INGAL ArmorBuffa MASH TL3 COMPLIANT User manual

www.ingalcivil.co.nz

Release 08/22

Product Manual

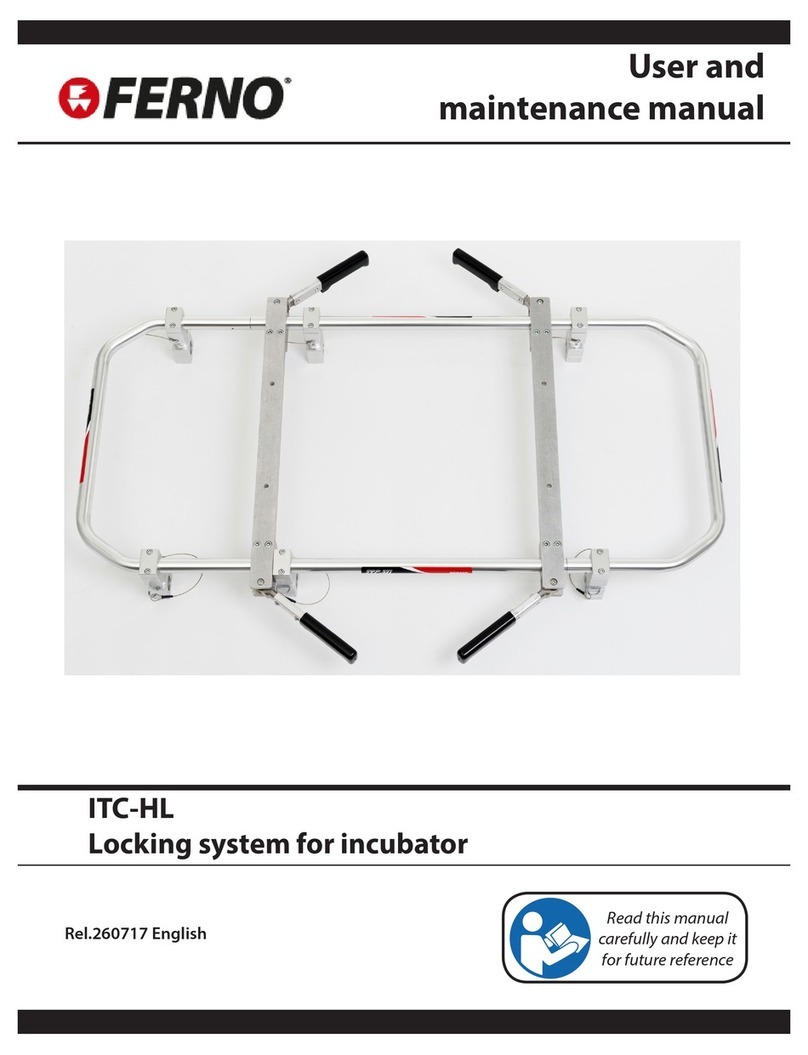

ArmorBua™

MASH TL3 Temporary End Treatment

MASH TL3

Australian State Road Authority approved for use in speed zones up to 80km/h

2

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

1.0 Introduction

The ArmorBua™ is a non-redirective, gating, crash

cushion designed to meet the latest test standards

dened in the Manual for Assessing Safety Hardware

(MASH), Second Edition, 2016. The ArmorBua™ system

utilises a Transition, water-lled Elements and a Nose

Piece to absorb kinetic energy and safely contain

or control the penetration trajectory of impacting

vehicles.

The system is comprised of a Nose Piece, water-lled

Elements, Pins, a Transition and mechanical anchors. All

Elements are always lled with water.

The system has a nominal 1100mm height, 460mm

width, and an eective length of 9,313mm for TL-3

when installed on a temporary concrete barrier.

ArmorBua™ is designed to protect the end of an

unanchored temporary F-Type concrete barrier.

2.0 Recommended Tools

NOTE: The list of tools, safety equipment, and trac

control is a general recommendation and should

not be considered a comprehensive list. Depending

on the specic characteristics of the job site and the

complexity of the repair or assembly, more or less tools

may be necessary.

Required Tools

• Tape Measure • Compressed Air

• Chalk Line • 3/4” Diameter Brush

• Marking Paint • 1/2” Drive Deep Sockets

M20, M16, M36

• Rotary Hammer • Impact Wrench

(pneumatic or electric)

• Masonry Bit 16mm x 200mm

• Torque Wrench

NOTE: Water source with a exible hose (maximum

76mm diameter) and a minimum 2800L capacity is

required for the 4 element, TL-3 system.

Safety Equipment

Trac Control

• Trac Control Equipment • Trac Control Plan

Gloves

Steel-Capped Footwear

Hard Hat

Safety Vest

Dust Mask

Safety Glasses

Hearing Protection

3

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

3.1 ArmorBua MASH TL3 Identication and Installation

3.0 Parts Identication

Use only Ingal Civil Products parts that are specied by Ingal Civil Products for use with

the ArmorBua™ System. The use of unspecied parts is prohibited and could result in

severe personal injury or death.

