ACG+

User Manual Int. Approved

Document ref: P0149-801-09 January 2018 Page 1of 96

Copyright © 2014 Analox Ltd. All Rights Reserved.

Commercial in Confidence

List of contents

1Contents checklist......................................................................................................... 3

1.1 Standard contents................................................................................................................. 3

1.2 Optional accessories.............................................................................................................. 3

2Safety information ........................................................................................................ 4

2.1 Capabilities to test gases against the EN 12021:2014 standard .................................................. 4

2.2 Electrochemical sensors (oxygen and carbon monoxide) ............................................................ 4

2.3 PID lamp cleaning kit ............................................................................................................ 5

2.4 Inlet pressure & flow ............................................................................................................. 5

3Introduction ................................................................................................................. 6

3.1 ACG+ overview .................................................................................................................... 6

4Installation details ........................................................................................................ 7

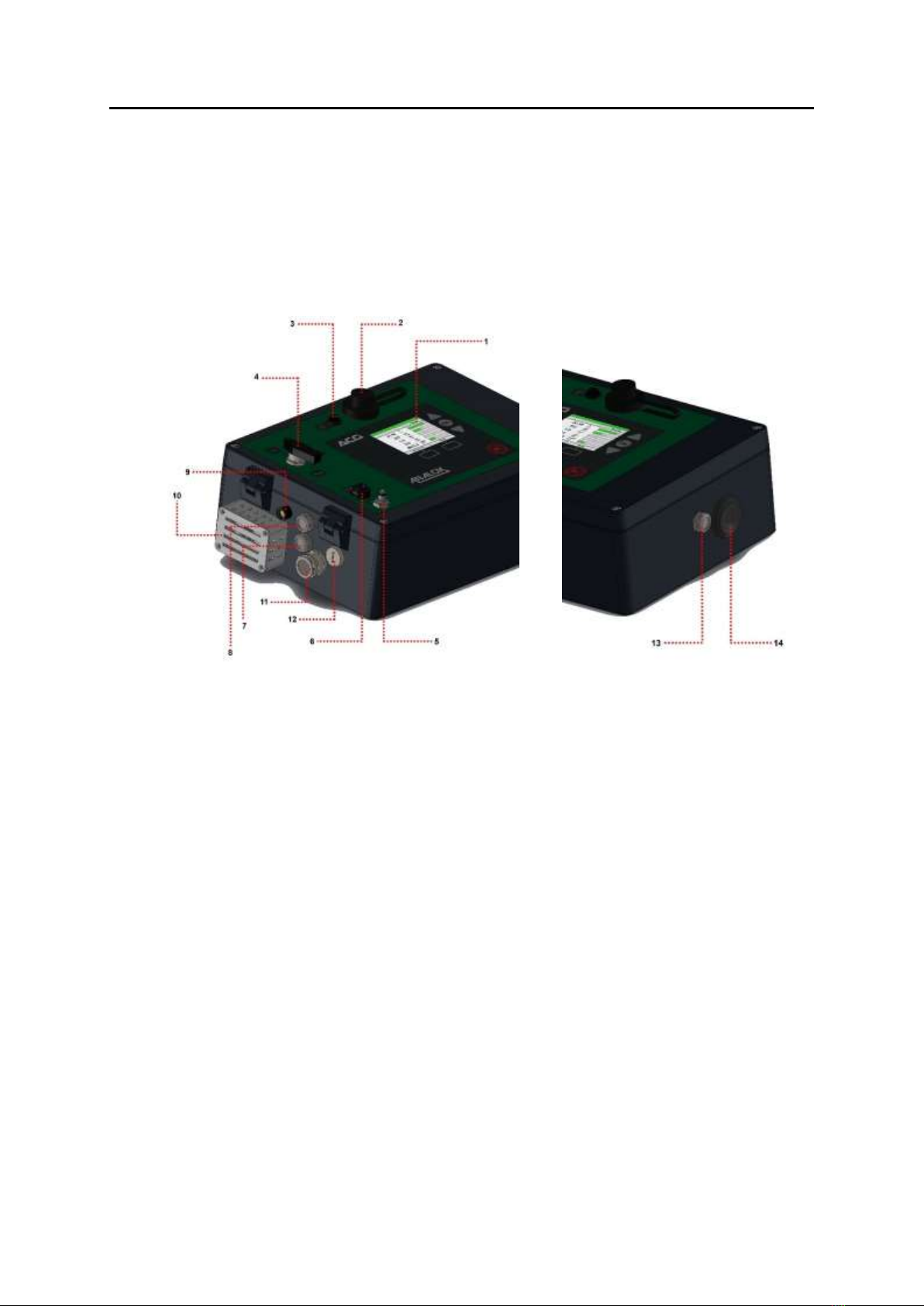

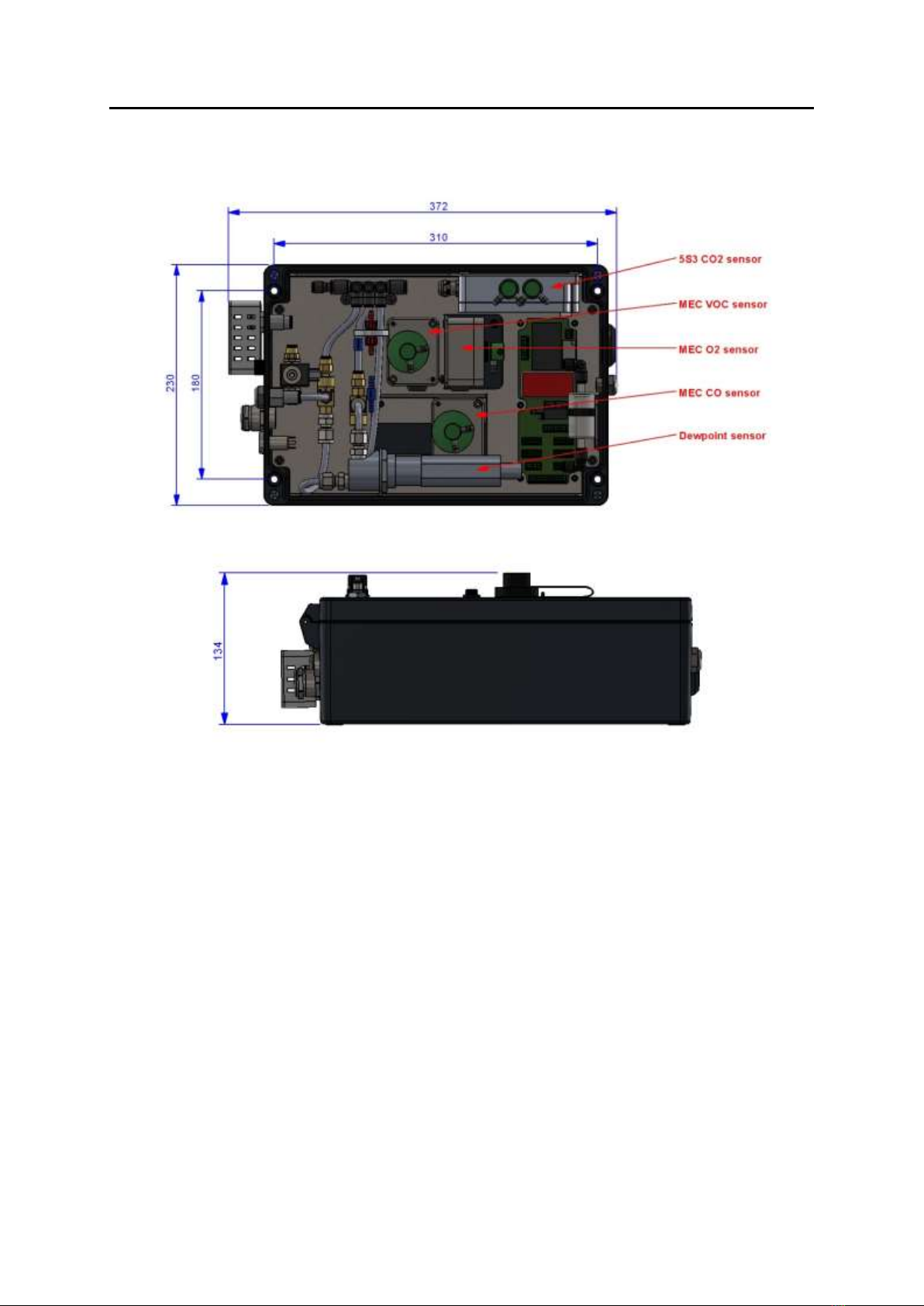

4.1 Mechanical overview ............................................................................................................. 7

