P/N 1011175 Rev. H 08/20 7

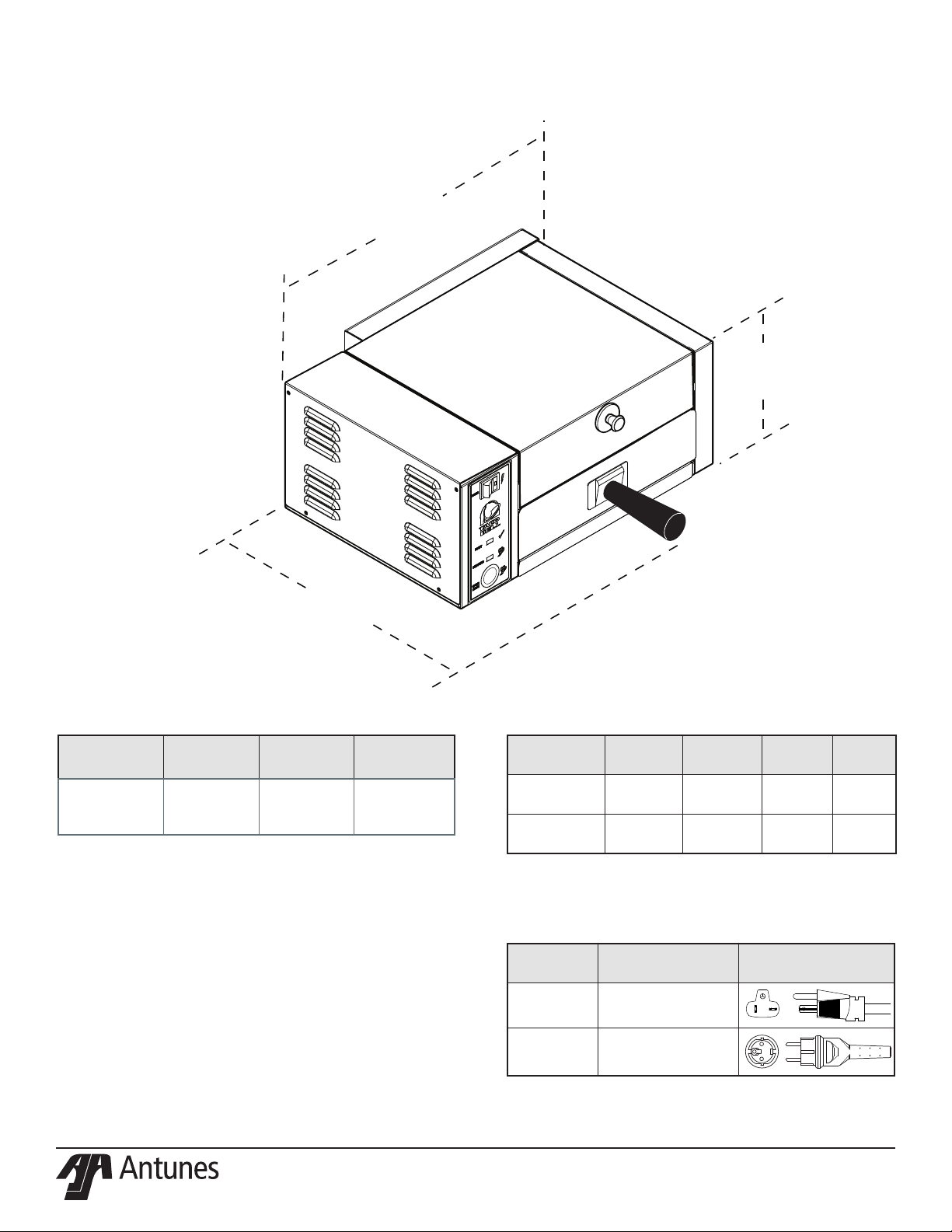

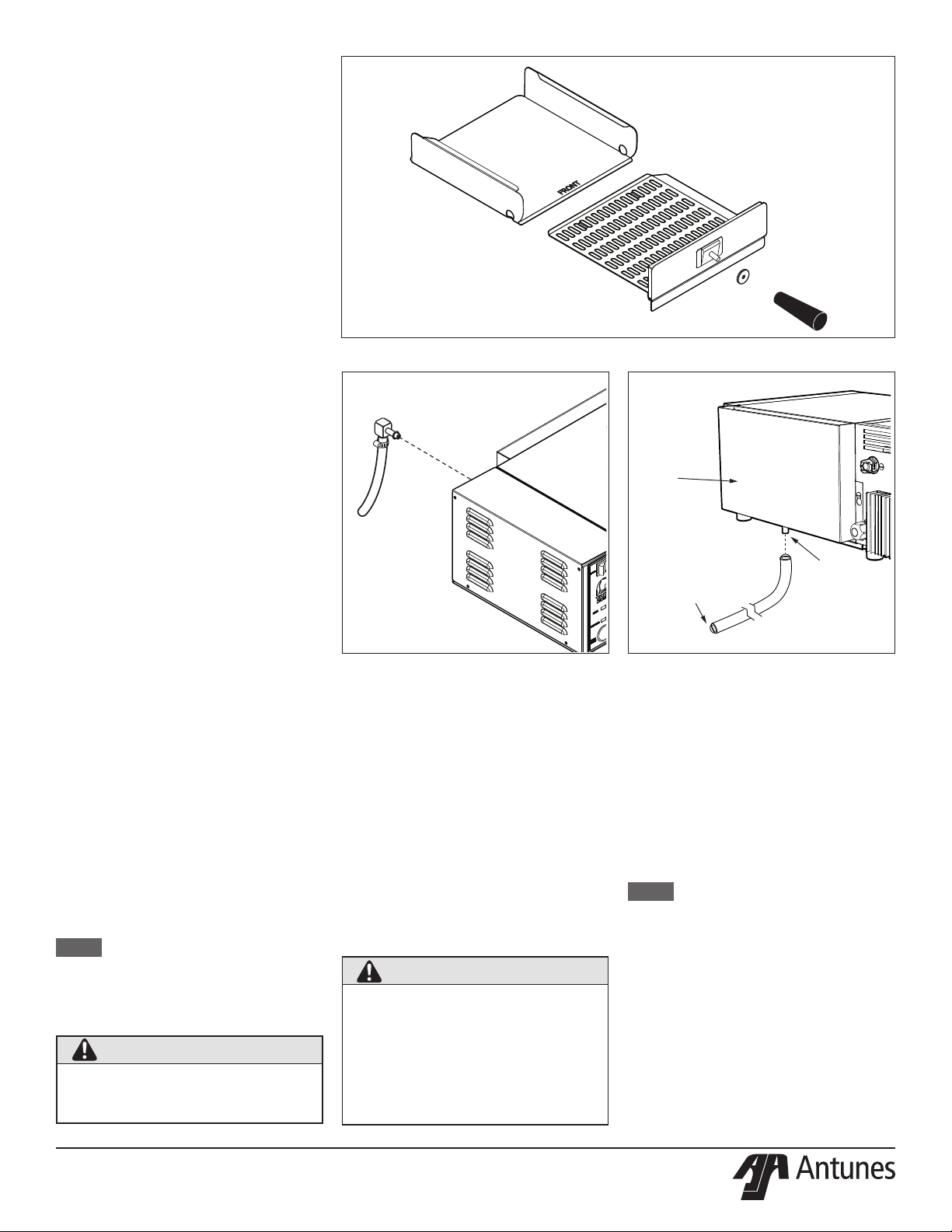

Figure 6. Components

Daily Cleaning

NOTE: Frequency of cleaning is

determinedbywaterconditions,

usage,andwaterltersystems.

1. Turn the unit o, unplug the power cord,

and allow the it to cool down before

proceeding.