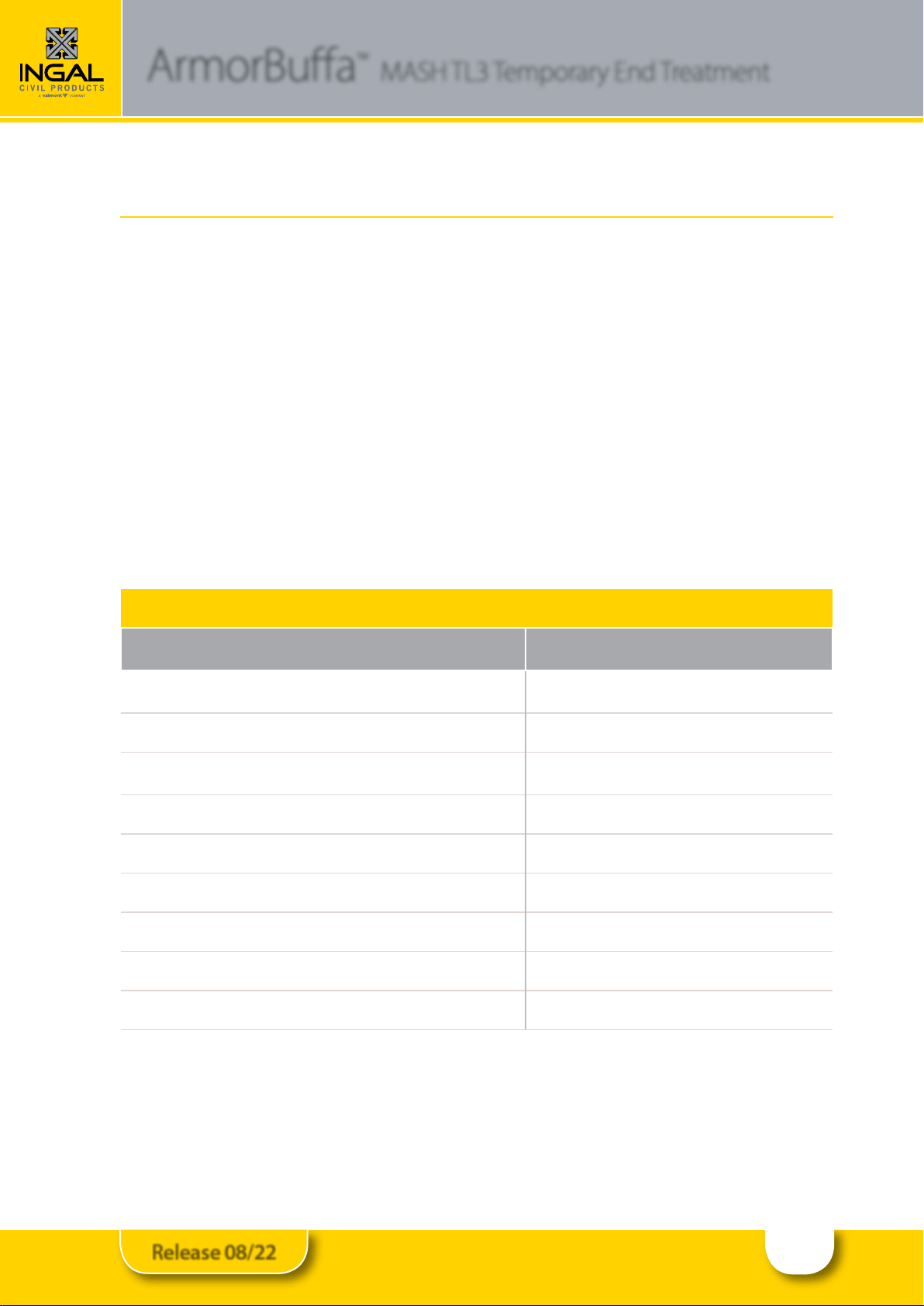

PART # DESCRIPTION CONCRETE

KIT

10200320 ArmorBua Transition F-Type Concrete 1

10200322 ArmorBua Element - Orange 1

10200323 ArmorBua Element - Yellow 3

10200324 ArmorBua Steel Nose Assembly 1

10200325 ArmorBua Nose Cover 1

10200326 ArmorBua Cable 1

10200327 ArmorBua Nose Pin 1

10200328 ArmorBua Asymmetric Pin 1

10200204 ArmorZone Pin 3

10200329 ArmorBua Transition F-Type Concrete Fixing Bolt Kit 1

10200045 ArmorBua MASH TL3 F-Type Concrete Kit - Complete

10200200 Drainage Bung

10200202 Bung Spanner 1

4

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

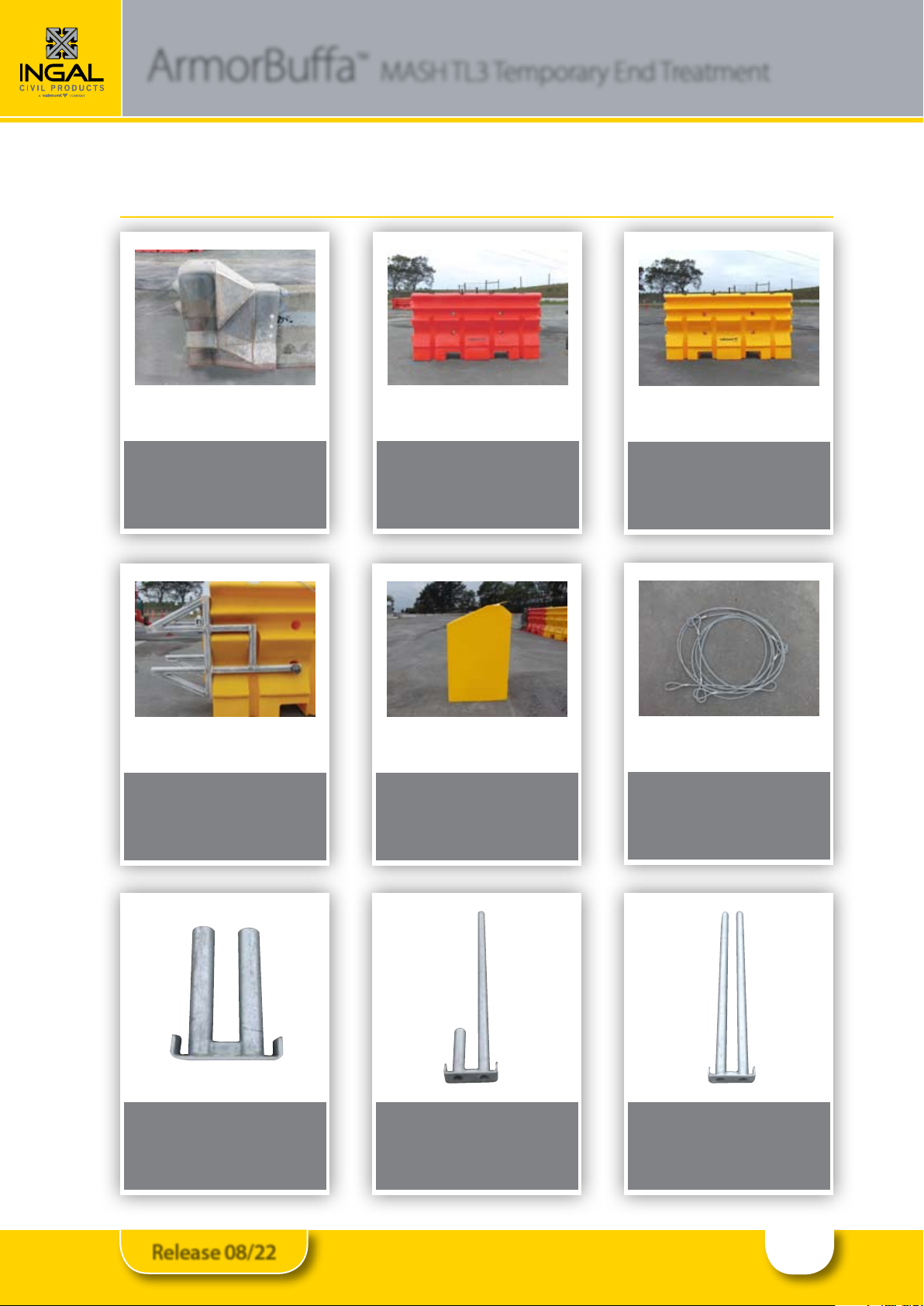

10200320

ArmorBua Transition F-Type Concrete

Concrete Kit: 1

10200204

ArmorZone Pin

Concrete Kit: 3

10200323

ArmorBua Element - Yellow

Concrete Kit: 3

10200326

ArmorBua Cable

Concrete Kit: 1

10200324

ArmorBua Steel Nose Assembly

Concrete Kit: 1

10200327

ArmorBua Nose Pin

Concrete Kit: 1

10200322

ArmorBua Element - Orange

Concrete Kit: 1

10200325

ArmorBua Nose Cover

Concrete Kit: 1

10200328

ArmorBua Asymmetric Pin

Concrete Kit: 1

3.0 Parts Identication (continued)

5

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

10200329

ArmorBua Transition F-Type

Concrete Fixing Bolt Kit

Concrete Kit: 1

10200202

Bung Spanner

10200045

ArmorBua MASH TL3 F-Type Concrete Kit

10200200

Drainage Bung

6

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

4.0 Preparation

4.1 Foundation

The ArmorBua™ system is designed to perform on a

variety of foundations including concrete, asphalt, and

any other surfaces capable of bearing the weight of the

system.

