IMPORTANT: The water pump in this unit incorporates a thermal cut-out. Should the

unit overheat, this will be tripped and the pump will temporarily stop working.

In this event, leave unit to cool for approx. 10 minutes (depending on conditions) for

the cut-out to reset and then restart the pump.

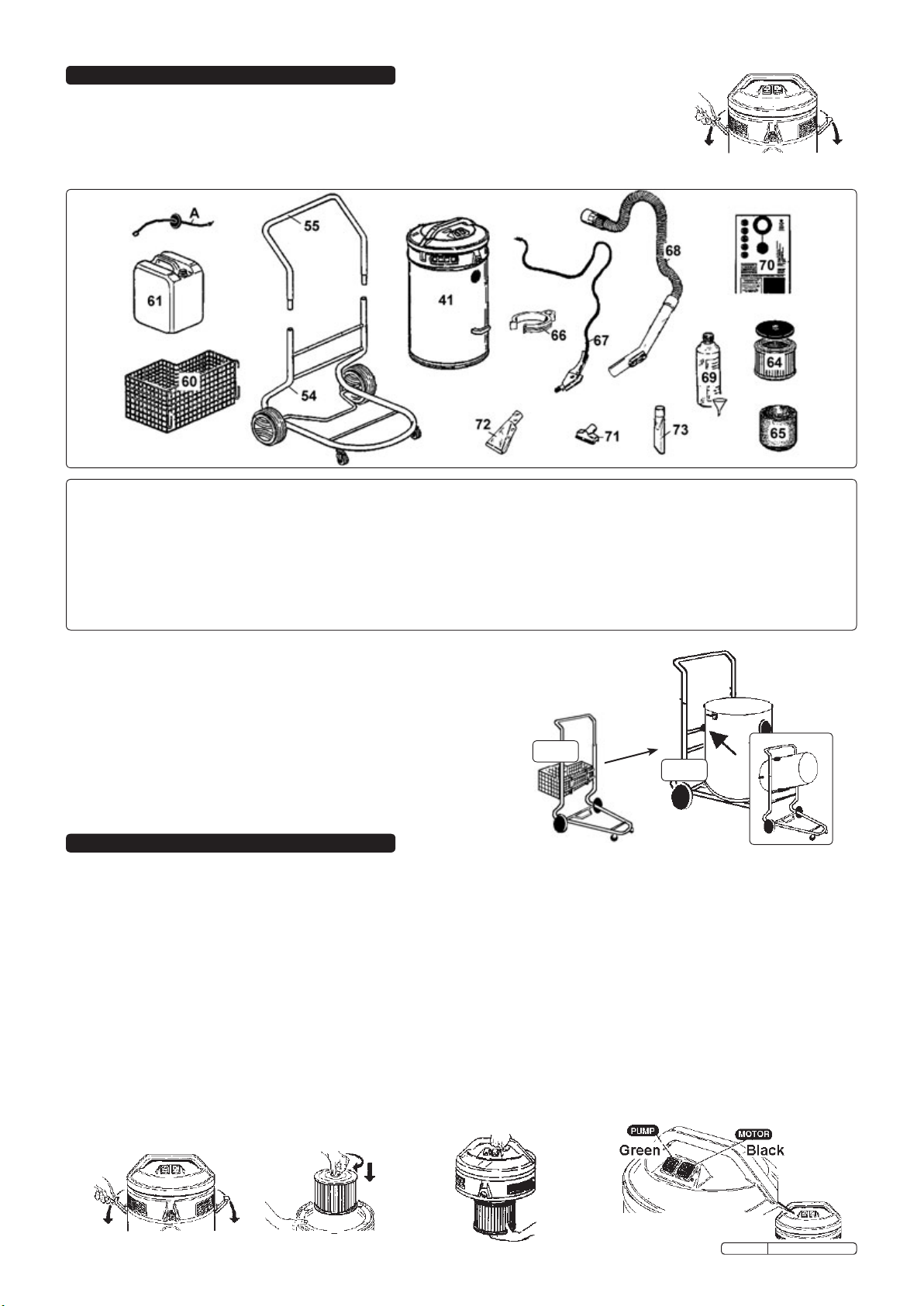

4. 1. Ensure the machine is unplugged from the mains power supply.

4. 2. Make sure the tank is clean and free from dust and dirt.

