Emist TruElectrostatic EX-7000 User manual

OPS MANUAL

Thank you for choosing the EMist®EX-7000TM TruElectrostaticTM Sprayer.

We’ve created an easy-to-use system that combines advanced liquid application technologies with

improved mobility. The result is superior application and enhanced disinfection, as well as a convenient

convertible design for users.

We recommend you read through this entire instruction manual before beginning.

Included are assembly, operating, and safety instructions. Following these manufacturer guidelines will

help the system perform at peak eectiveness, extend the life of the product, and ensure operator safety.

Questions?

Each component has been inspected prior to your purchase. However, in the event that there is a

problem, please contact our technical support center at Emist.com.

EX-7000TM TruElectrostaticTM Sprayer Operations Manual

TABLE OF CONTENTS

General Precautions

& Safety Warnings 1

3

5

7

6

8

Initial Inspection

& Set Up

Assembly & Operation

Instructions

Maintenance & Cleaning

Spray Application

Troubleshooting, Support, & Repair

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

A. GENERAL PROVISIONS: The warranties described below are provided by SanoTech 360, LLC, dba EMist®to

the original purchaser of the new EX-7000™ equipment from EMist or authorized reseller, with proof of purchase

which may be accomplished by registering the product at Emist.com/warranty/. Under these warranties, EMist will

repair or replace, at its option, any covered part which is found to be defective in material or workmanship during

the applicable warranty term. Warranty service must be performed by EMist, or its authorized service providers,

which will use only new or refurbished parts or components furnished by EMist. Warranty service will be performed

without charge to the purchaser for parts and labor. The purchaser will be responsible for any service call, and/

or transportation of product to and from EMist, for any premium charged for overtime labor requested by the

purchaser, and for any source and/or maintenance not directly related to any defect covered under the warranties

below.

B. WHAT IS WARRANTED: All parts of any new EMist equipment are warranted for the number of months or

days specied below.

C. WHAT IS NOT WARRANTED (EMist IS NOT RESPONSIBLE FOR THE FOLLOWING): (1) Any

equipment that has been altered or modied in a way not approved by EMist including, but not limited to, EMist

specications, and such alteration or modication caused the defect or damage; (2) Depreciation or damage

caused by normal wear, lack of reasonable and proper maintenance, failure to follow operating instructions,

misuse, lack of proper protection during storage, or accident; (3) Normal maintenance parts and service.

D. SECURING WARRANTY SERVICE: To secure warranty service, the purchaser must (1) Report the product

defect to EMist and request repair within the applicable warranty term; (2) Present evidence of the warranty start

date (proof of purchase); (3) Make the equipment available to EMist within a reasonable period of time; (4) Use of a

non water-soluble chemical in the system.

E. NO RESELLER WARRANTY: The reseller makes no warranty of its own and the reseller has no authority to make

any representation or promise on behalf of EMist, or to modify the terms or limitations of this warranty in any way.

F. LIMITATION ON IMPLIED WARRANTIES: Any implied warranties granted to the original purchaser of new

EX-7000™ equipment under law shall be limited to the limited warranty time frame set forth herein.

If further information is desired, contact EMist at Emist.com.

LIMITED WARRANTY FOR NEW EX-7000™ EQUIPMENT

* Each warranty term begins on the date of product delivery to the purchaser.

EX-7000 EQUIPMENT

EX70BPSY00

EX-7000 System

(consists of power pack,

hydroelectric cord and

applicator wand)

EP36BTLI20 Battery

EP36CHLI20 Battery Charger

EX70TK7000 Tank

EX70BPHA04 Harness

WARRANTY TERMS*

12 Months or 365 Days

3 Months or 90 Days

3 Months or 90 Days

1 Month or 30 Days

1 Month or 30 Days

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

1

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

This manual contains information that is important for you to

know and understand before operating the EMist TruElectrostatic

Sprayer. This information relates to protecting your safety and

ensures product reliability and performance. It is the owner’s

responsibility to ensure that all who operate this equipment

read this manual.

