Warning

Users must provide this instructions to the authorized persons. Then read and understand it carefully before use this equipment.

This User Instruction is not to be removed except by the user of this equipment.

Current User Instruction must always be available to the user.

Positioning lanyard is used to connect the safety harness or positioning belt to an anchorage point prevent the user reaching a

position where a fall is possible.

Lanyard used for "Positioning" should be of such a length or adjusted to such a length that a fall situation can’t occur.

Lanyard used in "work positioning" is designed to support the user when working at height and when needing a hands free

environment.

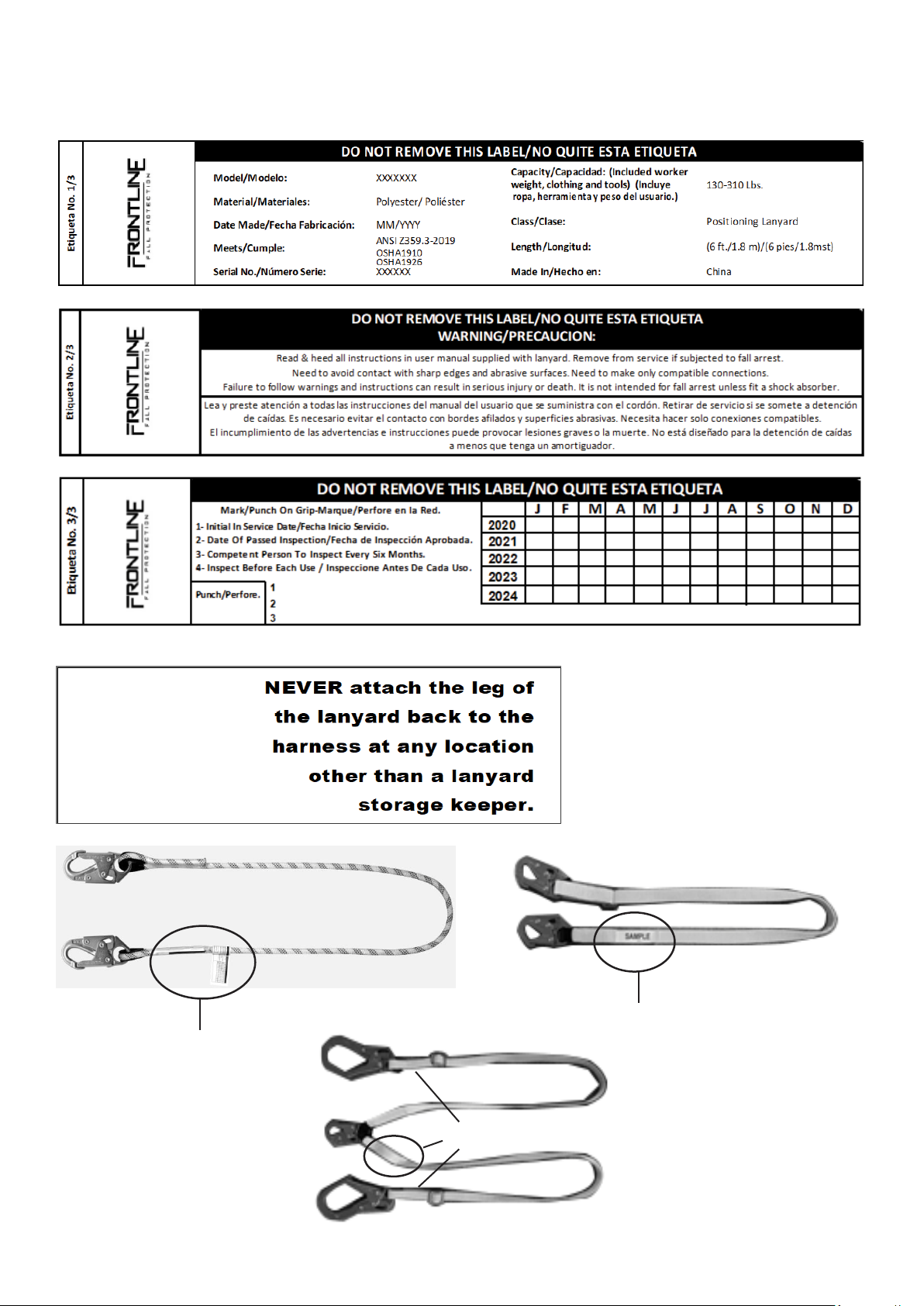

Do not wrap the Positioning lanyards around any structure and connect the lanyard back onto itself, unless the lanyard has been

specifically designed to do so.

The regulations included herein are for reference only. They are not all-inclusive and not intended to replace a Competent Person’s

judgement or knowledge of federal or state standards.