Uneven surfaces should be attened, and large debris

removed from the foundation prior to installation.

Cross slopes of up to 8% (5° or 1:12 slope) can be

accommodated with the standard hardware and the

instructions provided in this manual. For slopes in

excess of 8%, contact Ingal Civil Products.

4.2 Transition

ArmorBua™ is designed to accommodate a temporary

F-Type concrete barrier.

Placement and installation of the ArmorBua™

system must be accomplished in accordance with the

Austroads Design Guide and ASBAP and other state

and local standards.

Before installing the ArmorBua™ system, ensure that

all the materials required for the system are on site and

have been identied.

5.0 Documentation

Prior to installation and assembly of the ArmorBua™

system, ensure you have read and understand the

installation and assembly instructions. The following

items should be reviewed and understood prior to

installation.

Installation and Assembly Manual (check for current •

revision posted at www.ingalcivil.co.nz).

System Drawings (check www.ingalcivil.co.nz for•

current revision, located in installation manual).

6.0 Important Notes

Sign Convention•

The term Front = At the Nose Plate

The term Rear = At the Transition

This manual follows installation steps for a•

complete ArmorBua™ system that is installed on

site or relocated to another location.

See Page 16 for water lling instructions.

In regions where the water lled

elements could become frozen,

appropriate anti-freeze solutions

should be used.

Failure to do so will result in improper

performance of the system and may

cause serious bodily injury.

Care should be taken to ensure that appropriate Anti

-Freeze solutions are used in accordance with federal,

state, and local requirements.

7.0 Anchoring Specications

The ArmorBua™ system uses M16 x 150mm Excalibur™

Screw Bolts or equivalent for anchoring to temporary

concrete barrier.

7

Release 08/22

,'

'HVFULSWLRQ

3DUW1R

4W\

$UPRU%XIID7UDQVLWLRQ)7\SH&RQFUHWH

$UPRU%XIID(OHPHQW2UDQJH

$UPRU%XIID(OHPHQW<HOORZ

$UPRU%XIID6WHHO1RVH$VVHPEO\

$UPRU%XIID1RVH&RYHU

$UPRU%XIID&DEOH

$UPRU%XIID1RVH3LQ

$UPRU%XIID$V\PPHWULF3LQ

$UPRU=RQH3LQ

$UPRU%XIID7UDQVLWLRQ)7\SH&RQFUHWH)L[LQJ%ROW.LW

'=#VTJOFTT%FWFMPQNFOU=5FDIOJDBM-JCSBSZ=7BMNPOU)JHIXBZ=.FUIBOF=%SBXJOHT=.FUIBOF%SBXJOHT8*17JUPS='PS"QQSPWBM-FUUFST=

/%

-$

9%

7HPSRUDU\(QG7UHDWPHQW

$UPRU%XIIDWR--+RRNV

$50%--+

'5$:1

&+(&.('

$33529('

'5$:,1*180%(5

,7(0

&/,(17

0$7(5,$/

),1,6+

72/(5$1&(6

:KROH1XPEHUV

2QH'HFLPDO3ODFH

%HQG$QJOH

6WUDLJKWQHVV

5(9

'(6&5,37,21

$33'

