4.3 The Service menu......................................................................................................... 36

[2.1] Quick recipe pro

[2.2] Button settings

[2.3] Recipe settings...................................................................................... 38

Recipe settings (continued)................................................................... 39

[2.4] Settings ................................................................................................. 40

Settings (continued) ............................................................................. 41

Settings (continued) / [2.5] Reset counters ........................................... 42

[2.6] Service boiler ........................................................................................ 43

[2.7] Hardware test ....................................................................................... 44

Hardware test (continued) .................................................................... 45

[2.8] Read log / [2.9] Clear log / [2.10] Load defaults / [2.11] SD menu ....... 46

SD menu (continued) / [2.12] Change PIN ........................................... 47

[[2.16] Rinsing management............................................................................ 48

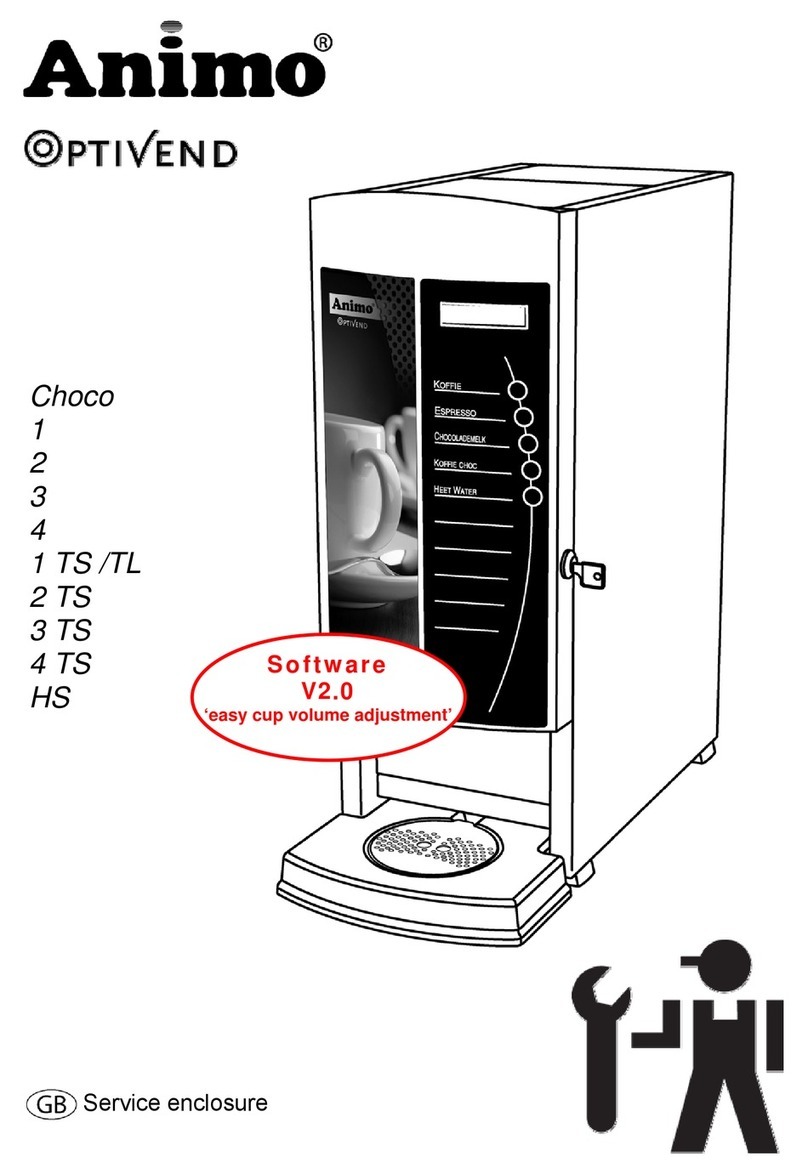

5. SOFTWARE .............................................................................................................. 49

5.1 Memory card specs

5.2 Machine settings management

5.3 Software installation

6. MAINTENANCE .............................................................................................................. 51

6.1 Daily rinsing program

6.2 Periodic maintenance.................................................................................................... 52

6.2.1 Service boiler

6.2.2 Service contracts ............................................................................................. 53

6.2.3 Servicing

6.3 Descaling instructions ................................................................................................... 55

7. TRANSPORT / STORAGE.................................................................................................... 59

8. COMPONENT ACCESSIBILITY ........................................................................................... 60

9. ELECTRONICS SUMMARY ................................................................................................. 62

9.1 Main control

9.1.1 Main circuit board inputs.................................................................................. 63

9.1.2 Main circuit board outputs ............................................................................... 64

9.1.3 Main circuit board communication ................................................................... 65

9.2 Interface / Display ......................................................................................................... 66

9.2.1 Connections

9.3 Power supply................................................................................................................. 67

9.3.1 Connections

10. FAULT ANALYSIS ................................................................................................................. 68

10.1 Read log

10.2 Clear log

10.3 Display messages during use ....................................................................................... 69

10.4 Fault analysis ................................................................................................................ 71