The analysis of the workplace must anticipate where workers will be performing tasks, the routes they will take to reach their tasks,

and the potential/existing exposure to fall hazards.

Work positioning equipment must be chosen by a Competent Person. Selections must account for all potential hazardous

workplace conditions.

All work positioning equipment should be purchased in a new and unused condition.

Select and install work positioning systems under the supervision of a Competent Person. Work positioning systems must be used

in a compliant manner.

Work positioning systems must be designed in compliance with all federal, state, and local safety regulations.

Forces applied to anchors must be calculated by a Competent Person.

Harnesses and connectors selected must be compliant with manufacturer’s instructions and must be of compatible size and

configuration.

A pre-planned rescue procedure is required as part of a complete work positioning program. The rescue plan must be project

specific. The rescue plan must either allow for employees to rescue themselves or provide an alternative means for their prompt

rescue. Store rescue equipment in an easily accessible and clearly marked area.

A Competent Person must train Authorized Persons to correctly erect, disassemble, inspect, maintain, store, and use equipment.

Training must include the correct use of personal fall arrest systems, the ability to recognize fall hazards, and how to reduce the

dangers of fall hazards.

Do not misuse positioning lanyard, NEVER use any work positioning equipment to hang, lift, support, or hoist tools or equipment

unless that equipment is explicitly certified for such use.

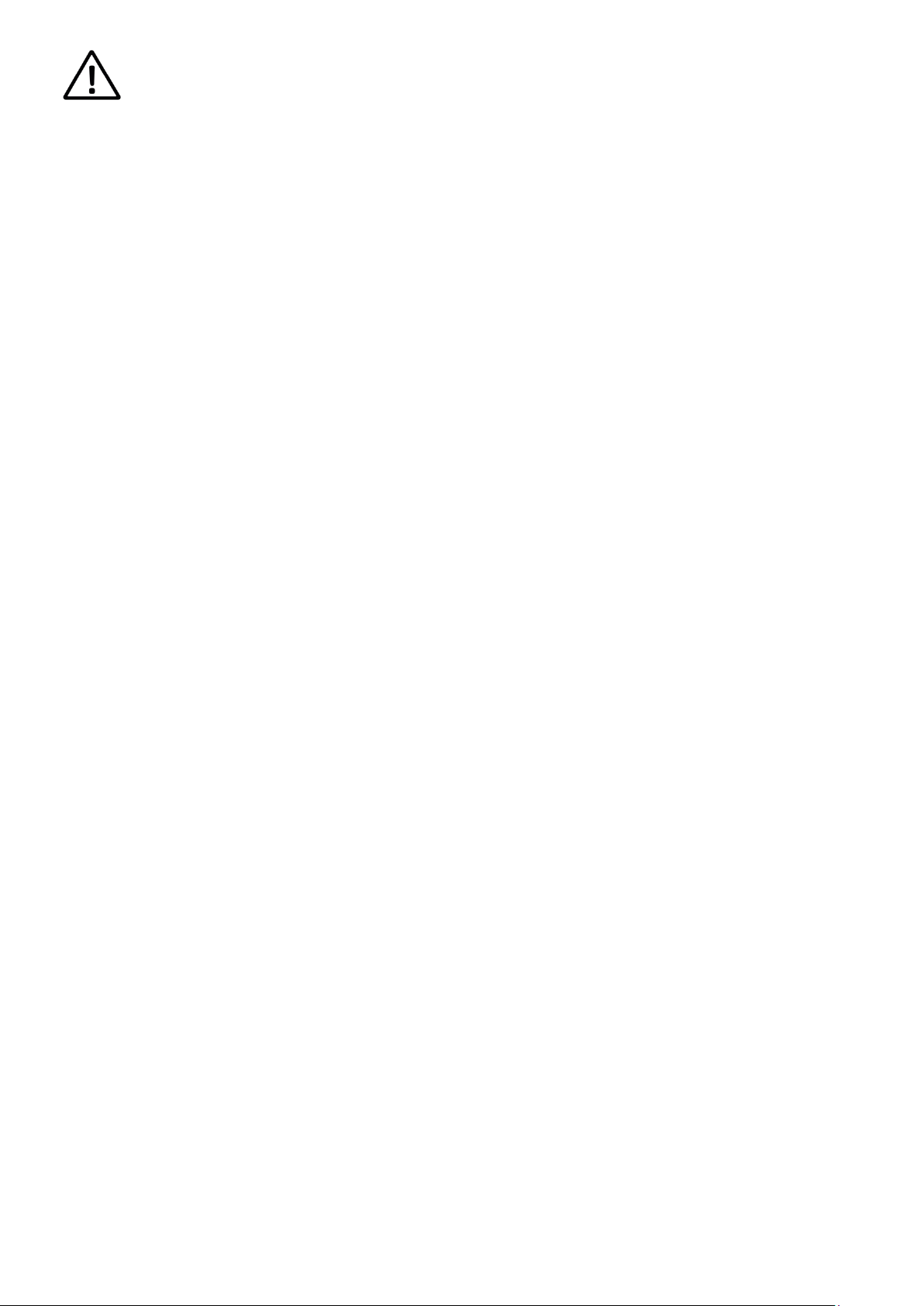

Equipment must be inspected for defects including (but not limited to): the absence of required labels or markings, improper

