BAG0210.8 10.22

1User information ..........................................................................................8

1.1 Purpose of the document.........................................................................................................8

1.2 Locations in the operating manual...........................................................................................8

1.3 Diagrams used.........................................................................................................................8

2General safety instructions.........................................................................9

2.1 Obligations and liability ............................................................................................................9

2.2 Representation of safety symbols..........................................................................................11

2.3 Organisational measures .......................................................................................................12

2.4 Safety and protection equipment ...........................................................................................12

2.5 Informal safety measures.......................................................................................................12

2.6 User training...........................................................................................................................13

2.7 Safety measures in normal operation ....................................................................................14

2.8 Dangers from residual energy................................................................................................14

2.9 Maintenance and repair work, fault elimination .....................................................................14

2.10 Constructive changes ............................................................................................................14

2.10.1 Spare and wear parts and aids ..............................................................................................15

2.11 Cleaning and disposal............................................................................................................15

2.12 User workstation ....................................................................................................................15

2.13 Warning pictograms and other signs on the machine ...........................................................16

2.13.1 Positioning of warning pictograms and other labels ..............................................................16

2.14 Dangers if the safety information is not observed..................................................................23

2.15 Safety-conscious working ......................................................................................................23

2.16 Safety information for users ...................................................................................................24

2.16.1 General safety and accident prevention information .............................................................24

2.16.2 Hydraulic system....................................................................................................................27

2.16.3 Electrical system ....................................................................................................................28

2.16.4 Attached machines ................................................................................................................28

2.16.5 Brake system .........................................................................................................................29

2.16.6 Tyres ......................................................................................................................................30

2.16.7 Cleaning, maintenance and repairs .......................................................................................30

3Loading and unloading .............................................................................31