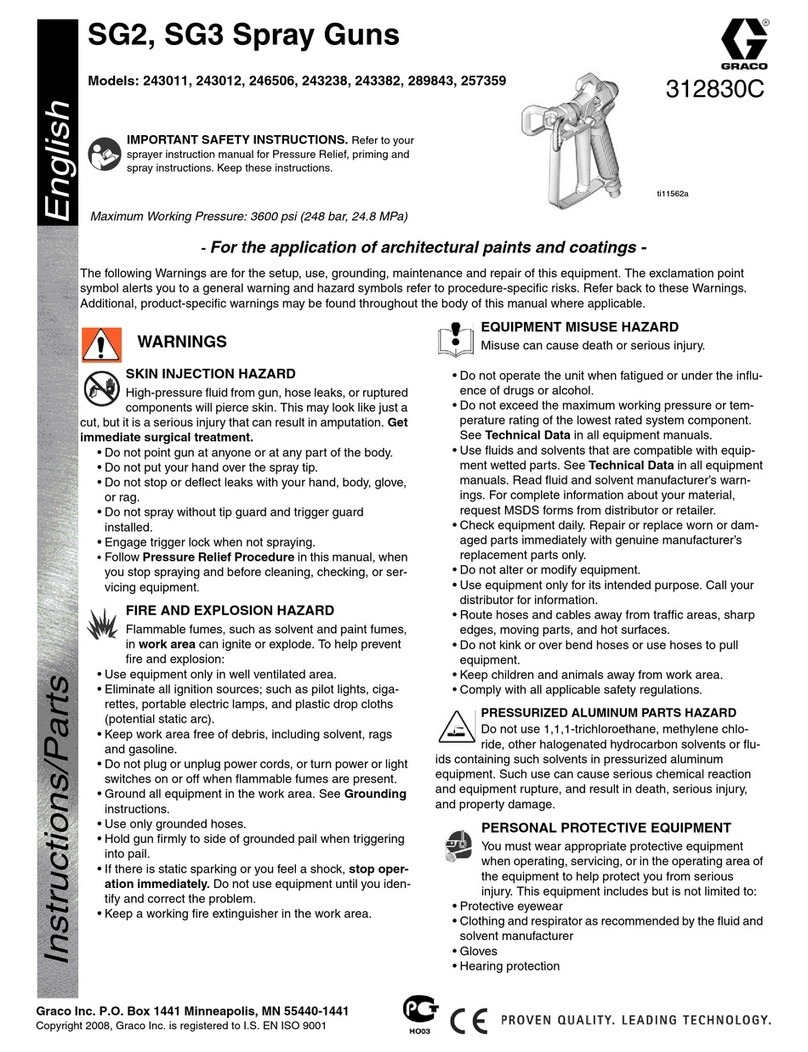

Warnings

Please read the manual carefully and pay special attention to the

symbols and warning labels. Warning labels indicate a potentially

hazardous situation which, if not avoided, could result in death or

serious injury.

SAFETY NOTICES

• Read and fully understand the EMist TruElectrostatic Sprayer

Operations Manual prior to using the electrostatic sprayer.

• EMist TruElectrostatic Sprayers should never be used in a

hazardous environment.

• EMist TruElectrostatic Sprayers should never be used in an

area containing volatile chemicals. Nor should it be used in any

area containing volatile or explosive levels of gas, vapor

or particulates.

• EMist TruElectrostatic Sprayers should never be used by

untrained personnel.

WARNINGS

• Use only water-based solvents to clean

equipment or parts.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Many solvents can degrade plastic parts and cause them to fail,

which can lead to serious injury or property damage. In order to

help prevent against degradation:

WARNINGS

• Electrostatic equipment must be used

only by trained, qualied personnel who

understand the requirements of this manual.

• Stop operation immediately if static

sparking occurs or you feel shock. Do not

use equipment until you identify and correct

the problem.

• Use and clean equipment only in well

ventilated area.

• Never spray a ammable chemical

(with a ashpoint less than 60˚C).

• Do not turn lights on or o when

ammable fumes are present.

• Keep spray area free of debris, including

solvents, rags, gasoline or any ammable

chemicals.

• Keep a working re extinguisher in the

work area.

• CAUTION, TO AVOID ELECTRICAL

SHOCK, DO NOT TOUCH OR

INSERT ANYTHING IN THE NOZZLE

OF THE SPRAYER

FIRE, EXPLOSION AND ELECTRIC SHOCK HAZARD

Flammable fumes, such as solvent and paint fumes, in work area

can ignite or explode. To help prevent fire, explosion and electric

shock:

WARNINGS

• Check equipment daily. Replace worn or

damaged parts immediately.