form/fit/function, evidence of cracks, sharp edges, deformation, corrosion, excessive heating, alteration, excessive wear, fraying,

knotting, abrasion, and absence of parts. Equipment that fails inspection in any way must immediately be removed from use or

repaired by an entity approved by Frontline.

Physical harm may still occur even if fall safety equipment functions correctly.

Do not remove or alter the labels when using this equipment.

Do not alter this equipment unless explicitly permitted by Frontline.

Do not use this equipment around moving machinery and electrical hazards.

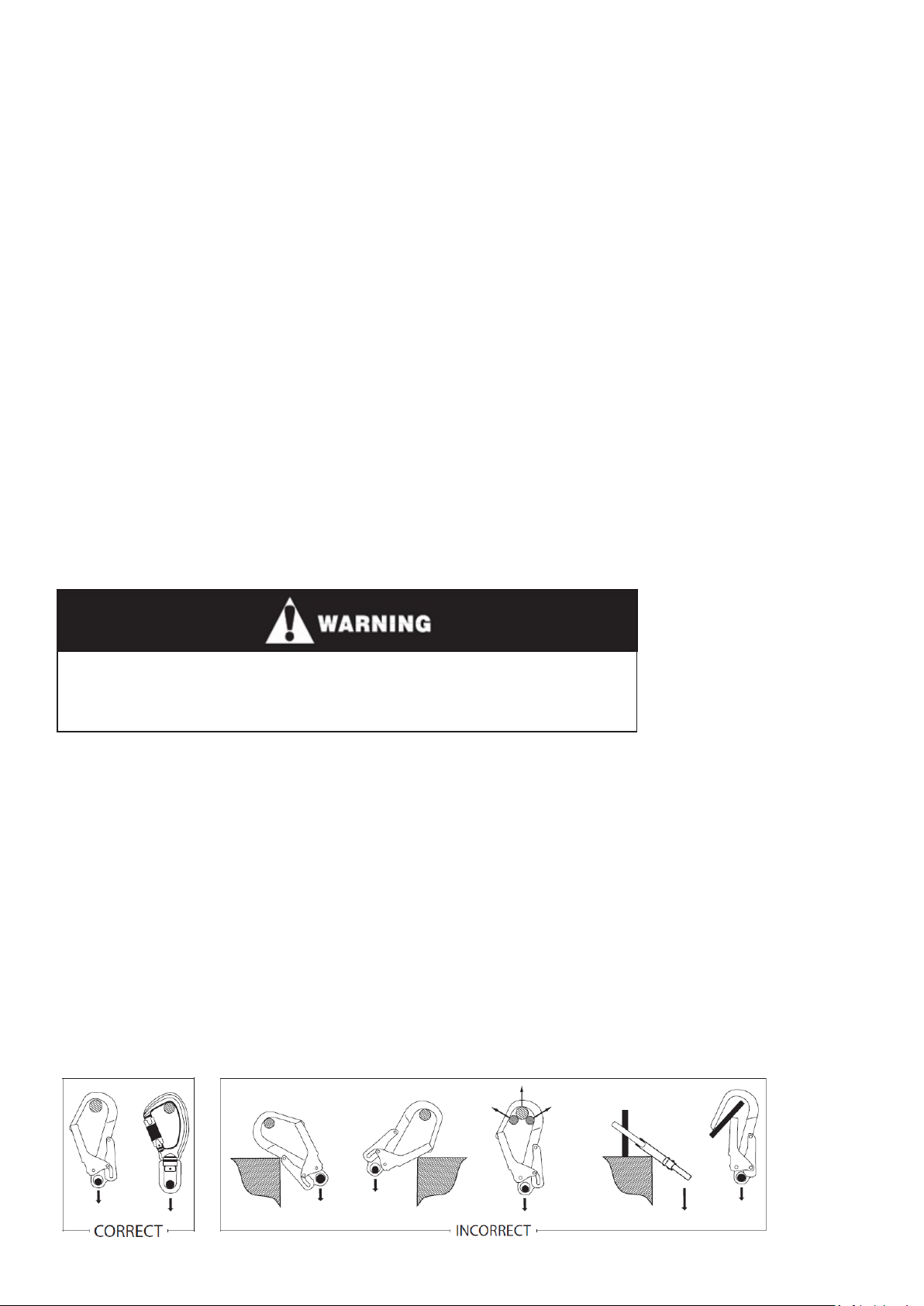

Do not use this equipment near sharp edges and abrasive surfaces.