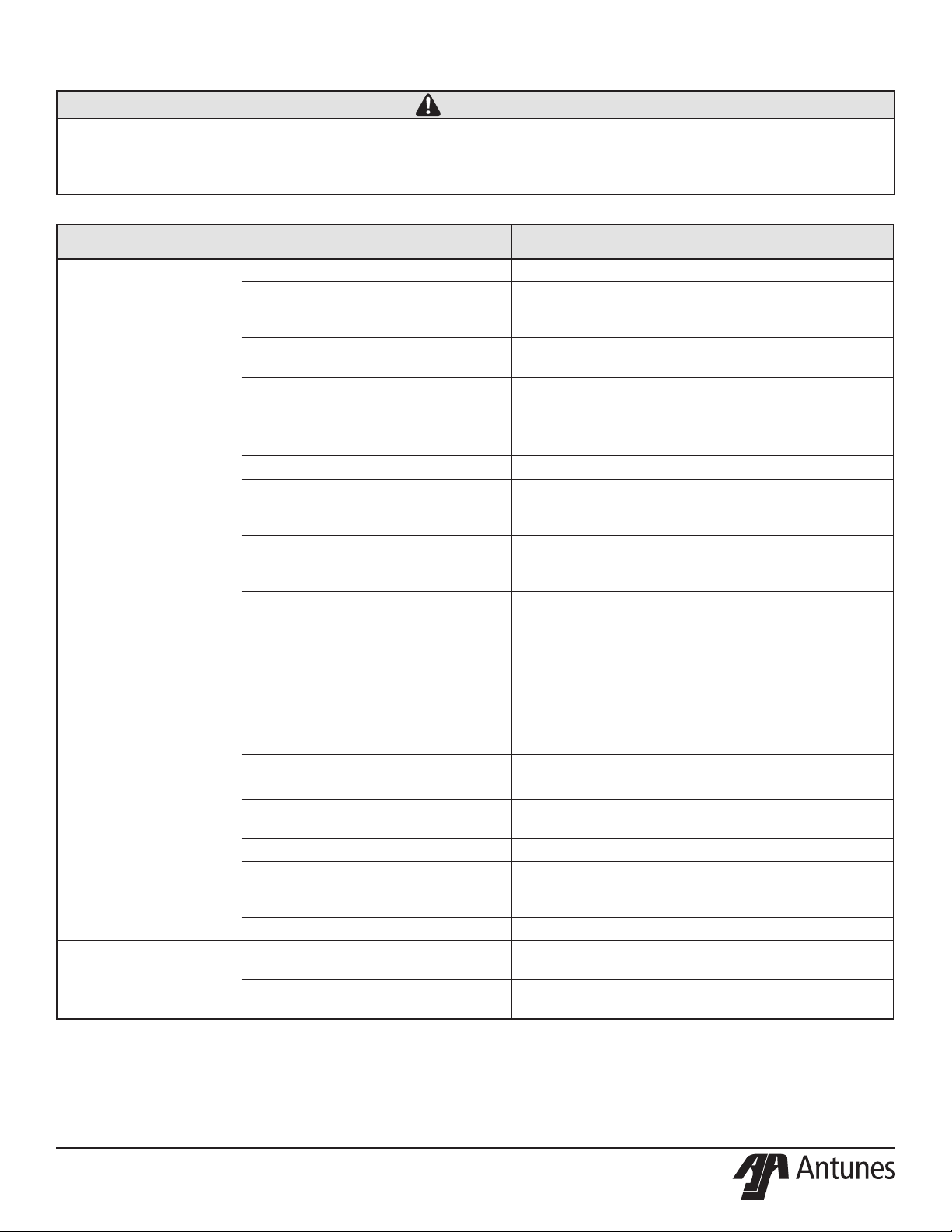

2. Check the Water Quick Disconnect

Fitting and all hose clamp connections

for leakage. If leakage is apparent,

tighten all clamps or replace part if

required.

3. Remove the Top Cover, Spatula, and

Liner.

4. Remove Chimney from rear of unit by

sliding upward and away from the unit.

5. Clean the Top Cover, Spatula, Liner, and

Chimney in hot, soapy water by hand.

Rinse in clear water and wipe dry.

