Doc 920-0017B - 8/27/12

Choosing a Power Supply

To nd out how to choose a power supply refer to the tech notes on our website.

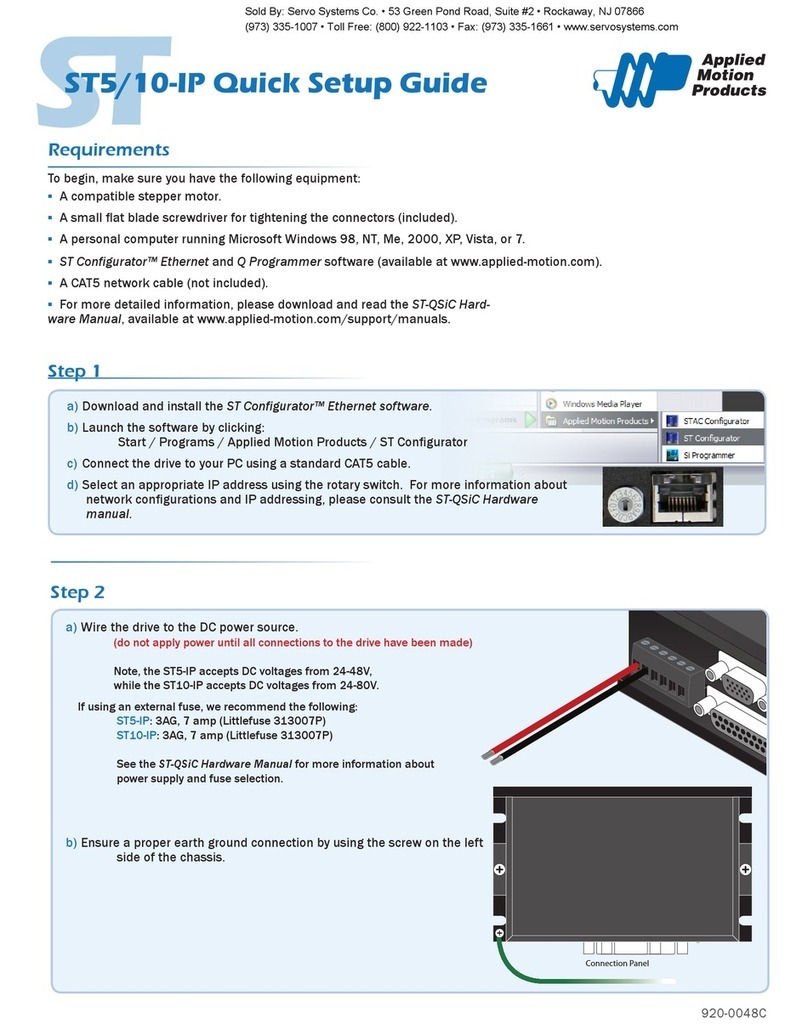

Mounting the Drive

To operate the drive continuously at maximumpower you must properly mount it on

a heat sinking surface with a thermal constant of no more than 4°C/watt. Often, the

metal enclosure of your system will make an effective heat sink.

smooth flat surface

#4 screws

wide side mount narrow side mount

Technical Specications

Ampliers Dual, bipolar MOSFET H-bridge, pulse width modulated

three state switching at 20kHz. 12-42 VDC input.

0.4 - 3.5 amps/phase output current, switch selectable

in 0.1 A increments. 122 watts maximum output power.

Automatic idle current reduction (switch selectable),

reduces current to 50% of setting after one second.

Minimum motor inductance is 1 mH.

Inputs Run/stop (cw limit), direction (ccw limit), hi/lo speed and

enable inputs are optically isolated, 5-24V logic. 3 - 15 mA

input current. 2200 ohms input impedance. Can be

congured for sinking or sourcing signals.

Recommended external pot/joystick resistance: 1K - 5K

Joystick dead zone: ± 80 mV.Potentiometer/analog signal

dead zone: 40 mV.

Recommended Maurey Instrument Corp., Chicago, IL (773)581-4555

Joystick JS31462S5T3 (2 axis) or SAJ2515-F-502 (1 axis)

Speed Ranges LO speed range: 0 - 5 rev/sec

HI speed range: 0 - 25 rev/sec

Accel/decel range: 1 to 250 rev/sec/sec

Tach Output Phototransistor, open collector, open emmiter.

24 volts max, 20 mA max.100 pulses per motor revolution,

50% duty cycle (square wave).