'$7(

6FDOH

25,*,1$/,668(

9DOPRQW+LJKZD\7HFKQRORJ\

/HYHO%XLOGLQJ$7DODYHUD5RDG

0DFTXDULH3DUN16:$XVWUDOLD

7ZZZYDOPRQWKLJKZD\FRP

'0-%&3

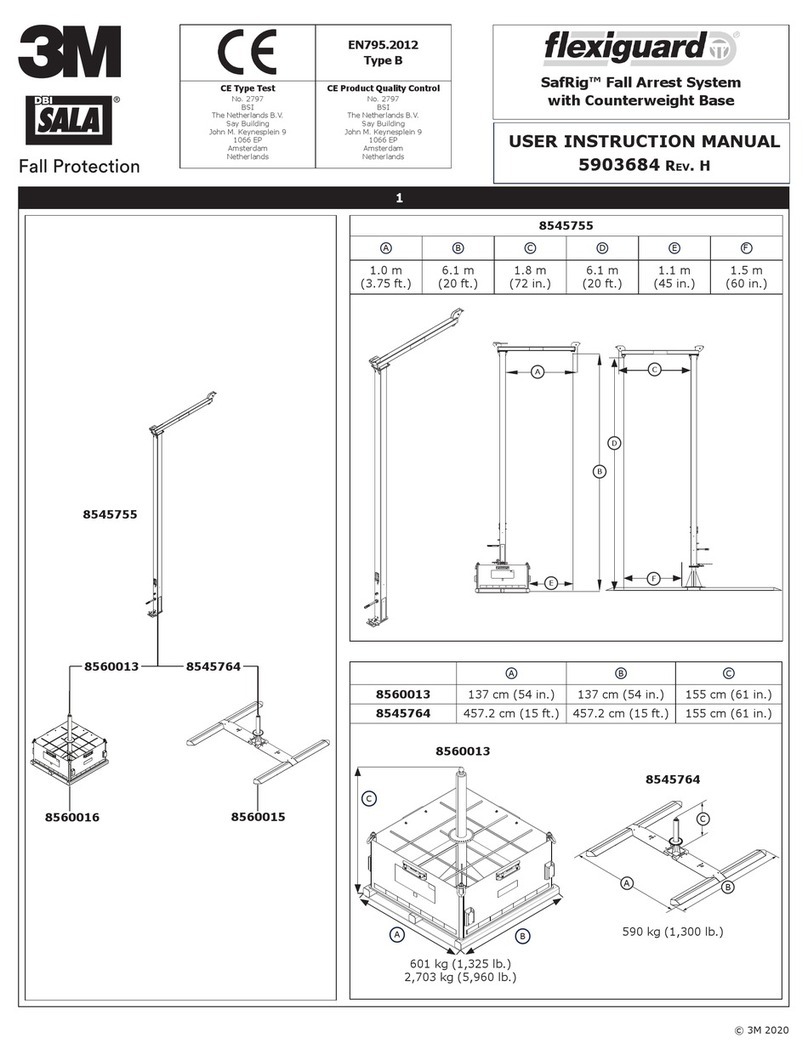

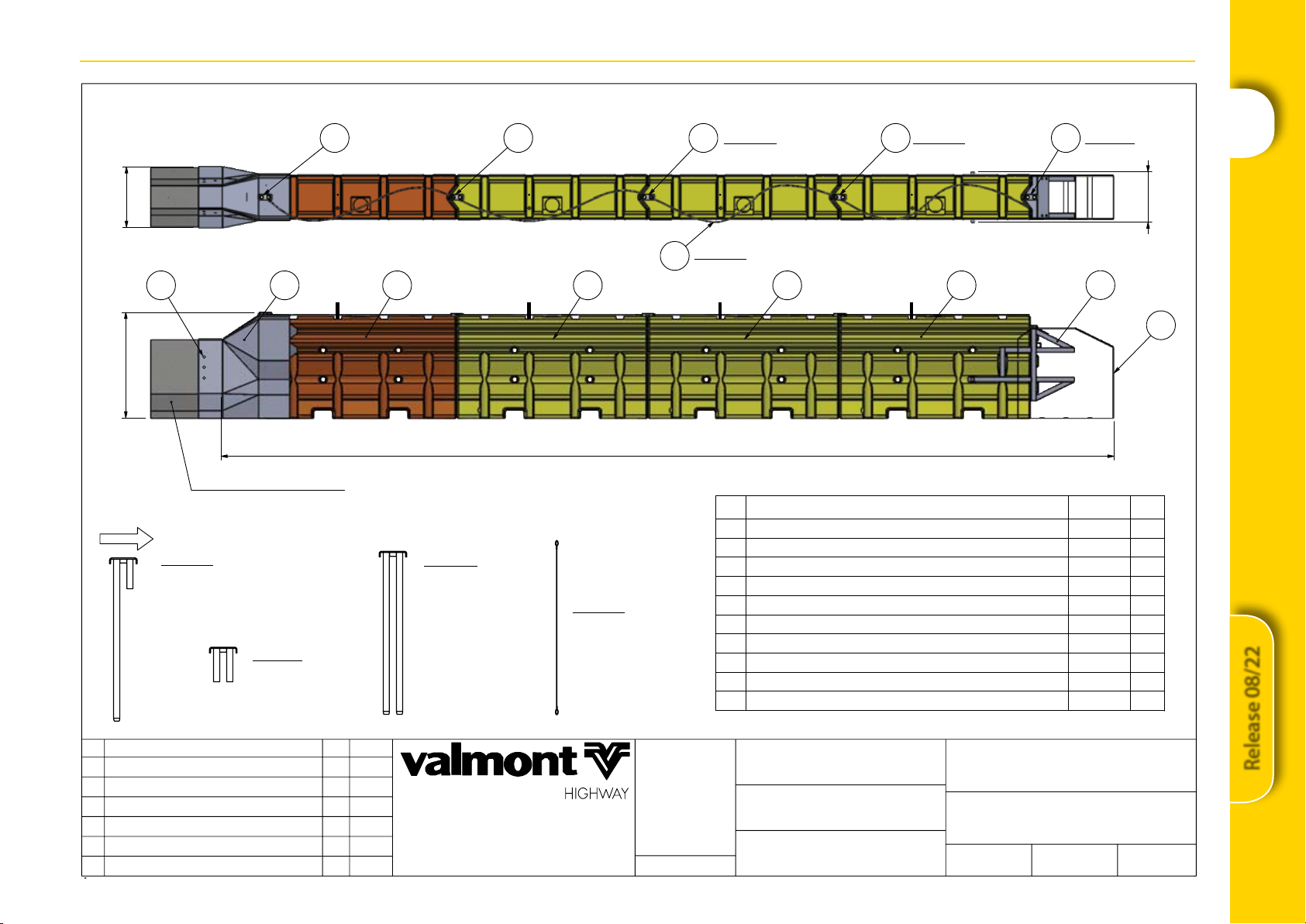

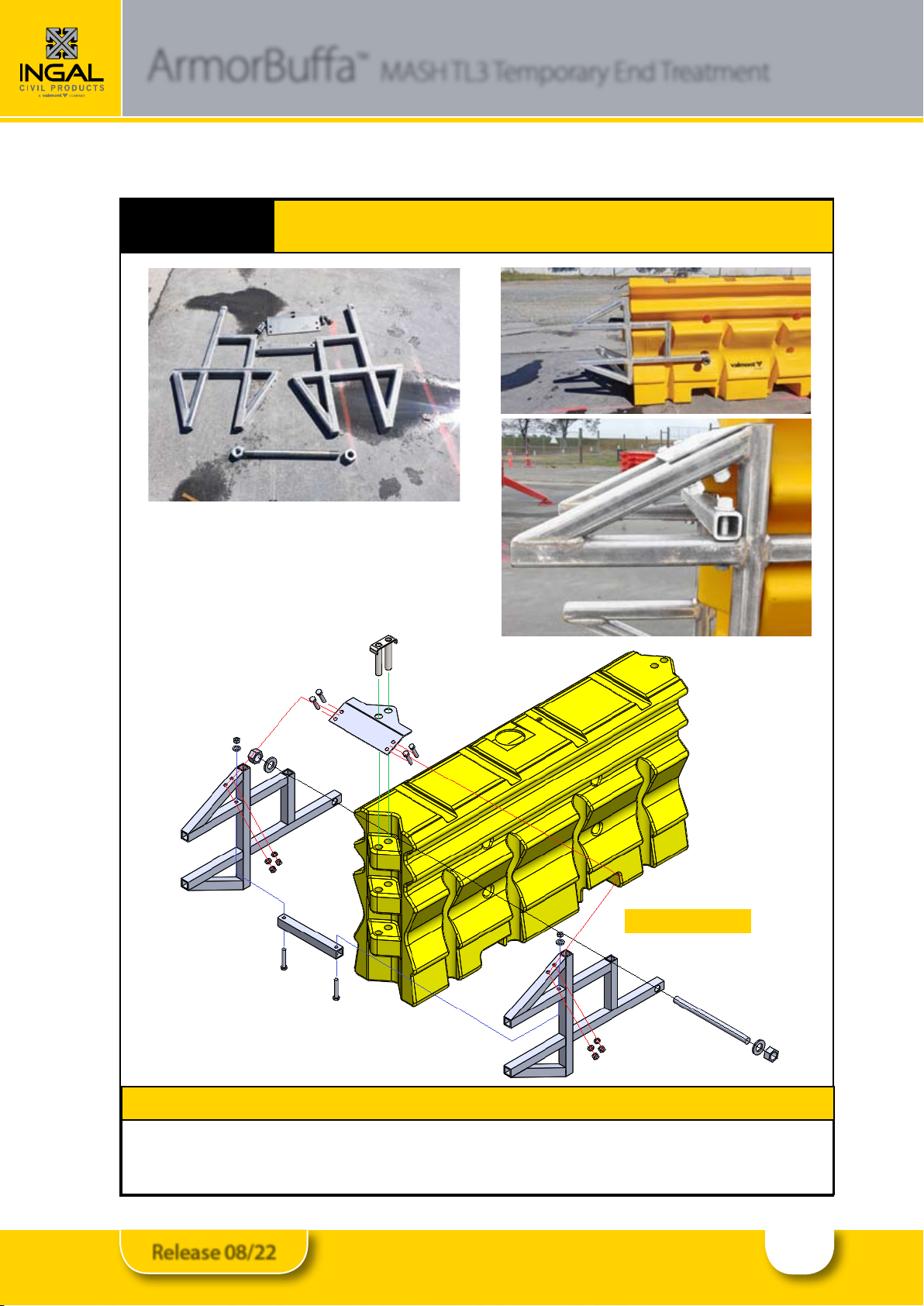

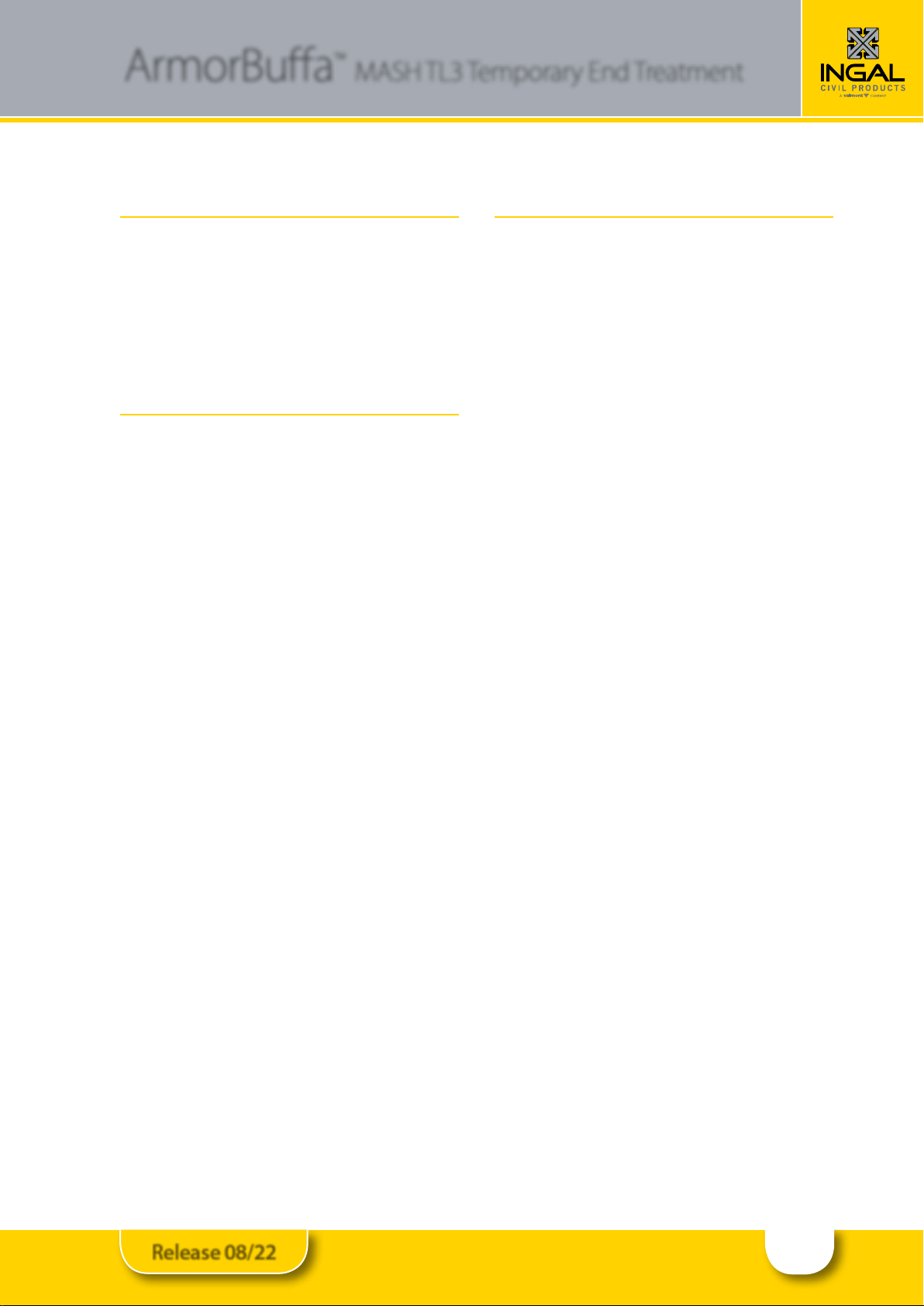

8.0 ArmorBua Exploded Assembly Overview

Important:

•AllpartsshownmustbeusedfortheArmorBuatoperformastested.

•Allpartsmustbeusedinthelocationsshown.

– Orange element must be installed into the transition.

– The 3 types of connector pins must be installed in the locations shown.

•Allelementsmustbecompletelylledwithwater.

•Allelementsmustbedrainedbeforemoving.

1

2

3

4

8

Release 08/22

9313

1100

Type-F Concrete Barrier

1 2 3 3 3 4

5

10

525

630

8 7999

6

Detail A

- Asymmetric Pin

orientation: short pin to the

front of the system.

Detail B

Nose Pin

Detail B

Detail A

Detail C

Detail C

ArmorZone Pin

Detail D

Detail D

ArmorBuffa Cable

(4x slings looped)

ID

Description

Part No.

Qty

1

ArmorBuffa Transition F-Type Concrete

10200320 1

2

ArmorBuffa Element - Orange

10200322 1

3

ArmorBuffa Element - Yellow

10200323 3

4

ArmorBuffa Steel Nose Assembly

10200324 1

5

ArmorBuffa Nose Cover

10200325 1

6

ArmorBuffa Cable

10200326 1

7

ArmorBuffa Nose Pin

10200327 1

8

ArmorBuffa Asymmetric Pin

10200328 1

9

ArmorZone Pin

10200204 3

10

ArmorBuffa Transition F-Type Concrete Fixing Bolt Kit

10200329 1

F:\Engineering\3. CURRENT DRAWINGS\COMPONENT DRAWINGS\SLDDRWs\10200045 - ArmorBua MASH TL3 F-Type Concrete Kit\

LB

JA

VB

F-Type Concrete KIT

ArmorBuffa MASH TL3

10200045

DRAWN

CHECKED

APPROVED

DRAWING NUMBER

ITEM

CLIENT

MATERIAL

FINISH

TOLERANCES

Whole Numbers :

One Decimal Place :

Bend Angle :

Straightness :

REV

DESCRIPTION

APPD

DATE

Scale:

ORIGINAL ISSUE - 23.10.2020

Valmont Highway Technology

Level 3, Building A, 11 Talavera Road

Macquarie Park, NSW 2113, Australia

T: +612 9814 1777 www.valmonthighway.com

FOLDER

8.1 ArmorBua MASH TL3 F-Type Concrete Kit

9

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

