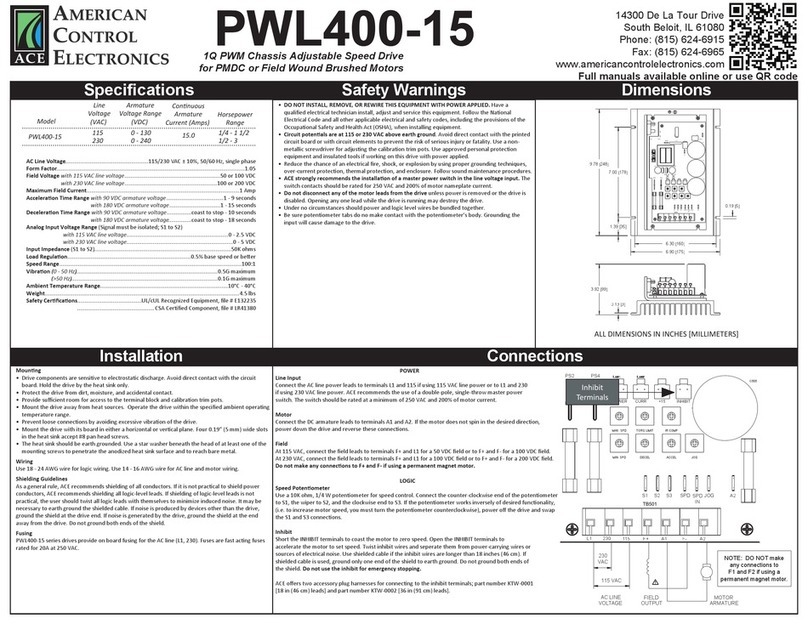

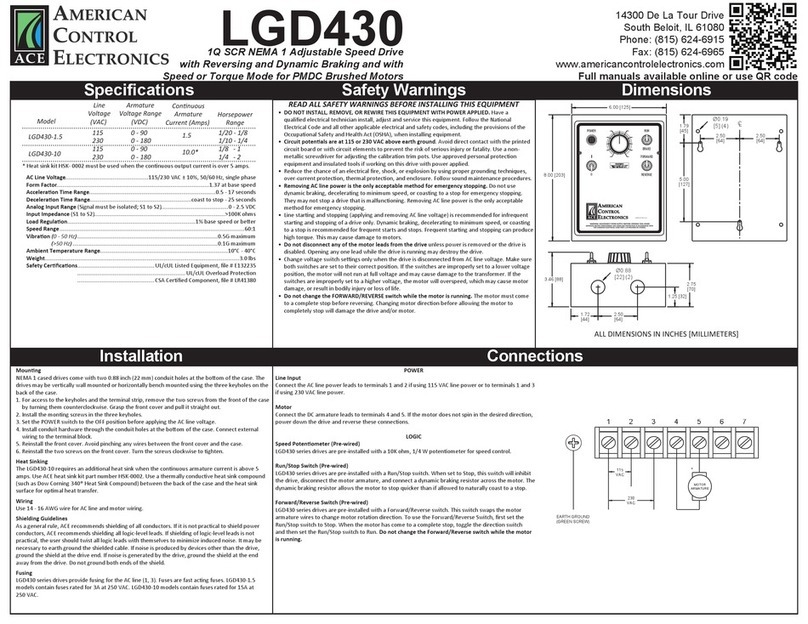

1Q PWM NEMA 4X Adjustable Speed Drive

for PMDC or Field Wound Brushed Motors

PWL4400-10

Full manual available online

14300 De La Tour Drive

South Beloit, IL 61080

Phone: (844) AMCNTRL

Fax: (800) 394-6334

www.americancontrolelectronics.com

TM

An ISO 9001:2008 Certified Company

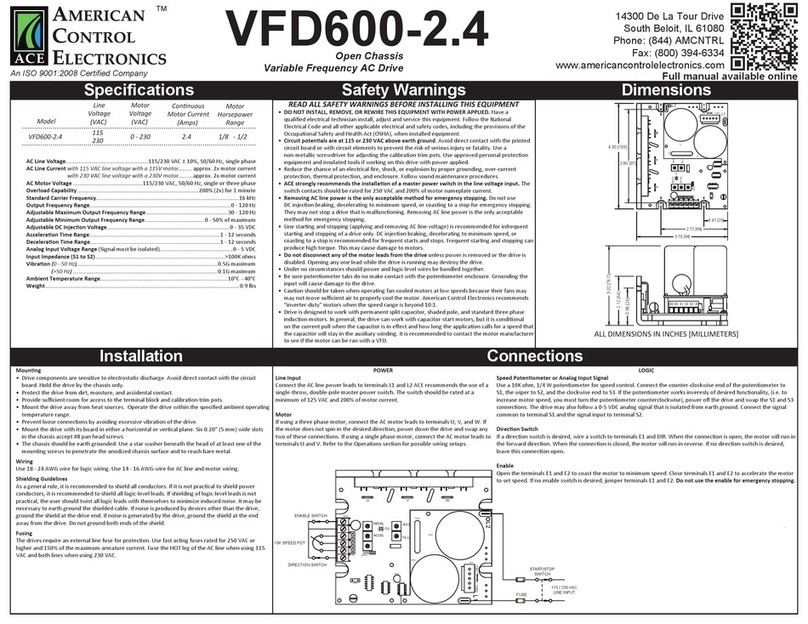

......................................................115/230 VAC ± 10%, 50/60 Hz, single phase

..........................................................................................................................1.05

..............................................................50 or 100 VDC

............................................................100 or 200 VDC

...................................................................................................1 Amp

..................................1 - 10 seconds

.................................1 - 15 seconds

................coast to stop - 10 seconds

...............coast to stop - 19 seconds

..................................................................0 - 2.5 VDC

.....................................................................0 - 5 VDC

.........................................................................................50K ohms

...................................................................................1% base speed or beer

......................................................................................................................100:1

............................................................................................0.5G maximum

...............................................................................................0.1G maximum

...................................................................................10°C - 40°C

..............................................................................................................................8.1 lbs

UL/cUL Recognized Equipment, file # E132235

CSA Cerfied Component, file # LR41380

AC Line Voltage

Form Factor

Field Voltage with 115 VAC line voltage

with 230 VAC line voltage