Physical Mounted on 1/4 inch thick black anodized aluminum

heat transfer chassis. 1.5 x 3.0 x 4.0 inches overall. Power

on red LED. Ambient temperature range: 0 - 70 C.

Connectors European style screw terminal blocks.

Power Supply & Motor: 6 position. Wire size: AWG 12 - 28.

Signal Input: 10 position. Wire size: AWG 16 - 28.

Microstepping CE Mark 1/64 step (12,800 s/r) with 1.8 motor. Pure sine

waveform.

CE Mark Complies with EN55011A and EN50082-1(1992).

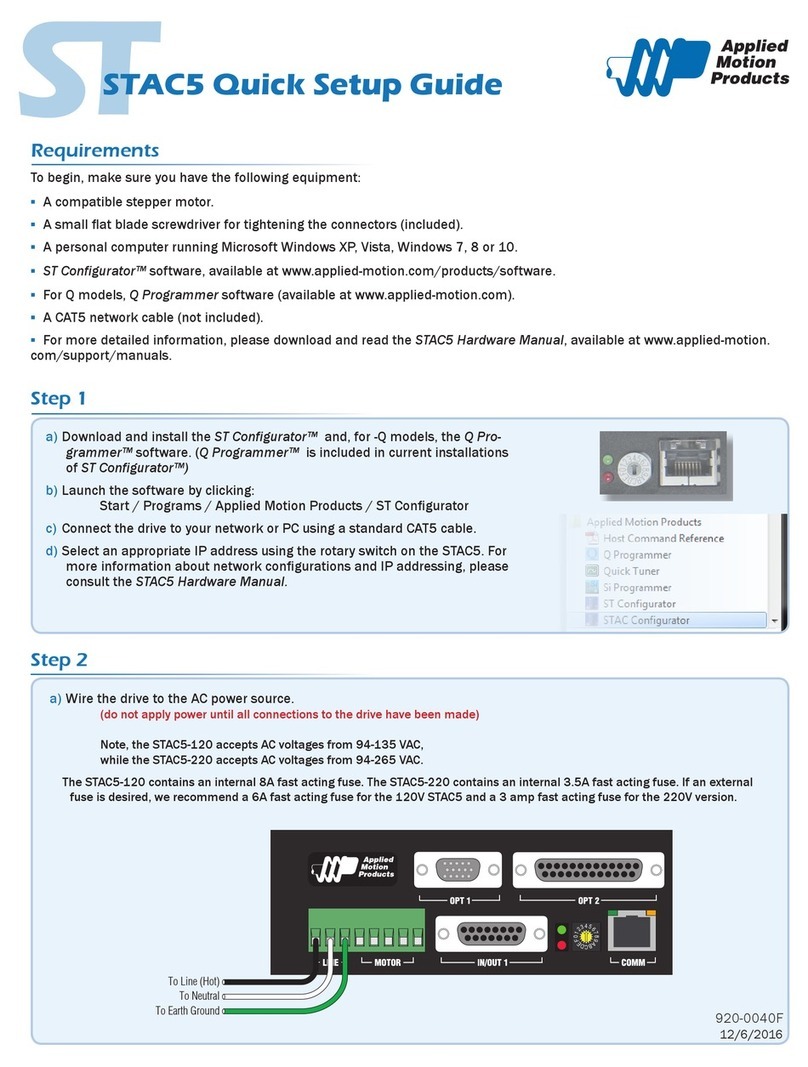

Idle Current Reduction

Your drive is equipped with a feature that automatically reduces the motor

current by 50% anytime the motor is not moving. . Idle current reduction is

enabled by sliding switch #4 toward the 50% IDLE label,as shown in the

sketch below. Sliding the switch away from the 50% IDLE label disables the

reduction feature

50% IDLE

4

4

50% IDLE

Idle Current Reduction

Selected

No Current Reduction

Microstepping

The 3540 MO divides each full step into 64 microsteps, providing 12,800 steps

per revolution for precise positioning and smooth motion.