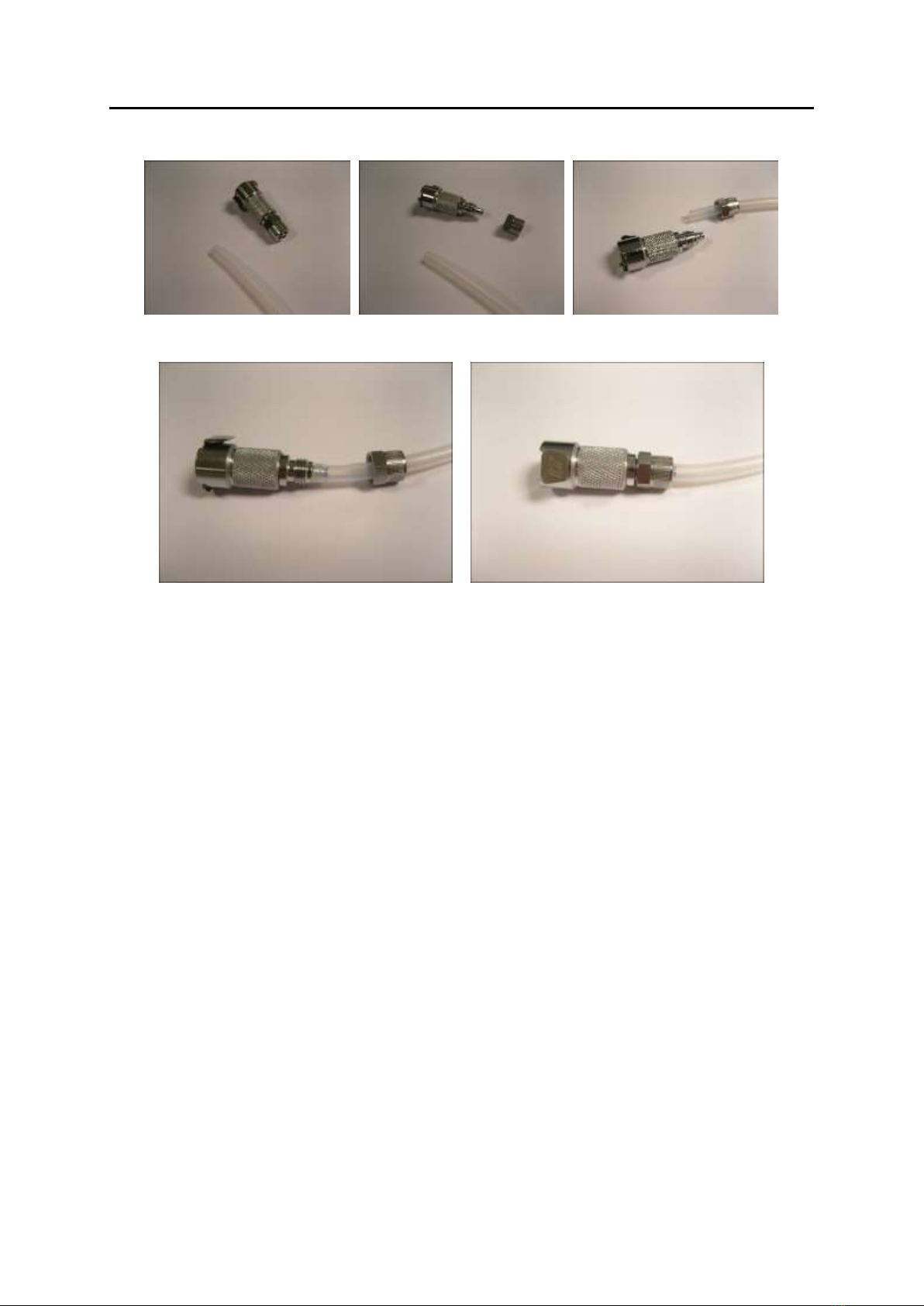

4.2 Gas sample connection (Both fixed and portable versions) ......................................................... 7

4.3 Installation (Portable)............................................................................................................ 9

4.4 Installation (Fixed)...............................................................................................................11

4.5 Safety interlock relay (ACG+ Fixed) .......................................................................................13

4.6 Safety interlock override key-switch (ACG+ Fixed)...................................................................14

4.7 Switched 24V DC outputs (ACG+ Fixed) .................................................................................15

5Operating instructions ................................................................................................. 16

5.1 Start-up..............................................................................................................................16

5.2 Controls..............................................................................................................................17

5.3 Inlet/purge valve .................................................................................................................18

5.4 Display ...............................................................................................................................18

5.5 Menu..................................................................................................................................19

5.6 Adjusting the backlight .........................................................................................................20

5.7 Power sub-menu..................................................................................................................20

5.8 System flow ........................................................................................................................21

5.9 Sensor readings...................................................................................................................22

5.10 Alarms................................................................................................................................24

5.11 Calibration adjustment .........................................................................................................27

5.12 Viewing device information....................................................................................................32

5.13 Viewing sensor information ...................................................................................................32

5.14 Data-logging .......................................................................................................................33

5.15 Sensor replacement reminder................................................................................................35

5.16 Timed sample draw ..............................................................................................................37

5.17 Setting the date and time .....................................................................................................39

6Configuration ............................................................................................................. 40

6.1 Software installation.............................................................................................................40

6.2 Making a connection.............................................................................................................55

6.3 Changing options .................................................................................................................56

6.4 Downloading data-logs .........................................................................................................57

6.5 Setting the time...................................................................................................................57

7Networking ................................................................................................................ 59

7.1 Overview ............................................................................................................................59

7.2 Connection..........................................................................................................................59

7.3 Transmission method ...........................................................................................................59

7.4 Setting the ACG Static IP Address ..........................................................................................60

7.5 Retrieving Data using TCP/IP Requests ...................................................................................61

7.6 Retrieving Data using UDP ....................................................................................................61

7.7 Datagram Structure .............................................................................................................62

8Troubleshooting.......................................................................................................... 68

8.1 System faults ......................................................................................................................68

9Recommended spares and accessories .......................................................................... 72

10 Maintenance requirements ....................................................................................... 74

10.1 Sensor & filter replacement ...................................................................................................74

10.2 Filter replacement................................................................................................................82

10.3 Service requirements ...........................................................................................................83

11 Specifications ......................................................................................................... 91

11.1 Instrument specification .......................................................................................................91

11.2 Sensor specification .............................................................................................................91

12 Declaration of conformity......................................................................................... 93