Maximum Field Current

Acceleraon Time Range with 130 VDC armature voltage

with 240 VDC armature voltage

Deceleraon Time Range with 130 VDC armature voltage

with 240 VDC armature voltage

Analog Input Voltage Range (Signal must be isolated; S1 to S2)

with 115 VAC line voltage

with 230 VAC line voltage

Input Impedance (S1 to S2)

Load Regulaon

Speed Range

Vibraon (0 - 50 Hz)

(>50 Hz)

Ambient Temperature Range

Weight

Safety Cerficaons..........................................

Safety Cerficaons..................................................

1/4 - 1

1/2 - 2

Horsepower

Range

10.0

Connuous

Armature

Current (Amps)

0 - 130

0 - 240

Armature

Voltage Range

(VDC)

115

230

Line

Voltage

(VAC)

PWL440-10

Model

Specifications Safety Warnings

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH POWER APPLIED. Have a

• qualified electrical technician install, adjust and service this equipment. Follow the Naonal

•Electrical Code and all other applicable electrical and safety codes, including the provisions of the

• Occupaonal Safety and Health Act (OSHA), when installing equipment.

• Circuit potenals are at 115 or 230 VAC above earth ground. Avoid direct contact with the printed

• circuit board or with circuit elements to prevent the risk of serious injury or fatality. Use a non-

• metallic screwdriver for adjusng the calibraon trim pots. Use approved personal protecon

• equipment and insulated tools if working on this drive with power applied.

• Reduce the chance of an electrical fire, shock, or explosion by using proper grounding techniques,

• over-current protecon, thermal protecon, and enclosure. Follow sound maintenance procedures.

• ACE strongly recommends the installaon of a master power switch in the line voltage input. The

• switch contacts should be rated for 250 VAC and 200% of motor nameplate current.

• Removing AC line power is the only acceptable method for emergency stopping. Do not use

• dynamic braking, decelerang to minimum speed, or coasng to a stop for emergency stopping.

• They may not stop a drive that is malfunconing. Removing AC line power is the only acceptable

•method for emergency stopping.