Maintenance

WARNING

Turn the power o, unplug the power

cord, and allow the unit to cool to room

temperature before performing any

service or maintenance.

CAUTION

Chlorides or phosphates in cleaning

agents (e.g., bleach, sanitizers,

degreasers, or detergents) can cause

permanent damage to stainless steel

equipment. The damage is usually

in the form of discoloration, dulling of

metal surface nish, pits, voids, holes,

or cracks. This damage is permanent

and is not covered by warranty. Follow

these tips for maintenance of stainless

steel equipment:

yUse a soft, damp cloth for

cleaning, rinse with clear water,

and wipe dry. Always rub in the

direction of metal polish lines.

yOnly use approved cleansers.

yFinger marks and smears should

be removed using soap and water.

yDo NOT use a metal

scraper on grill surfaces

yDo NOT wash any components

of the unit in a dishwasher.

Hand wash ONLY in a

three-compartment sink.

CAUTION

Grill surfaces will be hot. Extreme

care must be taken when operating or

cleaning this unit. Use heat-resistant

gloves when necessary.

NOTE: Do NOT wash in a power washer.

6. Clean the chamber of any product spills.

7. Clean entire unit with a clean, hot, damp

cloth (not dripping wet) and wipe dry.

8. Re-install Chimney, Liner, Spatula, and

Top Cover.

9. Plug in the power cord and test the unit

before returning it to service.

Monthly Cleaning

This unit utilizes an open steam generator.

Water sprayed onto the Generator surface

ashes into steam immediately, but the

minerals in the water do not steam; they stay

on the Generator surface. A small amount

of mineral deposits are needed for proper

operation, but a buildup of excessive mineral

deposits causes poor steaming eciency

and excessive moisture (wet steam) and

will eventually severely hinder the steaming

action.

Cleaning Steam Generator

1. Turn the power o, unplug the power

cord, and allow the unit to cool down.

2. Remove the Top Cover.

3. Remove the Wing Nut and Generator

Cover.

4. Remove the Diuser.

5. Examine all steam ports. If mineral

deposits have formed, place a at

blade screwdriver or wire brush into

the openings. Use a twisting motion to

scrape the openings clean.

NOTE:Ifthemineraldepositscomeo

inakesorlayers,buildupis

excessive.

6. Use a brass or stainless steel wire brush

and small scraper to loosen and remove

excessive deposits from the generator

surface. If deposits are still excessive

and/or dicult to remove, proceed to

Step 7.

7. Pour food safe delimer solution (not

supplied) or white vinegar onto the

Generator surface. Be sure to follow the

delimer manufacturer’s directions for

proper mixture and use. It must be safe

for use on aluminum.

8. Remove the delimer solution from the

Generator and rinse with clear water to

remove all traces of solution.

9. Clean the Spatula Liner, Chimney,

Diuser, Top Cover, and Generator

Cover in hot detergent water. Then rinse

in clear water and wipe dry.

10. Clean steam chamber of any product

spills.

11. Clean the surface of the unit with a hot,

clean, damp cloth (not dripping wet) and

wipe dry.

12. Re-install all parts and fasten the

Generator Cover.

13. Plug in the power cord and water line.

To ensure proper steaming characteristics,

some mineral deposits must be present on

the Generator surface. If during cleaning, the

surface does become free of mineral deposits

(bare aluminum), add plain tap water to

surface and allow to boil o.

In soft water areas, it may be necessary to

add a small amount of calcium/minerals to

the generator surface to season it. This will

ensure proper steaming characteristics by

producing a thin coating of mineral deposits

on the surface. Seasoning mixture consists

of 2 tablespoons baking soda, and 1 cup

water. Pour 1/4 cup of seasoning mixture

onto hot generator. After mixture is converted

to steam, the remaining loose powder can be

removed. Repeat as needed until there is a

thin, white mineral coating on the surface of

the generator.

Liner

Handle

Handle

Guard

Top Cover

Spatula

Chimney

Wing Nut

Generator

Cover

Diuser

Steam

Pots