42 05/2008 Rev. 0.6

CONTENT

PREFACE.....................................................................................................................................44

1. BASIC FUNCTIONING ..........................................................................................................45

1.1 Boiler System...................................................................................................................46

1.2 Temperature regulation....................................................................................................46

1.3 Hot water dispensing .......................................................................................................46

1.4 Cold water dispensing (optional) .....................................................................................46

1.5 Ingredients and mixer system..........................................................................................46

1.6 Evaporation extractor system ..........................................................................................47

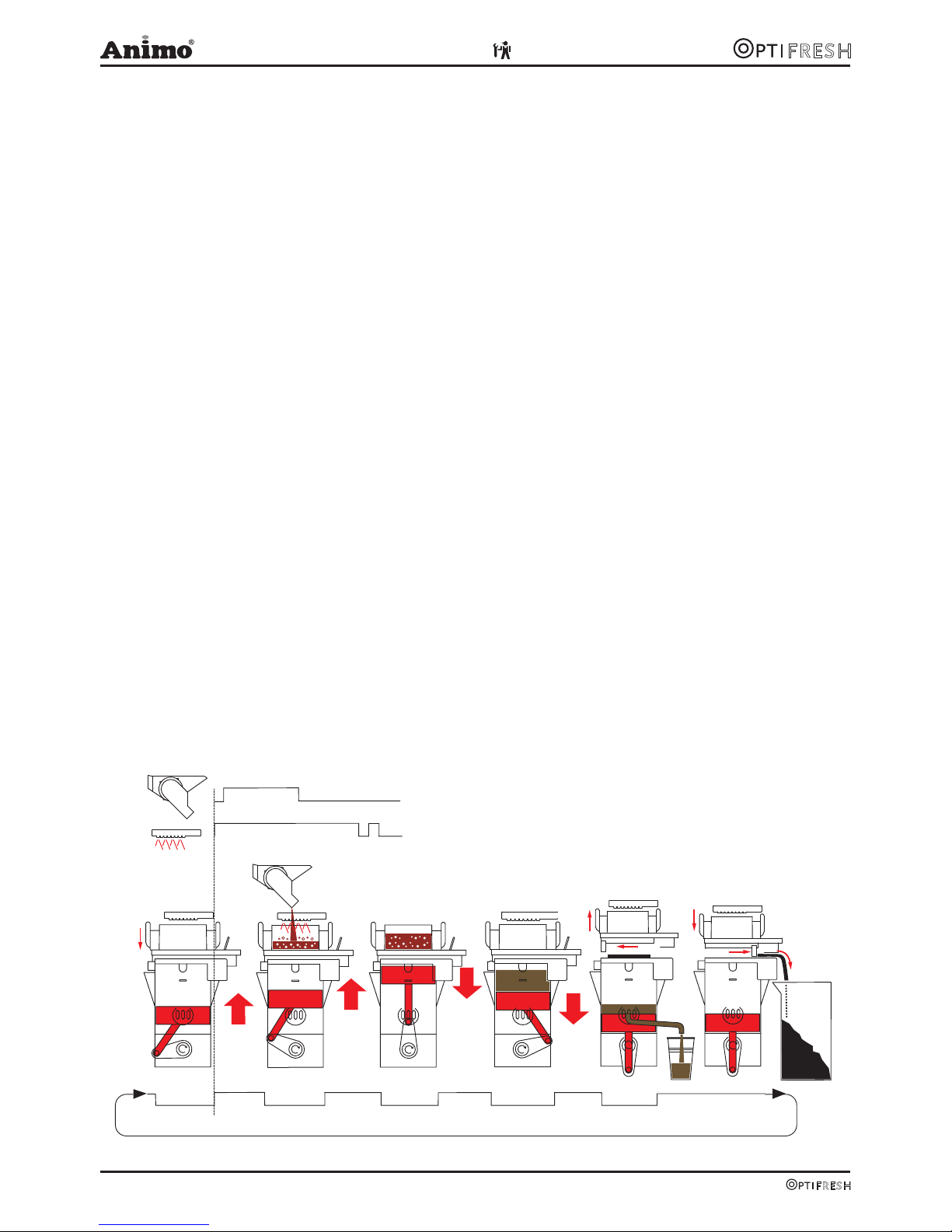

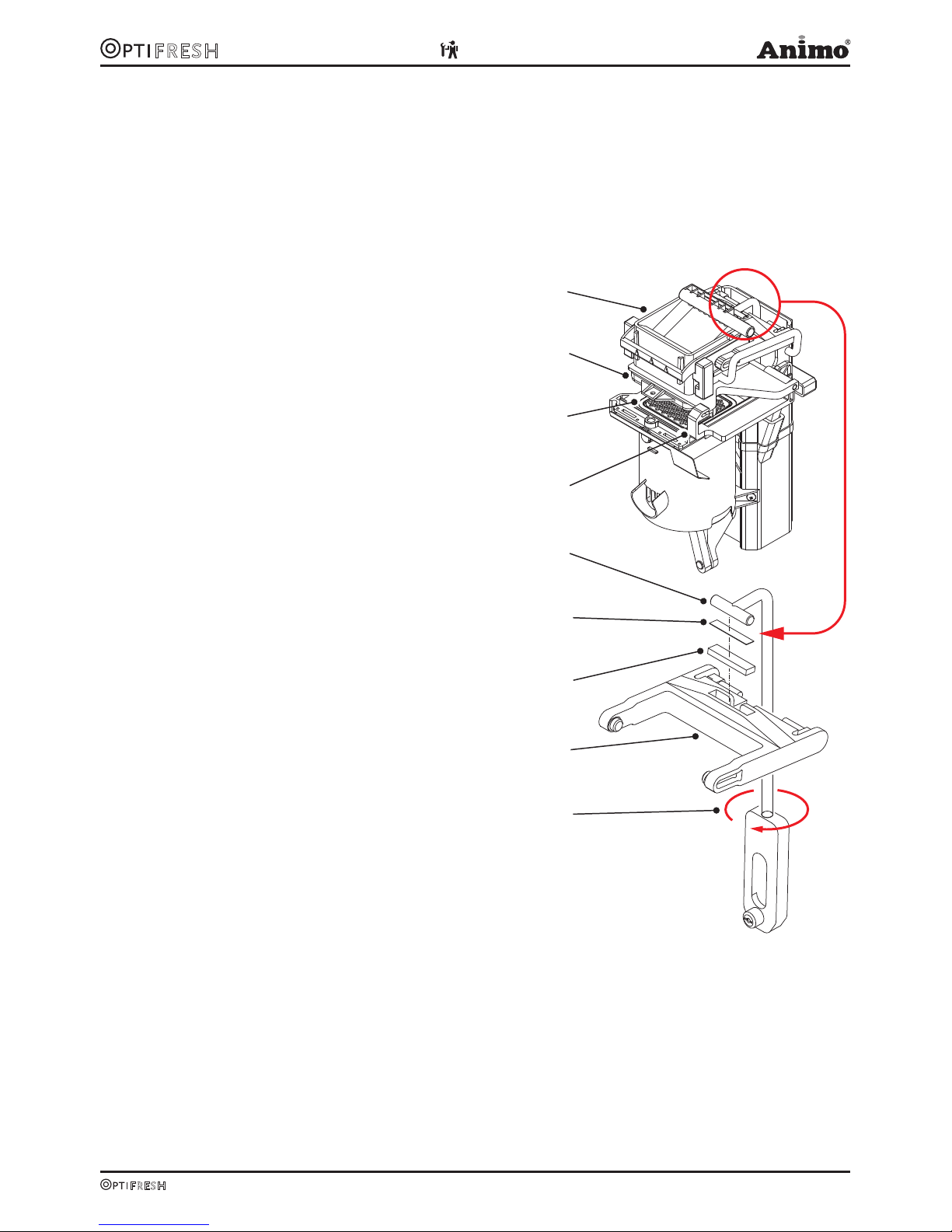

1.7 Brewer unit.......................................................................................................................47