PRESSURIZED EQUIPMENT HAZARD

Liquid from equipment that leaks or ruptures from a component

can splash in the eyes or on skin, causing serious injury. In order

help prevent a leak or rupture:

WARNINGS

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

2

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

• Be aware of rst aid procedures related to the product in use.

• It is a violation of Federal law to use a chemical in a manner

inconsistent with its label.

• For use with water-soluble, non-ammable, non-combustible

and non-volatile liquids only. Never spray a ammable chemical

(ash point less than 60˚C).

• Ensure the area being sprayed has proper ventilation.

• Store all chemicals in original containers in a cool, dry place,

away from heat and open ames.

• Do not reuse or rell a chemical container.

CHEMICAL USE HAZARD

Each chemical, such as a disinfectant, has a unique set of

hazards and needs to be handled properly to ensure worker

safety.

WARNINGS

• Recommend use of fully enclosed

eyewear protections, such as goggles,

when using this device.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment to help prevent

serious injury.

WARNINGS

• Do not operate the unit when fatigued or

under the inuence of drugs or alcohol.

• Use only water soluble uids that are

compatible with equipment wetted parts.

• Check equipment daily. Repair or replace

worn or damaged parts immediately with

genuine replacement parts from trusted

EMist partners only.

• Do not alter or modify equipment.

Alterations or modications void your EMist

warranty, and create safety hazards.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury

WARNINGS

SAFETY WARNING!

DO NOT USE THE ELECTROSTATIC

APPLICATION SYSTEM IF YOU HAVE

A PACEMAKER OR AN IMPLANTABLE

CARDIOVERTER DEFIBRILLATOR (ICD).

STATE OF CALIFORNIA

• This product may contain chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm.

