3

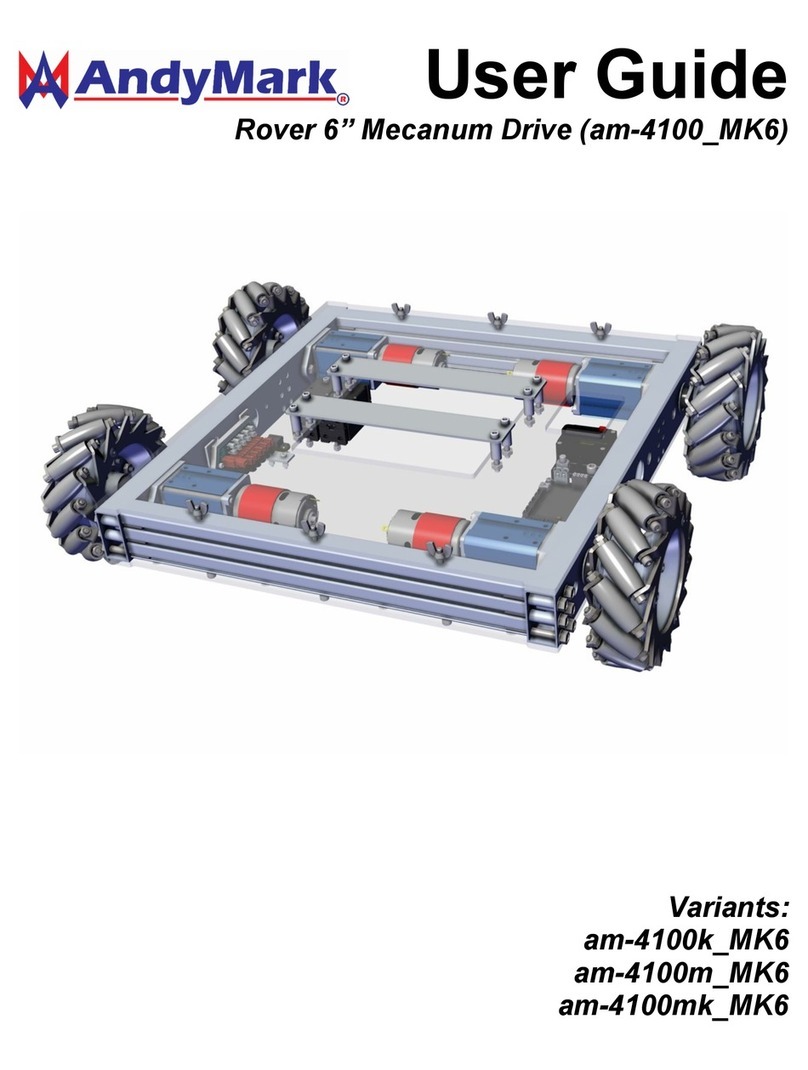

AM14U5 System Overview

The AM14U5 system designed by AndyMark engineers is a fully customizable drive platform for the FIRST® Robotics

Competition. The Kit of Parts Drive Chassis is a 6-Wheel Drive (6WD) AM14U5 configuration engineered to withstand

the rigors of this year’s game challenge. The AM14U5 Drive Chassis Kit includes standard AndyMark products and is

designed to be compatible with other AndyMark products. There are many ways to use the parts included in this kit.

•Utilize these step by step instructions to quickly build the standard drive chassis.

•Take advantage of convenient built-in features to convert to another pre-engineered drive solution.

•Take the existing parts and pieces included and re-design them in a new way

Gearbox Overview

Each AM14U5 Chassis Base Kit includes two (2) AndyMark Toughbox Mini Gearboxes, unassembled (am-2598). Each

Toughbox Mini includes the parts needed to mount two 2.5” CIM motors (am-0255) or NEO Brushless Motors (am-

4258). The gearbox also includes holes for optional encoders such as the USDigital E4T Optical Encoder (am-3132) or

REV Thru Bore Hex Encoder (am-4650) on both the inside and outside of the chassis.

]

Gear Ratio Specifications:

To change the drive speed of the AM14U5, different gear ratios can be used in the Toughbox Mini. To change the ratio

and drive speed, the standard 16 tooth Small Cluster Gear and 48 tooth Large Output Gear will need to be replaced

with two gears totaling 64 teeth. The higher the ratio, the slower the output speed.

More information about these optional gears can be found at "AndyMark.com/TBmini".

**AM14U5 speed estimation is based on calculations using 6” wheels, and one CIM motor per TB Mini running at 4100 rpm, or 75% of free speed.

(am-0034)

(am-0149)

(am-0177)

(am-0178)

(am-0034)

(am-0149)

(am-2564)

(am-2565)

(am-0034)

(am-0149)

(am-0176)

(am-0179)

(included)

(am-0034)

(am-0149)

(am-0747)

(am-0885)

(am-0034)

(am-0149)

(am-0151)

(am-0150)

∙ Gear Profile: 20 DP, 14.5° pressure

angle

∙ Gear Material: Cold-formed 4140

Steel

∙ Output Shaft: 1/2” Hex, 4140 Steel

∙ Housing Material: Nylon 6/6 with

long fiber reinforcements

Toughbox Micro

For use with Mecanum