4. 3. Remove cartridge filter and dust bag if fitted (see 3.9 & 3.10).

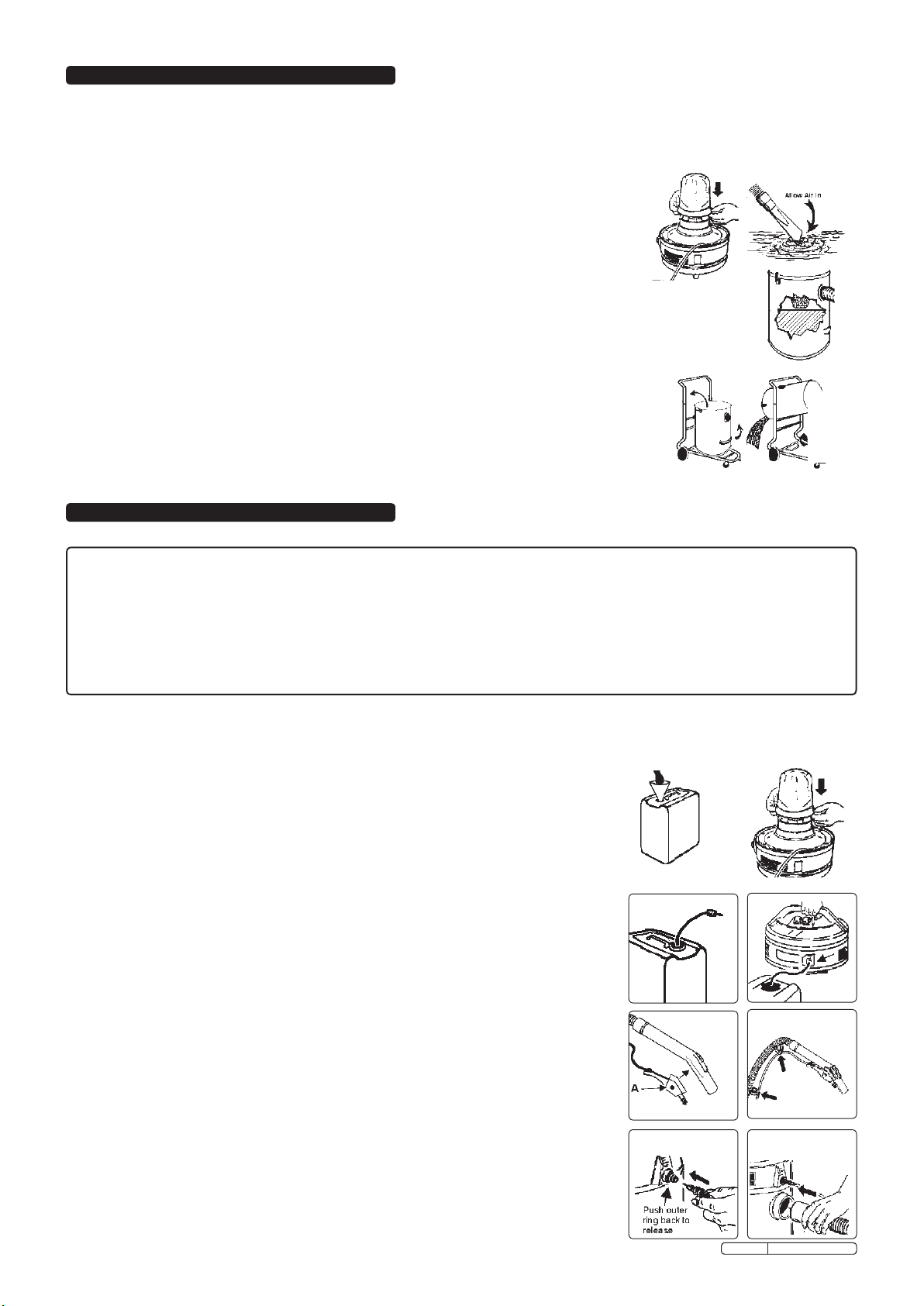

4. 4. Fit the blue foam filter in place (fig 8).

4. 5. Replace the head onto the drum body.

4. 6. To the same flexible hose as used in dry cleaning fit the Flat, or Tapered Nozzle.

4. 7. Ensure the BLACK Motor Switch is in the “OFF” position before plugging in.

4. 8. Plug the cleaner into the mains power socket.