WARNINGS

WARNINGS

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

3

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

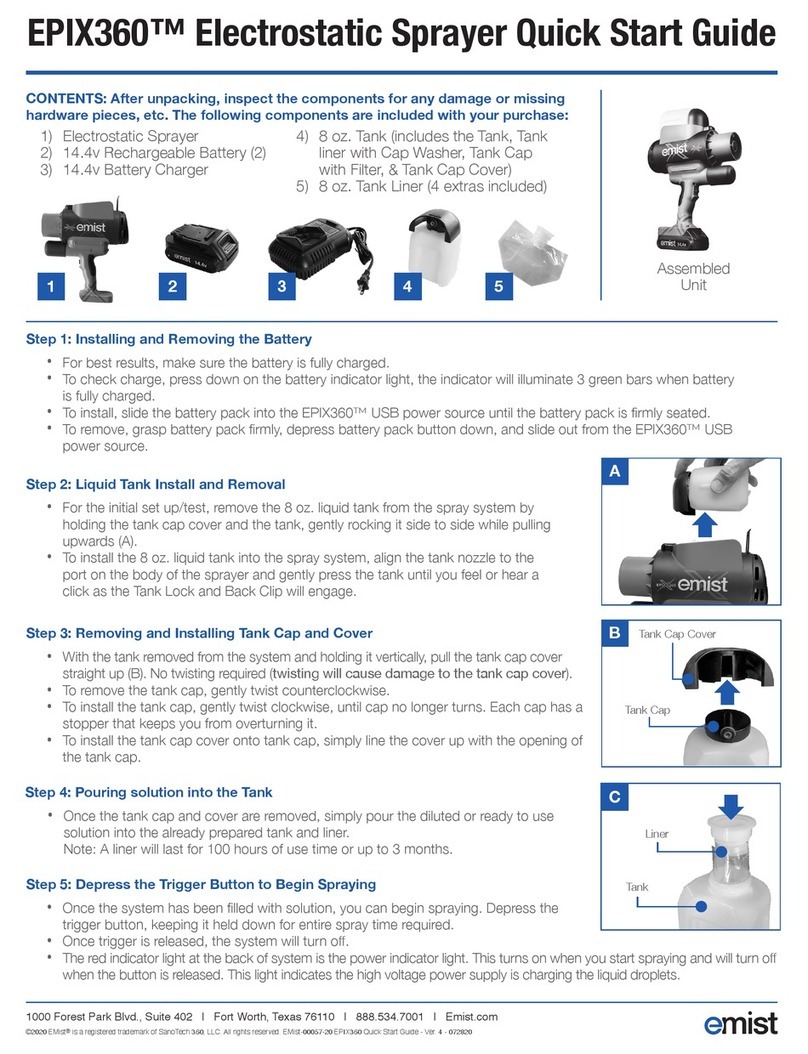

INITIAL INSPECTION & SET UP

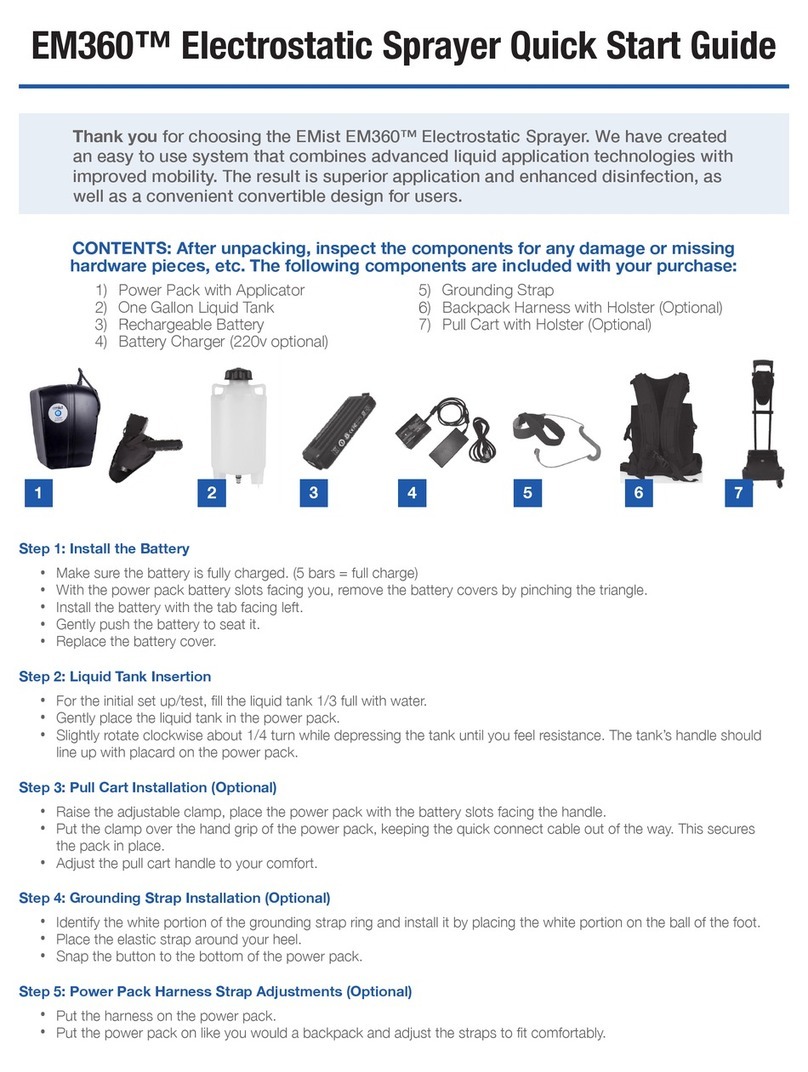

EMIST EX-7000 TRUELECTROSTATIC SPRAYER COMPONENTS

POWER PACK

Power pack with applicator may be used

with either the backpack harness or carried

by the handles.

TANK

Interchangeable 3.1 L liquid tank includes

strain lter and cap. It is inserted with a

light downward pressure then locked in

place by the tank latch located on the back

of the power pack.

APPLICATOR WAND

The applicator is connected to the

application power pack housing by a

hydroelectric cord. This hand-held device

is trigger activated for the charging and

applying of your liquids.

BATTERY

The system comes with two 14.4V lithium

ion batteries. Each has a green LED

indicator to determine charge. The system

can accommodate two batteries for longer

run time, but only requires one to operate.

BATTERY CHARGER

The battery charger kit comes with AC

adapter, cable, charger and provides

approximately 45 minutes recharge time.