Do not expose this equipment to chemicals which may produce a harmful effect and to consult with Frontline in cases of doubt.

Do not use combinations of components or subsystems or both which may affect or interfere with the safe function of each other.

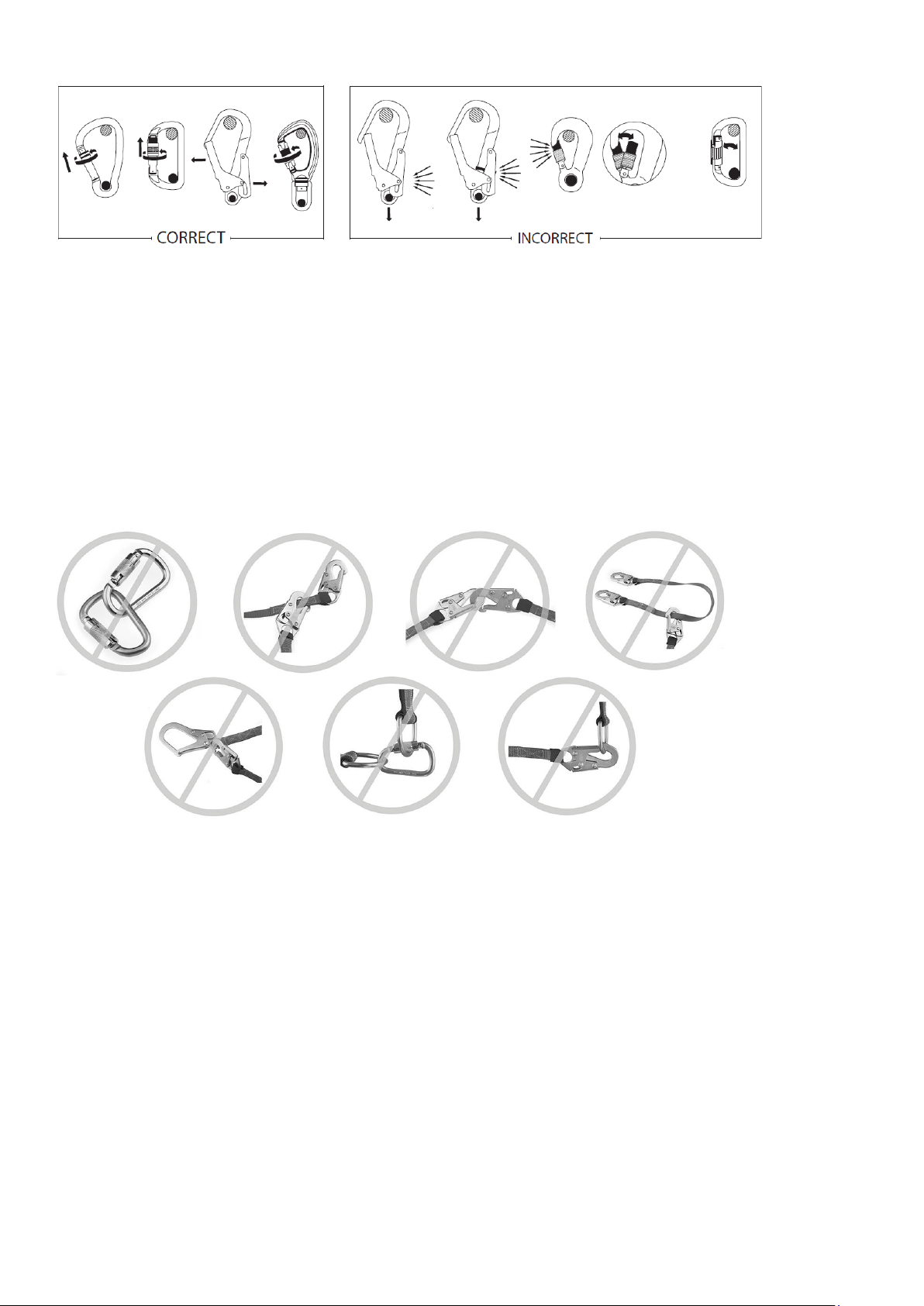

When using the positioning lanyard, need to make only compatible connections and limitations of compatibility.

When using the positioning lanyard, must use in conjunction with a fall arrest system, such as work positioning or restraint system.

When using the positioning lanyard, shall proper method of coupling the connector and checking that it is closed and locked.