4. 9. Press the BLACK MOTOR SWITCH “ON” ONLY. DO NOT SWITCH THE PUMP ON.

4. 10. To vacuum large quantities of liquid, i.e from a sink, or tank, etc; do not immerse the nozzle

completely in the liquid, leave a gap at one end of the nozzle to allow a partial air inflow. (fig 9).

4. 11. The machine is fitted with a FLOAT VALVE which stops the suction action when the tank has

reached its maximum capacity. The user will also be aware of increased motor speed.

When this happens, turn the machine off, disconnect from mains, remove the head from

tank. Take care to maintain balance and not let trolley slip, and empty liquid out of the tank into

an appropriate receptacle or drain (figs 10, 11). To continue vacuuming reverse the process and

proceed.

4.12. After WET vacuuming turn the machine off and remove the plug from mains power supply.

4.13. Empty the tank, then clean and dry the inside before storage.

fig 8

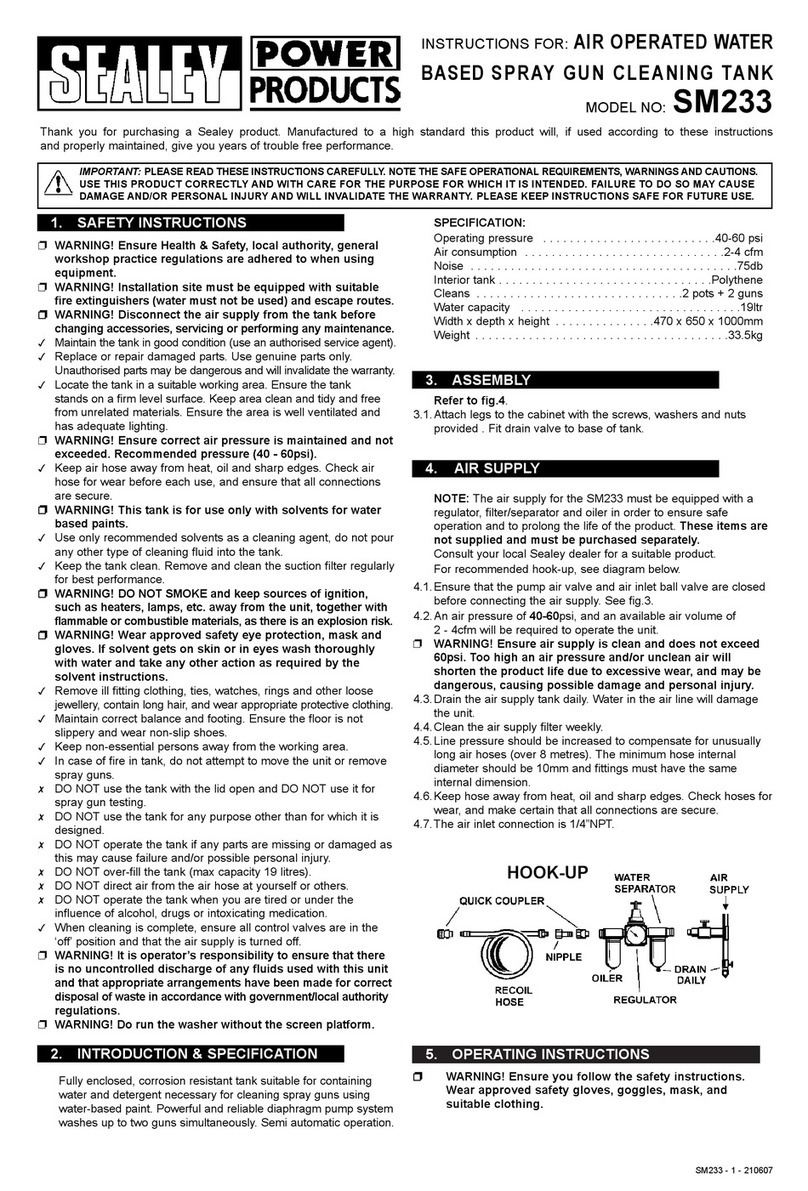

4. WET VACUUM CLEANING For the vacuuming of liquids only

WARNING! Ensure you read, understand and apply chapter 1 “Safety Instructions”. Reminder: Remove plug from mains power

supply before opening unit. DO NOT vacuum solvents, explosives, inflammable or hazardous liquids, petrol, oil, spirit, paint, thinner

and/or chemicals. The use of incorrect filter will invalidate your warranty.