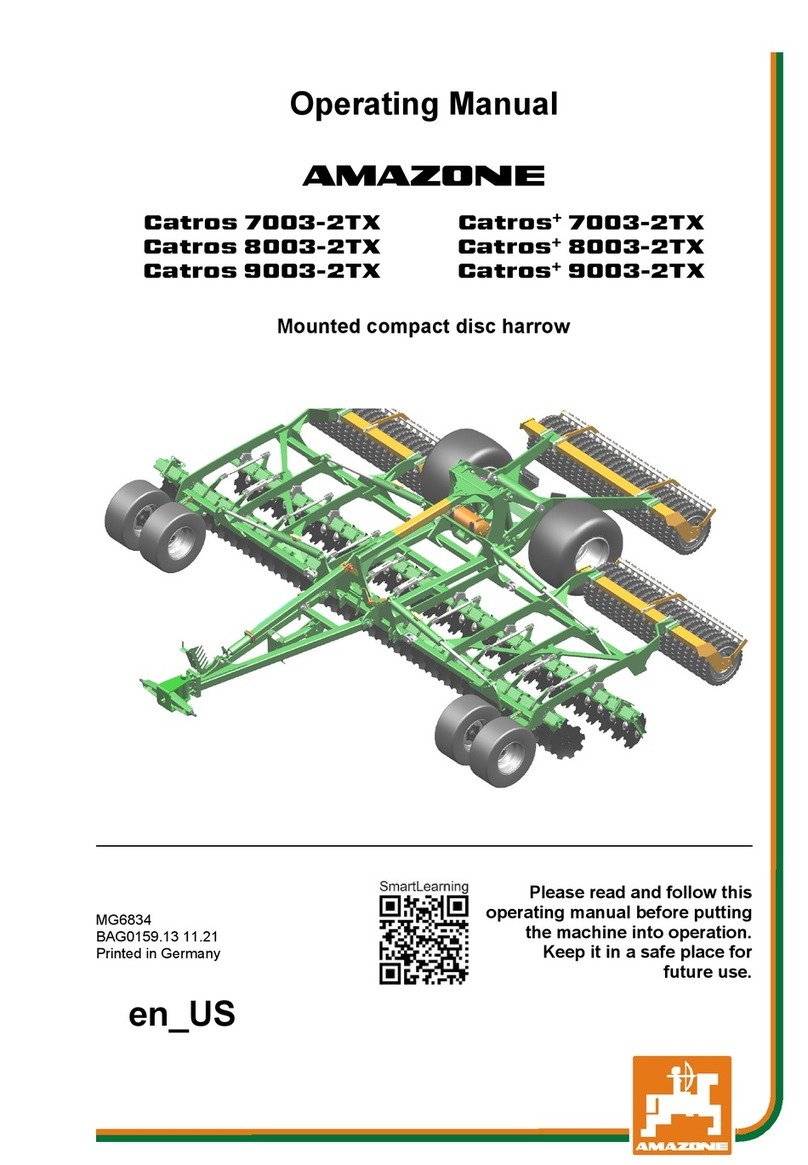

4Product description ...................................................................................32

4.1 Overview of subassemblies ...................................................................................................32

4.2 Safety and protection equipment ...........................................................................................33

4.3 Supply lines Safety and protection equipment.......................................................................33

4.4 Transportation equipment ......................................................................................................34

4.5 Intended use ..........................................................................................................................35

4.6 Danger area and danger points .............................................................................................36

4.7 Rating plate ............................................................................................................................37

4.8 Technical data........................................................................................................................38

4.8.1 Weights and tyre load capacity ..............................................................................................39

4.9 Necessary tractor equipment .................................................................................................40

4.10 Noise production data ............................................................................................................40

5Structure and function ..............................................................................41

5.1 Function .................................................................................................................................41

