September 2012L010194 2

Table of Contents

Section 1: Introduction.................................................................................................................................3

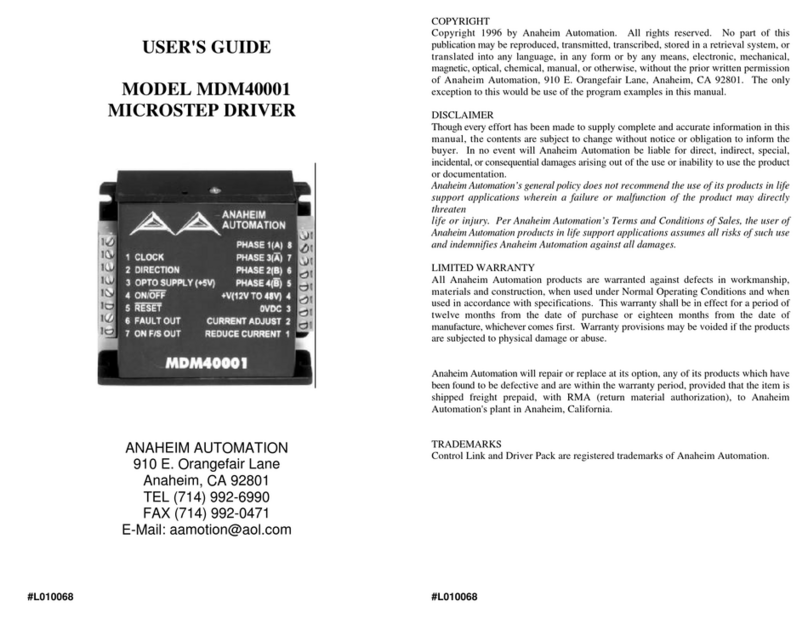

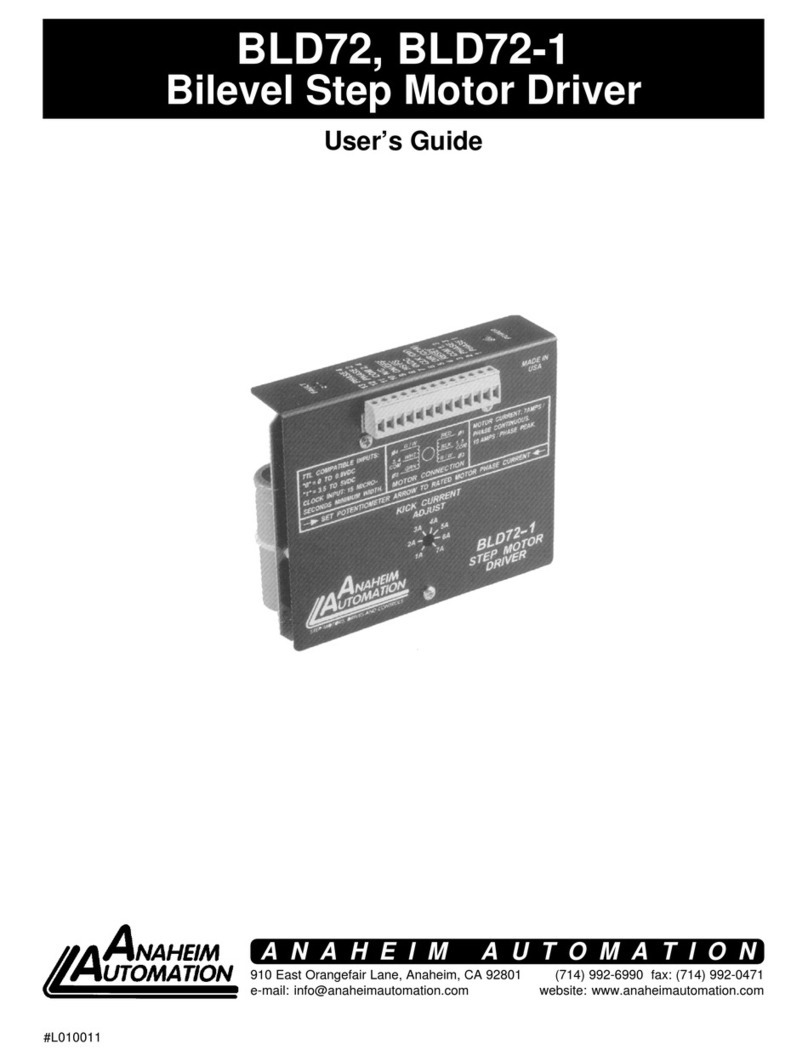

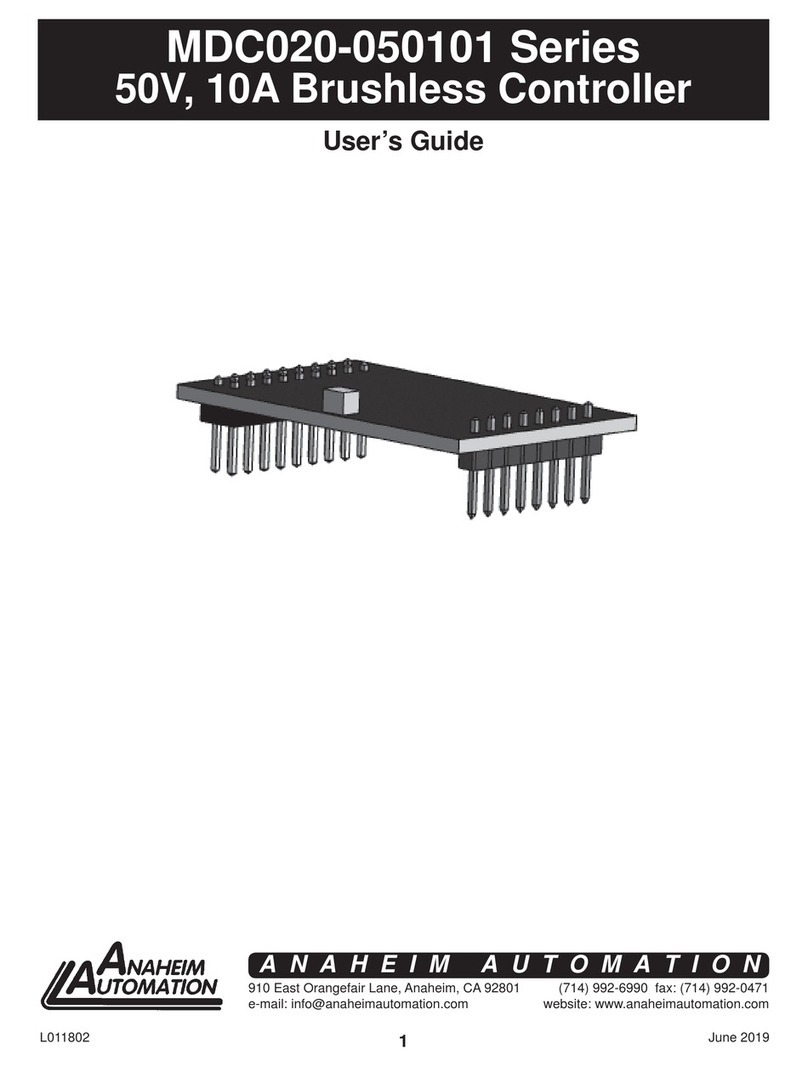

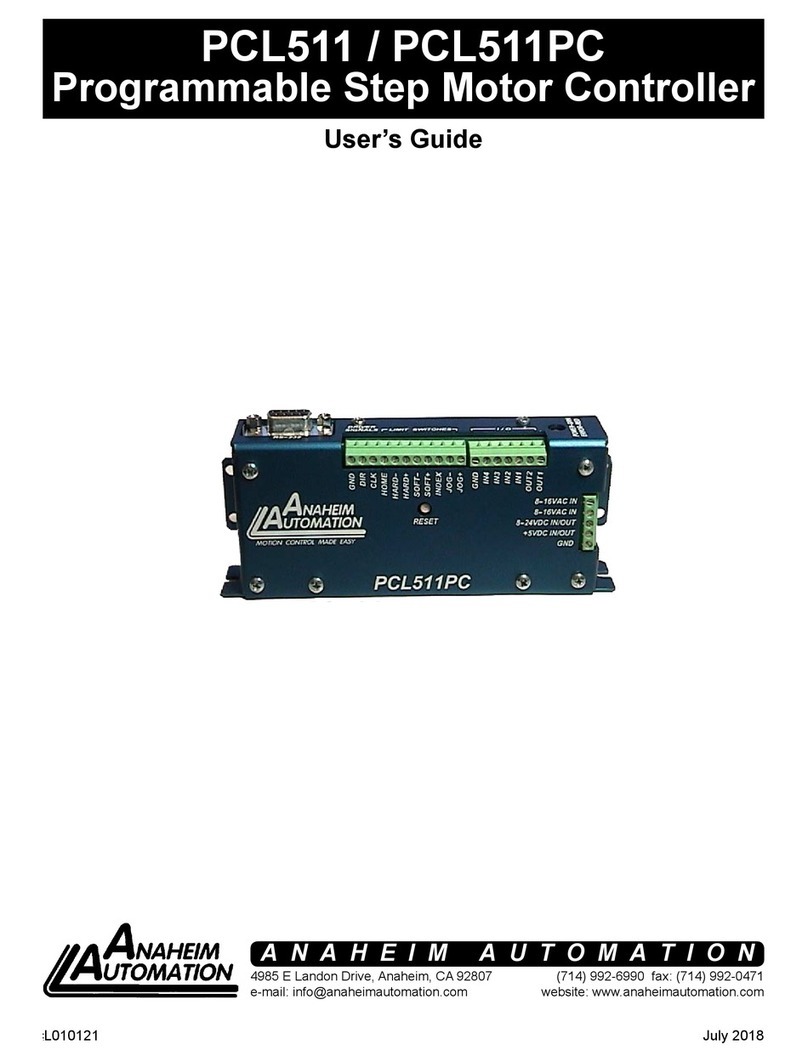

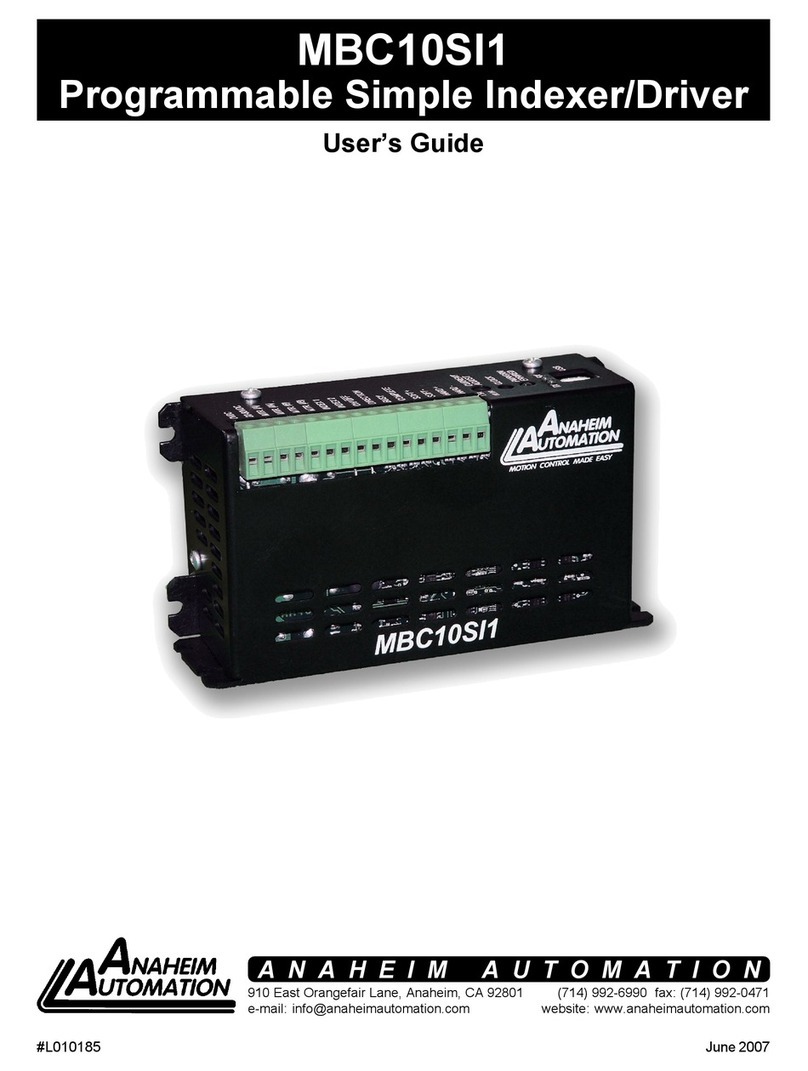

Description.....................................................................................................................................................3

Ordering Information.......................................................................................................................................4

Axis Selection.............................................................................................................................................4

Baud Selection............................................................................................................................................5

Baud Rates.................................................................................................................................................5

Methods of Communication.......................................................................................................................5

RS232 to RS485 Protocol...........................................................................................................................5

RS485.........................................................................................................................................................6

Two Wire Conguration..................................................................................................................................6

Four Wire Conguration...............................................................................................................................6

Terminating Resistor......................................................................................................................................7

Status LED (Controller)...................................................................................................................................7

Technical Support...........................................................................................................................................7

Electrical Specications..............................................................................................................................8