5. USE AS VALETING MACHINE

FOLLOWING INSTRUCTIONS REFER TO USE AS AN AUTOMOTIVE/INDUSTRIAL, FABRIC & UPHOLSTERY CLEANER.

WARNING! USE THE CORRECT DETERGENT: THE ONLY DETERGENT SUITABLE FOR THIS MACHINE IS SEALEY “VMR” or THE

DETERGENT SUPPLIED WITHTHE MACHINE. CONTACT YOUR SEALEY DEALER FOR SUPPLIES. DO NOT (UNDER ANY CIRCUMSTANCES)

USE DOMESTIC DETERGENT OR ANY OTHER GENERAL PURPOSE CARPET CLEANER, CAR WASH, CLEANING OR UPHOLSTERY DETERGENT.

OTHER DETERGENTS PRODUCE EXCESSIVE FOAM WHICH IS UNDESIRABLE FOR THE CLEANING PROCESS AND CAN DAMAGE THE WORKING

PARTS OF YOUR MACHINE. IF, WHEN USING THE RECOMMENDED DETERGENT, YOU FIND EXCESSIVE FOAM BEING PRODUCED,

THE CARPET OR FABRIC HAS BEEN PREVIOUSLY CLEANED WITHA FOAMING DETERGENT. SHOULD THIS HAPPEN, ADD 10cl OF ANTI-FOAMING

AGENT (SEALEY PART NO VMR922) TO THE MAIN WASTE WATER TANK.

WARNING! ENSURE YOU READ, UNDERSTAND AND APPLY CHAPTER 1 “SAFETY INSTRUCTIONS”. THE USE OF AN INCORRECT FILTER

OR DETERGENT, WILL INVALIDATE THE WARRANTY. ALWAYS TEST MATERIALS FOR COLOUR FASTNESS BEFORE USING THE AUTO VALET.

5.1. FABRIC PREPARATION & DETERGENT

5.1.1. If the condition of the vehicle fabric, or item of upholstery requires dry vacuuming first, you may prefer to use an alternative vacuum

cleaner, keeping your Auto Valet on standby ready for the wet clean.

5.1.2. Should you wish to use the Auto Valet for the preliminary dry clean, then set the machine up as in chapter 3.

5.1.3. To commence with the wet clean ensure you use the correct detergent as described in 5.1.

5.1.4. Remember to add ‘Anti-foaming agent VMR922’ to the waste tank if necessary.

5.1.5. Fill the plastic detergent tank with COLD water up to the “MAX” level indicator number 9,

or according to the amount you wish to use (fig 12).

5.1.6. Add 20cl of SEALEY “VMR” or Supplied detergent (Note: 20cl is about half a coffee mug).

5.1.7. DO NOT USE ANY OTHER DETERGENT.

5.1.8. DO NOT increase the strength of detergent mix beyond 80 -1.

5.1.9. If part of the fabric is badly soiled, rub in by gloved hand a mix of 80-1 detergent and leave

for 2-3 minutes before valeting.

5.2. SETTING UP THE AUTO VALET

How to prepare, and assemble your valet machine ready for wet cleaning.