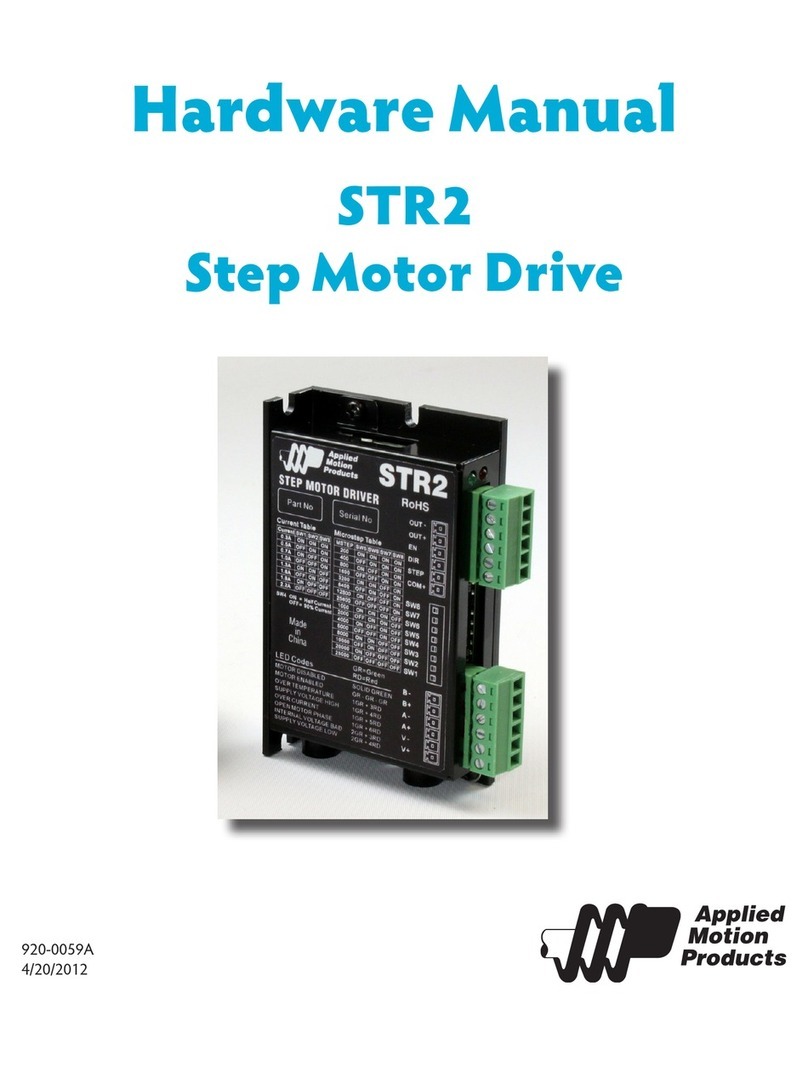

Connecting the Motor

STEP motors have 4, 6 or 8 leads , these are

wired to 4 connections on the drive in various

combinations.

Motors will perform differently according the

way it is connected, to nd out more about the

differnet way of connecting your motor , see the

technotes or FAQs on our website.

Warning: When connecting

the motor to the driver, be

sure that the motor power

supply is off. Secure any

unused motor leads so that

they can’t short to anything.

Never disconnect the motor

while the drive. Never con-

nect motor leads to ground

or to a power supply!