9.0 INSTALLATION PROCEDURE

STEP 1A Transition Fixing to Concrete F-Type

INSTRUCTIONS

1. Slide transition over the end of the temporary concrete barrier, ensuring it is pushed on as far as possible ush

up against the end of the barrier. Then mark the location of the 6 holes.

2. Remove the transition and drill 6 x 16mmx150mm holes as marked. If a hole cannot be drilled due to

encountering rebar, then the use of 2 screw bolts per side is permitted.

3. Slide the transition back into place and then screw in the 2 or 3 Excalibur™ bolts per side, rmly fastening the

transition to the barrier.

Wear proper PPE when clearing debris. This operation produces concrete dust.

Gloves

Dust Mask Safety Glasses Hearing Protection

10

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

STEP 2 Attachment to ArmorBua Elements

INSTRUCTIONS

1. Check the drain bung is tight so it will not leak.

2. Slide the orange element into the transition ensuring the element is orientated as shown in Note A with the

element end with the highest connecter lug inserted.

3. Insert standard twin pin into the transition holes, coupling the orange element and steel cable together, as

shown in Note B.

4. Slide the 3 yellow elements into position.

Note A

Note B

11

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

STEP 3 Adding ArmorBua Elements

INSTRUCTIONS

1. Pin the 3 yellow elements with the pins as shown, engaging the steel cable.

2. The the asymmetric pin must be used to connect the yellow elements 1 and 2.

4321

12

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

STEP 4 ArmorBua Nose Plate Assembly

INSTRUCTIONS

1. Bolt the steel nose onto the exposed end of yellow element No. 1, as shown above.

2. Tighten nuts and bolts to 50Nm.

Element No. 1

13

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

STEP 5 ArmorBua Steel Nose Assembly

INSTRUCTIONS

1. Fit the cable through the nose pin as shown in Note A.

2. Slide the yellow plastic nose cover into position and insert the nose pin through the nose cover into the

steel nose assembly as shown in Note B. Ensuring the pin engages the cable loop.

