AnyWire Bitty series POKA-YOKE Terminal

AnyWire System Products Guide

A027XB-02□2-P

The AnyWire System Products Guide describes individual products. Refer to the Guide as necessary.

[Notes on Safety]

[Features] [Warranty]

-A027XB02*2P 1/5-

A027XB-02G2-P

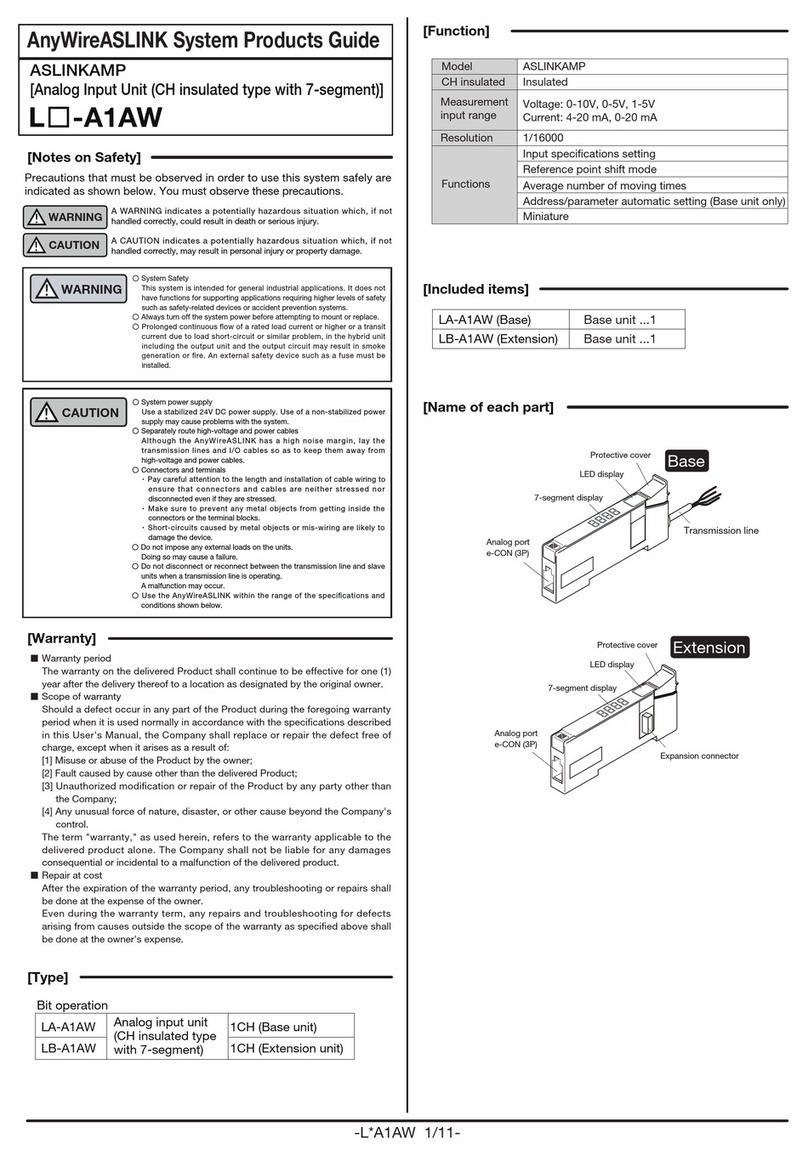

[Type]

Bit Operation

Eject check input

Eject indicator lamp (Green)

A027XB-02R2-P

One point input

One point output

One point input

One point output

Eject check input

Eject indicator lamp (Red)

○Do not use for power supply of

AnyWire Bitty

series and for switching parallel signal for SBC (Single Board Controller) and

controller, etc.

Commonalization of mutual power supply systems may result in system failure.

○Use the AnyWire Bitty

1

2

4

8

16

32

64

128

LINK

ADDRESS

ON

A027XB-02G2-P

ADDRESS No.

Precautions that must be observed in order to use this system safely are indicated as shown below.

You must observe these precautions.

○System power supply

○Separately route high-voltage and power cables

○Connectors and terminals

○Do not impose any external loads on the units. Doing so may cause a failure.

○Do not disconnect or reconnect between the transmission line and slave units. A malfunction may be caused.

Use a stable, 24V DC power supply. Use of an unstable power supply may cause problems with the system.

Although the AnyWire Bitty Series has a high noise margin, keep the transmission line and I/O cables away from high-voltage and power cables.

*

Pay careful attention to the length and installation of cable wiring to ensure that connectors and cables are neither overloade d nor disconnected.

* Make sure to prevent any metal objects from getting inside the connectors or the terminal blocks.

* Short-circuits caused by metal objects or mis-wiring are likely to damage the device.

Eject indicator lamp (Green) (Red)

Replaceable lever input

WARNING CAUTION

WARNING

○System Safety

○Always turn off the power before attempting to mount or replace.

This system is intended for general industrial applications. It does not have functions for supporting applications requiring h igher levels

of safety such as safety-related devices or accident prevention systems. The product must not be used for these purposes.

A WARNING indicates a potentially hazardous

situation which, if not handled correctl y, could

result in death or serious injury.

A CAUTION indicates a potentially hazardous situation

which, if not handled correctl y, may result in personal

injury or property damage.

CAUTION

* This product is compatible with the AnyWire Bitty series.

* This product has a replaceable lever switch (input) and

an indication to direct ejection (output) function.

* This product can be laid out with a φ28 pipe.

* Transmission and power supply can be connected with a

4-wire connection.

*

for transmission line connection.

* The distance for transmission is 100 m, and up to 128

units can be connected.

(Power supply to the entire system)

* The lever can be replaced.

■Warranty period

The warranty on the delivered Product shall continue to be

effective for one (1) year after the delivery thereof to a

location as designated by the original owne r.

■Scope of warranty

Should a defect occur in any part of the Product during

the foregoing warranty period when it is used normally in

Manual, the Company shall replace or repair the defect

free of charge, except when it arises as a result of:

[1] Misuse or abuse of the Product by the owner;

[2] Fault caused by other than the delivered Product;

by any person other than the Company's personnel;

[4] Any unusual force of nature, disaster or other cause

beyond the Company's control.

The term "warranty," as used herein, refers to the

warranty applicable to the delivered product alone. The

Company shall not be liable for consequential or

incidental damages resulting from any malfunction.

■Repair at cost

After the expiration of the warranty period, the owner shall

be responsible for all costs and expenses incurred for the

troubleshooting and repair of the Product. Even during the

warranty term, the Company shall repair any defects

arising from causes other than within the scope of the