• Line starng and stopping (applying and removing AC line voltage) is recommended for infrequent

• starng and stopping of a drive only. Dynamic braking, decelerang to minimum speed, or coasng

• to a stop is recommended for frequent starts and stops. Frequent starng and stopping can produce

•high torque. This may cause damage to motors.

• Do not disconnect any of the motor leads from the drive unless power is removed or the drive is

• disabled. Opening any one lead while the drive is running may destroy the drive.

• The field output is for shunt wound motors only. Do not make any connecons to F1 and F2 when

•using a permanent magnet motor.

• Change voltage switch sengs only when the drive is disconnected from AC line voltage. Make sure

• both switches are set to their correct posion. If the switches are improperly set to a lower voltage

• posion, the motor will not run at full voltage and may cause damage to the transformer. If the

• switches are improperly set to a higher voltage, the motor will overspeed, which may cause motor

• damage, or result in bodily injury or loss of life.

• Under no circumstances should power and logic level wires be bundled together.

• Be sure potenometer tabs do no make contact with the potenometer’s body. Grounding the

• input will cause damage to the drive.

• This product does not have internal solid state motor overload protecon. It does not contain speed-

• sensive overload protecon, thermal memory retenon, or provisions to receive and act upon

• signals from remote devices for over temperature protecon. If motor protecon is needed in the

• end-use product, it needs to be provided by addional equipment in accordance with NEC standards.

READ ALL SAFETY WARNINGS BEFORE INSTALLING THIS EQUIPMENT

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Dimensions

6.90 [175]

6.30 [160]

1.40

[36]

0.22

[6]

10.22

[260]

9.80

[249]

7.00

[178]

5.79

[146]

4.69

[119]

2.31

[58]

0.12

[3] 1.50 [38] 1.50 [38]

1.45 [37]

Ø0.88

[22] (3)

Installation

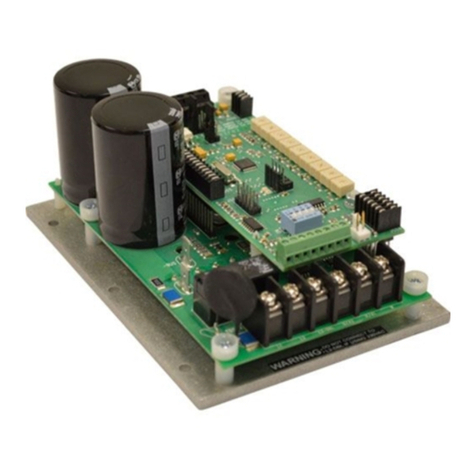

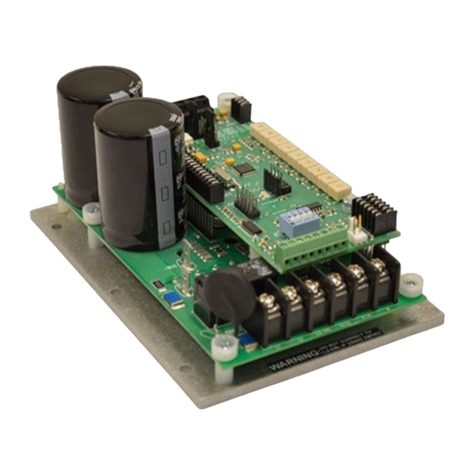

Mounng

NEMA 4X cased drives come with two 0.88 inch (22 mm) conduit knockout holes at the boom of the

case. The drives may be vercally wall mounted using the four 0.19 inch (5 mm) sloed holes on the

aached heat sink. For loads less than 5 amps, the drive may be bench mounted horizontally or

operated without mounng.

1. Install the mounng screws.

2. For access to the terminal strip, turn the sloed screw on the front cover counterclockwise unl it is

2. free from the case. The right side of the cover is hinged to the case. Pull the sloed screw to open

2. the case.

3. Carefully remove the conduit knockouts by tapping them into the case and twisng them off with

3. pliers.

4. Set the POWER switch to the OFF posion before applying AC line voltage.

5. Install conduit hardware through the 0.88 inch (22 mm) knockout holes. Connect external wiring to

4. the terminal block.

6. Grasp the sloed screw and lt the front cover back into place. Avoid pinching any wires between

5. the front cover and the case.

7. Turn the sloed screw clockwise unl ght to secure the front cover.

Wiring

Use 14 - 16 AWG wire for AC line and motor wiring.