Note A Note B

14

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

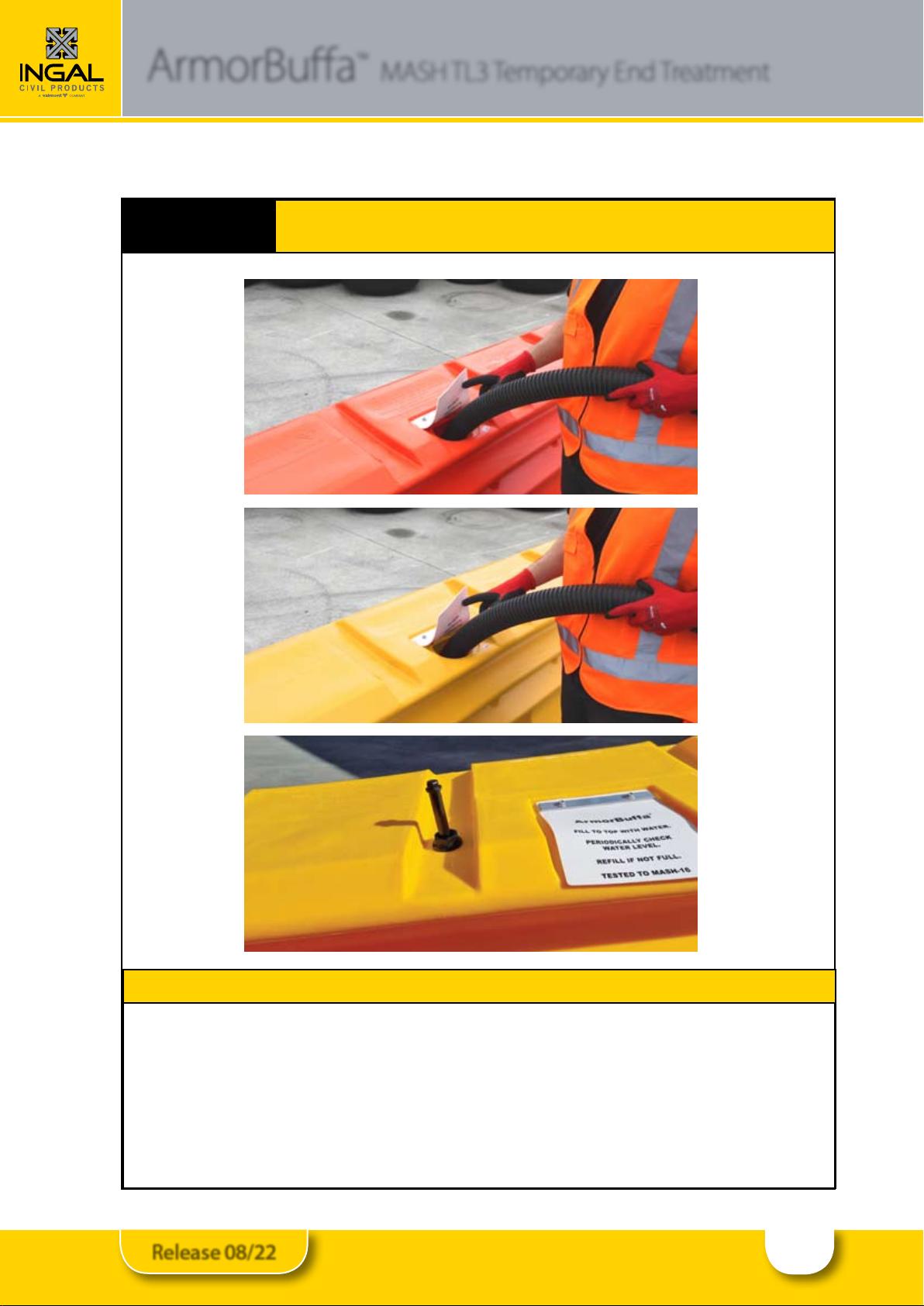

STEP 6 Final Inspection and Filling of Elements

INSTRUCTIONS

1. Inspect installed system ensuring the correct pins are in the correct locations and that the steel cable is

engaged through each pin.

2. Fill all 4 elements (1 x orange and 3 x yellow) with water to capacity (within 25mm of the top) using the

lling port, 700 litres per element.

3. Ensure the Water Fill Level Indicators are raised above the top of the element, indicating the element is

full of water.