HARNESS

This commercial harness for the backpack

conguration is designed for comfort and

safety. It is adjustable to the user from

small to large frame individuals.

� Power Pack with Applicator

�3.1 L Interchangeable Liquid Tank

� (2) 14.4V Rechargeable Batteries

�Battery Charger

�Backpack Harness

INSPECTION

AFTER UNPACKING, INSPECT COMPONENTS

FOR ANY DAMAGE OR MISSING HARDWARE PIECES, ETC.

1. INSTALL BATTERY (PROCEDURE SAME

FOR BOTH BATTERY PORTS):

Charge the battery rst:

a. Plug charger cord into wall outlet.

1. Install battery into charger.

2. Reference power indicator (3 bars = full charge).

b. With the power pack battery ports located toward the

bottom of each side:

1. Install the battery into one port.

2. Gently push battery into the port, with the battery

release button facing up, the battery will click into

place.

3. Depress the trigger on the applicator to verify

power is on. Red indicator light on the back of the

handle will turn red and the system will engage.

2.LIQUID TANK REMOVAL:

a. Locate the tank latch toward the top center of the

back panel of the power pack. Gently pull and hold the

latch away from the unit, this will release the tank.

b. With the latch pulled back, rmly grip the tank’s

handle and pull straight up.

c. Lift the liquid tank out of the power pack.

3.LIQUID TANK INSTALLATION:

a. For initial set up/test, ll the liquid tank 1/4 full with water.

b. Gently slide the tank back into the power pack.

c. When the tank is fully insterted, it will lock/click into place.

INITIAL

INSPECTION &

SET UP

4

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

6.HARNESS INSTALLATION INSTRUCTIONS:

a. Refer to instructions below on how to attach the power

pack to the harness. Following harness installation,

put the power pack on like you would a backpack and

adjust the straps to fit comfortably.

1. Position the hydroelectric cord toward

the front of the system. Open the flap

on the harness. Feed it under the

vertical nylon strap attached to the

power pack of the EX-7000 system.

Fold it back toward the harness and

match the two sides of hook and loop

fastening strips, securing the harness to

the power pack.

2. Repeat step 1 for the second strap.

3. Connect the two ends of the side

squeeze buckle connectors between

the harness and the power pack.

4.POWER PACK HARNESS STRAP ADJUSTMENTS:

a. Place the power pack on just as you would a backpack

and adjust the straps to t comfortably.

5.POWER PACK AND APPLICATION FUNCTION

CHECK:

a. With the tank and battery installed, depress the trigger

switch located on the front of the applicator handle.

b. The clear LED on the back of the applicator handle will

light up RED. This indicates power on and the high

voltage power system is charging the liquid droplets.

c. Once the trigger switch is released, the liquid spray will

stop, and the fan will turn o. This indicates the system

is turned o.

3

1

3

HOW TO ATTACH POWER PACK TO HARNESS

INITIAL

INSPECTION &

SET UP

2

Assembled System

5

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

ASSEMBLY INSTRUCTIONS AND TIPS

IMPORTANT: DO NOT DROP TANK INTO THE TANK

WELL. CAREFULLY SLIDE THE TANK BACK INTO

THE POWER PACK TANK WELL UNTIL IT LOCKS/

CLICKS INTO PLACE.

CAUTION: ATTEMPTING TO REMOVE THE

TANK WITHOUT RELEASING THE TANK LATCH

CAN CAUSE DAMAGE OR BREAK THE LATCH.

DROPPING OR FORCING THE TANK INTO THE

POWER PACK TANK WELL CAN CAUSE DAMAGE

TO THE SPRAYER.

a. The battery should be fully charged prior to the start of a

project.

b. Inspect the quick connectors for any debris or damage prior to

inserting.

c. The indication bar at the end of the battery will light up to show

remaining charge (3 bars = full charge).

d. One bar during startup may limit time of use without charging.

e. The connector side of the battery enters the power pack case.

f. The battery easily seats in the power pack. Over applying

pressure may make the battery difficult to remove without

causing overall damage.

1. RECHARGEABLE BATTERY:

The system uses up to two lithium-ion batteries.

Remove the vented cap, leaving strain lter in place.

Fill as needed and replace vented cap.