5.2.1. Ensure you unplug the machine from the main supply.

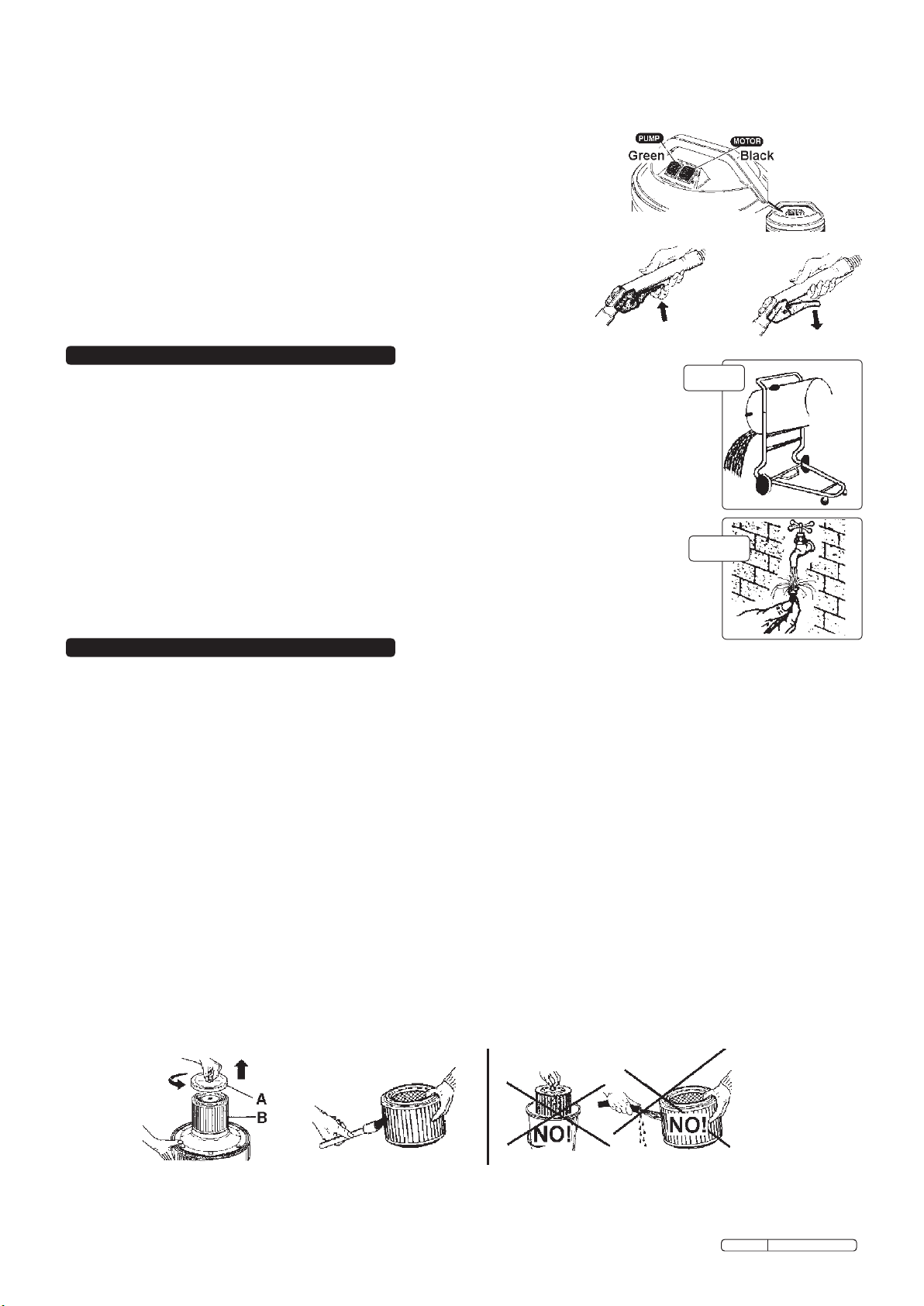

5.2.2. Having filled the detergent tank, place it in the trolley basket.

5.2.3. Remove the vacuum motor head and fit the blue foam filter (fig 13).

Remove the cartridge filter and paper dust bag if fitted as they are

for dry cleaning only.

5.2.4. Replace the motor head and secure with the side clips.

5.2.5. Insert the filter end of the detergent pick up pipe into the detergent tank, and seal by

screwing (finger tight) the attached tank cap (fig 14).

5.2.6. Insert the other end of the pick up pipe to the rear of the motor head (fig 15).

5.2.7. Loosen the thumb screw on the pistol head (fig 16 A), and clip the pistol over the end

of the vacuum hose (fig 16). Finger tighten the thumb screw and check that the pistol

is adequately attached to the hose. Connect the detergent delivery tube to the main

vacuum hose with clips provided (fig 17).

5.2.8. Push the other end of the delivery tube into the outlet located in the front

of the motor head above the main hose outlet (fig 18). When disconnecting this tube,

push the inlet ring back to release the delivery tube. DO NOT PULL THE TUBE.

5.2.9. The flexible vacuum hose should be fitted to the machine as normal (fig 19).

5.2.10. Attach the valeting tool head to the hose and detergent dispenser tube.

fig 9

fig 10

fig 11

fig 13

fig 14

fig 12

fig 15

fig 16

fig 18 fig 19

fig 17

Steady

the

trolley

whilst

lifting

tank

Original Language Version VMA913 Issue: 2 - 18/01/10