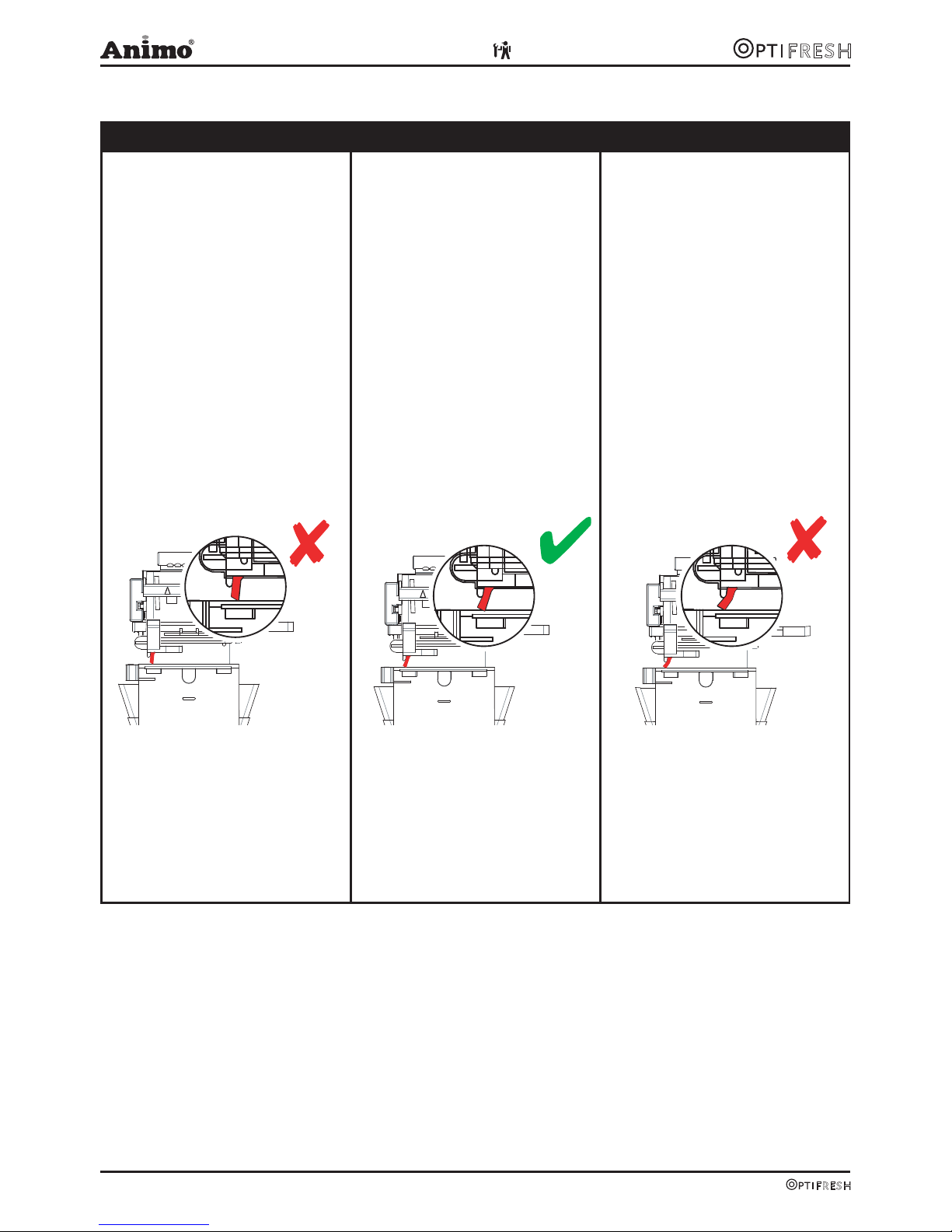

1.7.1 Adjustment.............................................................................................................48

1.7.2 Setting tips.............................................................................................................49

1.7.3 Troubleshooting.....................................................................................................50

2. MENU STRUCTURE .............................................................................................................51

2.1 The operator/service menu..............................................................................................51

2.2 The operator menu ..........................................................................................................52

2.3 The service menu ............................................................................................................53

3. RECIPE SETTINGS...............................................................................................................61

3.1 Quick recipe.....................................................................................................................61

3.2 Model code system ..........................................................................................................61

3.3 Button settings.................................................................................................................62

3.3.1 Standard canister configuration..............................................................................62

3.3.2 Different canister configuration...............................................................................63

3.4 Detailed recipe settings....................................................................................................62

3.5 Timebar recipe settings....................................................................................................62

3.6 Calibrating the hot water valves.......................................................................................64

4. SOFTWARE ..........................................................................................................................65

4.1 Memory card ....................................................................................................................65

4.2 Installing software............................................................................................................65

4.3 Installing a language........................................................................................................65

5. SERVICE ..........................................................................................................................96

5.1 Setting a service parameter.............................................................................................66

5.2 Preventative maintenance ...............................................................................................66

5.2.1 Service contracts...................................................................................................66

5.2.2 Servicing................................................................................................................67

5.3 Descaling instructions......................................................................................................68