Utilize liquids for duration of project or until rell is

required.

You may exchange tanks with dierent liquids at

any time.

a)

b)

c)

d)

2. INTERCHANGEABLE 3.1 LITER LIQUID TANK:

ASSEMBLY & OPERATING INSTRUCTIONS

TANK

Keep the battery release

button facing upwards as it

slides into the battery ports.

TANK

LATCH

ASSEMBLY &

OPERATION

INSTRUCTIONS

�Optimal distance from a target is 24”-36”.

�Applicator will shut off once battery is completely drained

of charge.

�Ensure applicator is secured while putting the backpack

on/adjusting straps/taking backpack o to avoid damaging

the applicator.

TIPS

6

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

TIP: IF THE APPLICATOR BECOMES WET OR

BEGINS TO DRIP, YOU ARE MOVING TOO SLOW

OVER THE SURFACE TARGET AREA AND NEED

TO SPEED UP THE APPLICATION PROCESS. DO

NOT OVER-SATURATE THE SURFACE. IF YOU SEE

RUNS OR PUDDLES YOU ARE APPLYING TOO

MUCH CHEMICAL. THE GOAL IS TO ACHIEVE EVEN

COVERAGE OVER THE TARGET SURFACE AREA.

1. Begin at the farthest point from the doorway, work back

toward the doorway so you can step out when application

is complete.

2. Aim applicator 24”-36” (optimal distance) from the

surface target area, begin with a smooth figure “S”

movement aiming below, at, and above the surface target

area while walking at an average pace (continuously

moving).

3. Make sure you are working in a methodical “S” pattern and

let your passes overlap when moving to the next surface

target area.

4. Allow treated area to sit for contact time as recommended

by the chemical manufacturer’s label before re-entry into

the area.

B. SPRAY APPLICATION PROCESS:

C. FLUID MANAGEMENT:

1. Make sure food and drinks are removed, or covered before

application.

2. Spotless, clean interiors require no prep work prior to

application.

3. Loose debris must be swept from floors and other surfaces

prior to application.

4. Inspect the area for mechanical barriers such as:

magazines on table tops, chairs touching each other,

a table or a wall. The intended target surface area for

application will need to be accessible.

5. Please cover and remove valuables. Electronics, furniture,

paper or other common necessities do not need to be

removed from the area.

6. Once the area has been cleaned, application can begin.

7. This system is NOT a mechanical cleaner.

A. PREPARING THE SPRAY AREA:

The system is designed for single or multiple application

environments. Please use the multiple tank applications carefully

by marking tanks with your chemical identiers when necessary.

Application Tips:

1. While depressing the trigger button, move the

applicator in an “S” pattern from bottom to the top

of the surface target area in a continuous motion.

2. Stay in motion, electrostatically charged droplets will

accumulate in higher levels at the tip of the applicator if

you move too slowly while the device is in use.

3. Do not over apply.

4. In between chemical changes, press the trigger while

pointing to the floor or other safe target area for four to

five seconds to clear the remaining chemical in

the system.

C. FLUID MANAGEMENT:

SPRAY APPLICATION

Tips:

1. Fully charge each battery before use.

2. Keep connectors clean and dry at all times.

3. Insert with the battery release button facing upwards into

the battery port. The battery indicator light bar will be inside

the system when insertion is completed into battery port.

4. Do not expose batteries to standing liquid.

D. BATTERY MANAGEMENT:

SPRAY

APPLICATION

7

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

TIP: IT IS GOOD PRACTICE TO FLUSH THE APPLICATION

SYSTEM EVERY 24 HOURS WITH CLEAN WATER.

DO NOT STORE CHEMICALS IN THE RESERVOIR WHILE

THE SYSTEM IS NOT IN USE FOR GREATER THAN A 24

HOUR PERIOD.

TIP: IT’S IMPORTANT TO FLUSH THE SYSTEM IN

BETWEEN USE OR WHEN SWITCHING CHEMISTRY

TO PREVENT RESIDUAL BUILD UP AND TO AVOID

MIXING CHEMICALS.

CHANGING CHEMICALS:

The system is designed to minimize maintenance and

cleaning.

Tips:

• Clear the system at least once a day by spraying clean

water through the system for at least

ten seconds.

• Keep batteries charged.

