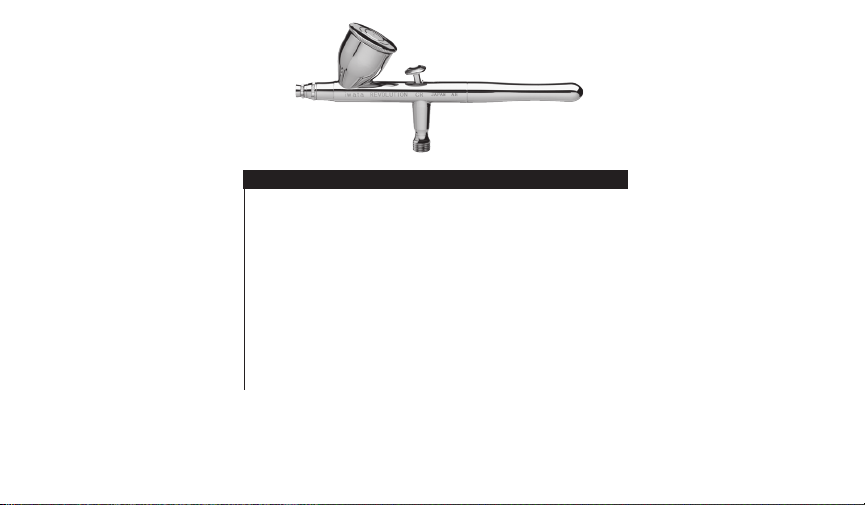

Wide-Line and Background Spraying (SAR)

1. Depress the main lever (#7).

2. Position the airbrush farther away from the surface, from

1/2 to 6 inches is common.

3. Unscrew the fluid adjustment knob (#15) back much

farther releasing more paint to cover the bigger area.

Increase the distance between the airbrush and painted surface

to control the line’s width. Increasing the air pressure will also

effect the spray width.The Revolution’s maximum usable line

width is approximately 2-1/2 inches.

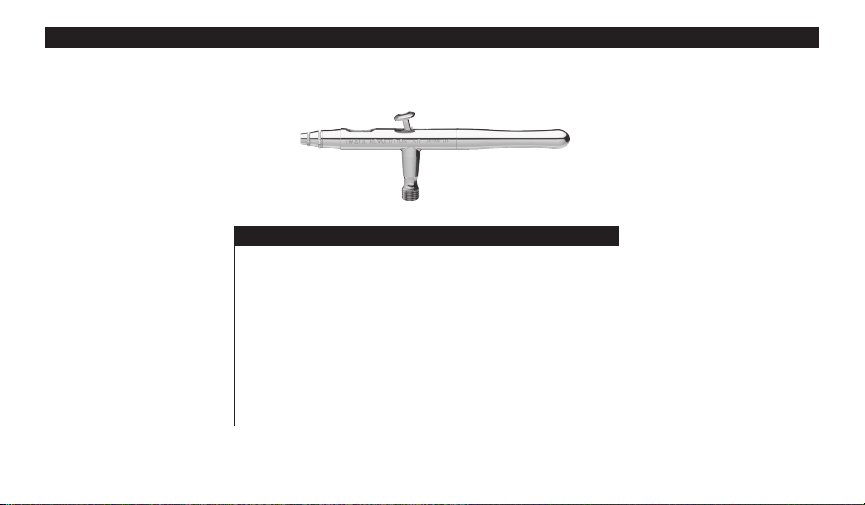

Ergonomic Handle

The ergonomic handle (#13 and #14) is a special feature

on the Revolution. It helps prevent fatigue from extended

airbrush use and provides a balanced feel in your hand.

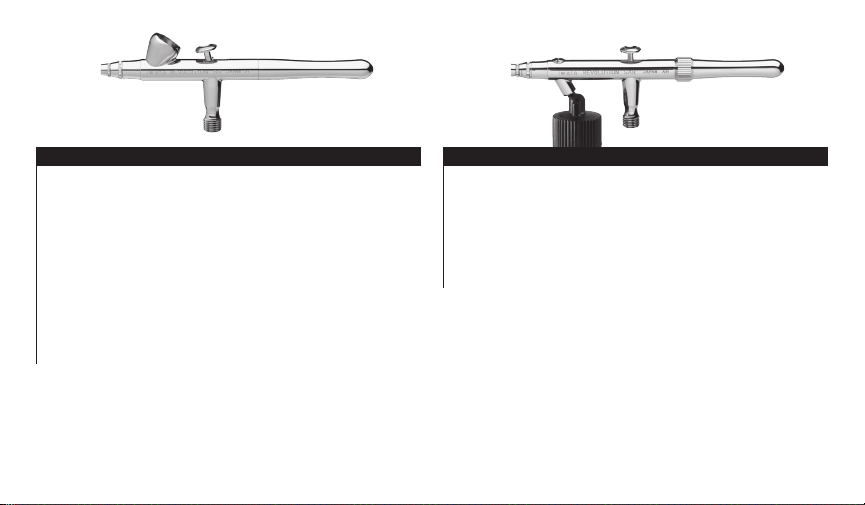

Stippling

Iwata airbrushes are designed to produce a wide range of

stippling textures.

1. Unscrew the needle cap (#1).

2. Unscrew the nozzle cap (#2).

3.Adjust the air pressure between 5 and 50 psi.

Lower air pressure will give you coarse stipple whereas higher

pressure will provide a ne stipple effect. Paint viscosity will

also effect the stippling texture.

Air Pressure

For the Revolution, working pressures generally vary between

20 and 60 psi, depending on what type of work is being done

and what textures are desired. A good working pressure may

average around 25 psi. The viscosity of the paint and your

desired spray characteristics will also effect your ideal pressure.

As a general rule, larger amounts of paint or thicker paints,

will be sprayed with higher pressures.

WARNING: Do not exceed 100psi.

Paint Preparation

For non-specic airbrush paints proper preparation, including

ltering the paint through a nylon mesh, is recommended for

best performance. Paint should be thinned with its proper

solvent. It is best to prepare paint relatively thin and make

repeated passes across the work to achieve the desired

shade. This will also improve the quality of your work and

decrease the cleaning time of your airbrush.

Safety Tips

• Always spray in a well-ventilated area.

• Do not spray solvent-based (flammable) paints around open flames.

• Use the appropriate respirator to safely lter out the paint

vapors particular to the kind of paint you are using.

• Wear eye protection to prevent paint contact with eyes.

• Never use air pressure that exceeds the airbrush’s limit. (98 psi)

GENERAL OPERATION

10