4

INTRODUCTION

Solar radiation at Earth’s surface is typically defined as total radiation across a wavelength range of 280 to 4000 nm

(shortwave radiation). Total solar radiation, direct beam and diffuse, incident on a horizontal surface is defined as global

shortwave radiation, or shortwave irradiance (incident radiant flux), and is expressed in Watts per square meter (W m-2, equal

to Joules per second per square meter).

Pyranometers are sensors that measure global shortwave radiation. Apogee SP series pyranometers are silicon-cell

pyranometers, and are only sensitive to a portion of the solar spectrum, approximately 350-1100 nm (approximately 80 % of

total shortwave radiation is within this range). However, silicon-cell pyranometers are calibrated to estimate total shortwave

radiation across the entire solar spectrum. Silicon-cell pyranometer specifications compare favorably to specifications for

World Meteorological Organization (WMO) moderate and good quality classifications and specifications for International

Organization of Standardization (ISO) second class and first class classifications, but because of limited spectral sensitivity,

they do not meet the spectral specification necessary for WMO or ISO certification.

Typical applications of silicon-cell pyranometers include incoming shortwave radiation measurement in agricultural,

ecological, and hydrological weather networks, and solar panel arrays.

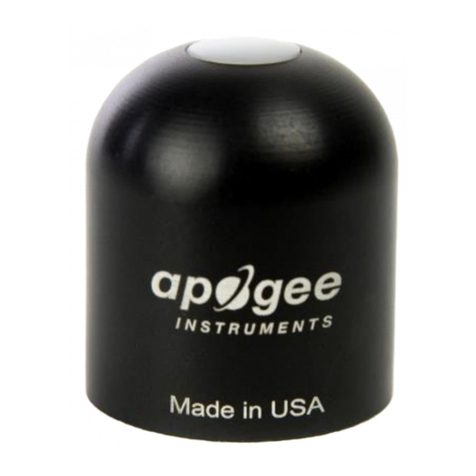

Apogee Instruments SP series pyranometers consist of a cast acrylic diffuser (filter), photodiode, and signal processing

circuitry mounted in an anodized aluminum housing, and a cable to connect the sensor to a measurement device. Sensors

are potted solid with no internal air space and are designed for continuous total shortwave radiation measurement on a

planar surface in outdoor environments. SP series sensors output an analog voltage that is directly proportional to total

shortwave radiation from the sun. The voltage signal from the sensor is directly proportional to radiation incident on a planar

surface (does not have to be horizontal), where the radiation emanates from all angles of a hemisphere.