• Inspect cord for cuts, tears or damage.

• Inspect applicator for debris or damage. STORAGE

• Empty fluid or run until empty.

• Insert at least 1 inch (2.5cm) of clean water in the liquid

tank.

• Run the electrostatic sprayer for at least 45-60

seconds to flush active chemicals from the system.

• Remove batteries and re-charge by placing on

the charger.

• Wipe down exterior with water or alcohol to remove dirt

and soil.

• Use the power indicator on the end of the battery to

determine the battery state of charge (3 bars = full

charge).

• Coil the hydroelectric cord up neatly and securely.

• To flush the system, empty the liquid tank and fill with at

least 1 inch (2.5cm) of clean water.

• Spray for at least 45-60 seconds to flush the previous fluid

from the system.

BATTERY REMOVAL

• Remove battery by depressing the battery release button.

• The battery will slide easily from the port once it is disengaged.

• When covers are off, a pull-tab will be visible to assist in

removal of the batteries.

• Place batteries into charger to fully charge for next usage.

Each battery takes approximately 45 minutes to fully charge.

CAUTION: DO NOT STORE THE SYSTEM IN AN AREA

THAT MAY FREEZE (TO AVOID DAMAGE FROM LIQUID

REMAINING IN THE SYSTEM AND LINES). THIS WILL

VOID THE WARRANTY.

CAUTION: TO PREVENT CROSS CONTAMINATION OF

CHEMICALS, YOU MUST PERFORM A FLUSH ANY TIME

YOU CHANGE THE TYPE OF CHEMICALS BEING USED.

FLUSHING THE ELECTROSTATIC SPRAYER

MAINTENANCE & CLEANING

MAINTENANCE

& CLEANING

8

ASSEMBLY &

OPERATION

INSTRUCTIONS

MAINTENANCE

& CLEANING

INITIAL

INSPECTION &

SET UP

SPRAY

APPLICATION

TROUBLESHOOTING,

SUPPORT

& REPAIR

GENERAL

PRECAUTIONS &

SAFETY WARNINGS

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00097-20 EX-7000 Ops Manual - 102620

TROUBLESHOOTING, SUPPORT, & REPAIR

The EX-7000™ is designed and manufactured to function without defects. The system will operate normally with properly maintained

batteries and without abuse to the connector or other system parts.

INDICATIONS & REMEDIES

PLEASE SEE BELOW FOR EASY INSTRUCTIONS FOR ADDRESSING ISSUES THAT MAY ARISE

WHILE USING THE EX-7000™

If your system fails to function, excluding obvious user damage, please contact EMist or your

authorized EMist distributor.

If an issue occurs that is not addressed in the troubleshooting methods, please contact a technical support

representative at: 888.534.7001 or visit Emist.com.

SUPPORT OR REPAIR

TROUBLESHOOTING,

SUPPORT

& REPAIR

Issue Reason Troubleshooting Result

No power to the system

Battery not charged Fully charge the battery (3 bars = full) Return to normal use

Battery not installed correctly

Install battery with connector side

of battery entering the power pack;

keep battery release button facing

upwards as it slides into the port

Return to normal use

Battery connection not working

Verify battery connector issue by

using the opposing battery port with

charged battery

Return to normal use

Red LED not illuminating when

trigger switch is engaged

Verify a fully charged battery,

installation of battery is correct, no

obstruction when inserting the battery

Return to normal use

No mist/inadequate mist

Tank is empty Fill tank with appropriate liquid Return to normal use

Battery not charged Fully charge the battery (3 bars = full) Return to normal use

Tank is not installed correctly

in the power pack

Verify the tank is locked into place

as instructed for insertion Return to normal use

Leaking at the nozzle Verify the nozzle tip is hand tightened

in place Return to normal use

Nozzle clogged Remove nozzle tip from sprayer, rinse

with water. Reinstall, hand tightened Return to normal use

Pump not engaged Verify all the above troubleshooting

steps for results Contact tech support

Other manuals for TruElectrostatic EX-7000

1

Table of contents

Other Emist Paint Sprayer manuals

Emist

Emist EM360 User manual

Emist

Emist TruElectrostatic EX-7000 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360RC User manual

Emist

Emist EPIX360 User manual

Emist

Emist EM360 User manual