4. Check there are no leaks in the elements or around the drain bungs.

15

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

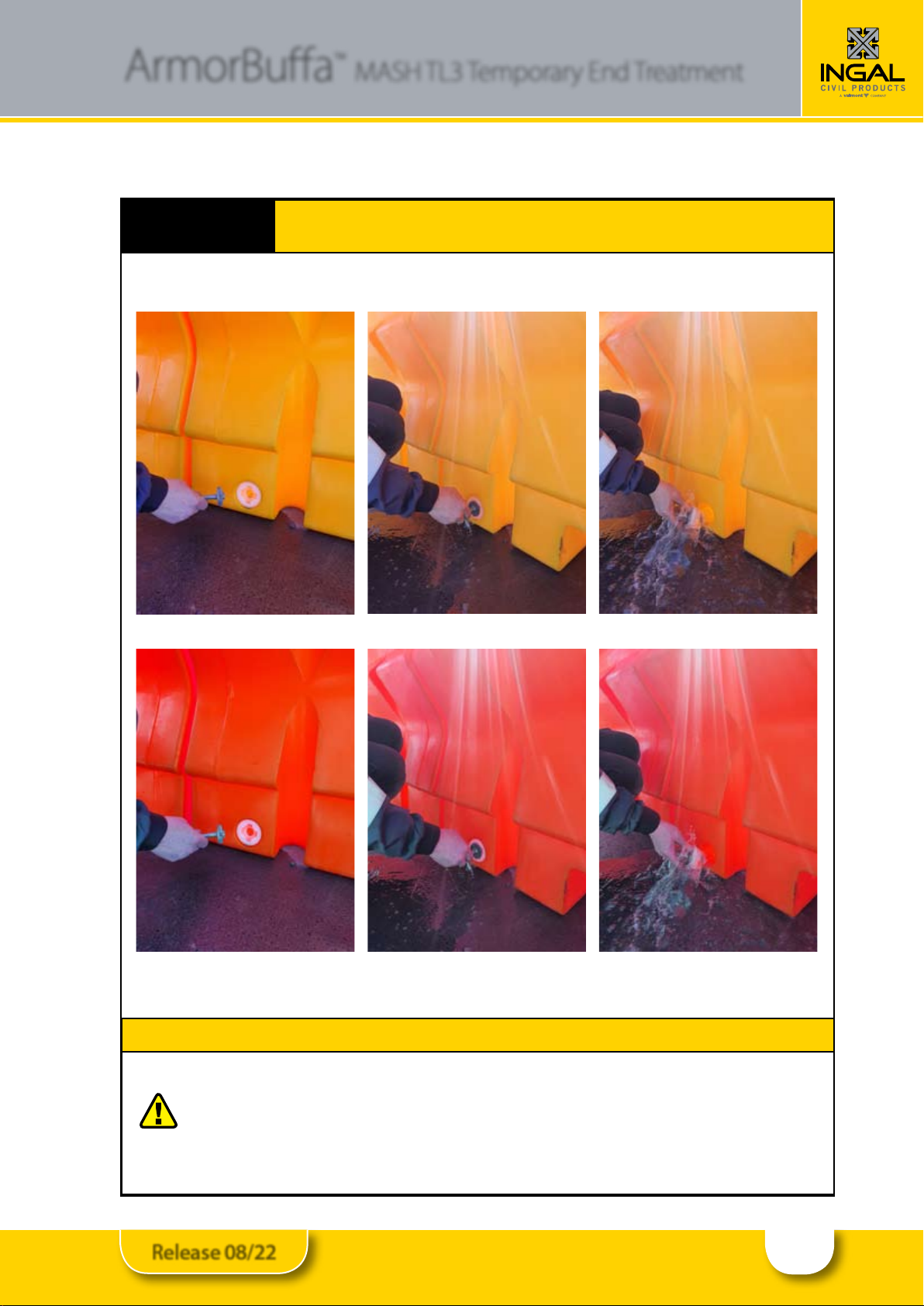

STEP 7 Disassembly and Relocation

INSTRUCTIONS

1. Drain elements by removing the bungs and then disassemble in the reverse order of assembly.

Do not stack full elements! Do not lift or move full elements!

Note: The transition can be left on the end of the temporary barrier for transportation and relocation, as

can the steel nose assembly be left on the plastic Element No. 1.

16

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

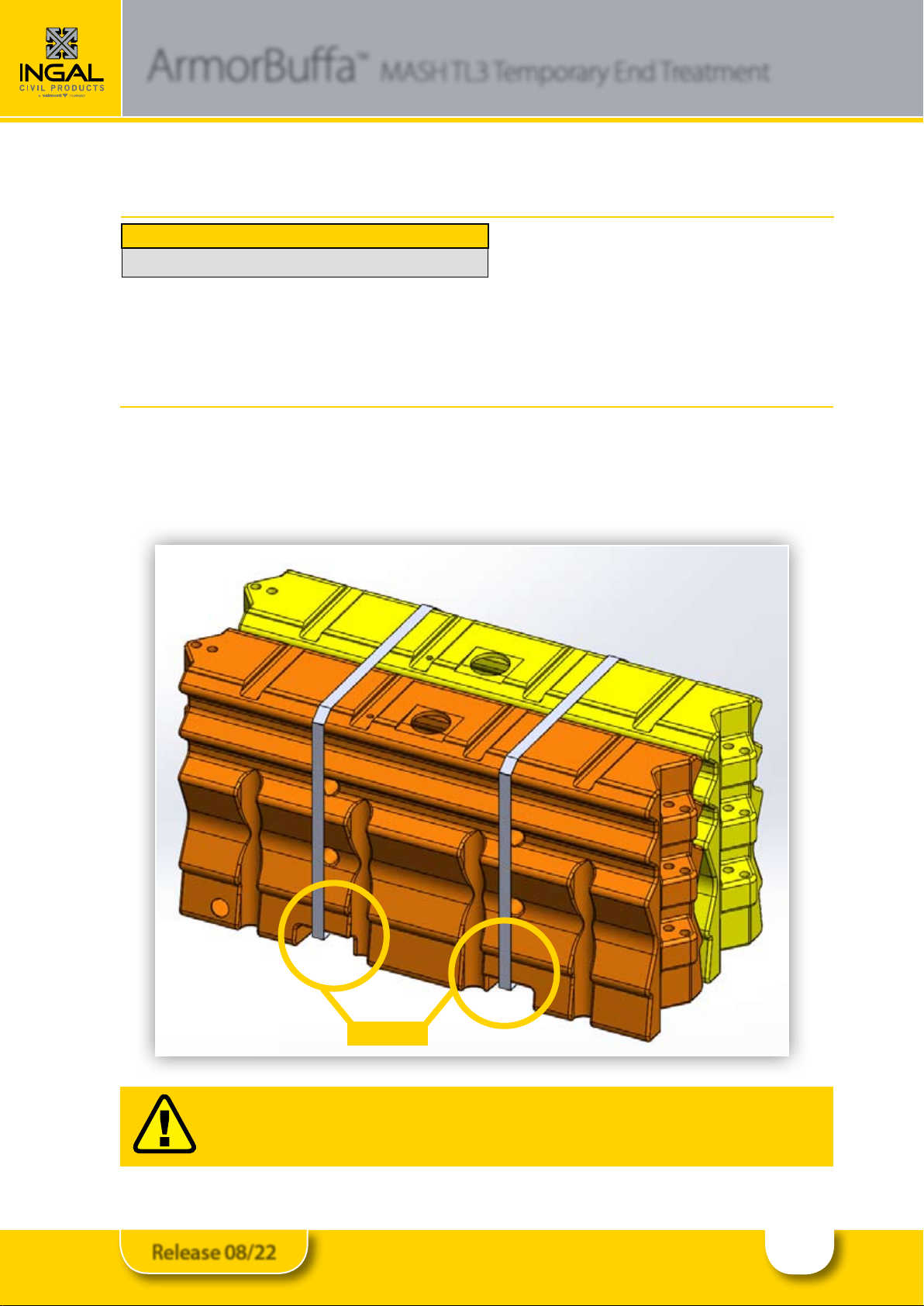

11.0 Transportation and Storage

When empty, Elements are designed to be transported and stored in strapped bundles of 2, as shown below, and can

be lifted via the forklift pockets shown in Note A.

The Transition Piece, Steel Nose Assembly and Nose Cover are to be strapped to pallets for transportation.

WARNING : Elements must be emptied before being moved or transported.