Shielding Guidelines

As a general rule, it is recommended to shield all conductors. If it is not praccal to shield power

conductors, it is recommended to shield all logic-level leads. If shielding of logic-level leads is not

praccal, the user should twist all logic leads with themselves to minimize induced noise. It may be

necessary to earth ground the shielded cable. If noise is produced by devices other than the drive,

ground the shield at the drive end. If noise is generated by the drive, ground the shield at the end

away from the drive. Do not ground both ends of the shield.

Fusing

The drive provides on board fusing for the AC line (L1, 230). Fuses are fast acng fuses rated for 15A at

250 VAC.

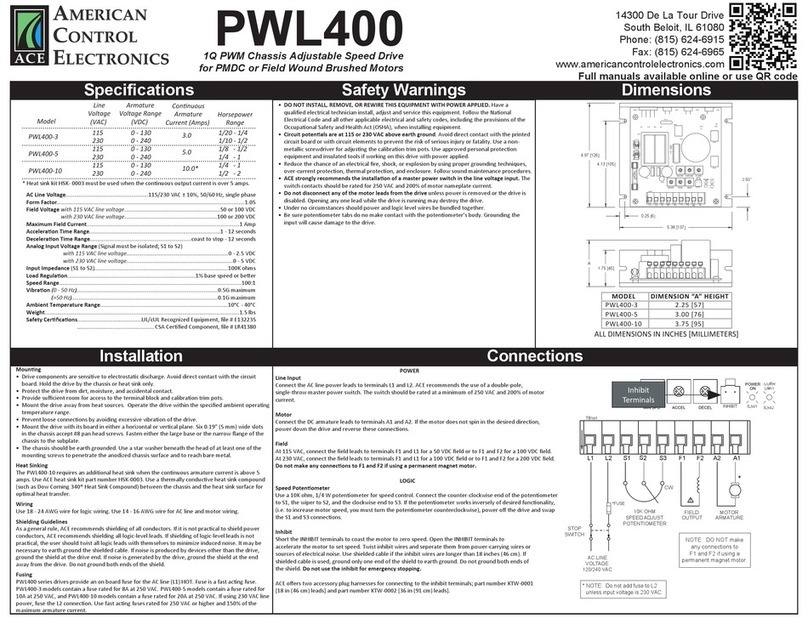

Line Input

Connect the AC line power leads to terminals L1 and 115 if using 115 VAC line power or to terminals

L1 and 230 if using 230 VAC line power.

Motor

Connect the DC armature leads to terminals A1 and A2. If the motor does not spin in the desired direcon,

power down the drive and reverse these connecons.

Field

At 115 VAC, connect the field leads to terminals F+ and L1 for a 50 VDC field or to F+ and F- for a 100 VDC field.

At 230 VAC, connect the field leads to terminals F+ and L1 for a 100 VDC field or to F+ and F- for a 200 VDC field.

Do not make any connecons to F+ and F- if using a permanent magnet motor.

Speed Potenometer (Pre-wired)

PWL440 series drives are pre-installed with a 10K ohm, 1/4 W potenometer for speed control.

Inhibit

Short the INHIBIT terminals to coast the motor to zero speed. Open the INHIBIT terminals to

accelerate the motor to set speed. Twist inhibit wires and seperate them from power-carrying wires or

sources of electrical noise. Use shielded cable if the inhibit wires are longer than 18 inches (46 cm). If

shielded cable is used, ground only one end of the shield to earth ground. Do not ground both ends of

the shield. Do not use the inhibit for emergency stopping.

ACE offers two accessory plug harnesses for connecng to the inhibit terminals; part number KTW-0001

[18 in (46 cm) leads] and part number KTW-0002 [36 in (91 cm) leads].

Connections

POWER

LOGIC

P

S

2

P

S4

POWER CURR +15 INHIBIT

MIN SPD DECEL ACCEL JOG

MAX SPD TORQ LIMIT IR COMP

MOTOR

ARMATURE

FIELD

OUTPUT

AC LINE

VOLTAGE

230

VAC

115 VAC

NOTE: DO NOT make

any connections to

F1 and F2 if using a

permanent magnet motor.

11

L1 230

S1 S2 S3 SPD SPD

IN

JOG

Inhibit

Terminals