2

1. Carefullyexaminetheshippingcontainerforexternaldamage. When damage isnoted,notifythe

deliverycarrier immediately. Saveallpackingmaterialsfor damageclaim examination.

2. Ifnoexternaldamageisnoted,remove theshippingcontainerfromthefilterand examinetheunit

carefullyfordamage. Place thefilterin asafelocation,if damageisnoted,sothat thefreightdamage

claimsadjustercanexamineit.

SHIPPING CONTSHIPPING CONT

SHIPPING CONTSHIPPING CONT

SHIPPING CONTAINER INSPECTIONAINER INSPECTION

AINER INSPECTIONAINER INSPECTION

AINER INSPECTION

NOTE: A Parts List for each Anets Filter System is among the items shipped with each unit. If an

additional copy of this list is needed, please contact the factory as directed on the back cover.

Models CoModels Co

Models CoModels Co

Models Covv

vv

verer

erer

ered Byed By

ed Byed By

ed By TT

TT

This Manhis Man

his Manhis Man

his Manualual

ualual

ual

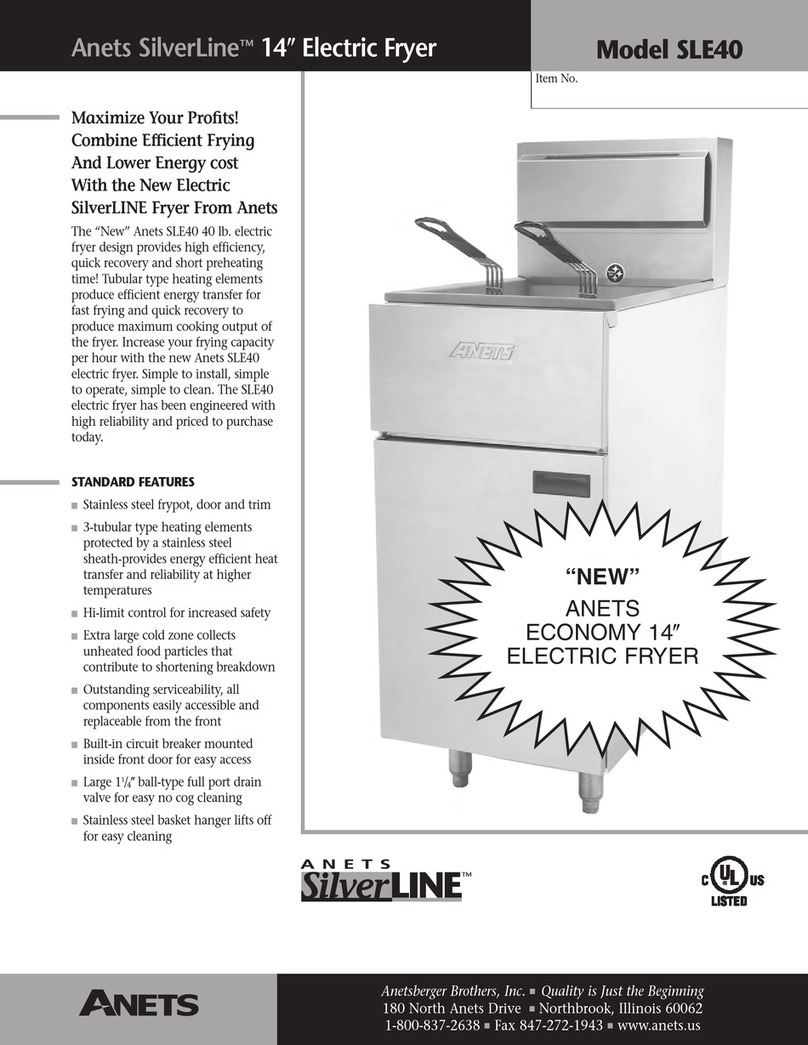

FM-14 Filter Mate, Under Fryer Filter System - 14”

FM-18 Filter Mate, Under Fryer Filter System - 18”

Filt II-14 14” Filtronic Filter System in Cabinet

Filt II-14W 14” Filtronic Filter System with Heat Lamp

Filt II-18 18” Filtronic Filter System in Cabinet

Filt II-18W 18” Filtronic Filter System with Heat Lamp

StandardAccessories furnishedinthe shippingcarton withthis filterinclude:

(1) FilterScreenAssembly

Box of Filter Paper (100 pcs.)

OtheravailableOptionalequipment may includeaseparatehose assemblyforshorteningremoval anda

cleaningbrush. These would be packed withthe fryers,if ordered.

TABLE OF CONTENTS

ShippingContainerInspection ....................................................... 2

CodeRequirements ...................................................................... 2

FilterUnitPreparationInstructions ................................................ 3

FilterSystemDiagrams .................................................................. 4

FilteringInstructions ...................................................................... 5

OilDisposalInstructions ............................................................... 6

ReplacingTheFilterPaper ............................................................ 7

FilterTroubleshootingGuide .......................................................... 8

FilterWarranty .............................................................................. 9

DD

DD

DANGERANGER

ANGERANGER

ANGER

Read these specifications, Code Requirements, Installation Requirements, Installa-

tion Instructions, and Operating Instructions very carefully. Failure to follow the Instruc-

tions could cause the filter system to malfunction. A filter system malfunction can result

in property damage, serious bodily injury, or death.

!