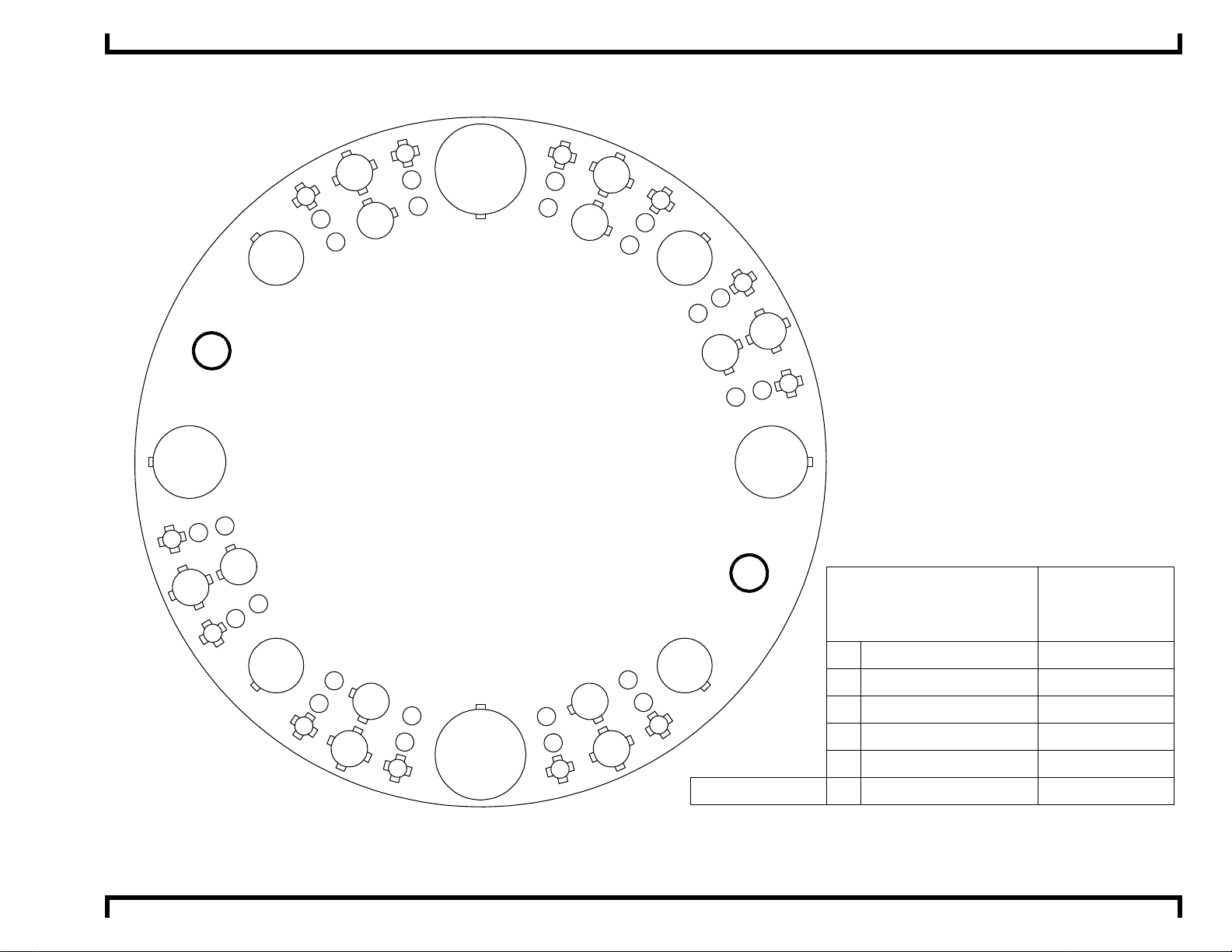

Turret Configuration - 58 Station - 2 Auto-Index.........................................................................................................................8

Specifications - Fanuc 18PC Controller ...........................................................................................................................................9

Specifications - Hydraulic Systems..................................................................................................................................................9

Power Hydraulic Numerical Control............................................................................................................................................9

Hydraulic Power Unit ..................................................................................................................................................................9

Supply Requirements - Electrical...................................................................................................................................................10

Optional Equipment..................................................................................................................................................................10

Installing the Electrical Power Supply.......................................................................................................................................11

Supply Requirements - Pneumatic.................................................................................................................................................12

Optional Equipment..................................................................................................................................................................12

Installing the Pneumatic Supply................................................................................................................................................12

Planning the Location of the Vipros 357 Queen.............................................................................................................................13

Moving the Vipros 357 Queen ..................................................................................................................................................13

Plan View - Vipros 357 Queen..................................................................................................................................................14

Plan View - Vipros 357 Queen with V357hs conveyor..............................................................................................................15

Plan View - Vipros 357 Queen with V357hs conveyor and MP1225 loader .............................................................................16

End View - Vipros 357 Queen...................................................................................................................................................17

Elevation View - Vipros 357 Queen..........................................................................................................................................18

SBC EX 5.5 Chiller.........................................................................................................................................................................19

SBC EX 5.5Chiller Placement...................................................................................................................................................19

Chiller Connections...................................................................................................................................................................20

Foundation Requirements..............................................................................................................................................................21

Foundation Anchoring Procedure ..................................................................................................................................................22

Foundation J-bolt Detail............................................................................................................................................................22

Plan View - Foundation Vipros 357 Queen...............................................................................................................................23

Elevation - Foundation Vipros 357 Queen................................................................................................................................23