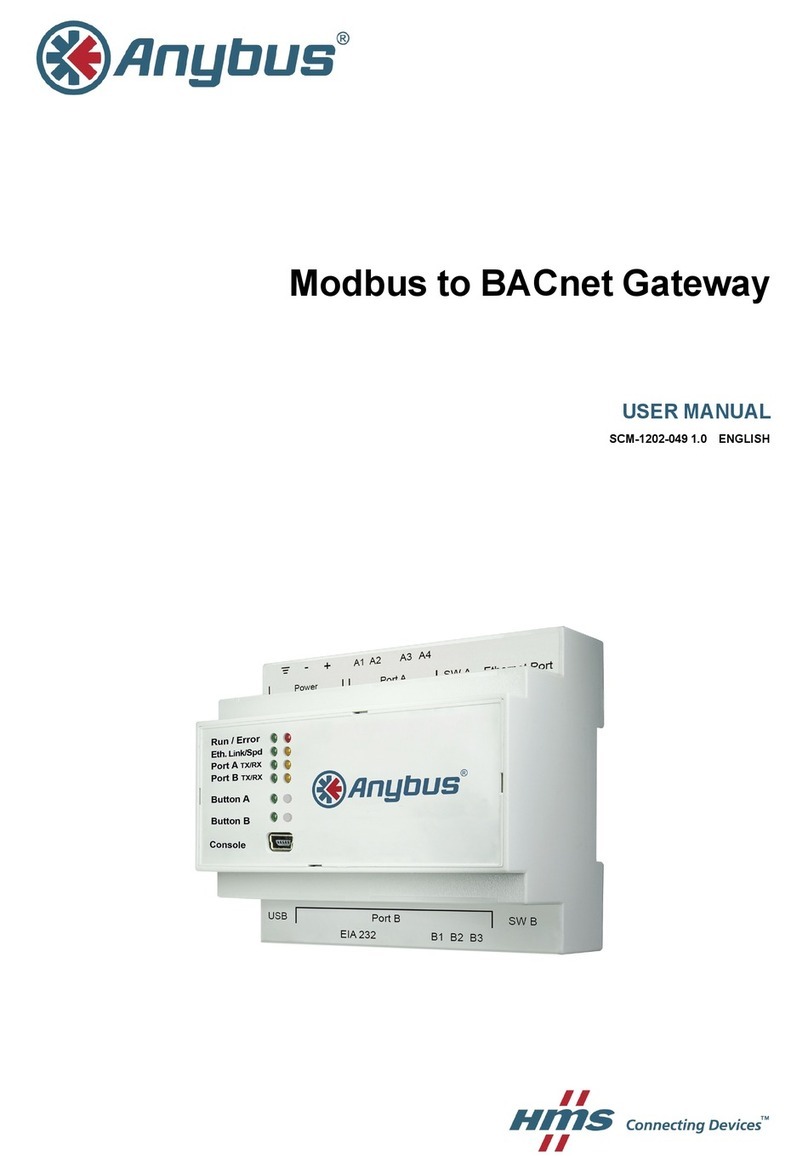

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual SCM-1202-035 1.0

Table of Contents Page

1 Preface ............................................................................................................................... 3

1.1 About This Document.....................................................................................................3

1.2 Related Documents .......................................................................................................3

1.3 Document history...........................................................................................................3

1.4 Trademark Information ...................................................................................................3

1.5 Conventions ..................................................................................................................4

2 Description ....................................................................................................................... 5

2.1 Introduction ...................................................................................................................5

2.2 Basic Operation .............................................................................................................6

2.3 Data Exchange Model ....................................................................................................7

2.4 PROFINET IRT Protocol.................................................................................................8

2.5 CAN Network Protocol ...................................................................................................9

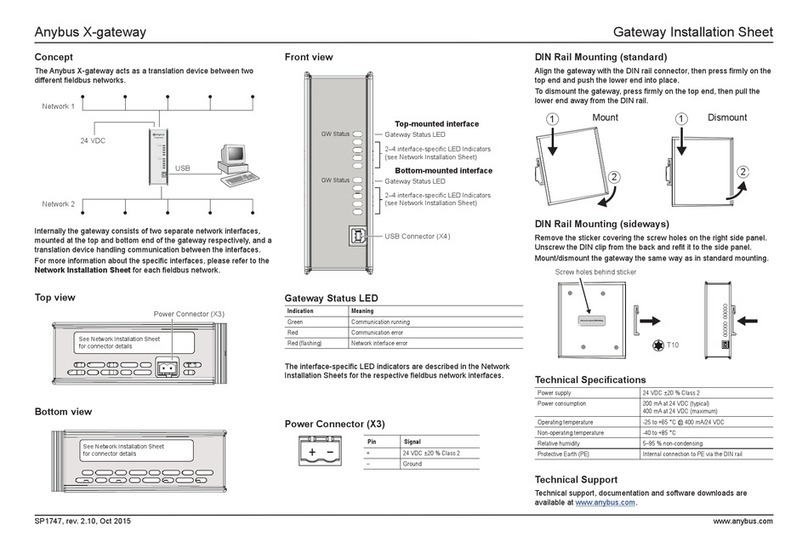

3 Installation ...................................................................................................................... 13

3.1 Installation Overview ....................................................................................................13

3.2 Connectors and Indicators............................................................................................14

3.3 DIN Rail Mounting........................................................................................................14

3.4 CAN Interface..............................................................................................................15

3.5 PROFINET Interface ....................................................................................................15

3.6 Power Connector .........................................................................................................15

3.7 USB Connector............................................................................................................15

3.8 LED Indicators.............................................................................................................16

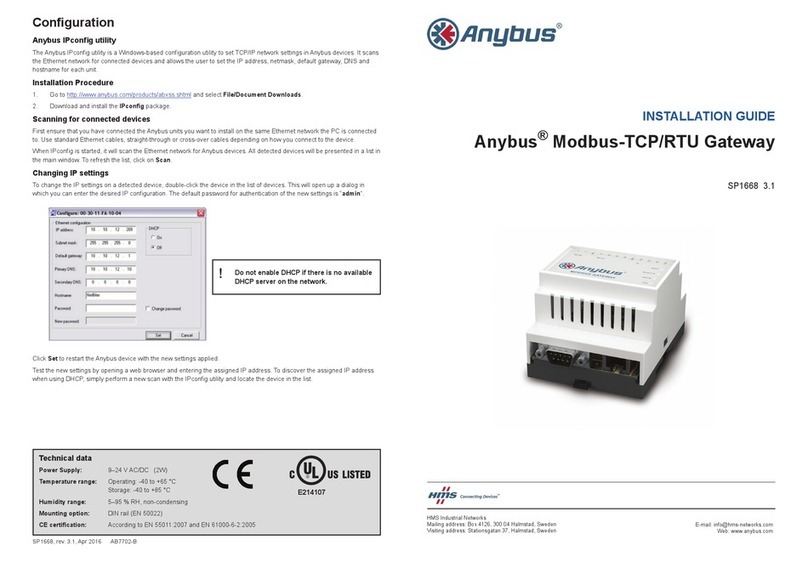

4 Configuration ................................................................................................................. 17

4.1 Configuration Overview ................................................................................................17

4.2 Network Configuration..................................................................................................18

4.3 Web Pages..................................................................................................................22

5 Anybus Configuration Manager ................................................................................ 23

5.1 Main Window...............................................................................................................23

5.2 Basic Settings..............................................................................................................24

A Technical Data................................................................................................................ 27

B Regulatory Compliance............................................................................................... 28

C Licenses .......................................................................................................................... 29