A+

A–

B+ B–

4

lead

motor

Red

Blue

Yellow White

4 Leads

A+

A–

NC

B+

B– NC

6

lead

motor

Red Black

Red/

Wht

Green

Grn/Wht

White

6 Leads

Series

Connected

A+

A–

NC

B+B– NC

6

lead

motor

Grn/Wht

White

Green

Red

Red/

Wht

Black

6 Leads

Center Tap

Connected

A+

A–

B+ B–

8

lead

motor

8 Leads

Series

Connected

Orange

Org/Wht

Blk/Wht

Black

Red Red/

Wht Yel/

Wht

A+

A–

B+ B–

8

lead

motor

Orange

Org/

Wht

Blk/Wht

Black

Red

Red/Wht

Yel/

Wht

Yel

low

8 Leads Parallel Connected

A+

A–

B+ B–

8

lead

motor

Orange

Org/

Wht

Blk/Wht

Black

Red

Red/Wht

Yel/

Wht

Yel

low

8 Leads

Parallel

Connected

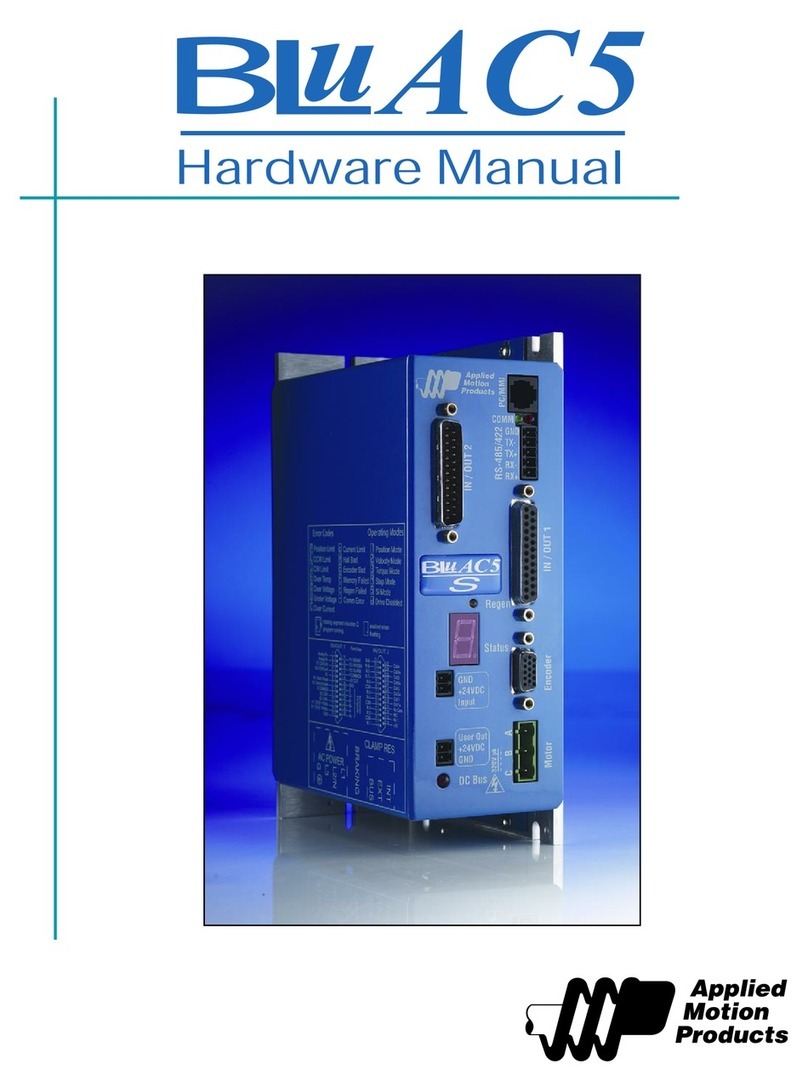

Tach Output

The Tach Out signal is provided for measuring the motor speed. It generates

100 pulses per revolution, so if you connect a frequency counter, the speed

reads out in revs/second with two decimal places. The schematic diagram of

the Tach Out optoisolation circuit is shown below.

Do not connect the Tach output to more than 24VDC.

The current into the Tach+ terminal must not exceed 20 mA.

Internal Tach Circuit

330W

internal

tach

signal

+5V

TACH–

TACH+

Optoisolator

NEC PS2501 or equiv.

inside 3540 MO

Connecting Tach Output

to a Frequency Counter

4700W

5 - 24V

DC

Power

Supply

TACH–

TACH+

–

+

Freq

Counter

3540 MO

GND

IN

Connecting Digital Inputs and Limit Switches

You must supply 5-24 volts DC to supply current to the LEDs on the input side

of the opto-isolators.Your controlling logic must be capable of sinking or sourc-

ing at least 3 mA at 5 volts and 10 mA at 24 volts to control each drive input.

Sinking Circuits (NPN) - If your output devices prefer to sink current, then

connect the COM terminal to your positive power supply. If you are using a

TTL circuit to drive the 3540 MO, connect the COM terminal to your 5 volt bus.

No ground connection is needed. If you are using a PLC or proximity sensor,

you’ll need a power supply.

Sourcing circuits (PNP) - If your output devices can only source current (some

PLC outputs are this way), connect the COM terminal to the ground of the DC

power supply that powers your output circuits Note: We refer to an input as

being ON when current is owing through the input. A signal is OFF when no

current is owing. An input is OFF when COM and the input terminal are at the

same voltage, or when the input is left unconnected (open).

The ENABLE input allows the user to turn off the current to the motor by

setting this signal on. The logic circuitry continues to operate, so the drive

“remembers” the step position even when the ampliers are disabled. If you

have no need to disable the ampliers, you don’t need to connect anything to

the ENABLE input.

Servo Systems Co. • 53 Green Pond Road, Suite #2 •

Rockaway, NJ 07866

NJ, 07045-0097

335-1007 • Toll Free: (800) 922-1103

Fax: (973) 335-1661 • www.servosystems.com

Sold By: Servo Systems Co. • 115 Main Road • P.O. Box 97

Montville, NJ, 07045-0097

(973) 335-1007 • Toll Free: (800) 922-1103

Fax: (973) 335-1661 • www.servosystems.com