User Manual Carbon-cleaning machine ANTISMOG

6

A mini-display is located in the middle of the control panel. The mini-display continuously

circles across preconfigured screens, while each display is shown for approximately 8

seconds, to present the following information to the operator:

•Current time (hours : minutes : seconds)

•Daily cumulative work hours value (hours : minutes : seconds)

•Cell temperature value (deg C)

•Machine connection status, Wi-Fi signal information, server connection information

•Wi-Fi access point information

Mini-display

The normal stop of HHO gas production is performed by pressing the black –or red lit in

some variants –STOP button, located immediately to the right of the HHO gas regulator

potentiometer. To minimise the electrical and thermal stress on the system during the

normal shutdown, it is recommended that the HHO gas production is reduced to zero by

turning the HHO gas regulator fully counterclockwise, and only then pressing the Stop

button.

The START button is located to the right of the Stop button. Pressing the START button

commences the production of HHO gas, provided the gas production setpoint is set to a

value greater than zero, and all safety conditions are cleared.

Similarly to the normal Stop procedure described above, to minimise the electrical and

thermal stress on the system during the normal start, it is recommended that the HHO gas

production regulator is initially set to zero by turning the HHO gas regulator fully counter-

clockwise, then the Start button is pressed, and only then the HHO gas production regulator

is turned clockwise to reach the desired value.

The Timer set dial is located to the right of the Start button. The desired HHO gas production

time interval is set by rotating the dial. The time interval is set in minutes. The available

timer range is 0-99 minutes.

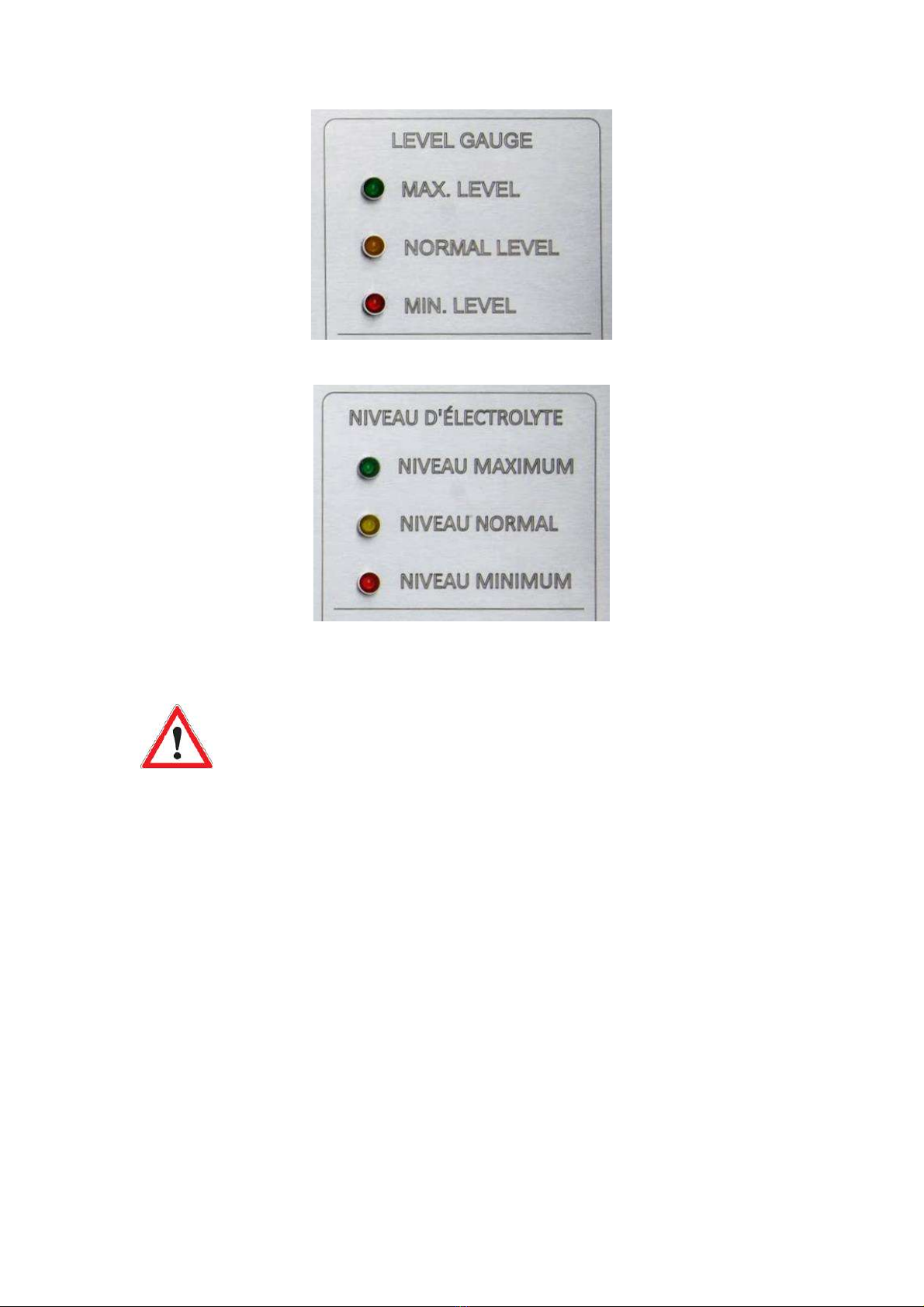

The block of signal LEDs is located on the right-hand side end of the Control Panel.