INSTRUCTION MANUAL

& PARTS BREAKDOWN

AME INTERNATIONAL - 2 - WWW.AMEINTL.NET

To avoid serious personal in-

jury, always wear proper pro-

tective gear, such as hard

hats, safety glasses, gloves,

and steel toe shoes when us-

ing hydraulic equipment.

Failure to chock the wheels

and crib the vehicle can re-

sult in Serious injury or

death. Always deflate tires

before removing a wheel, a

rim, or part of a rim clamp or

nut. If you do not deflate the

tire, the tire could explode,

causing serious injury of

death. Always stand to one

side of the rim when using

the bead breaker. Standing to

one side of the bead breaker

allows you to maintain con-

trol of the bead breaker. If it

is not seated properly and

flies off the rim, the bead

breaker could cause serious

injury or death.

AME INTERNATIONAL WWW.AMEINTL.NET

! WARNING !

IMPORTANT RECEIVING INFORMATION

Visually inspect all parts for shipping damage. If you find shipping dam-

age, notify the carrier at once. Shipping damage is not covered by your

warranty. The carrier is responsible for all costs of replacement or repair

caused by shipping damage.

DESCRIPTION

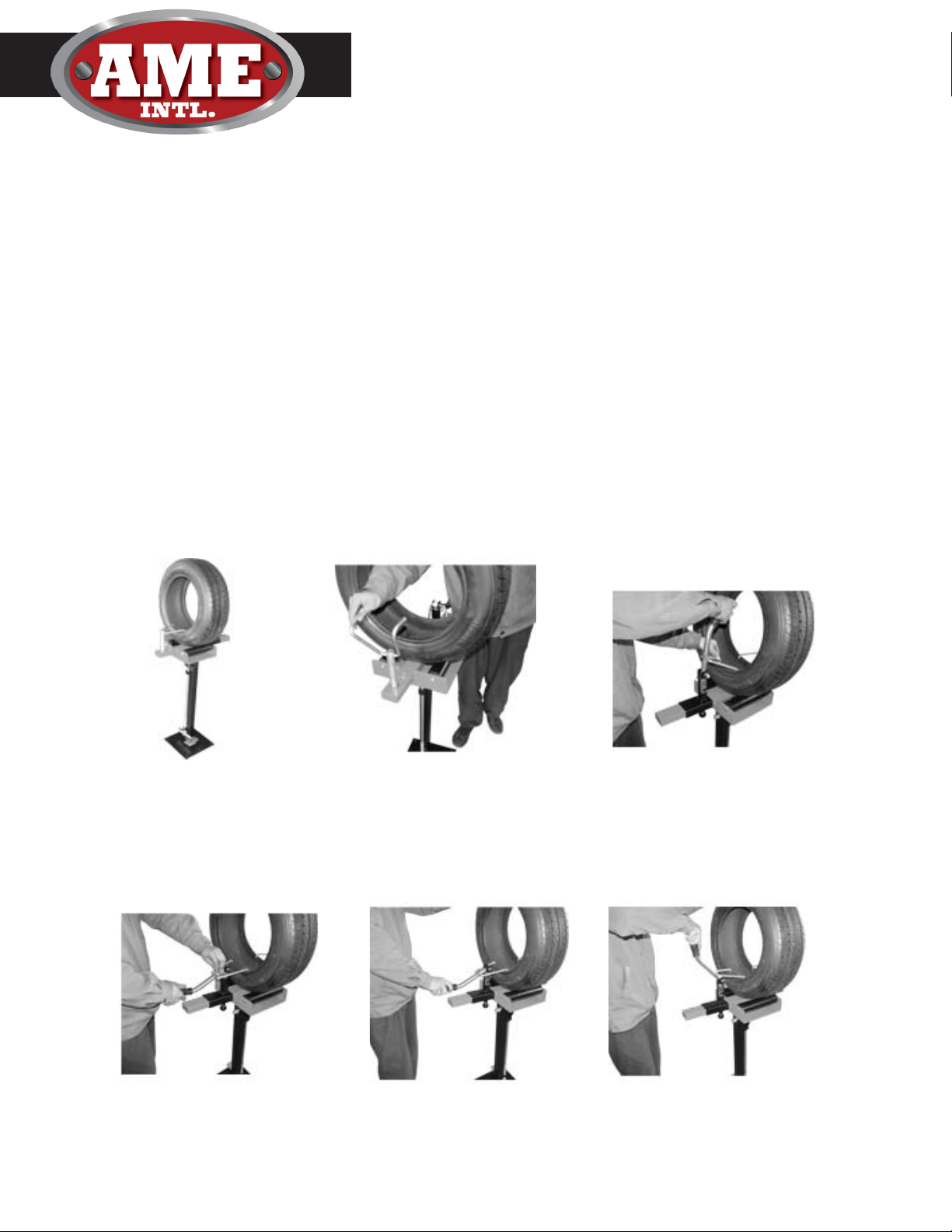

The 73080 Floor Mount Tire Spreader is equipped with multiple height

and width adjustments. It is for use with passenger and light trucks (13”

– 20”). Heavy duty rollers cradle the tire. Weight: 63 lbs (29 kg).

SAFETY INFORMATION

To avoid personal injury or property damage while using this product,

read and follow all DANGERS, WARNINGS, CAUTIONS, and IN-

STRUCTIONS that are attached to, or included with, this product.

1. Follow the instructions of the tire manufacturer and the vehicle

manufacturer when deflating, demounting, mounting, and inflating

tires.

2. These operating instructions do not apply to any specific rim. There-

fore, contact the rim manufacturer for the correct procedure for your

rim.

3. For the publication, “Multipiece Rim Matching Chart” contact the

United States Department of Labor, Occupational Safety, and Health

Administration (OSHA), Washington, DC, 20210, 202-219-6091, or

contact AME Intl at 1-877-755-4263. If you are outside the U.S., con-

tact your local government officials.

4. AME Intl cannot be held responsible for damage or injury resulting

from unsafe use of this product; lack of maintenance; or incorrect

product and system application.

5. Contact AME Intl. when in doubt about safety precautions or applica-

tions.

The floor mount tire spreader, and all tire tools, should be used

only by per-sons properly trained according to OSHA Regulation

#29CFR1910.177, “Servicing Single-Piece & Multi-Piece Wheels.”

Free copies of this regulation are available upon request from AME

Intl.

WARNING

To avoid serious personal injury, always wear proper protective gear,

such as hard hats, safety glasses, gloves, and steel toe shoes when using

hydraulic equipment.

CAUTION