Terminal Descriptions.................................................................................................................................8

Dimensions.................................................................................................................................................9

Wiring Diagram............................................................................................................................................9

Motor Selection..........................................................................................................................................10

Step Motor Selection Guide.......................................................................................................................11

Reducing Output Current............................................................................................................................11

Determining Output Current...........................................................................................................................11

Step Motor Congurations.........................................................................................................................12

Connecting the Step Motor........................................................................................................................13

Short-Circuit, Mis-Wire, and Over-Current Conditions...................................................................................13

Section 2: Controller Functions................................................................................................................14

Section 3: SMC50WIN Software...............................................................................................................17

Installation.................................................................................................................................................17

Getting Started...........................................................................................................................................17

“The Unit is Connected” / “The Unit is NOT Connected”....................................................................................18

File Menu..................................................................................................................................................18

Setup Menu...............................................................................................................................................18

Toolbar........................................................................................................................................................18

Tab Sheets................................................................................................................................................19

Current Program Filename.............................................................................................................................21

Add/Change/Insert Commands..................................................................................................................21

Calculator..................................................................................................................................................25

Section 4: Direct Talk Mode..................................................................................................................26

COM Port Settings....................................................................................................................................26

Unit Selection...........................................................................................................................................26

Instructions...............................................................................................................................................26

Section 5: Troubleshooting....................................................................................................................31

Error Codes..................................................................................................................................................32

Section 6: Tutorial...................................................................................................................................33

Sample Program 1:......................................................................................................................................33

Sample Program 2:......................................................................................................................................34

Appendix 1: ASCII Table for Direct Mode.....................................................................................................36

Copyright ..................................................................................................................................................37

July 2018