EVAL-SSM2311

Rev. 0 | Page 3 of 12

EVALUATION BOARD HARDWARE

POWER SUPPLY

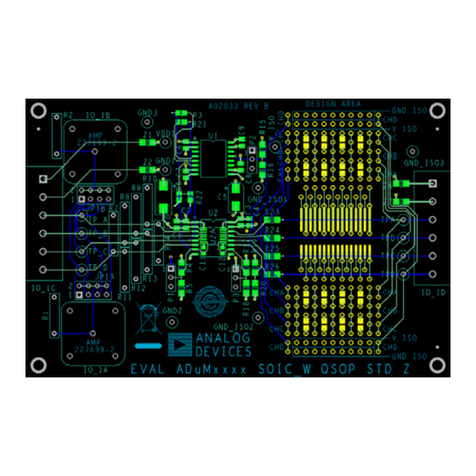

The schematic is shown in Figure 4.

On the upper left corner, there is a PCB footprint to populate a

standard power jack (J1), which accepts a 2.5 V ~ 5.5 V dc

power supply. The user can also use the two-pin header (JP3) to

power the board. In either case, care must be taken to connect

the dc power with correct polarity and voltage. The J1 jack is

not populated during PCB assembly.

Warning

The wrong power supply polarity or overvoltage may damage

the board permanently

The maximum peak current is approximately 0.33 A when

driving an 8 Ω load and when the input voltage is 5 V.

HEADERS

On the left side and below the power jack, there is a standard

3.5 mm audio stereo jack connector (J2). Below J2 is a three-pin

header (JP4). These are used to feed the audio signal into the board.

If the input audio signal is differential (IN+ and IN−), the user

can use either J2 or JP4. In this case, all three pins of J2 or JP4

are used for IN+, IN−, and the ground.

For a single-ended audio input, using JP4 as the input connector

is recommended. In this case, only two pins of JP4 are used.

One is for the ground and the other is for either IN+ or IN−. If

IN+ is used, the user should place a jumper between Pin 2 and

Pin 3 of JP4, shorting IN− to ground. If IN− is used, the jumper

should be placed between Pin 1 and Pin 2 of JP4, connecting IN+

to the ground.

The two-pin header, JP2, is used to turn on/off the SSM2311

amplifier. Putting a jumper on JP2 shuts down the SSM2311 so

that only a minimum current (about 20 nA) is drawn from the

power supply. Removing the jumper puts the SSM2311 in normal

operation.

The output connector, JP1, is located on the right side of the

board. JP1 drives a loudspeaker whose impedance should be no

less than 3 .

While the SSM2311 does not require any external LC output filters

due to a low noise modulation scheme, if the speaker length is

>10 cm, it is recommended to put a ferrite bead (L1 and L2) near

each output pin of the SSM2311 to reduce electromagnetic interfe-

rence (EMI), as shown in the schematic in Figure 4. On the board,

there are two inductors, L3 and L4, that are not loaded and not

required for normal operation (they are shorted by the solder gaps,

G1 and G2), but some users may add these inductors to evaluate

their certain applications with tighter EMI constraints. If L3 and

L4 are loaded, the solder on G1 and G2 must be removed by a

soldering iron. As a courtesy to the end user, a properly tuned

ferrite bead based EMI filter is assembled at the output terminals

of the device. For optimal performance, as specified in the

SSM2311 data sheet (in particular THD and SNR), the entire

EMI filter should be removed. Short across the ferrite bead

terminals and open the capacitor terminals.

GETTING STARTED

To ensure proper operation, carefully follow Step 1 through Step 4.

1. If a jumper is on JP2, remove the jumper to turn on the

amplifier.

2. Connect the load to the audio output connector, JP1.

3. Connect the audio input to the board, either in differential

mode or single-ended mode, depending on the application.

4. Connect the power supply with the proper polarity and

voltage.

WHAT TO TEST

EMI. Connect wires for the speakers of the same length as

for the actual application environment and complete the

EMI test.

Signal-to-noise ratio.

Output noise. Make sure to use an A-weighted filter to

filter the output before reading the measurement meter.

Maximum output power.

Distortion.

Efficiency.

COMPONENT SELECTION

Selecting the proper components is the key to achieving the

performance required at the cost budgeted.

Input Coupling Capacitor Selection—C11 and C12

These capacitors, C11 and C12, should be large enough to

couple the low frequency signal components in the incoming

signal and should be small enough to filter out unnecessary low

frequency signals. For music signals, the cutoff frequency

chosen is often between 20 Hz to 30 Hz. The value of the input

capacitor is calculated by

C= 1/(2Rfc)

where:

R= 150 kΩ.

fcis the cutoff frequency.

Output Ferrite Beads—L1 and L2

The output beads, L1 and L2, are necessary components for

filtering out the EMI caused at the switching output nodes

when the length of the speaker wire is greater than 10 cm. The

penalty for using ferrite beads for EMI filtering is slightly worse

noise and distortion performance at the system level due to the

nonlinearity of the beads.

Ensure that these beads have enough current conducting capability

while providing sufficient EMI attenuation. The current rating

needed for an 8 Ω load is approximately 420 mA, and impedance

at 100 MHz must be ≥220 . In addition, the lower the dc resis-