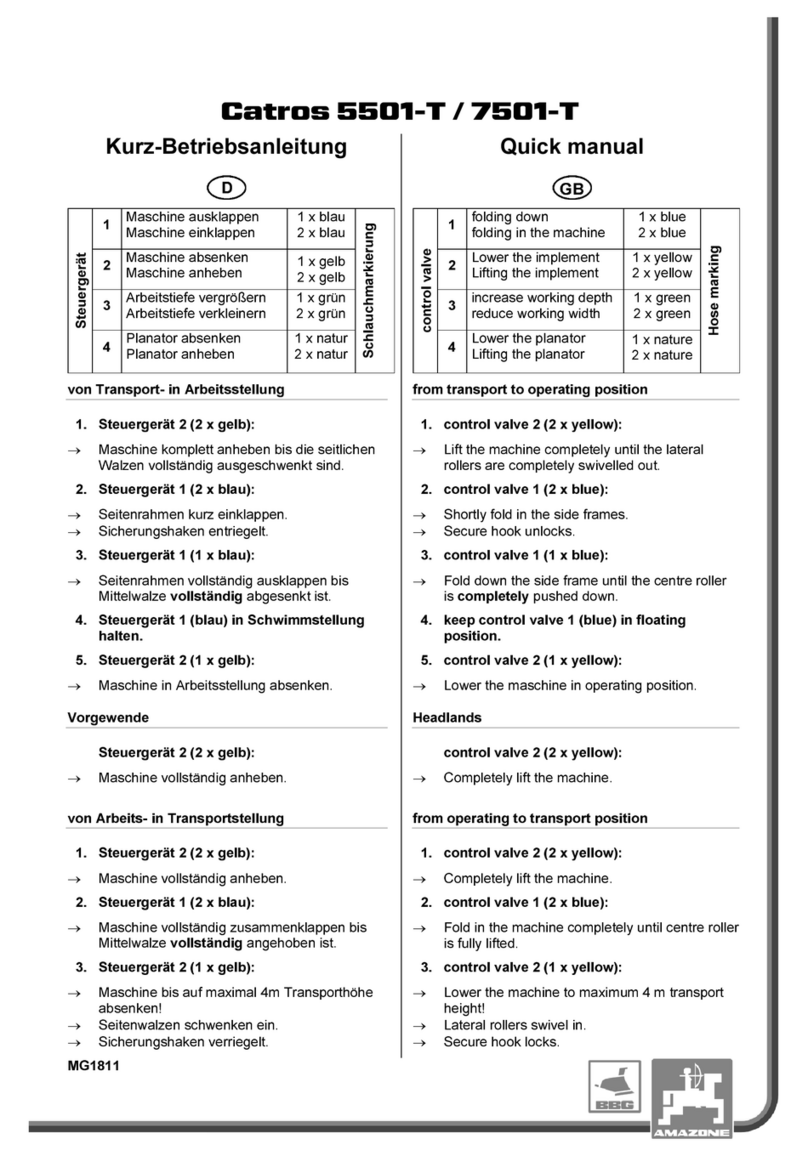

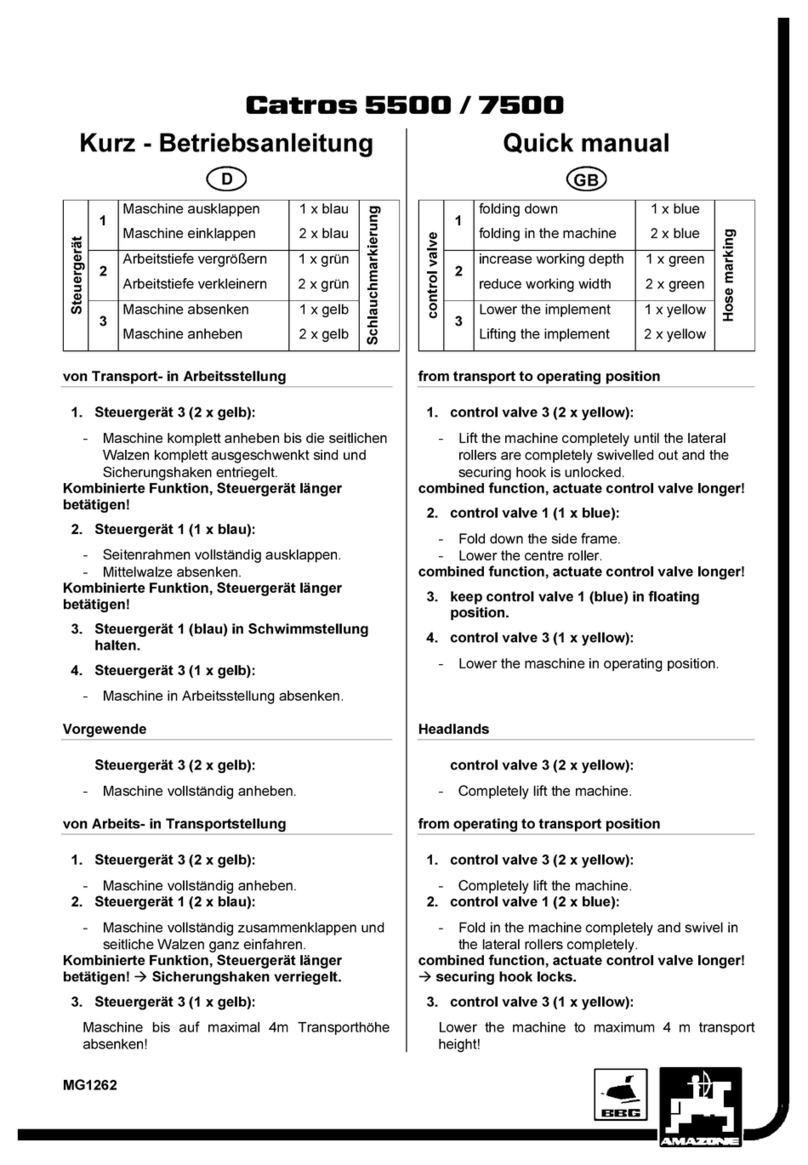

5.2 Hydraulic system connections ...............................................................................................42

5.2.1 Coupling the hydraulic hose lines ..........................................................................................43

5.2.2 Uncoupling the hydraulic hose lines ......................................................................................44

5.3 Dual-circuit service brake system ..........................................................................................45

5.3.1 Coupling the brake and supply lines ......................................................................................46

5.3.2 Uncoupling the brake and supply lines ..................................................................................47