10.0 ArmorBua Element Capacity

Liquid Capacity L

700 Litres

Note A

17

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

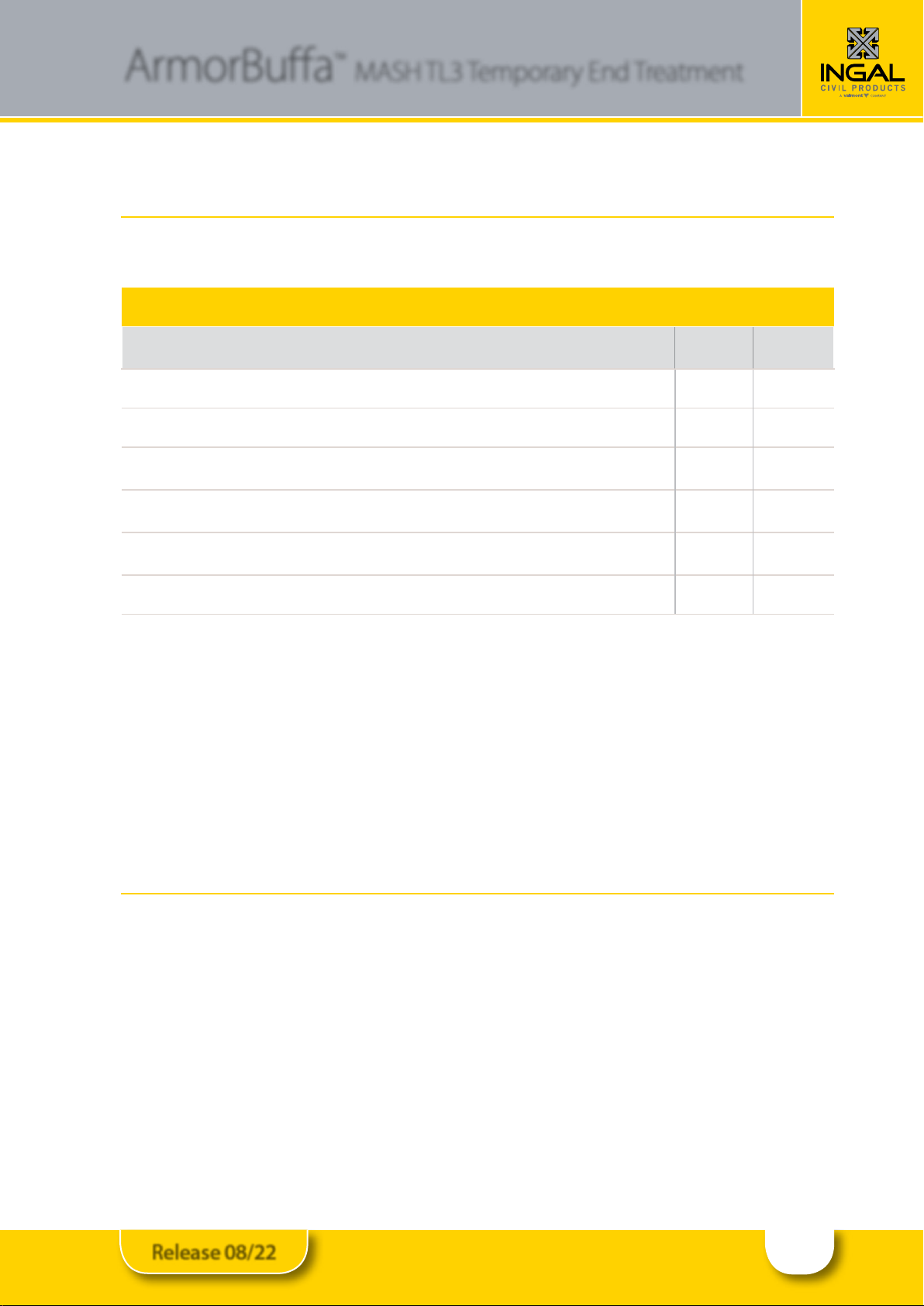

12.0 Inspector Checklist

Conrm all items in the checklist have been properly completed and hardware installed properly.

Installation Checklist

Item Date Initial

Nose Piece is rmly attached to Element No. 1.

The cable assembly is linked through each of the ve (5) connector pins.

All Elements and Nose Cover are connected with the correct pin

(refer to diagrams on pages 7, 8 and 9).

Transition is secured to the Transition Barrier with

two or three (2 or 3) M16 Anchors on each side

All Element(s) full of water and the Water Fill Level Indicators are raised

above the top of the element.

Plug at drain ports fully seated and secure with no sign of leakage.

Inspector signature: ___________________________ Date: ________________________

13.0 Maintenance Inspection

Crash cushions, like all roadside safety hardware, require inspection to ensure they are in acceptable working

condition. Regular inspections of the ArmorBua™ system is recommended and shall be made by the local highway

authority. Frequency of the inspections shall be made based on site conditions, trac volumes, and crash history.

The water level in all elements must be checked regularly. This can be done by checking that the Water Fill Level

Indicators are raised above the top of the elements. Please follow the Local guidelines for frequency of inspections to

ensure adequate repairs are made to the system. Walk-up inspections are recommended at least twice a year.

18

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

14.0 Walk-Up Inspections

Recommended Frequency – Twice a Year

Before performing walk-up inspections, ensure trac control is deployed in accordance with local guidelines.

Check for:

Water level is within 25mm of the top of the Element’s ll ports (veried by the Water Fill Level Indicators being •

raised above the top of the elements).

Damage caused by vehicle impacts•

Damage caused by impacts from roadside maintenance equipment•

Misalignment•

Missing components•

Vandalism•

Clear and dispose of any debris in and around the system•

After inspection is complete, ensure all items identied during the inspection process are corrected.The ArmorBua™

system shall be returned to proper condition as outlined in the installation instructions.

Walk-Up Inspection

Item Comment

Water level is within 25mm of the top (check the Water Fill Level

Indicators are raised above the top of the element).

Damage caused by vehicle impacts

Minor damage caused by impacts from roadside maintenance

equipment

Misalignment

Missing components

Vandalism

Clear and dispose of any debris in and around the system

Grading around system

Fill Lids are fully seated. (Step 6, Page 16)

Inspector Signature: ____________________________________ Date: _______________________________

Print Name: ___________________________________________ Location: ____________________________

19

Release 08/22

ArmorBua™MASH TL3 Temporary End Treatment

15.0 Design Life

The design life of the ArmorBua MASH TL3 End

Treatment is 20 years. This is based on the properties

and performance of the UV stabilised HDPE and MDPE

plastic and also the hot dip galvanizing of the connector

pins, steel transition and steel nose assembly. Please

note each plastic element has a unique serial number

to enable manufacturing traceability.

16.0 Maintenance

ArmorBua™ MASH TL3 is a maintenance free system

but it is recommended that inspections are carried out

periodically to ensure that the system is installed as

required.

Over a long period of time in extreme conditions it

may be possible for evaporation to take place and it

is imperative that all the elements remain lled to the

correct level.

17.0 Recycling

The ArmorBua™ MASH TL3 End Treatment is

manufactured from UV stabilised HDPE and MDPE and

therefore the material in any units damaged beyond

repair can be recycled. The connector pins, nosepiece

and transition are manufactured from steel and can

also be recycled.

20

Release 08/22

825

250375325

1070

5

630

482

F-Type Concrete

Fixing Bolt Kit

80

Notes:

Finish = HDGalv AS/NZS 4680

(PN 10200329)

5

5

FOLDER

Valmont Highway Technology

Level 3, Building A, 11 Talavera Road

Macquarie Park, NSW 2113, Australia

T: +612 9814 1777 www.valmonthighway.com

ORIGINAL ISSUE - 23.10.2020

Scale:

DATE

APPD

DESCRIPTION

REV

Straightness :

Bend Angle :

One Decimal Place :

Whole Numbers :

TOLERANCES

FINISH

MATERIAL

CLIENT

ITEM

DRAWING NUMBER

APPROVED

CHECKED

DRAWN

10200320

ArmorBuffa Transition

F-Type Concrete

VB

JA

LB

5mm BMT G250

HDGalv

F:\Engineering\3. CURRENT DRAWINGS\COMPONENT DRAWINGS\SLDDRWs\10200320 - ArmorBua Transition F-Type Concrete\

0

1

HOLES FOR FIXING BOLTS UPDATED

JA

29/10/20

Table of contents

Other INGAL Safety Equipment manuals

Popular Safety Equipment manuals by other brands

KRATOS SAFETY

KRATOS SAFETY FA 60 034 00 manual

Clevertronics

Clevertronics L10 LWELED-IPREM Series Installation & maintenance instructions

FALL SAFE

FALL SAFE INSPECTOR General Instruction

Dräger

Dräger saver CF Series Instructions for use

Mifold

Mifold Grab-and-Go Child Restraint manual

TEUFELBERGER

TEUFELBERGER RescLoop instruction manual